Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Lattice stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479ALattice stabilizationGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentSlurryZircon

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

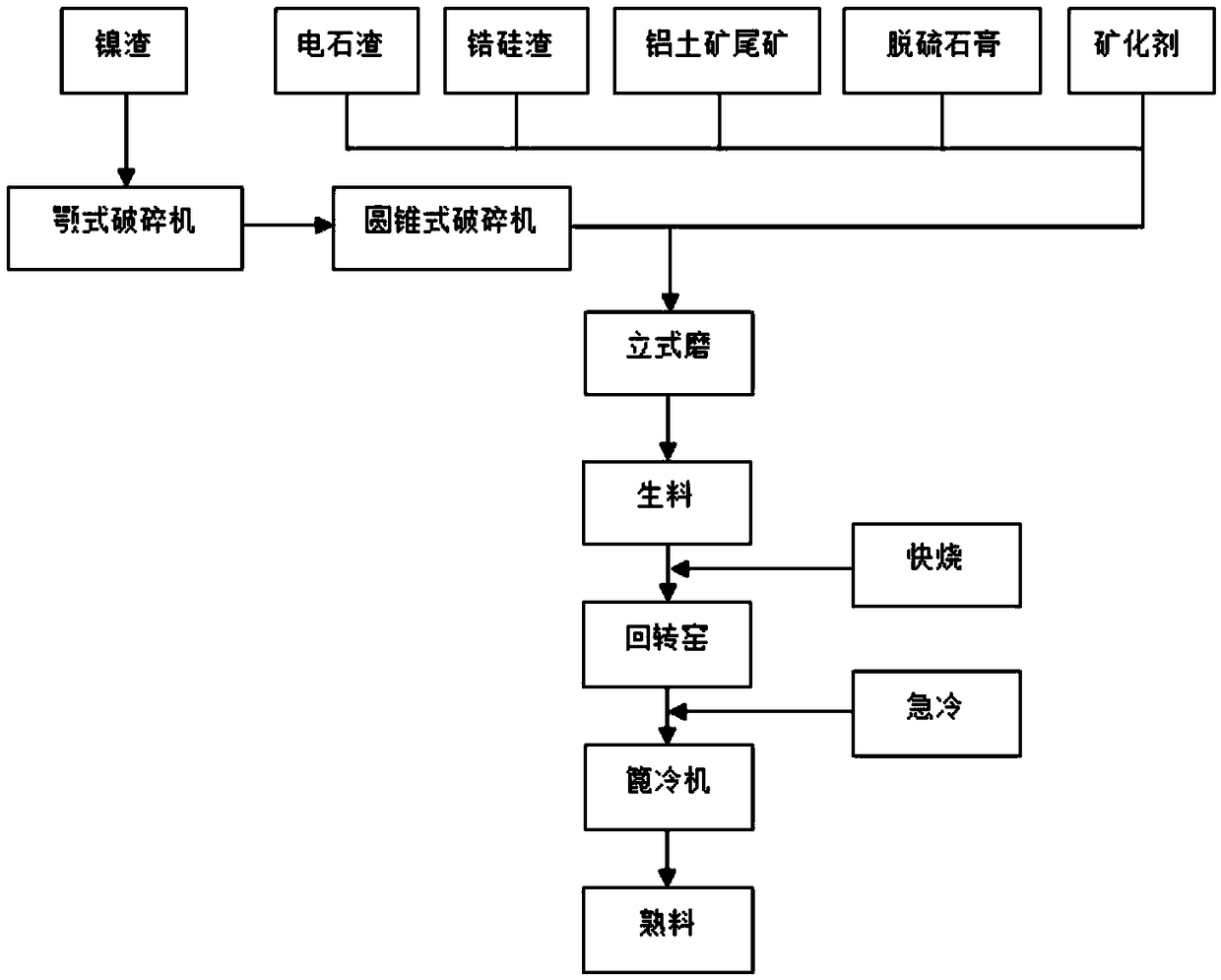

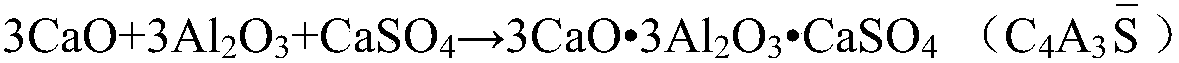

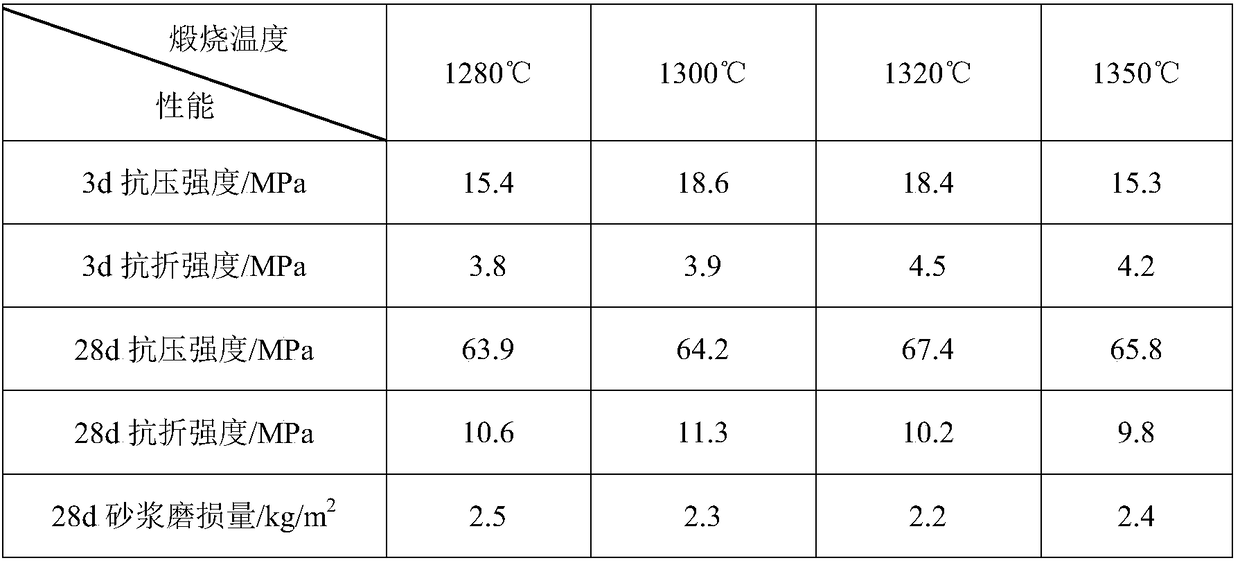

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Preparation method for MOF derived oxide coated NCA high nickel ternary cathode material

InactiveCN110061224AEasy to operateInnovative designCell electrodesSecondary cellsMass ratioMetal-organic framework

The invention discloses a preparation method for an MOF derived oxide coated NCA high nickel ternary cathode material and belongs to the technical field of a lithium ion battery. The preparation method comprises the steps of (1), preparing corresponding metal organic frameworks (MOFs) containing specific metal elements; (2), mixing an NCA high nickel ternary cathode material with the specific MOFsaccording to a mass ratio, and carrying out ball milling, thereby enabling the MOFs to be attached to the surface of the NCA high nickel ternary cathode material uniformly; and (3), calcining the material in air, thereby changing a coating material from the MOFs to MOF derived oxides, and obtaining a final product. According to the method, through utilization of features of the nano-material MOFs, a coating layer is kept at a nano-level, so the surface of the material is protected, side reaction due to direct contact with electrolyte is reduced, and battery performance of the cathode materialis improved. The method is novel and convenient and is obvious in effect.

Owner:TIANNENG SAFT ENERGY JOINT CO

Lithium manganate material and preparation method thereof and lithium ion battery cathode material

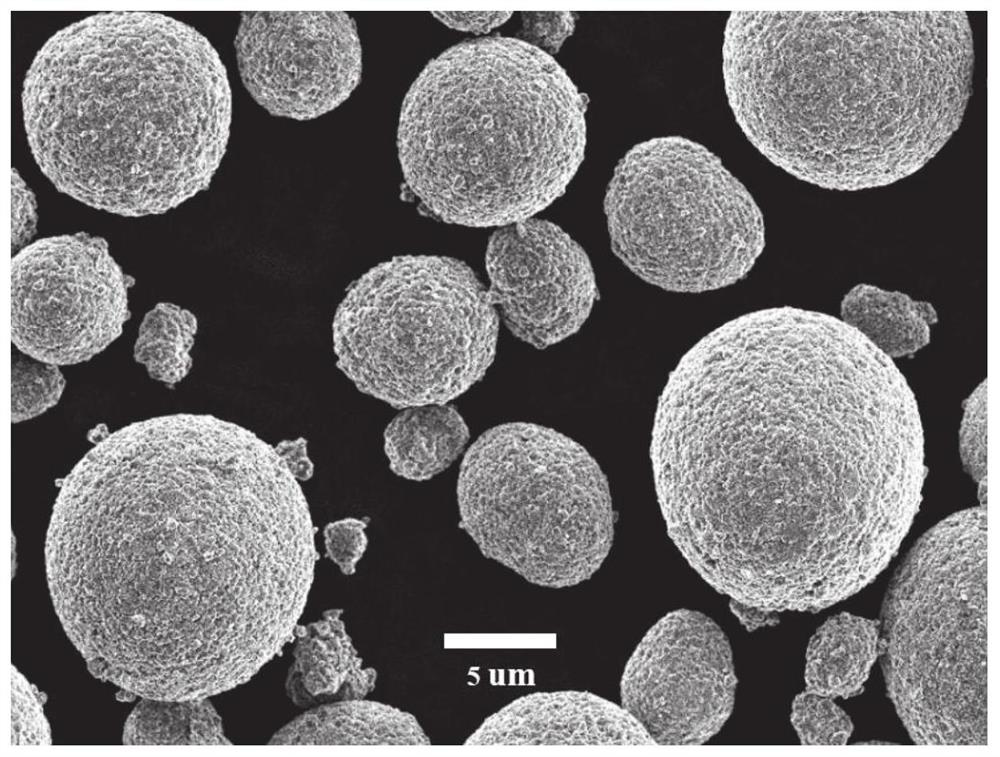

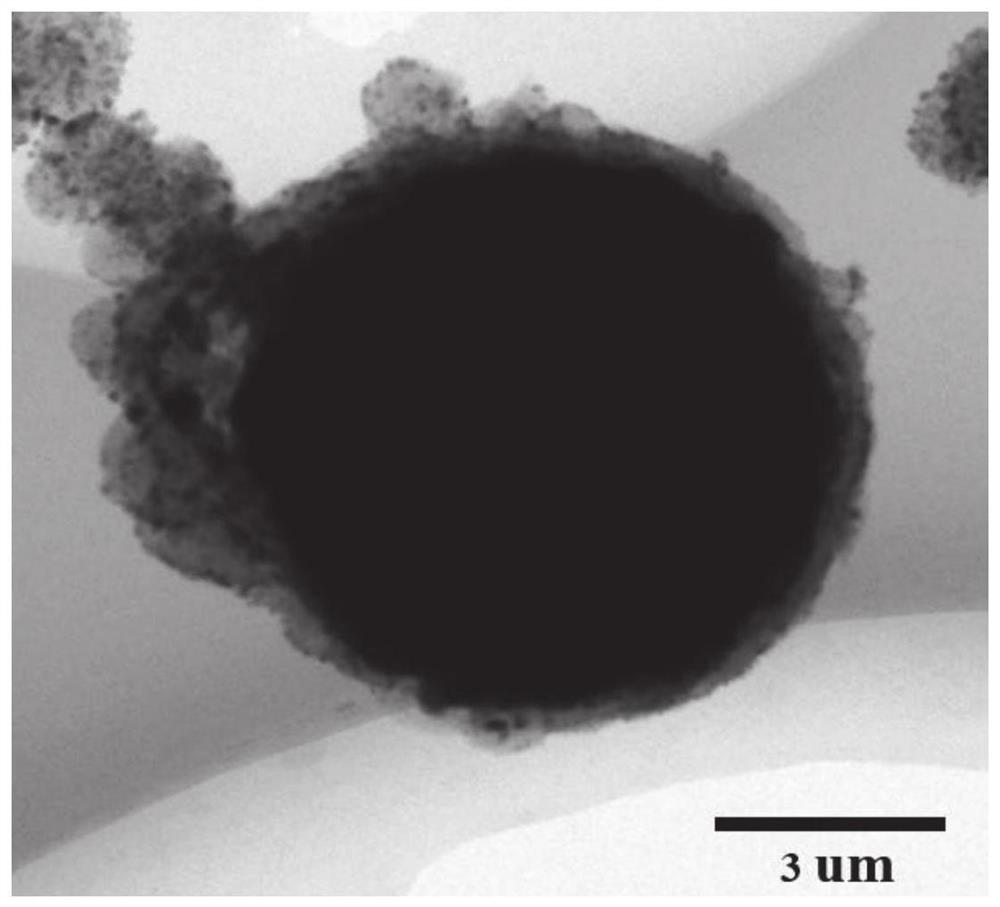

ActiveCN104425814ASmall specific surface areaLarge specific surface areaCell electrodesManganateSlurry

