High-frequency induction brazing method and high-frequency inductor for a new type of feed horn

A technology of high-frequency induction brazing and feeding horns, which is applied in the field of brazing and waveguide manufacturing. It can solve problems such as weak electroplating, excessive material waste, and flange falling off, so as to achieve uniform weld quality and shorten the processing cycle. , The effect of ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] Such as Figure 1-1 to Figure 7-2 As shown, the present invention provides a kind of high-frequency induction brazing method of novel feed horn, comprises the following steps:

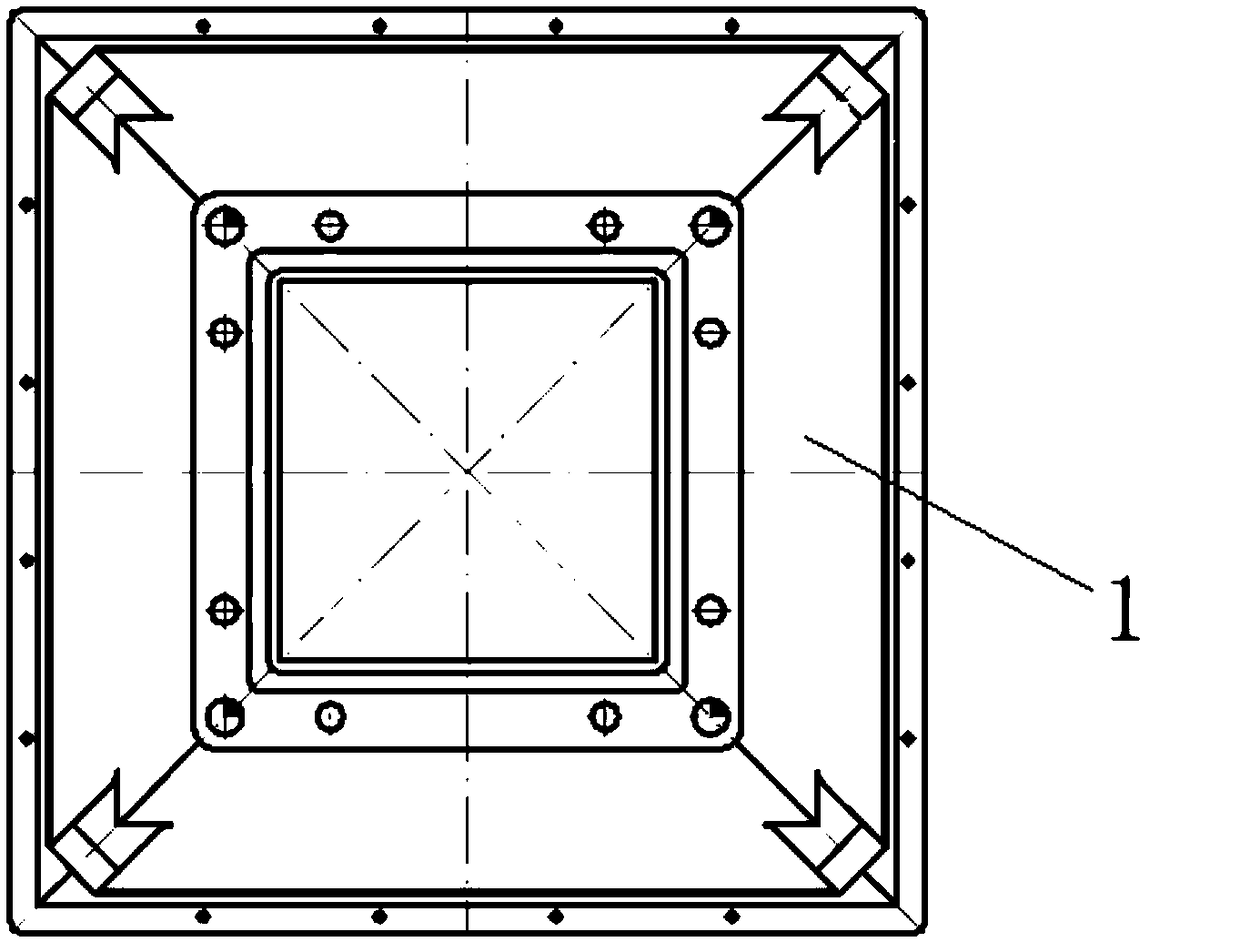

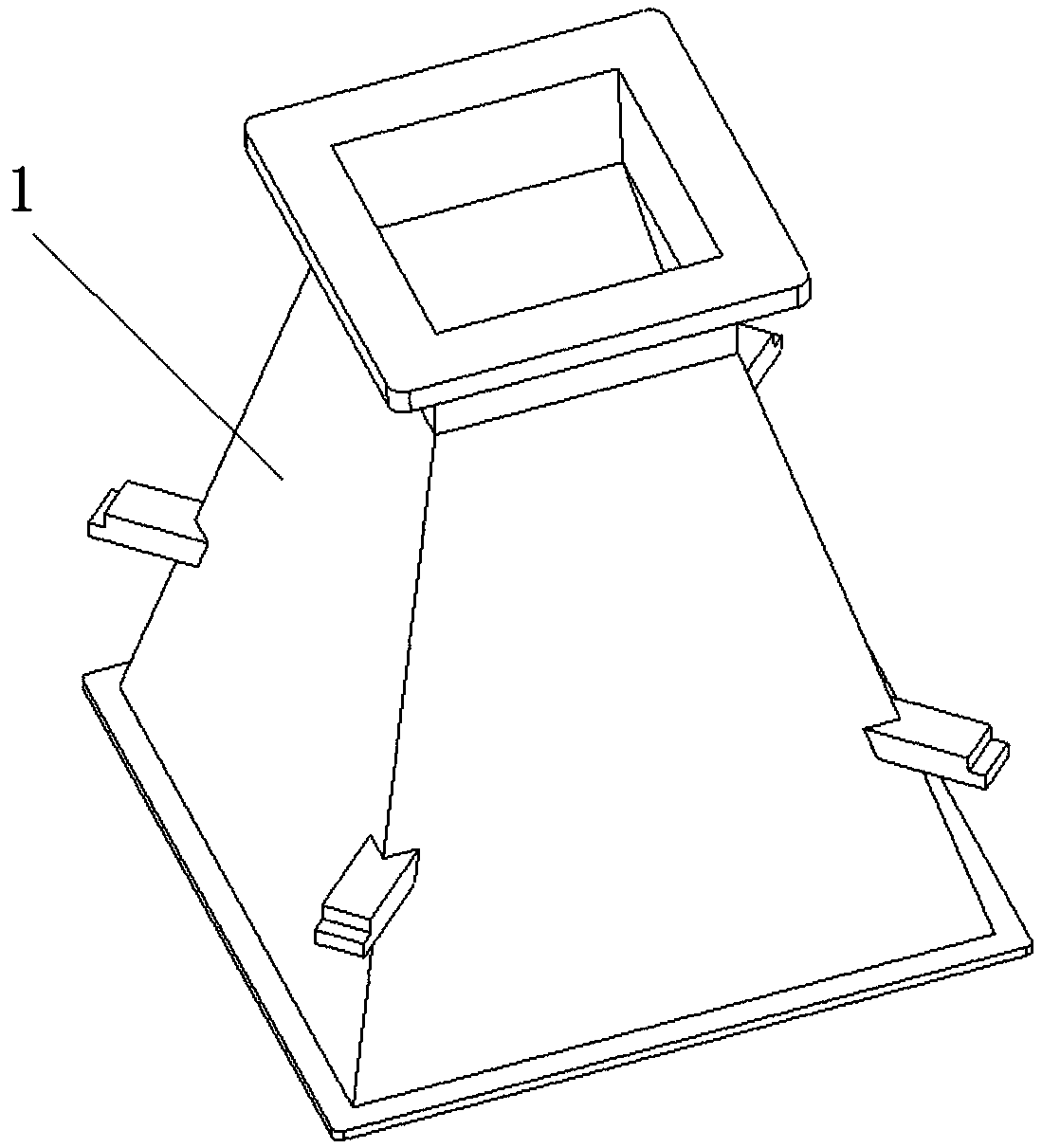

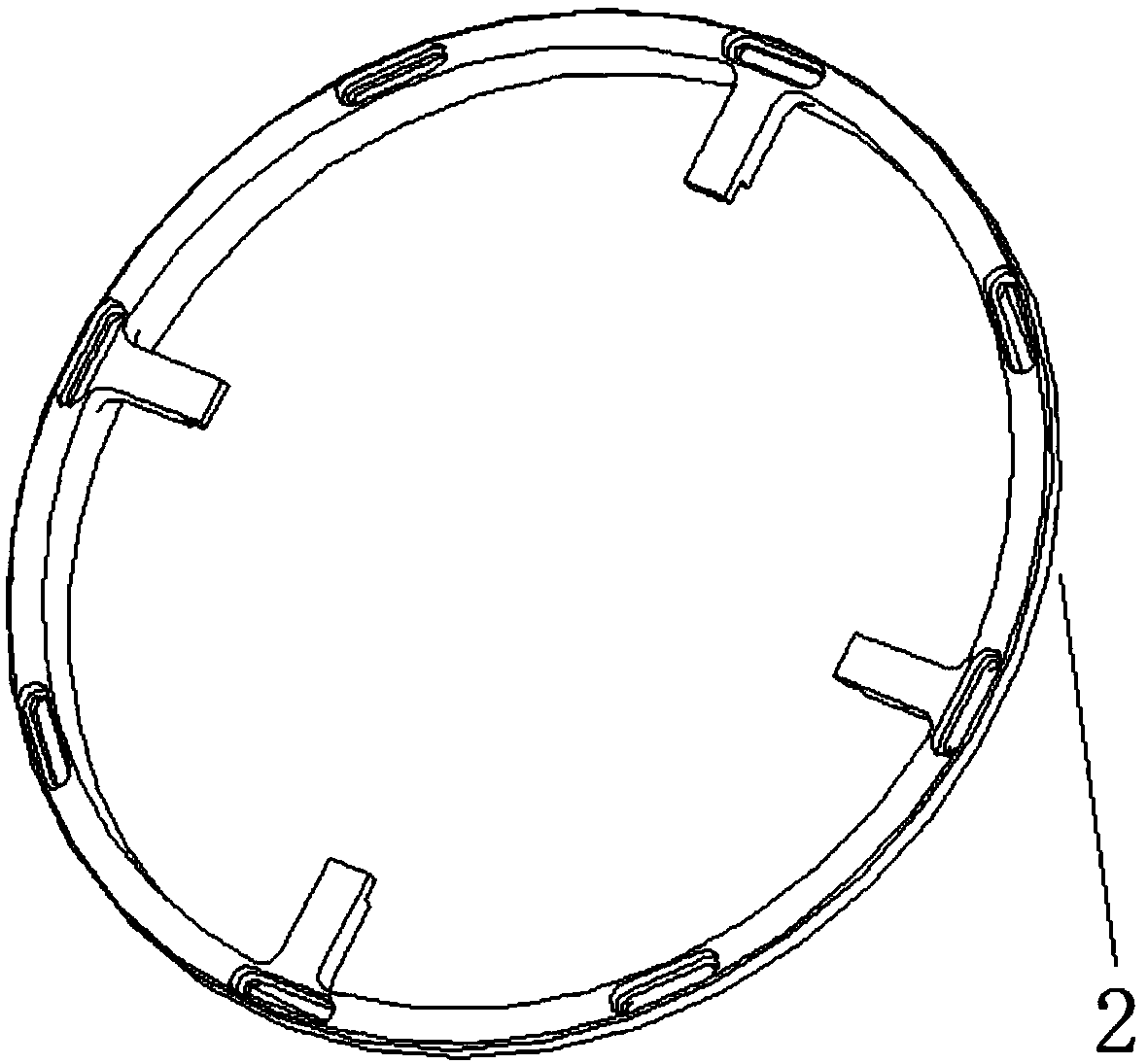

[0048] Step 1. Design the structure of the horn 1 as an overall wire-cut structure, the flatness of the large surface is 0.05mm, the surface roughness is Ra1.6, the dimensional accuracy and symmetry of the port are 0.05mm, and the symmetry between the horn diameter and the small diameter in the X and Y directions is 0.05 mm, the flange 2 and the horn 1 are symmetrical brazed joints, and the assembly gap of the joint 6 of the feed horn 3 is less than 0.1mm;

[0049] Step 2. After the horn 1 and flange 2 are processed, they are pre-assembled and numbered in sequence to ensure the consistency of the welding gap, and screen out the horn 1 and flange 2 with unqualified gaps;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com