Double-light path CO2 laser processing device and method of alumina ceramics

An alumina ceramic and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing production costs, difficult to debug the processing effect, and the nozzle cannot be adjusted in horizontal position, so as to improve the processing efficiency. Efficiency, improved cutting and dicing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations will now be described in detail with reference to the accompanying drawings.

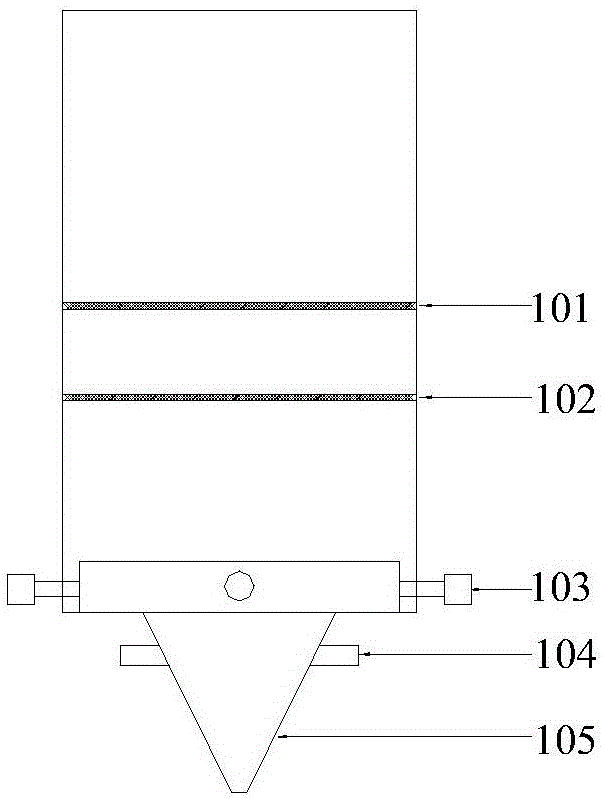

[0025] Such as figure 1 As shown, the dual optical path of alumina ceramic CO 2 The laser processing device includes two sets of optical path systems with the same optical path structure, and the first set of optical path systems both contain the first radio frequency CO 2 Laser 11, first circular polarizer 12, first beam expander 14, first laser cutting head 17, first reflector 13, second reflector 15, third reflector 16, the second set of optical path system includes the first Two RF CO 2 A laser 21 , a second circular polarizer 22 , a second beam expander 24 , a second laser cutting head 27 , a fourth reflector 23 , a fifth reflector 25 , and a sixth reflector 26 .

[0026] First RF CO 2 A first circular polarizer 12 is arranged at the output end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com