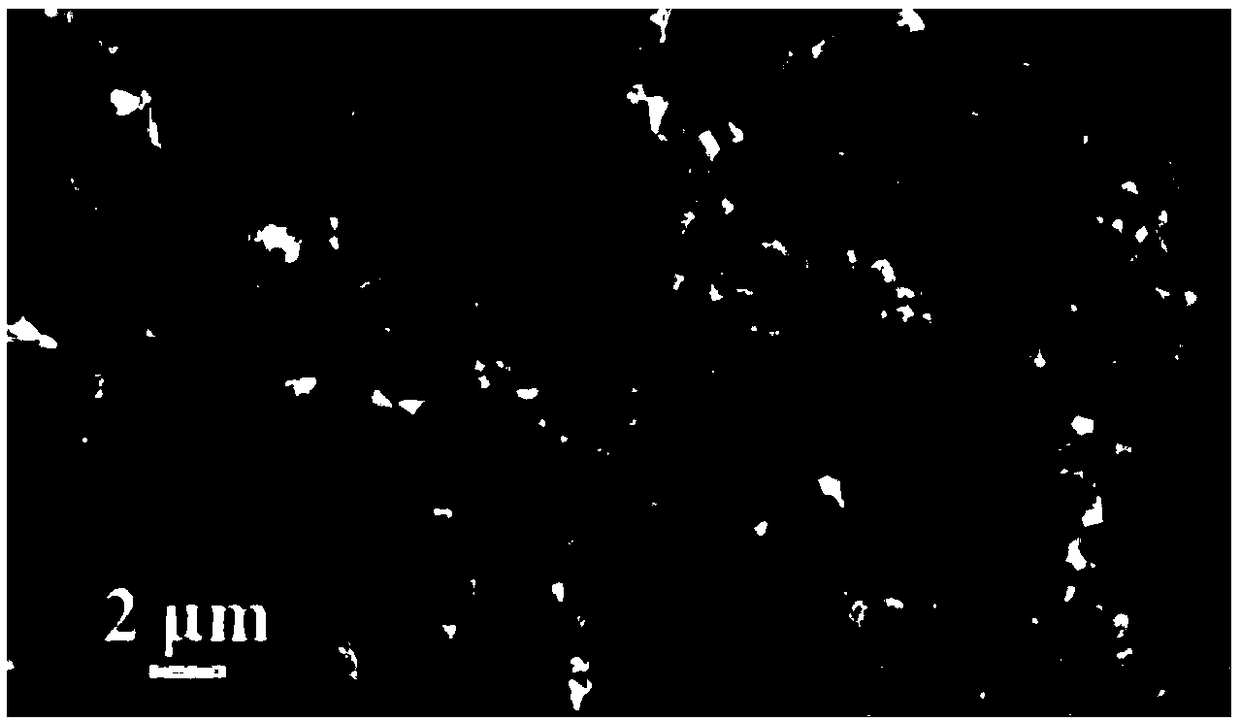

The invention provides a lithium manganate material and a preparation method thereof and a lithium ion battery cathode material. The preparation method comprises the following steps: mixing a manganese source, a lithium source and a compound of one or more doped metals and adding a fluxing agent and ball-milling in a solvent, when the particle size reaches below 1 micrometers, further crushing by using a superfine mill and uniformly mixing so that the particle size of first-time particles reaches 200-300nm and slurry is uniformly mixed; and driving the slurry in a centrifugal spray dryer after iron is removed for sphere granulating, and finally performing step-wise sintering to prepare the lithium manganate material. Because doping of multiple metals, modifying of the surface of the fluxing agent, fine crushing of a sand mill and spray-granulating, the lithium manganate material has high conductivity, smooth surface and low specific surface area, good mixing uniformity and uniform spherical particles.

Owner:BEIJING NAT BATTERY TECH

Method used for treating VOCs exhaust gas at low cost

InactiveCN107583453ALattice stabilizationHigh tap densityOther chemical processesDispersed particle filtrationExhaust gasCopper salt

The invention discloses a method used for treating VOCs exhaust gas at low cost. According to the method, a soluble manganese salt and a soluble copper salt are taken as raw materials; coprecipitationis adopted to prepare a catalyst; a cloth bag-type dust collector is used for dedusting of VOCs exhaust gas; after dedusting, the VOCs exhaust gas is delivered into a reactor containing an adsorbent;after adsorption saturation, heating and desorption are carried out; after desorption, the obtained gas is delivered into a reactor containing the catalyst, and the reactor is heated so as to realizecatalytic combustion of the gas; after combustion, purified gas is obtained and discharged. The method is capable of removing VOCs gas in exhaust gas effectively; no secondary air pollution is caused; and cost is low.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

