Preparation method of dried zanthoxylum bungeanum maxim

A technology for drying Zanthoxylum bungeanum and Zanthoxylum bungeanum, applied in drying, drying machines, drying chambers/containers, etc., can solve the problems of high power consumption, etc., and achieve the effects of reducing emissions, increasing prices, and improving product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]A preparation method of dried pepper, the steps include:

[0028]Step 1. Natural air-drying: Naturally air-dry the picked fresh peppers, and put them into the drying room of the drying equipment after natural drying;

[0029]Step 2. Hot air dehumidification: Turn on the drying equipment, and dry the naturally air-dried prickly ash in a drying room at 32°C for 2 hours, 3 hours in a drying room at 35°C, and a drying room at 37°C. Bake for 3 hours,

[0030]Step 3, oil and oil collection: drying in a drying room at 39°C for 8 hours to achieve the purpose of oil production, and drying in a drying room at 41°C for 9 hours to achieve the purpose of oil collection;

[0031]Step 4. Dry the pepper that has completed step 2 in a drying room at 43°C for 5 hours, and then in a drying room at 45°C for 3 hours;

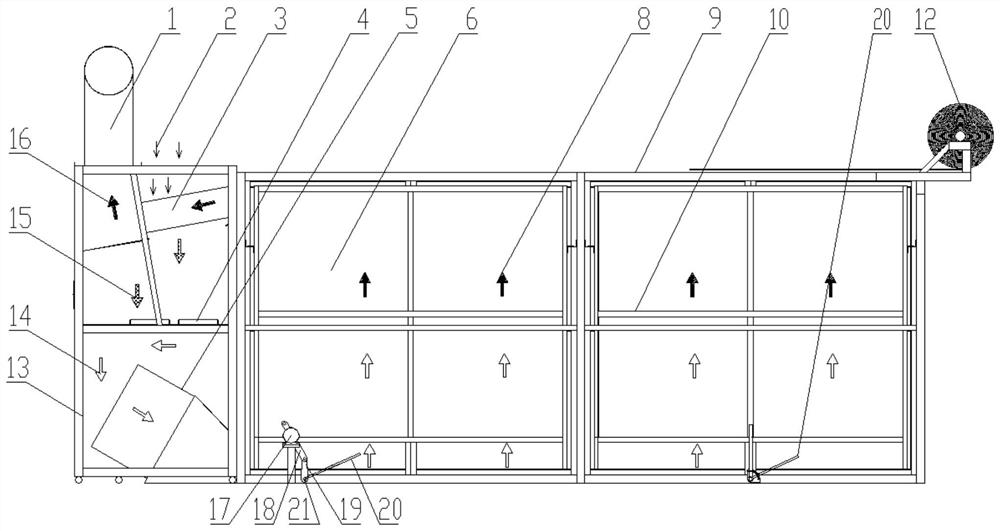

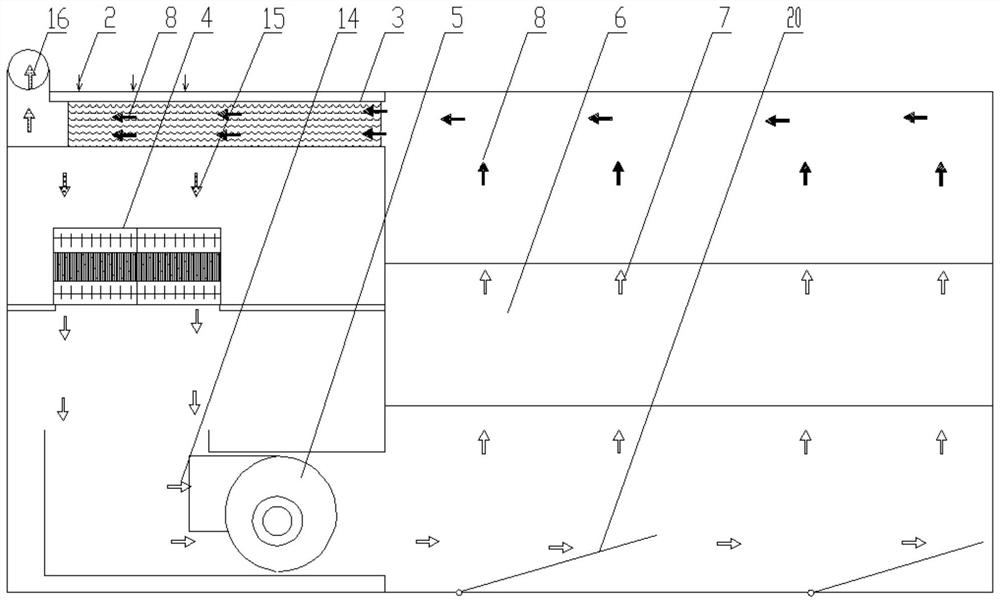

[0032]During the drying process, the cold air 2 is introduced into the heat exchanger 3 for heat exchange, the warm air 15 obtained from the heat exchange is introduced into the heater 4 for heati...

Embodiment 2

[0038]A preparation method of dried pepper, the steps include:

[0039]Step 1. Natural air-drying: The picked fresh peppers are air-dried naturally, and the fresh peppers are dried naturally and then put into the drying room of the drying equipment;

[0040]Step 2. Hot air dehumidification: Turn on the drying equipment, and dry the naturally air-dried pepper in the drying room at 31.5°C for 3 hours, then in the drying room at 34.5°C for 3 hours, and in the drying room at 36.5°C. Bake for 4 hours;

[0041]Step 3. Oil out and oil collection: Bake in a drying room at 38.5°C for 9 hours to allow the pepper oil to overflow the surface; bake in a drying room at 40.5°C for 10 hours to allow the pepper to absorb the pepper oil attached to the surface;

[0042]Step 4. Dry the pepper that has completed step 3 in a drying room at 42.5°C for 6 hours, and then in a drying room at 44.5°C for 4 hours;

[0043]During the drying process, the cold air 2 is introduced into the heat exchanger 3 for heat exchange, the...

Embodiment 3

[0046]A preparation method of dried pepper, the steps include:

[0047]Step 1. Natural air-drying: The picked fresh peppers are air-dried naturally, and the fresh peppers are dried naturally and then put into the drying room of the drying equipment;

[0048]Step 2. Hot air dehumidification: Turn on the drying equipment, and dry the naturally air-dried prickly ash in a drying room at 32.5°C for 1 hour, in a drying room at 35.5°C for 2 hours, and in a drying room at 37.5°C. Bake for 2 hours;

[0049]Step 3, oil and oil collection: bake in a drying room at 39.5°C for 7 hours to allow the pepper oil to overflow the surface; bake in a drying room at 41.5°C for 8 hours to allow the pepper to absorb the pepper oil attached to the surface;

[0050]Step 4. Dry the pepper that has completed step 3 in a drying room at 43.5°C for 4 hours, and then in a drying room at 455°C for 2 hours;

[0051]During the drying process, the cold air 2 is introduced into the heat exchanger 3 for heat exchange, the warm air 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com