Electroluminescent device, manufacturing method thereof and display device

An electroluminescent device and a manufacturing method technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of different electron mobility and hole mobility, and the limitation of hole transport layer material selection, etc. Achieve the effect of reducing production cost and ensuring luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

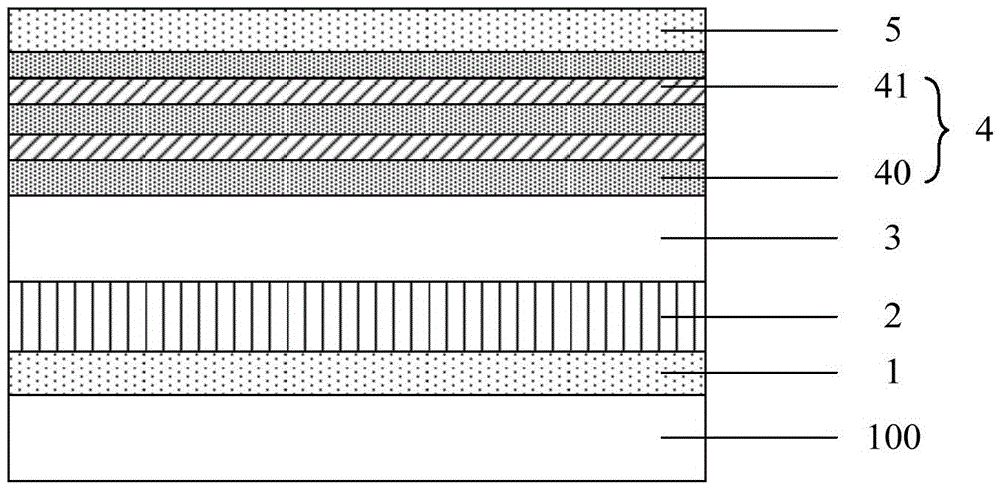

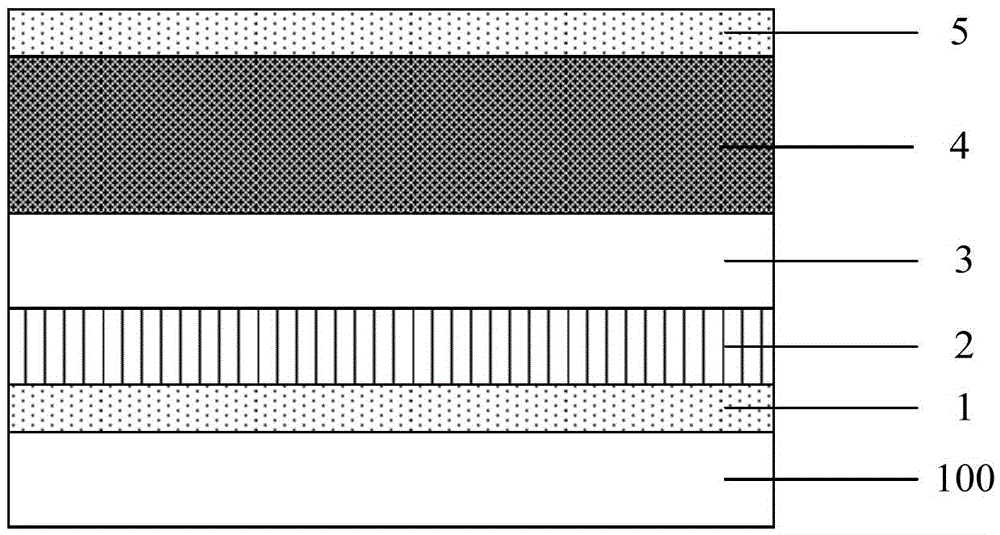

[0017] In this embodiment, an electroluminescent device is provided, comprising an anode 1 , a hole transport layer 2 , a light emitting layer 3 , an electron transport layer 4 and a cathode 5 sequentially arranged on a substrate 100 . The luminescent layer 3 is made of electroluminescent materials such as quantum dot materials and organic luminescent materials, and the recombination of electrons and holes in the luminescent layer 3 can excite the luminescent layer 3 to emit light. In order to improve luminous efficiency, a hole injection layer (not shown) can also be set between the anode 1 and the hole transport layer 2, and an electron injection layer (not shown) can be set between the electron transport layer 4 and the cathode 5. out).

[0018] The electron transport layer 4 includes a first film layer for transporting electrons, and also includes an adjustment structure arranged in contact with the first film layer, and the adjustment structure is used for adjusting the e...

Embodiment 2

[0033] Based on the same inventive concept, this embodiment provides a method for manufacturing the electroluminescent device in Embodiment 1, including:

[0034] An anode, a hole transport layer, a light emitting layer, an electron transport layer and a cathode are sequentially formed on a substrate. The light-emitting layer can be made of quantum dot materials, such as CdSe / ZnS, CdS / ZnS and other core-shell structure quantum dots, or can be made of organic light-emitting materials such as fluorescent materials and phosphorescent materials. In order to improve luminous efficiency, a hole injection layer may be formed between the anode and the hole transport layer, and an electron injection layer may be formed between the electron transport layer and the cathode.

[0035] Wherein, the step of forming electron transport layer comprises:

[0036] A first film layer for transporting electrons is formed.

[0037] An adjustment structure disposed in contact with the first film la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com