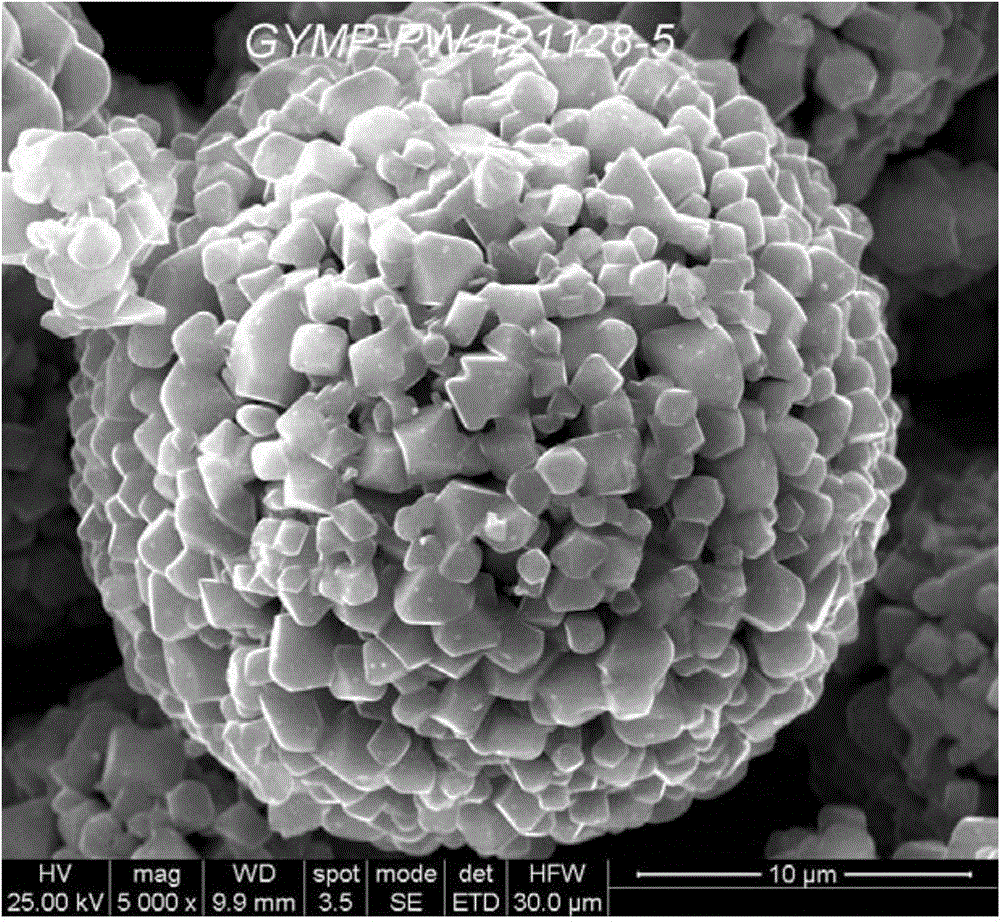

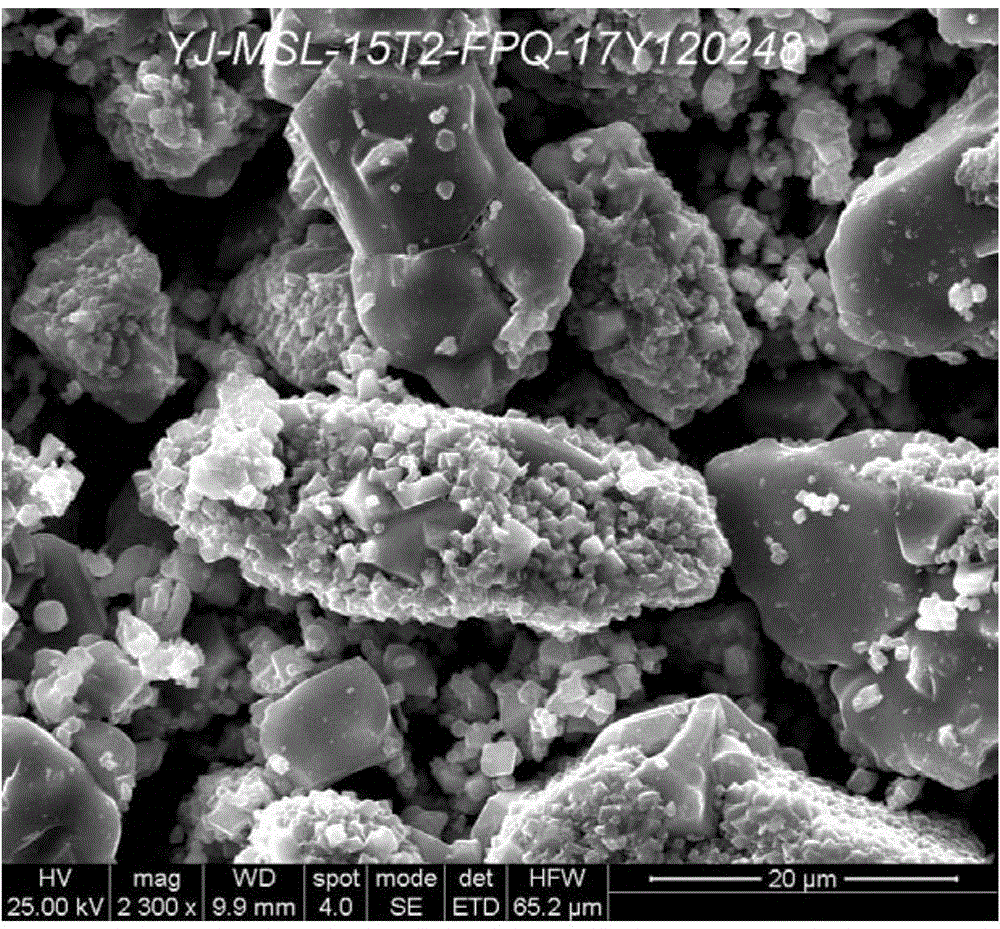

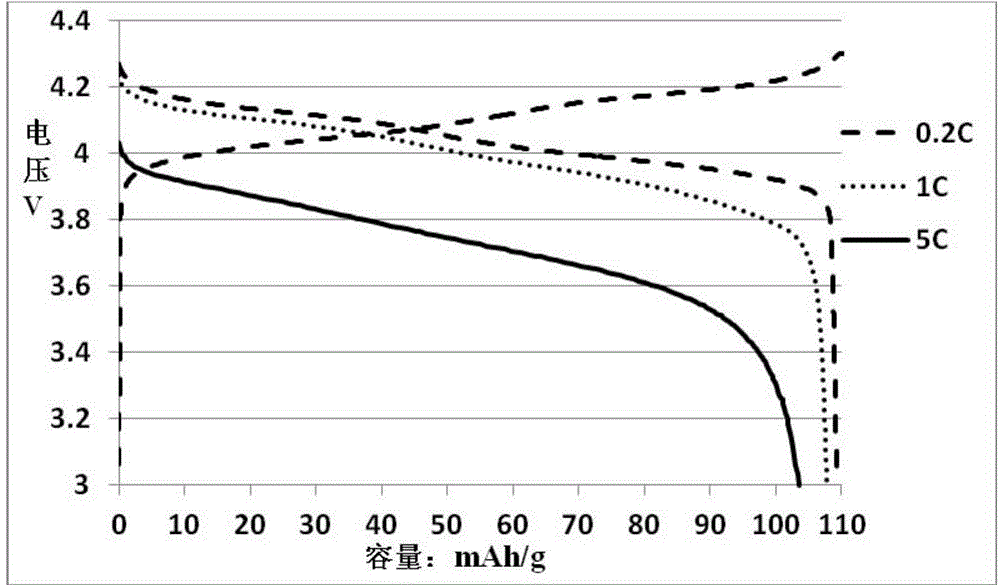

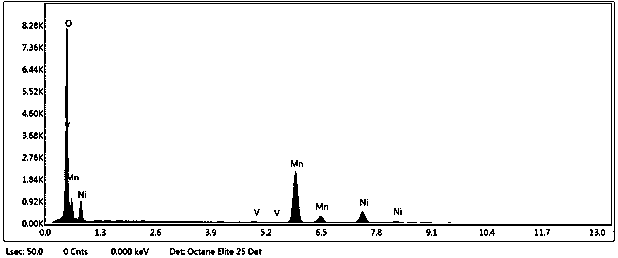

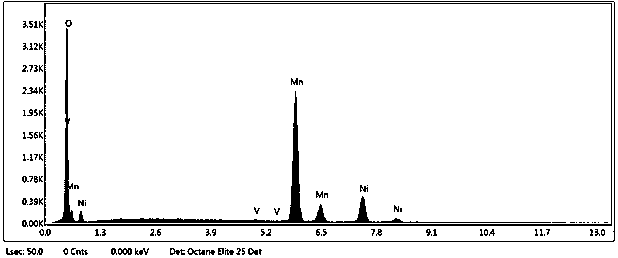

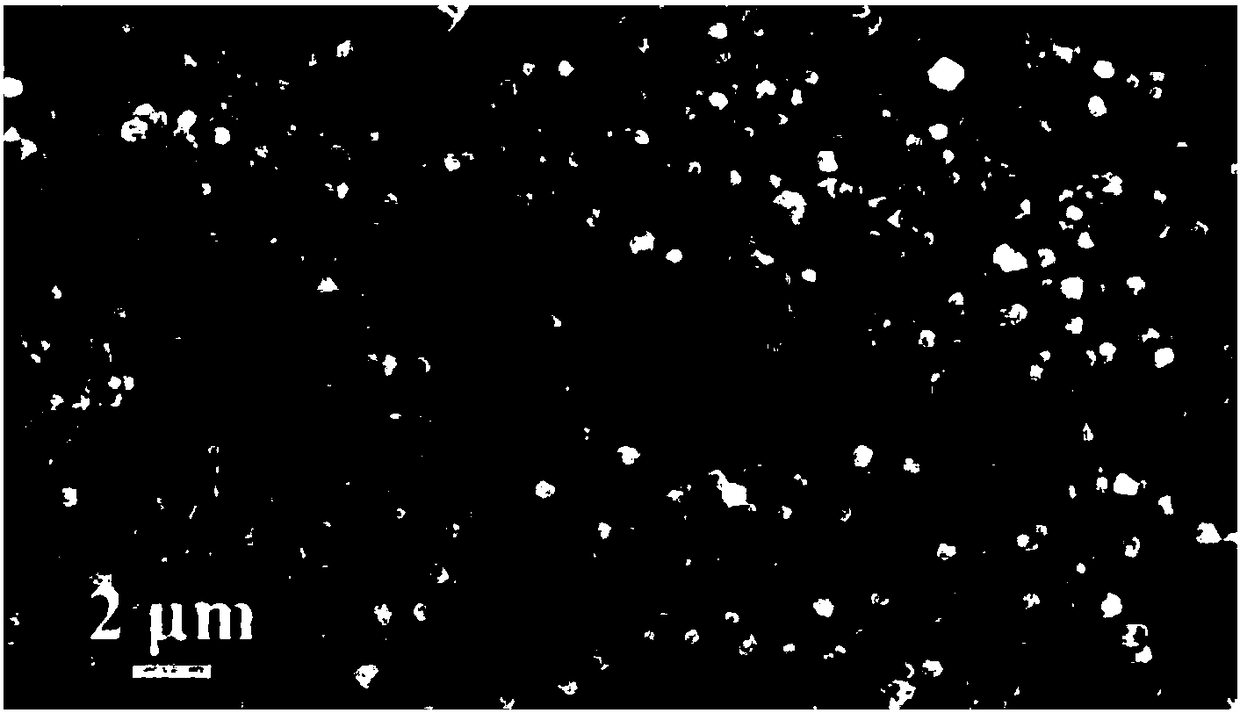

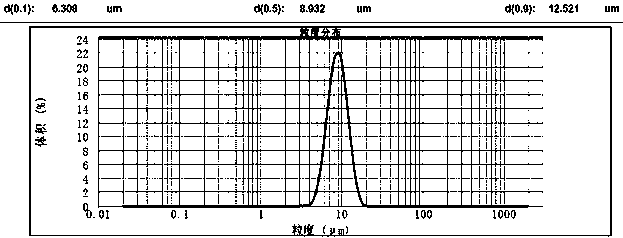

Vanadium-doped nickel-manganese composite hydroxide and preparation method thereof

InactiveCN110943212ALess impuritiesImprove cycle performanceCell electrodesSecondary cellsManganesePhysical chemistry

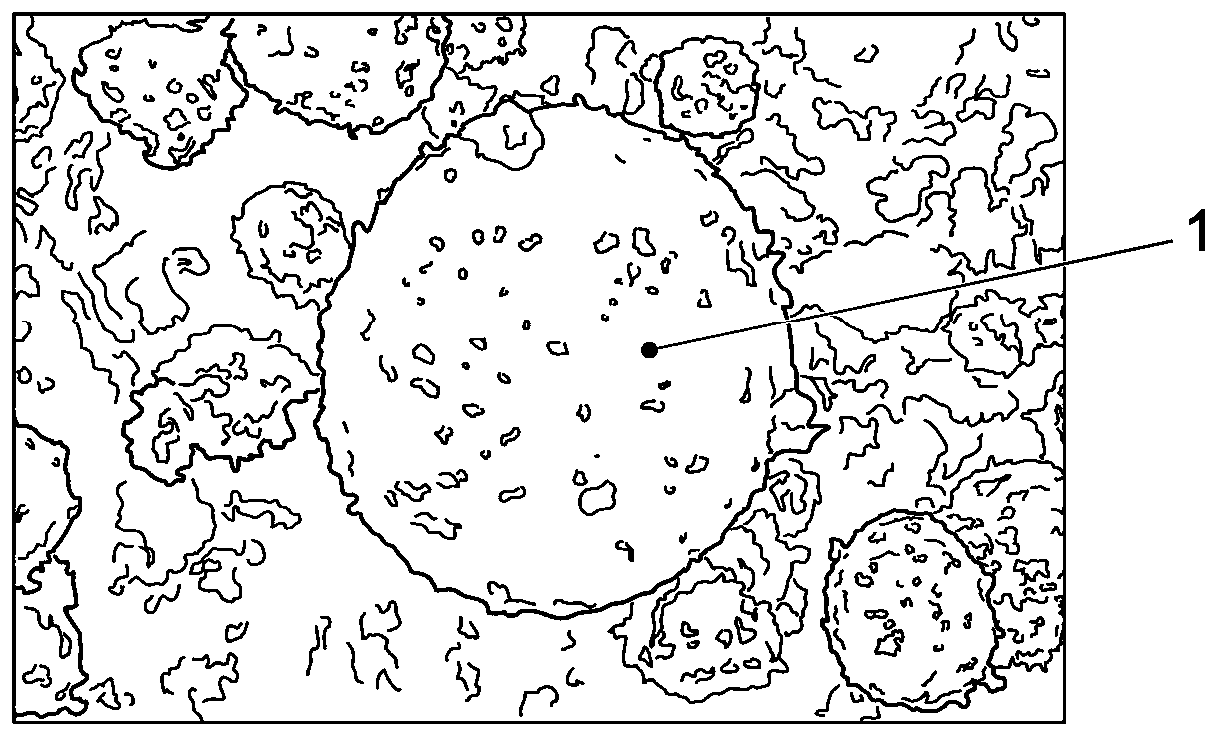

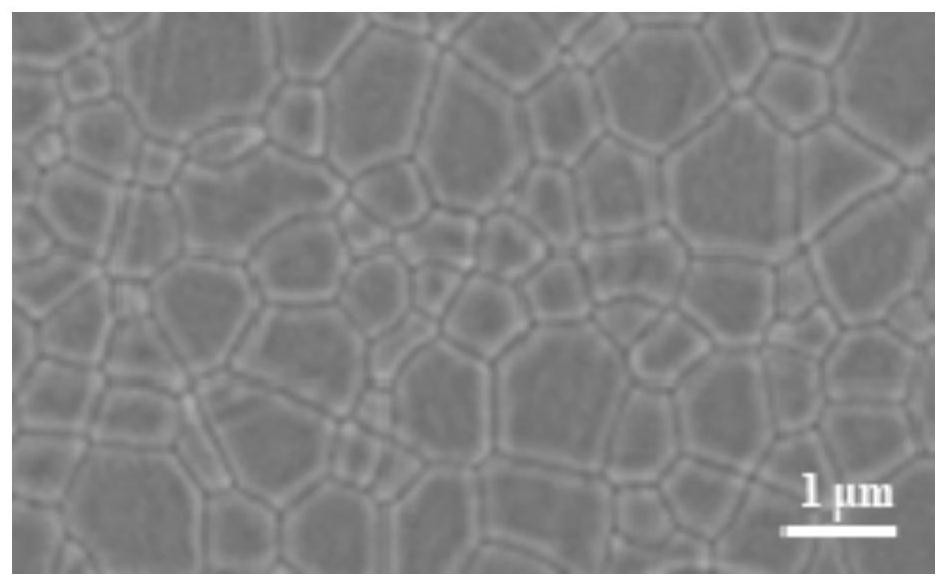

The invention relates to a vanadium-doped nickel-manganese composite hydroxide and a preparation method thereof. The vanadium-doped nickel-manganese composite hydroxide is represented by a general formula Ni < x > Mn < 1-x > Vz (OH) < 2 + a >, wherein x is greater than or equal to 0.1 and less than or equal to 0.9, 0.001 < = z < = 0.01; wherein a is more than or equal to 0.005 and less than or equal to 0.05, the microstructure is determined to be sphere-like by an analytical scanning electron microscope method, the D50 is determined to be 3.0-16.0 mu m by a particle size analysis laser diffraction method, and the specific surface area is determined to be 4.0-13.0 m < 2 > / g by a gas adsorption BET method; the vanadium element is introduced to stabilize the structure of the catalyst; according to the preparation method, atomic-scale mixing of nickel, manganese and vanadium elements is achieved, the obtained vanadium-doped nickel-manganese composite hydroxide has the advantages of being uniform in element distribution, good in sphericity degree and stable in crystal lattice, the problems that in the prior art, vanadium element doping is not uniform, and particles are prone to breakageare solved, and the safety, the cycle performance and the rate performance of the nickel-manganese positive electrode material are further improved.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

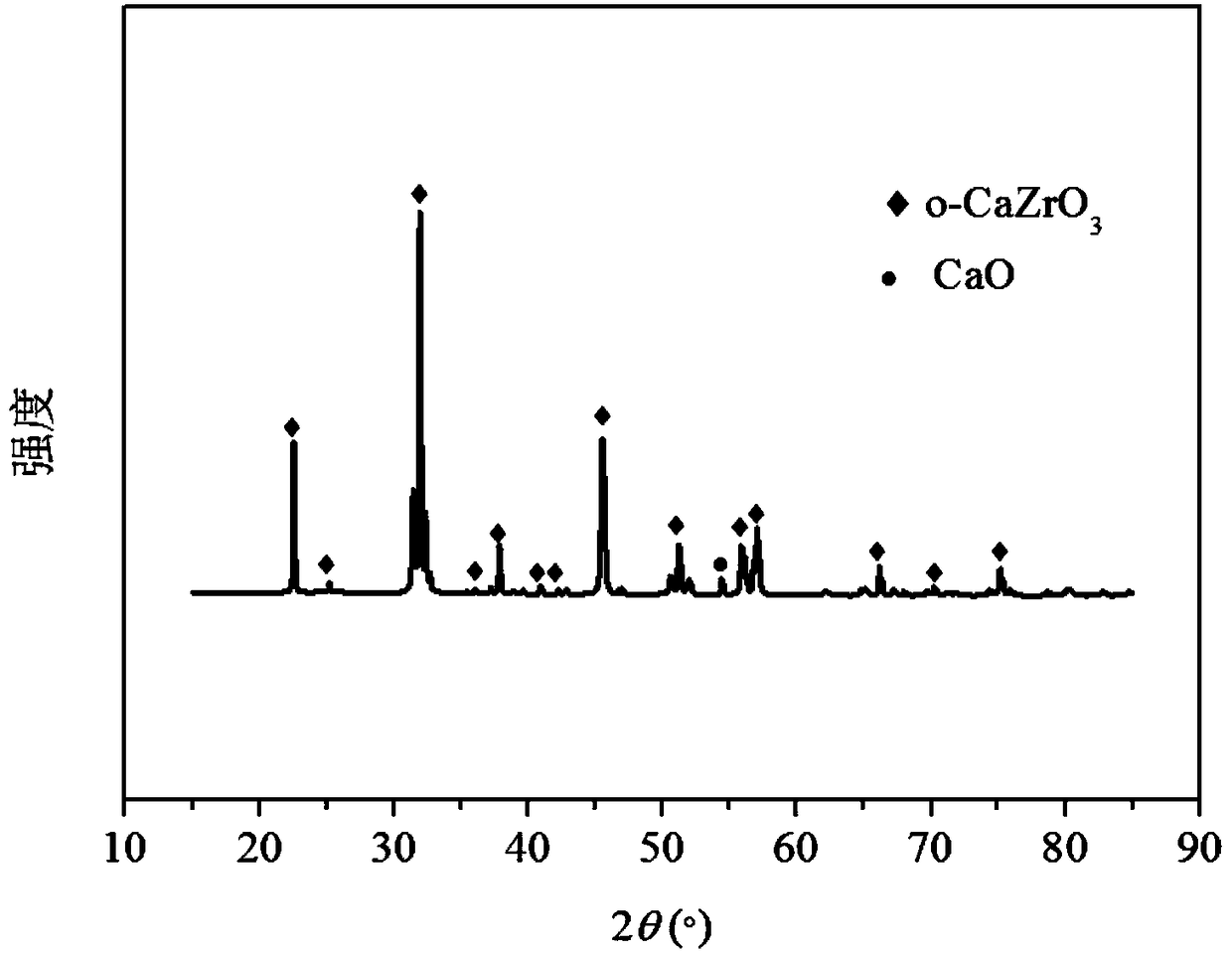

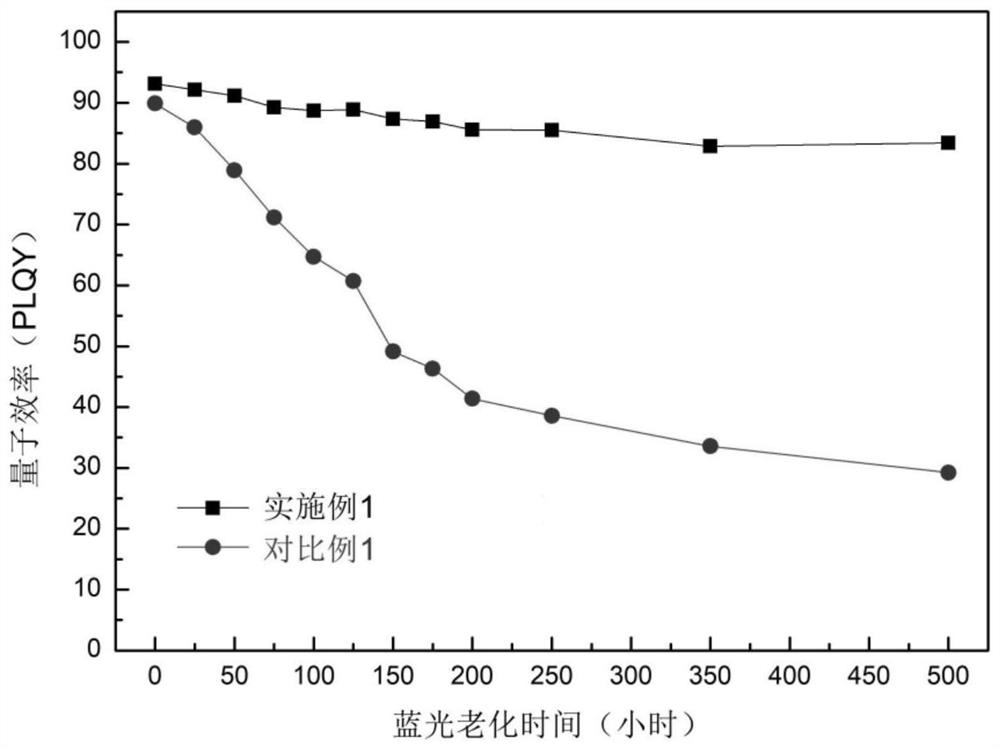

Calcium zirconate material doped with metal and preparation method and application of calcium zirconate material

