Light emitting device

A light-emitting device and optical transmission technology, applied in the field of lighting systems, can solve the problems of reducing light extraction efficiency, luminous flux, and luminous area, and achieve the effects of improving light extraction efficiency, ensuring luminous efficiency, and increasing luminous flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

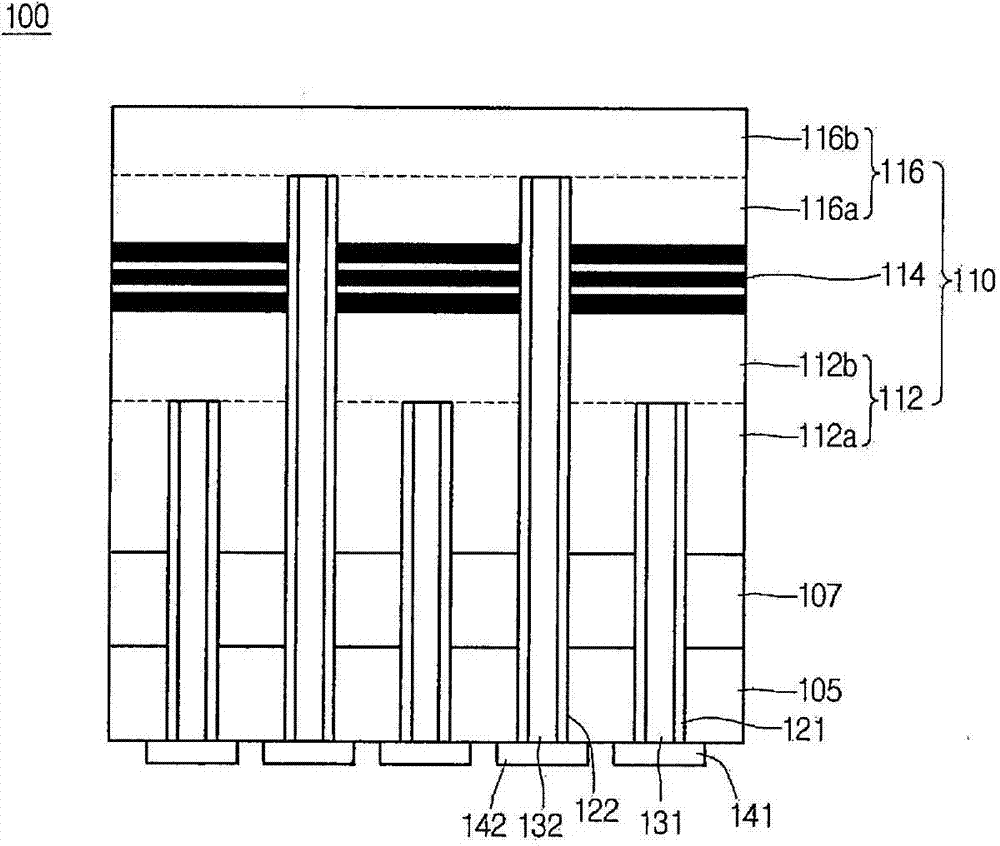

[0025] figure 1 To illustrate a cross-sectional view of the light emitting device 100 according to the first embodiment.

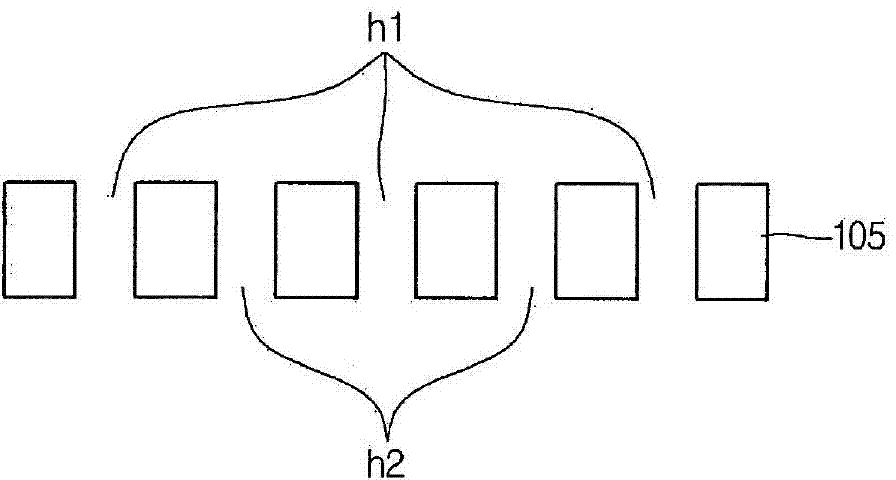

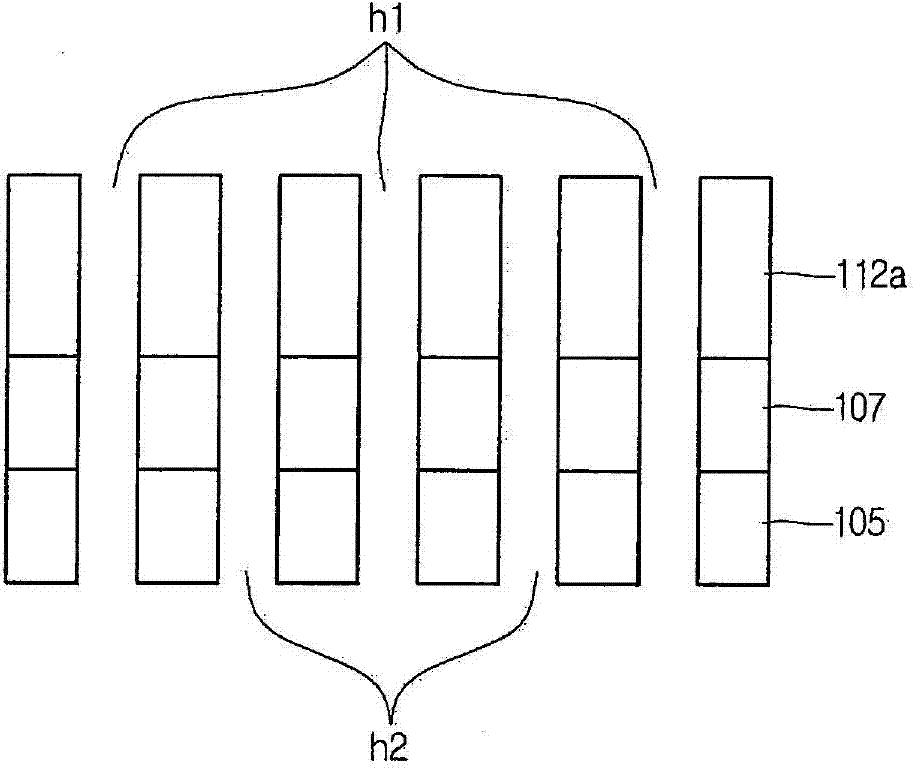

[0026] The light emitting device 100 according to the first embodiment may include: a substrate 105; a first conductive semiconductor layer 112 on the substrate 105; an active layer 114 on the first conductive semiconductor layer 112; a second conductive semiconductor layer on the active layer. Two conductive semiconductor layers 116; a first via electrode 131, the first via electrode 131 is in contact with the first conductive semiconductor layer 112 through a through hole h1 formed through the substrate 105; and a second via electrode 132, the The second via electrode 132 contacts the second conductive semiconductor layer 116 through the second via hole h2 formed through the substrate 105 , the first conductive semiconductor layer 112 and the active layer 114 .

[0027] The first conductive semiconductor layer 112 , the active layer 114 and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com