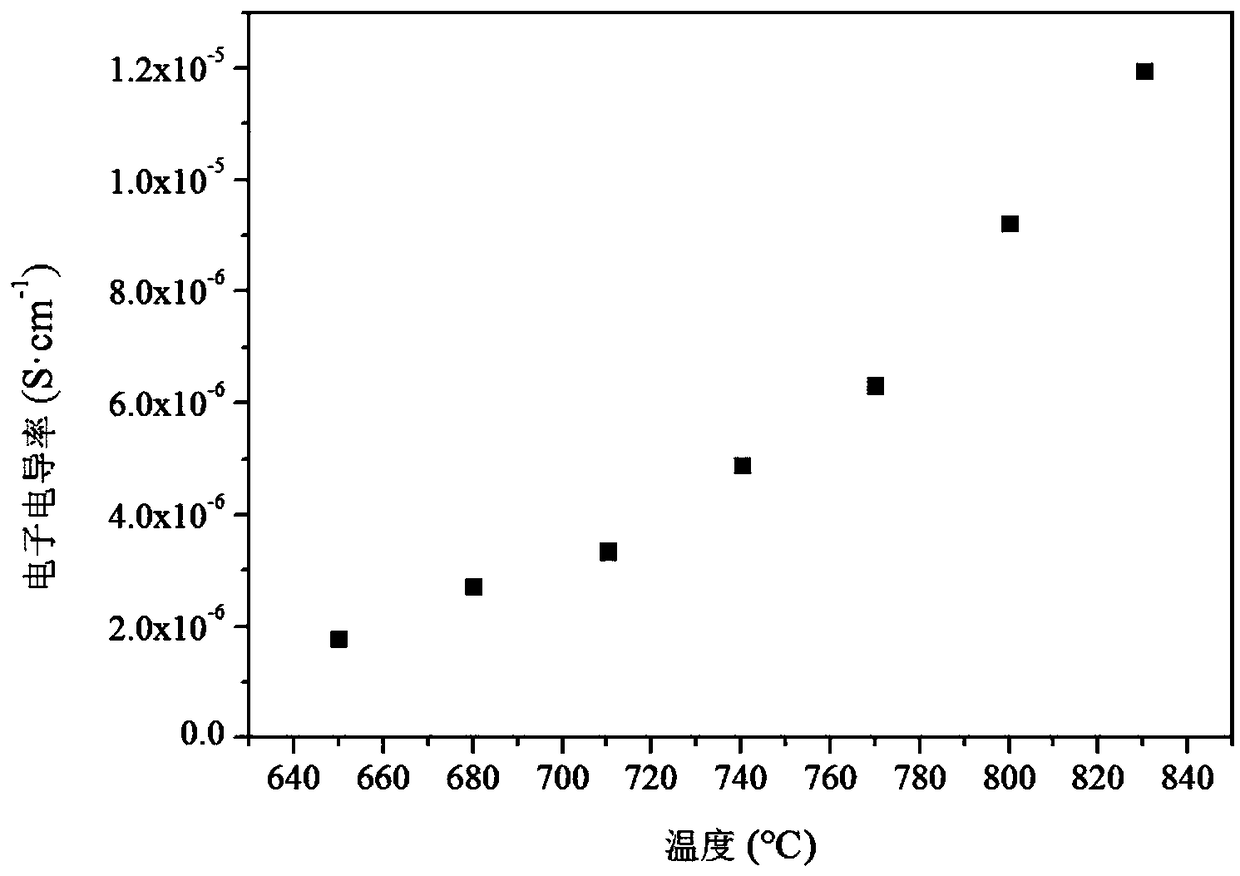

InactiveCN108529671APossess electronic conductivityLow costCell electrodesZirconium compoundsOxygen ionsZirconate

The invention relates to a calcium zirconate material doped with metal and a preparation method and application of the calcium zirconate material. The calcium zirconate material doped with metal comprises the following raw materials of: calcium carbonate powder, zirconia powder and chromium oxide powder, wherein the molar ratio of the total of the zirconia powder and chromium oxide powder to the calcium carbonate powder is 1:1, and the chromium oxide powder accounts for 0.05-0.15, by mole, of the total of the zirconia powder and chromium oxide powder. The calcium zirconate material doped withchromium has both oxygen ion conductivity and electron conductivity at the same time, and has low price, excellent mechanical properties and stability. The preparation method of the calcium zirconatematerial doped with chromium has a simple process and low cost, the prepared calcium zirconate material doped with chromium has few pores, and the compactness and mechanical properties are improved greatly; the calcium zirconate material doped with chromium can be applied to a dense diffusion barrier layer in an oxygen sensor, a cathode of a solid oxide fuel cell or an oxygen separation membrane.

Owner:NORTHEASTERN UNIV

Nickel-cobalt-manganese composite hydroxide added with hexavalent elements and preparation method of nickel-cobalt-manganese composite hydroxide

ActiveCN110957482AOvercome uniformity issuesGood dispersionCell electrodesSecondary cellsPhysical chemistryManganese

The invention relates to a nickel-cobalt-manganese composite hydroxide added with hexavalent elements and a preparation method of the nickel-cobalt-manganese composite hydroxide. The nickel-cobalt-manganese composite hydroxide added with the hexavalent elements is represented by a general formula NixCoyMnz (OH) 2-2a (MO4) a, wherein x is greater than or equal to 0.30 and less than or equal to 0.92, y is greater than or equal to 0.08 and less than or equal to 0.40, z is greater than or equal to 0.02 and less than or equal to 0.50, a is greater than or equal to 0.001 and less than or equal to 0.02, x + y + z is equal to 1, and M is an added hexavalent element and represents one or a combination of molybdenum and tungsten; according to the invention, a hexavalent element-containing compound is dissolved into an alkaline solution to form a mixed alkaline solution, so atomic-scale mixing of nickel, cobalt, manganese and hexavalent elements is achieved, the internal structure of the nickel-cobalt-manganese composite hydroxide is stabilized through introduction of the hexavalent elements, and the obtained nickel-cobalt-manganese composite hydroxide added with the hexavalent elements has the advantages of being uniform in element distribution, good in dispersity and sphericity degree and stable in crystal lattice.

Owner:HUAYOU NEW ENERGY TECH (QUZHOU) CO LTD +1

Method for preparing pigment by utilizing waste flue gas denitrification catalyst

ActiveCN104973623ALow toxicityTo achieve the purpose of harmless treatment and resource utilizationAntimony compoundsManganese oxides/hydroxidesPtru catalystFlue gas

The invention relates to a method for preparing pigment by utilizing a waste flue gas denitrification catalyst. The method comprises the following steps of: crushing the waste flue gas denitrification catalyst by a crusher, adding a metal oxide stabilizer and a metal oxide developing agent into the crushed waste flue gas denitrification catalyst to uniformly mix; and grinding the uniformly-mixed raw materials into powder particles by a ball mill, then, putting the powder particles into an industrial roasting furnace, heating the powder particles to 800 DEG C at certain heating rate to generate combustion reaction , preserving the temperature for 8-16 hours at 1000 DEG C in the roasting furnace, and naturally cooling and grinding the powder particles to prepare the pigment. The pigment prepared by the method disclosed by the invention is stable in property, relatively good in heat resistance, light resistance, weather resistance, acid resistance, and alkali resistance. The method disclosed by the invention is simple, and used equipment is few and uncomplicated in structure, so that innocent treatment and resource utilization of the waste flue gas denitrification catalyst can be realized, and the popularization is convenient.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

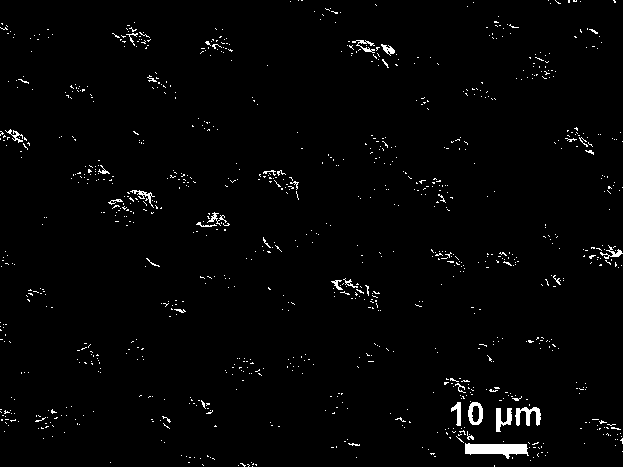

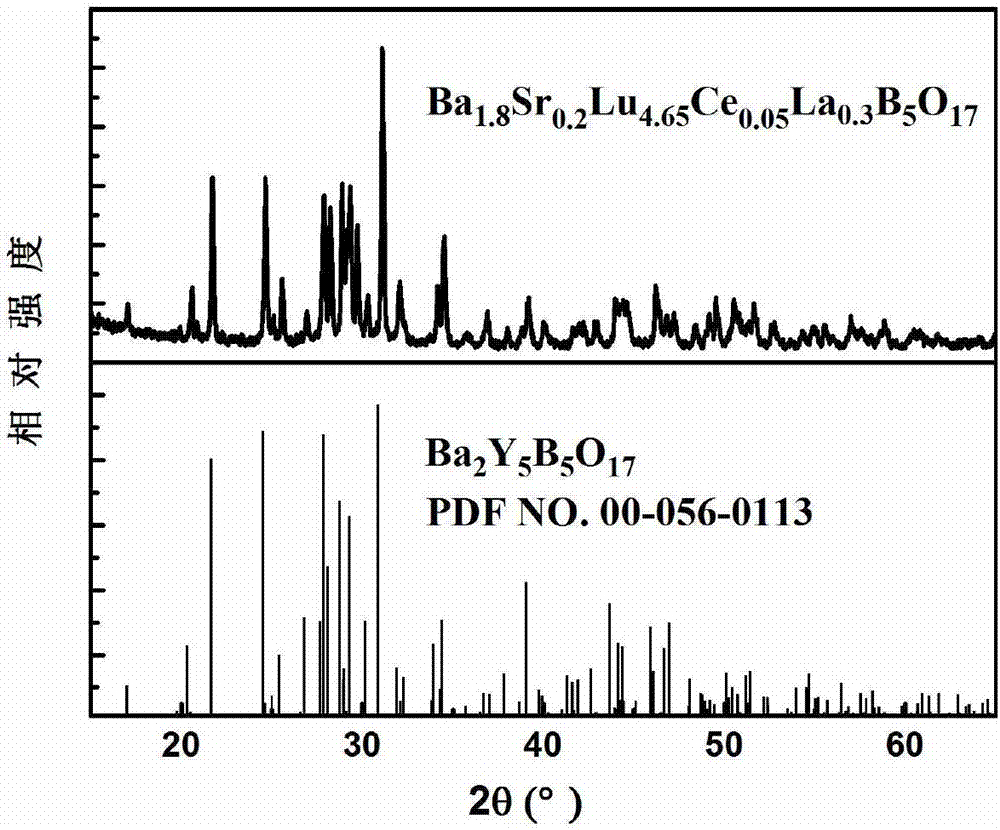

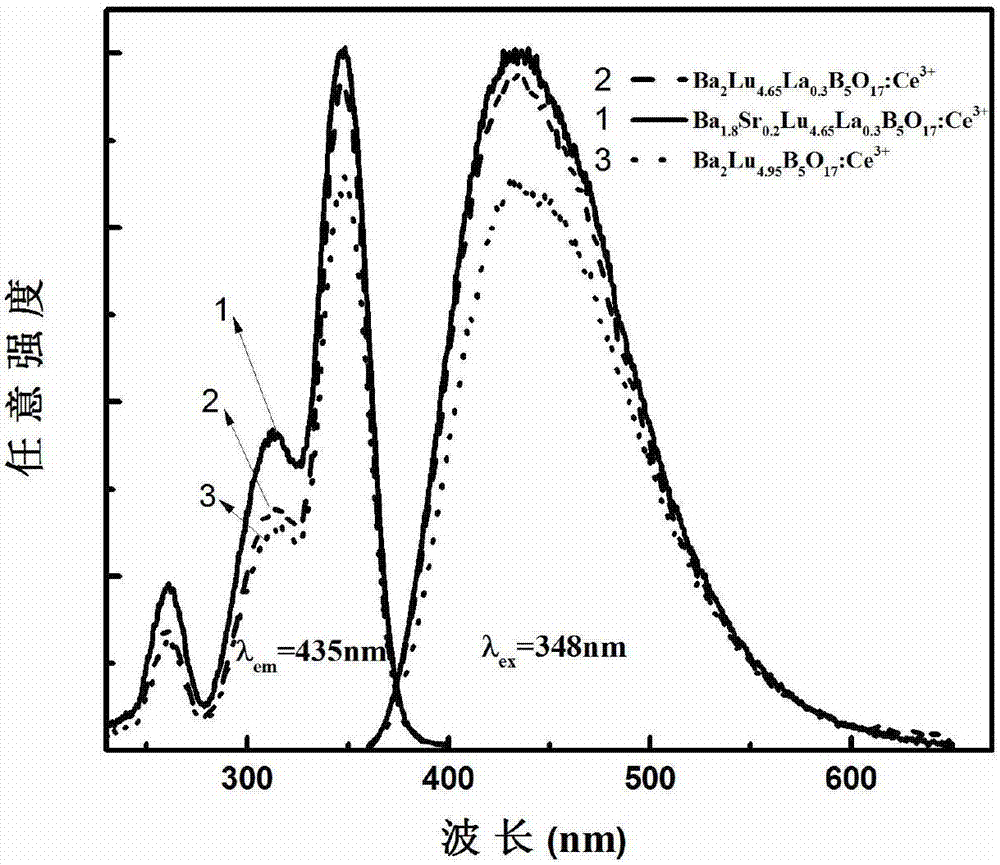

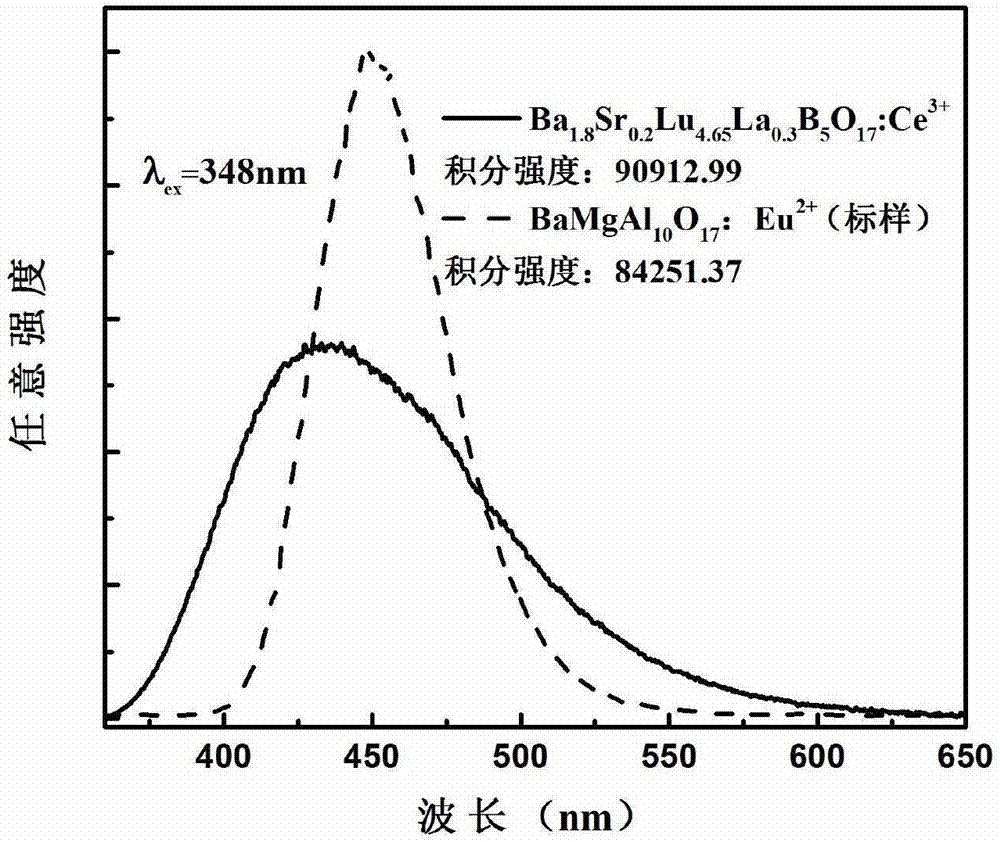

White light LED (light-emitting diode) blue fluorescent powder, preparation method thereof and application

InactiveCN107033896AProcess stabilitySimple processEnergy efficient lightingLuminescent compositionsHeat stabilityUltraviolet lights

The invention relates to white light LED (light-emitting diode) blue fluorescent powder, a preparation method thereof and an application, belongs to the technical field of light-emitting materials, and solves the technical problems that Ba2Lu5B5O17:Ce3+ crystal-phase structures are unstable, synthetic process conditions are not easily controlled, heat stability is poor, and light-emitting efficiency is low in the prior art. The chemical formula of the fluorescent powder is Ba2-mAmLu5-x-nLnCexB5O17, wherein A refers to one of Ca and Sr, L refers to one or more of Y, La, Gd, Sc, Yb and Er, and x, m and n are mole fractions and have the value ranges of 0<x< / =0.6, 0< / =m< / =1 and 0< / =n< / =2. The prepared fluorescent powder can be effectively excited by 200-380nm ultraviolet light and near ultraviolet light, is high in quantum efficiency, excellent in heat stability, simple and flexible in process and good in repeatability, and can be potentially applied to ultraviolet / near ultraviolet LEDs and chip base white LEDs.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

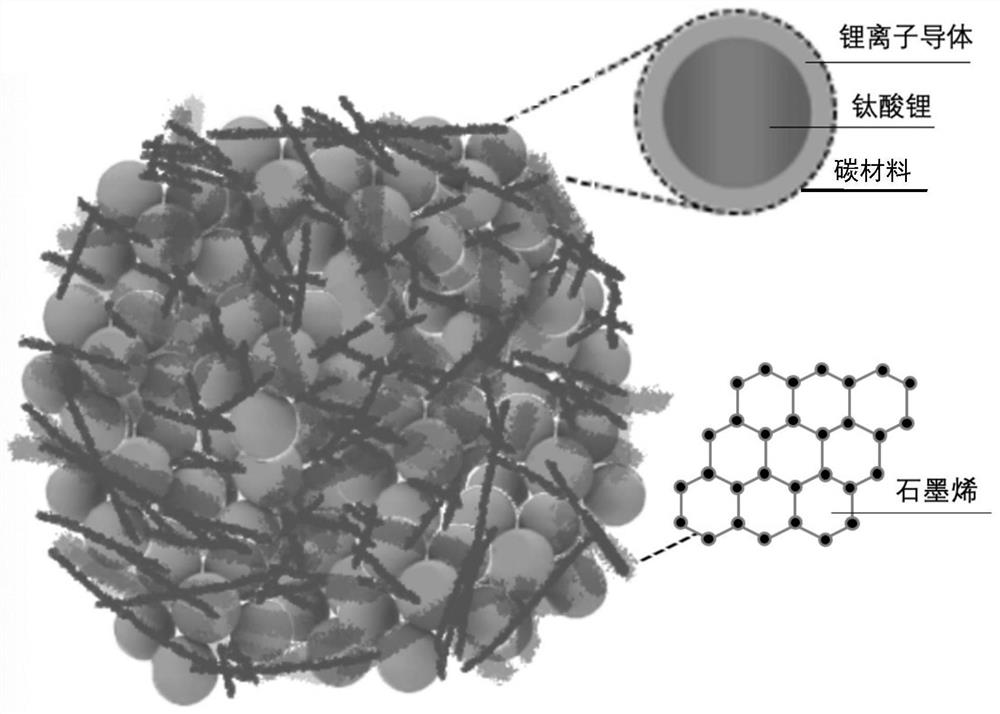

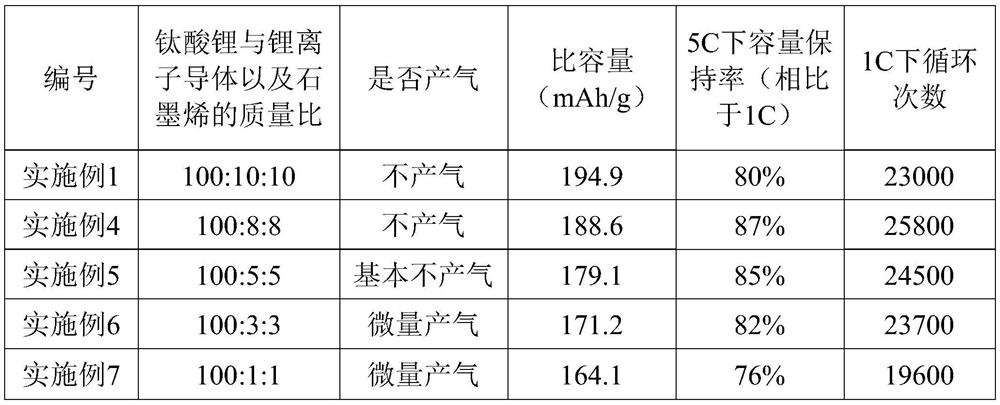

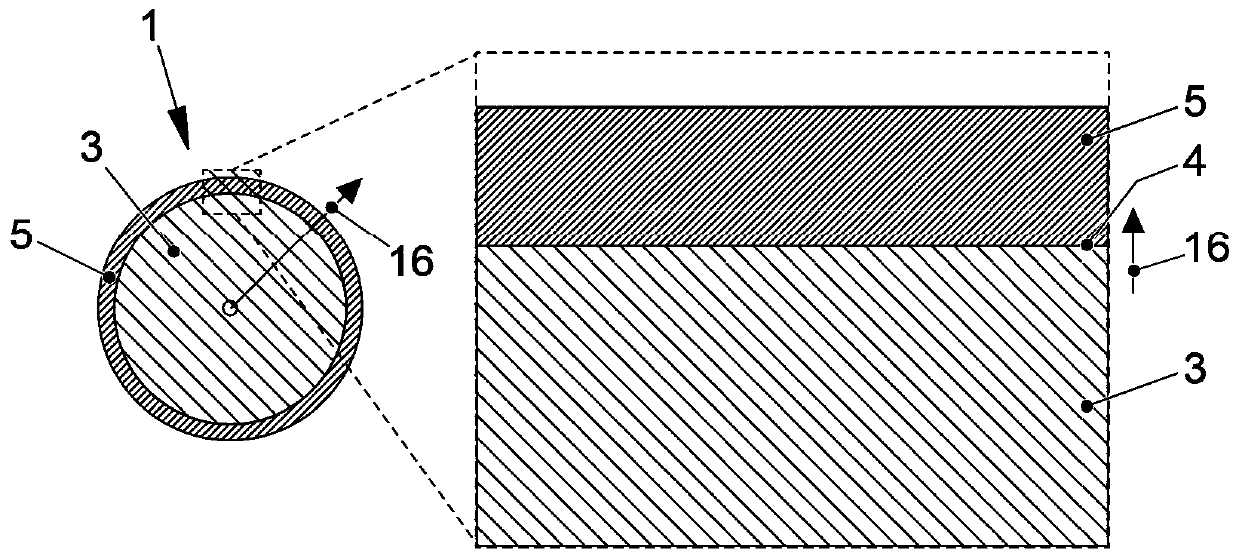

Lithium titanate/lithium ion conductor/carbon composite material and preparation method and application thereof

PendingCN113937260AAvoid direct contactAvoid reactionNegative electrodesSecondary cells servicing/maintenanceCarbon compositesElectrical conductor

The invention belongs to the technical field of battery materials, and particularly relates to a lithium titanate / lithium ion conductor / carbon composite material, a preparation method thereof and a secondary battery. The lithium titanate / lithium ion conductor / carbon composite material sequentially comprises a lithium titanate inner core, a lithium ion conductor middle layer and a carbon material shell layer from inside to outside. According to the lithium titanate / lithium ion conductor / carbon composite material, through the synergistic effect of the lithium titanate inner core, the lithium ion conductor middle layer and the carbon material shell layer, the composite material has the characteristics of being not prone to flatulence, excellent in electron / ion transmission performance, good in high and low temperature characteristics, good in structural stability, excellent in fast charging performance, high in safety and the like.

Owner:SHENZHEN INST OF ADVANCED TECH +1

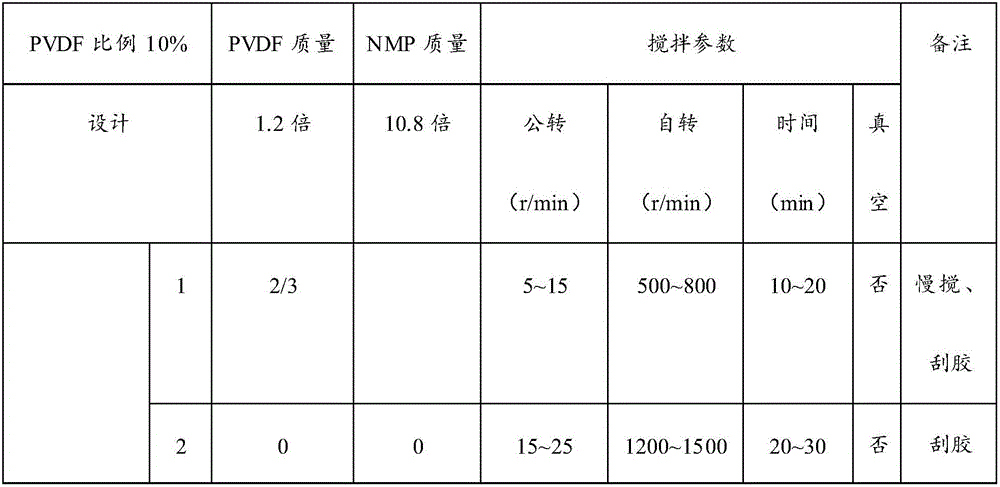

Positive electrode slurry and preparation method thereof and lithium-ion battery

ActiveCN106299351AImprove securityImproved magnification performanceCell electrodesSecondary cellsDecompositionNano al2o3

The invention provides positive electrode slurry, which comprises the following raw materials in parts by weight: 93-97.5 parts of lithium cobalt oxide materials, 1.5-2.5 parts of conductive agents, 1.5-3 parts of binders and 0.1-0.5 part of a nano-aluminum oxide and a solvent. In a plurality of influence factors of the lithium-ion battery, first of all, nano Al2O3 is added to the positive electrode slurry from components and proportion of the positive electrode slurry, so that the positive electrode slurry can effectively play roles in heat insulation and insulation and the safety performance of the battery is improved. Furthermore, a lithium cobalt oxide and the nano Al2O3 form a solid solution and can stabilize lattices and the rate capability and the cycle performance of the battery are improved. Meanwhile, the nano Al2O3 coats the lithium cobalt oxide, so that the heat stability can be improved, the cycle ability and the overcharge resistance are improved, generation of oxygen and decomposition of LiPF6 are inhibited, contact of the lithium cobalt oxide and an electrolyte can be reduced and the capacity loss is reduced, so that the capacity is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Titanium-containing calcium hexaluminate material and preparation method thereof

ActiveCN111377727AWide variety of sourcesSimple processProcess efficiency improvementManganeseMechanical press

The invention relates to a titanium-containing calcium hexaluminate material and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps:by taking 60-80wt% of aluminum oxide micro powder, 5-20wt% of calcium-containing micro powder, 10-20wt% of titanium oxide micro powder and 1-10wt% of manganous oxide micro powder as raw materials, uniformly mixing the raw materials in a planetary ball mill to obtain a mixture; then, the mixture is subjected to mechanical pressing forming under the condition of 100-200 MPa, and a green body is obtained; and drying the green body at 110-200 DEG C for 12-36 hours, and carrying out heat preservation at 1500-1800 DEG C for 1-8 hours to obtain the titanium-containing calcium hexaluminate material. Wherein the particle size D50 of the aluminum oxide micro powder is 1-8 microns; wherein the particle size D50 of the calcium-containing micro powder is 1-10 microns; wherein the particle size D50 of the titanium oxide micro-powder is 1-10 [mu] m; wherein the particle size D50 of the manganous oxide micro powder is 1-8 microns. The preparation method is low in cost and simple in process, and the prepared product has the characteristics of good chemical stability, good thermal shock resistance and strong titanium-aluminum alloy melt resistance.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

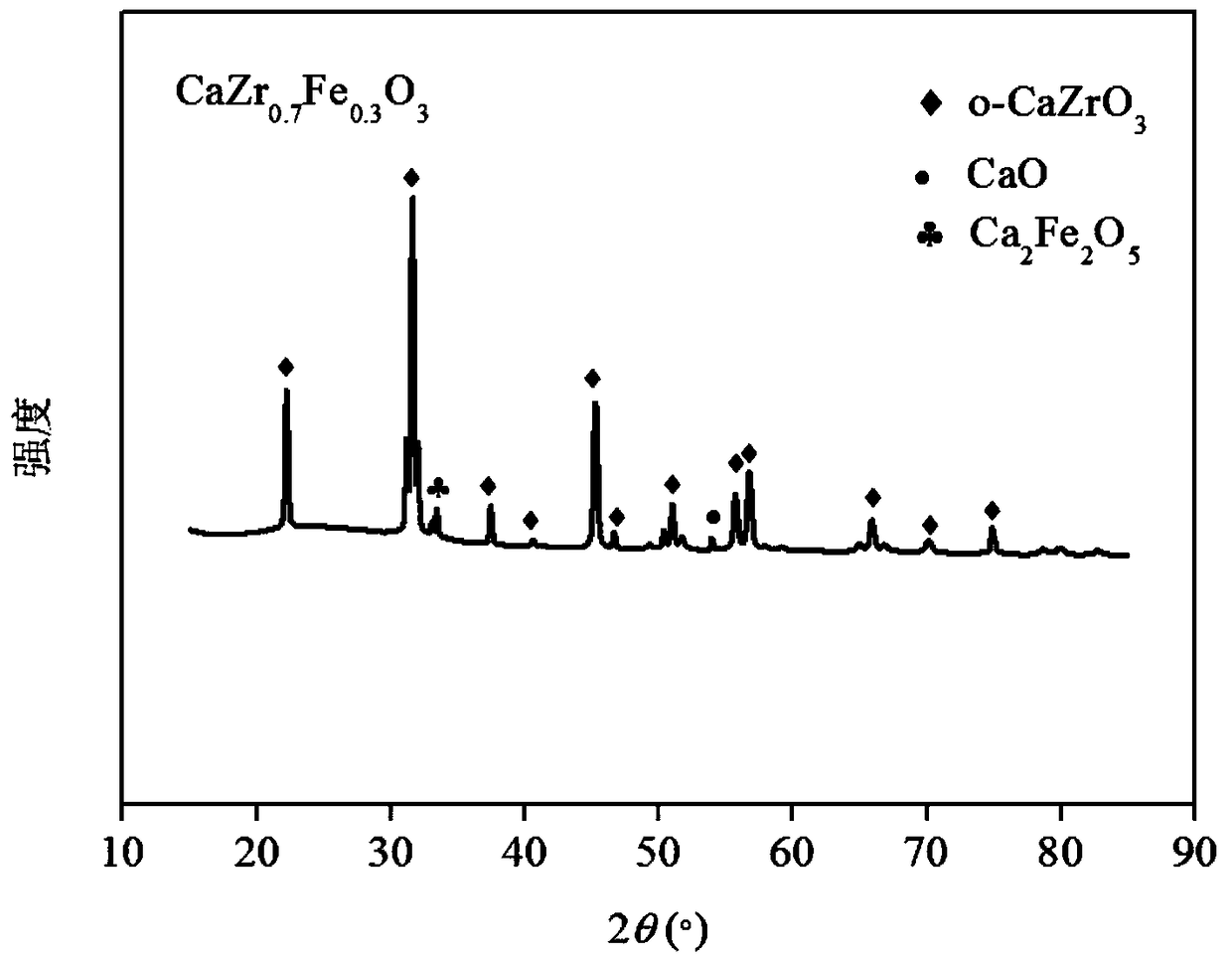

Metal-doped calcium zirconate material, and preparation method and use thereof

InactiveCN108828045APossess electronic conductivityLow costCell electrodesZirconium compoundsZirconateOxygen

The invention relates to a metal-doped calcium zirconate material, and a preparation method and a use thereof. The metal-doped calcium zirconate material comprises calcium carbonate powder, zirconia powder and iron oxide powder, and a ratio of the total mole of the zirconia powder and the iron oxide powder to the mole of the calcium carbonate powder is 1:1; and the iron oxide powder accounts for 0.05-0.15 of the total mole of the zirconia powder and the iron oxide powder. The iron-doped calcium zirconate material has the advantages of oxonium ion conductivity, electron conductivity, low price,excellent mechanical performances and excellent stability. The preparation method of the iron-doped calcium zirconate material has the advantages of simple process and low cost; and the prepared iron-doped calcium zirconate material has the advantages of extremely few pores, greatly increased compactness and greatly improved mechanical performances. The iron-doped calcium zirconate material can be used in compact diffusion barrier layers in oxygen sensors, cathodes of solid oxide fuel cells, or oxygen separation films.

Owner:NORTHEASTERN UNIV

Preparation method of 1,3-propane sultone

InactiveCN108997303AControl sedimentation rateLattice stabilizationOrganic chemistryDistillationPrecipitation

The invention discloses a preparation method of 1,3-propane sultone. The preparation method comprises the steps as follows: firstly, preparing a calcium chloride solution, adding citric acid to prepare a mixed solution A, mixing the mixed solution A with a sodium polyacrylate to prepare a mixed solution B, then, quickly adding the mixed solution B to a sodium carbonate solution for precipitation to prepare porous calcium carbonate, and soaking the porous calcium carbonate in a peroxybenzoic acid solution to prepare a catalyst; mixing sodium allylsulfonate and a sulfuric acid solution, adding the catalyst for a reaction, adding an ethanol solution of sodium hydroxide for a reaction, and finally, adding hydrochloric acid for acidization to prepare 3-hydroxypropanesulfonic acid; mixing prepared 3-hydroxypropanesulfonic acid and n-hexane, adding the mixture to a three-neck flask to be stirred to react, cooling a product to the room temperature after the reaction, and performing reduced pressure distillation to prepare the target product 1,3-propane sultone. The method is simple to operate, low in energy consumption and high in product yield.

Owner:SUZHOU GAIDE FINE MATERIALS CO LTD

Method for producing special rutile type titanium white powder for power coating

ActiveCN101880479BHeat-resistant and anti-yellowingLattice stabilizationPigment treatment with organosilicon compoundsPigment physical treatmentSlurryRutile

The invention discloses a method for producing special rutile type titanium white powder for power coating, which comprises the following steps of: preparing slurry of which titanium dioxide concentration is 300 to 400g / l by using bleached metatitanic acid, and adding a calcining auxiliary agent into the slurry; filtering the obtained metatitanic acid, then calcining solid, and grinding the solidto obtain a primary product; preparing titanium dioxide slurry of which titanium dioxide concentration is 650 to 850g / l by using the obtained primary product, adding a wetting agent into the titaniumdioxide slurry, and performing dispersion and grinding; heating the obtained titanium dioxide slurry to between 40 and 90 DEG C, adding dispersant, zircon salt or titanium salt, silicon salt and aluminum salt into the slurry in turn, adjusting the pH value to between 5 and 9, ageing the mixture, and adjusting the pH value to between 7 and 8; and then filtering, washing and drying the mixture, treating the dried product by an organic surface treatment agent, and vaporizing the product to obtain the rutile type titanium white powder. Compared with the prior art, the rutile type titanium white powder obtained by the method has the properties of stable crystal lattice, good dispersion, heat and yellowing resistance, and good oily whiteness, reducing power, covering power and weather resistance and the like; the appearance and properties of the rutile type titanium white powder are close to that of the rutile type titanium white powder prepared by a chlorination process; and the productionmethod has the advantages of easily obtained process raw materials and stable process control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

A preparing method and an application for a mixed oxide of alkaline earth metal or lanthanide metal M and aluminium oxide

InactiveCN108620051AImprove stabilityGreat catalytic flexibilityRare earth metal oxides/hydroxidesHydrogenAlkaline earth metalLanthanide

The invention provides a preparing method for a mixed oxide of alkaline earth metal or lanthanide metal M and aluminium oxide. The method includes the following steps: a soluble salt solution of aluminum and a soluble salt solution of alkaline earth or lanthanide metal M are weighed and then mixed; a precipitating agent is added into the mixing solution, and the precipitation reaction is under thecondition of 5-85 DEG C; the obtained solid suspension is aged for 0.1-8 hours and then filtered and washed; the obtained sediment is dried under 80-150 DEG C for 2-20 hours; the sediment after drying is calcinated under 800 DEG C for 0.5-12 hours at a constant temperature; the temperature is raised to 1200 DEG C, the calcination is continued for 1-24 hours; the temperature is reduced to the roomtemperature, and the mixing oxide composed of MAlxOy and Al2O3 is obtained. The obtained mixing oxide of MAlxOy and aluminium oxide has the heat stability of MAlxOy, the characteristic of aluminium oxide which can easily form a porous structure is realized, the load active substance of rhodium, platinum and the like are loaded on the mixing oxide, and a load high efficiency natural gas selectingoxidation catalyst with excellent stability and high temperature resistance can be obtained.

Owner:單岩崑

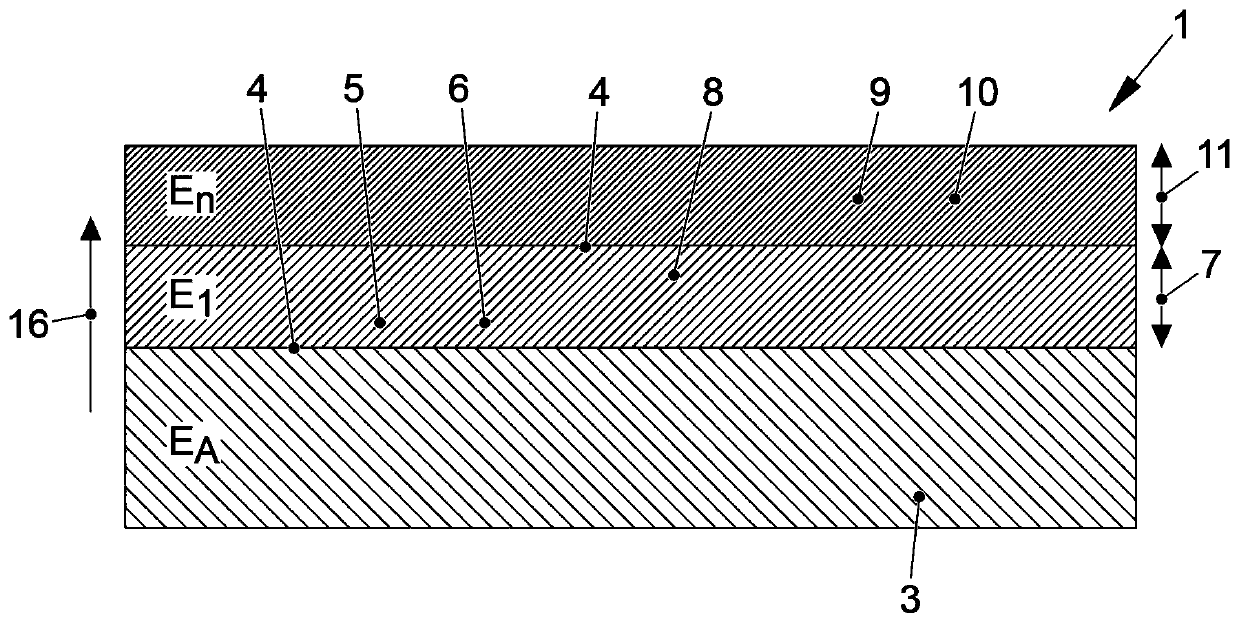

Active material body for a battery

ActiveCN110600686AAvoid defectsImprove electrical and lithium ion conductivityNon-aqueous electrolyte accumulator electrodesLi-accumulatorsEngineeringYoung's modulus

The invention relates to an active material body for a rechargeable battery, whereby the active material body comprises at least one active material that has a Young's modulus EA and at least one layered first coating applied on the surface of the active material, whereby the coating consists of a first material that has a first Young's modulus E1 whereby the following applies: first Young's modulus<=Young's modulus of the active material.

Owner:VOLKSWAGEN AG

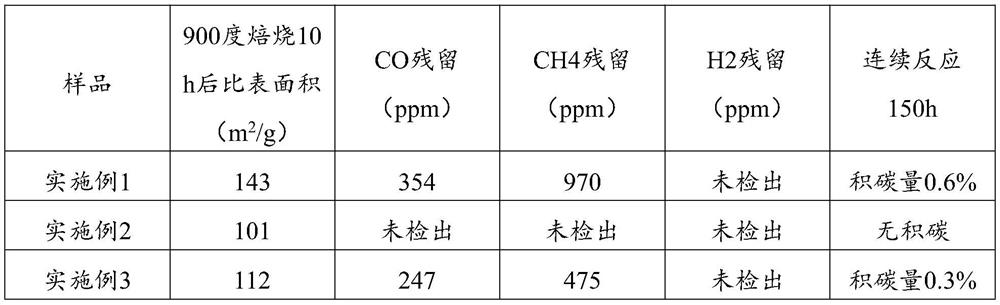

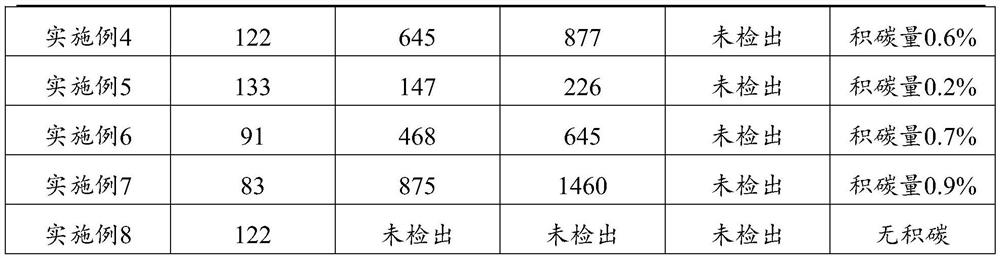

High-temperature anoxic catalytic combustion catalyst as well as preparation method and application thereof

ActiveCN113457721AAvoid the problem of easy sinteringSolve the problem of not adapting to the hypoxic environmentMolecular sieve catalystsCatalyst activation/preparationPtru catalystCatalytic oxidation

The invention relates to the technical field of tail gas catalytic oxidation, in particular to a high-temperature anoxic catalytic combustion catalyst as well as a preparation method and the application thereof. The high-temperature oxygen-deficient catalytic combustion catalyst comprises a carrier with a mesoporous structure and a noble metal active component loaded in the carrier with the mesoporous structure, the carrier with the mesoporous structure is CeO2-ZrO2 (at) HMS; ceO2-ZrO2 in the CeO2-ZrO2 (at) HMS is doped with yttrium oxide and lanthanum oxide, and the yttrium oxide and the lanthanum oxide are doped in the CeO2-ZrO2 (at) HMS; the noble metal active components are Ru and Pt. The high-temperature oxygen-deficient catalytic combustion catalyst has good catalytic efficiency and carbon deposition resistance under the high-temperature oxygen-deficient condition.

Owner:KUNMING UNIV OF SCI & TECH

A method for preparing pigments using waste flue gas denitrification catalyst

ActiveCN104973623BLow toxicityTo achieve the purpose of harmless treatment and resource utilizationAntimony compoundsManganese oxides/hydroxidesPtru catalystWeather resistance

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

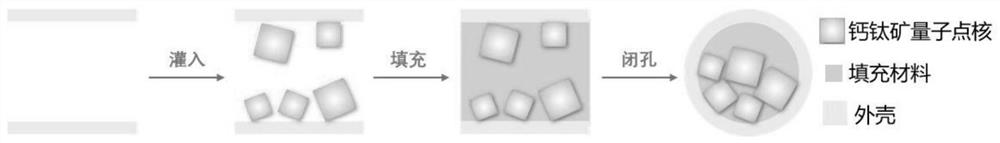

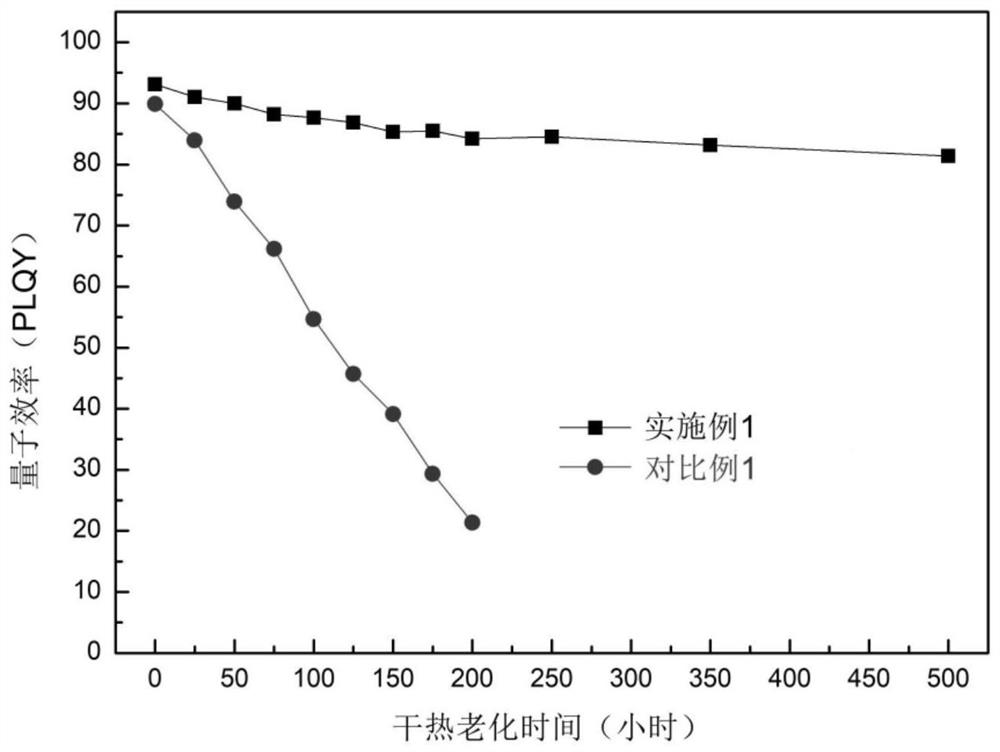

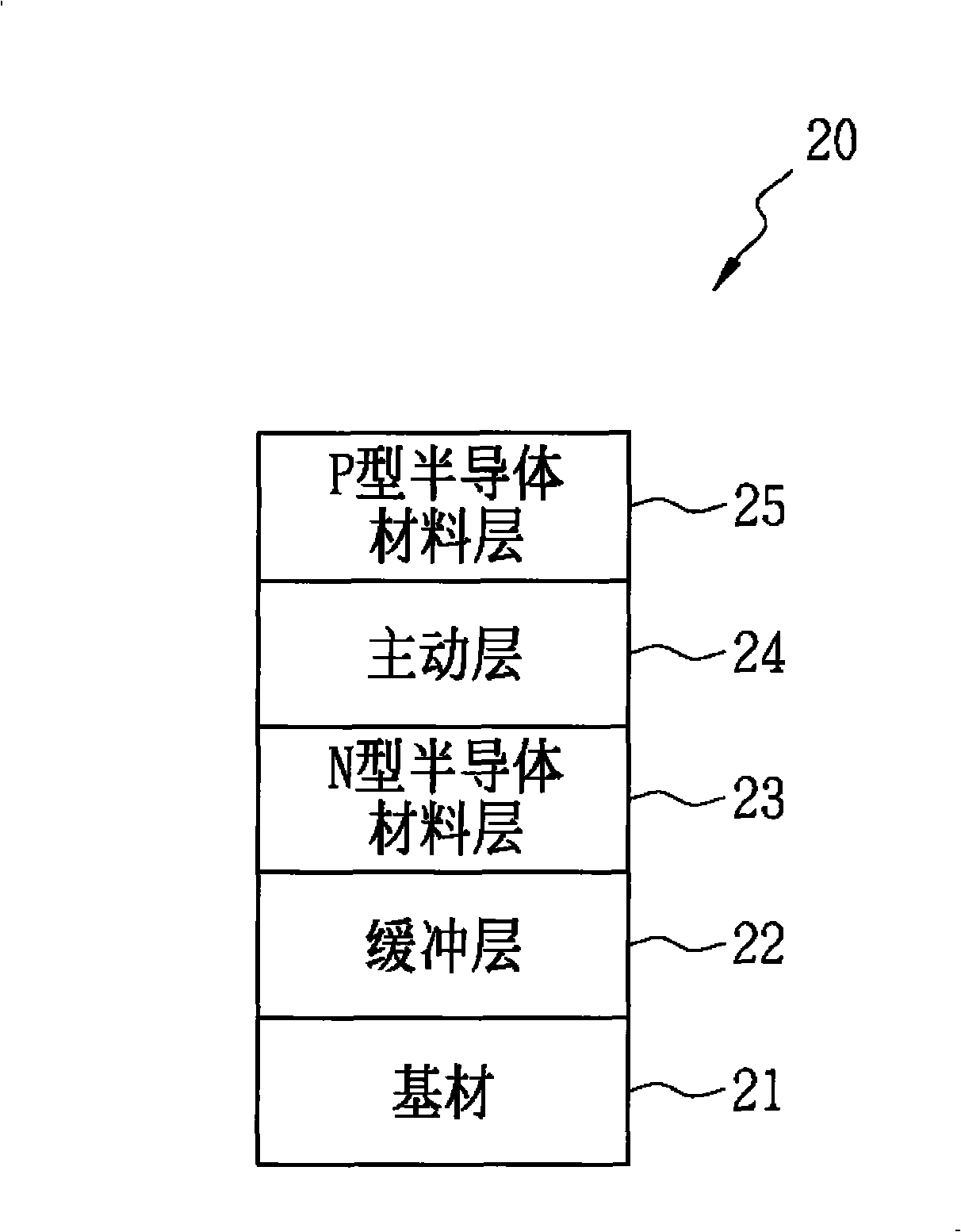

Perovskite quantum dot with core-shell filling layer, preparation method and application

PendingCN114196394AReduce surface defectsLattice stabilizationLuminescent compositionsFilling materialsPerovskite (structure)

The invention provides a perovskite quantum dot with a core-shell filling layer, a preparation method and an application, the perovskite quantum dot with the core-shell filling layer comprises a shell and perovskite quantum dot cores arranged in the shell, and a filling material is filled between the perovskite quantum dot cores in the shell. The filling material is arranged in the core-shell structure, firm chemical bonding is formed between the filling material and the surface of the quantum dot, the filling material and the perovskite quantum dot core are matched to fill the inner space of the shell, and the space confinement effect is achieved through space occupation, so that quantum dot lattices are in a relatively stable state; and the service life of the perovskite quantum dot material is further prolonged.

Owner:WUXI UTMOST LIGHT TECH CO LTD

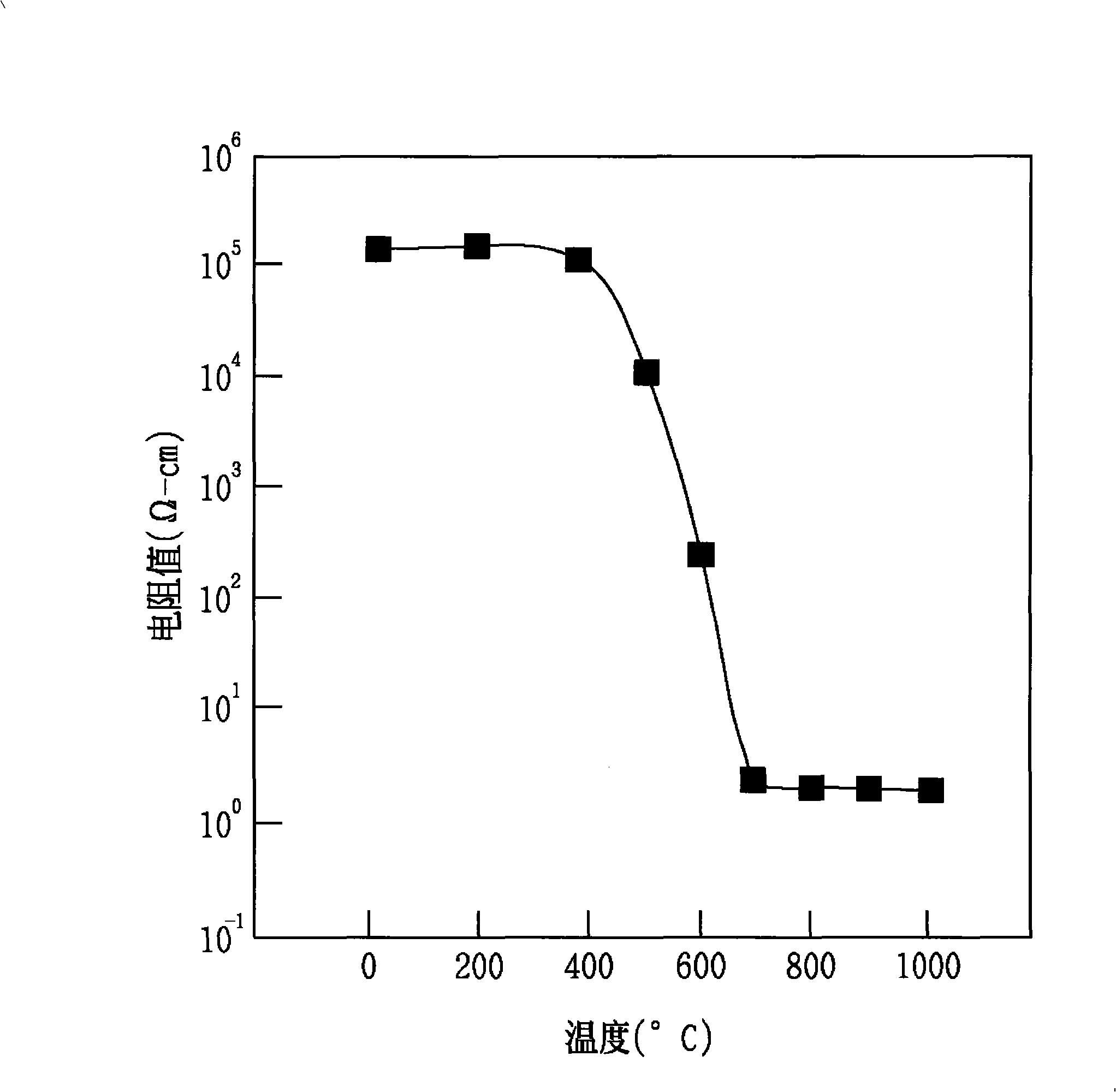

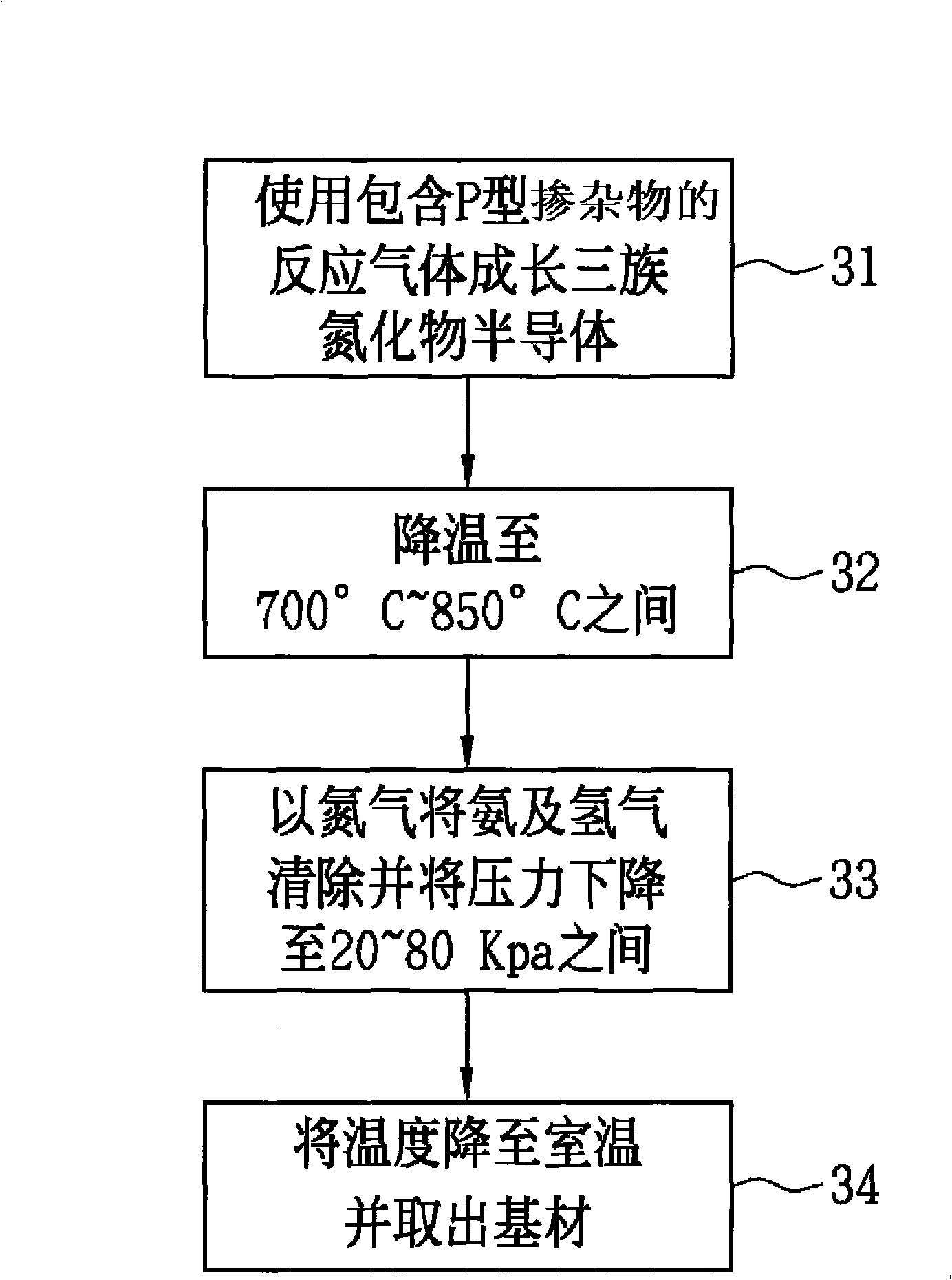

Method for manufacturing photoelectricity semiconductor element of semiconductor containing P-type three-tribe nitrogen compound

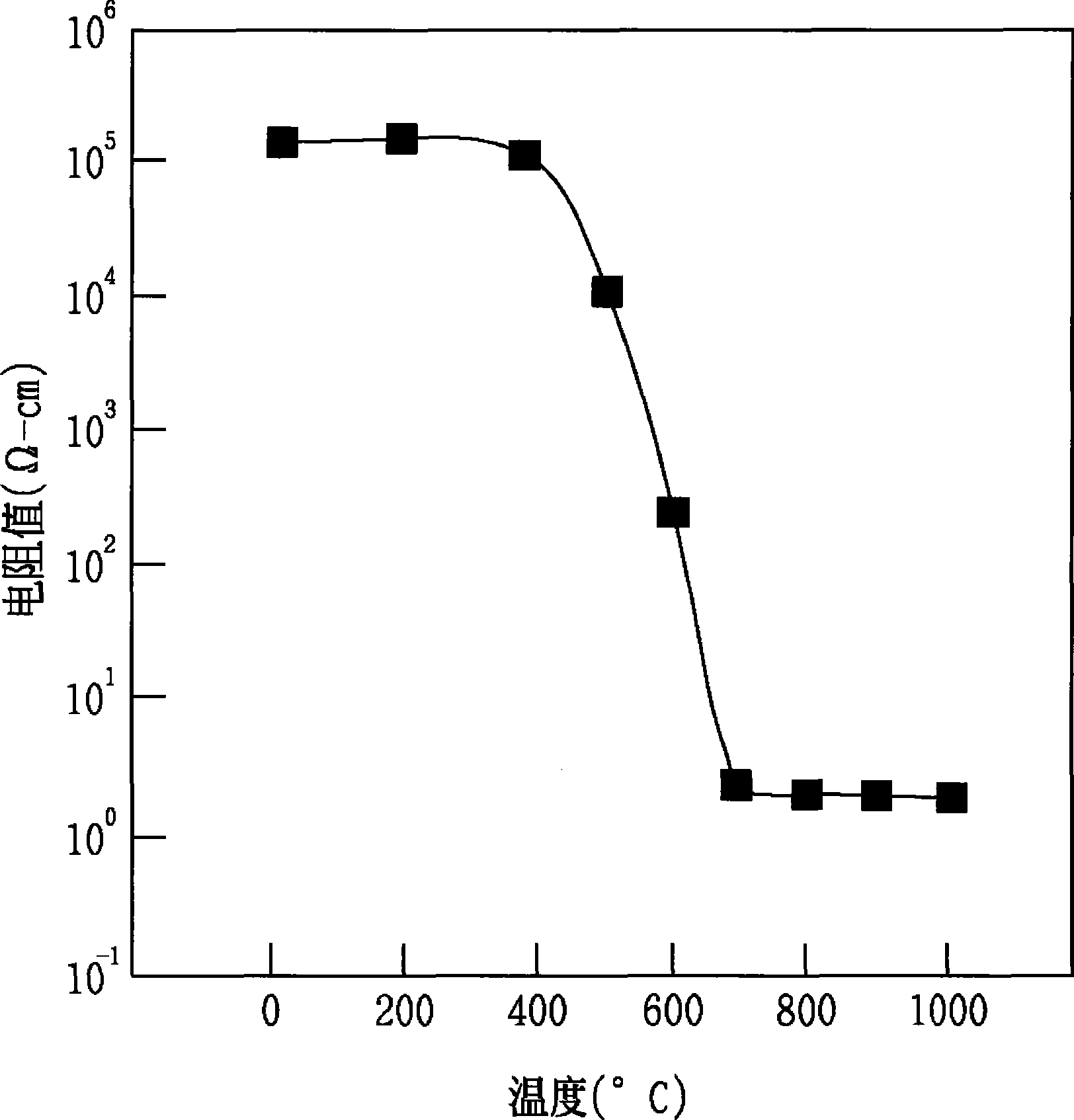

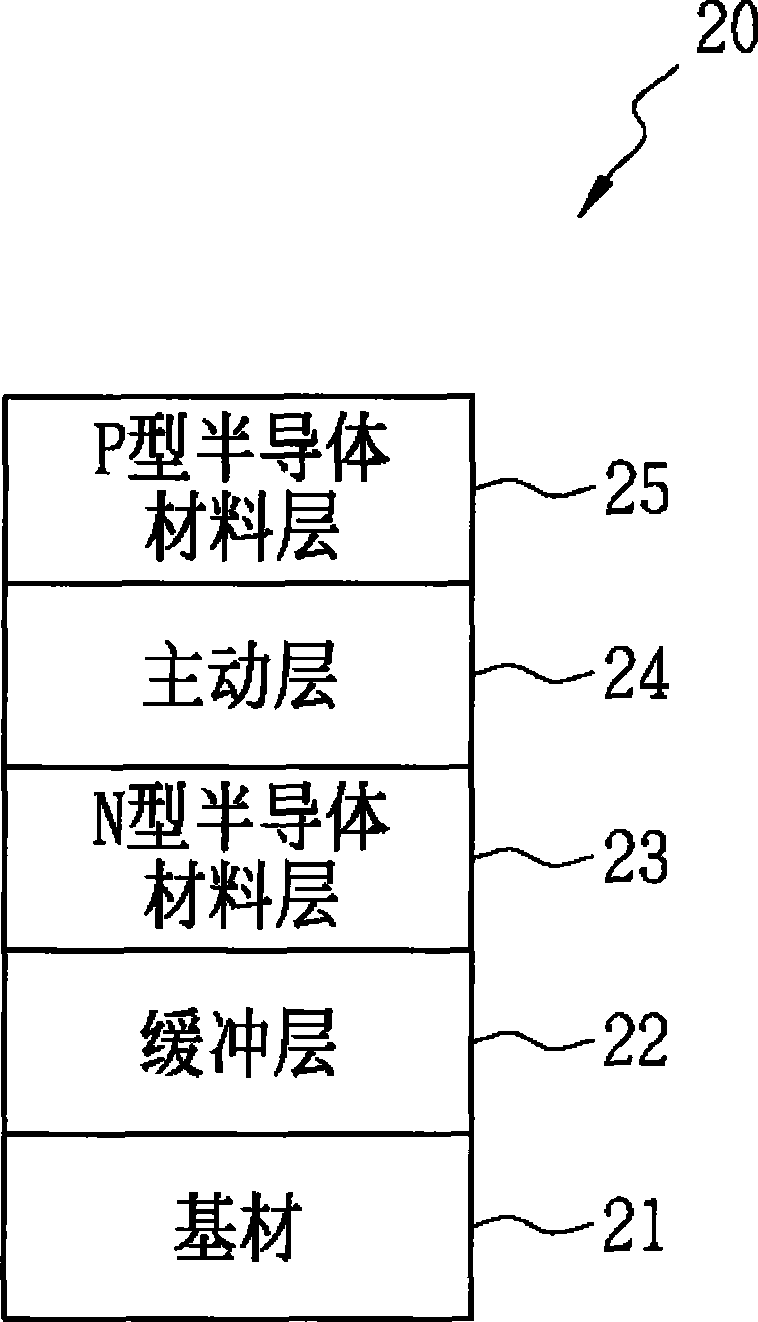

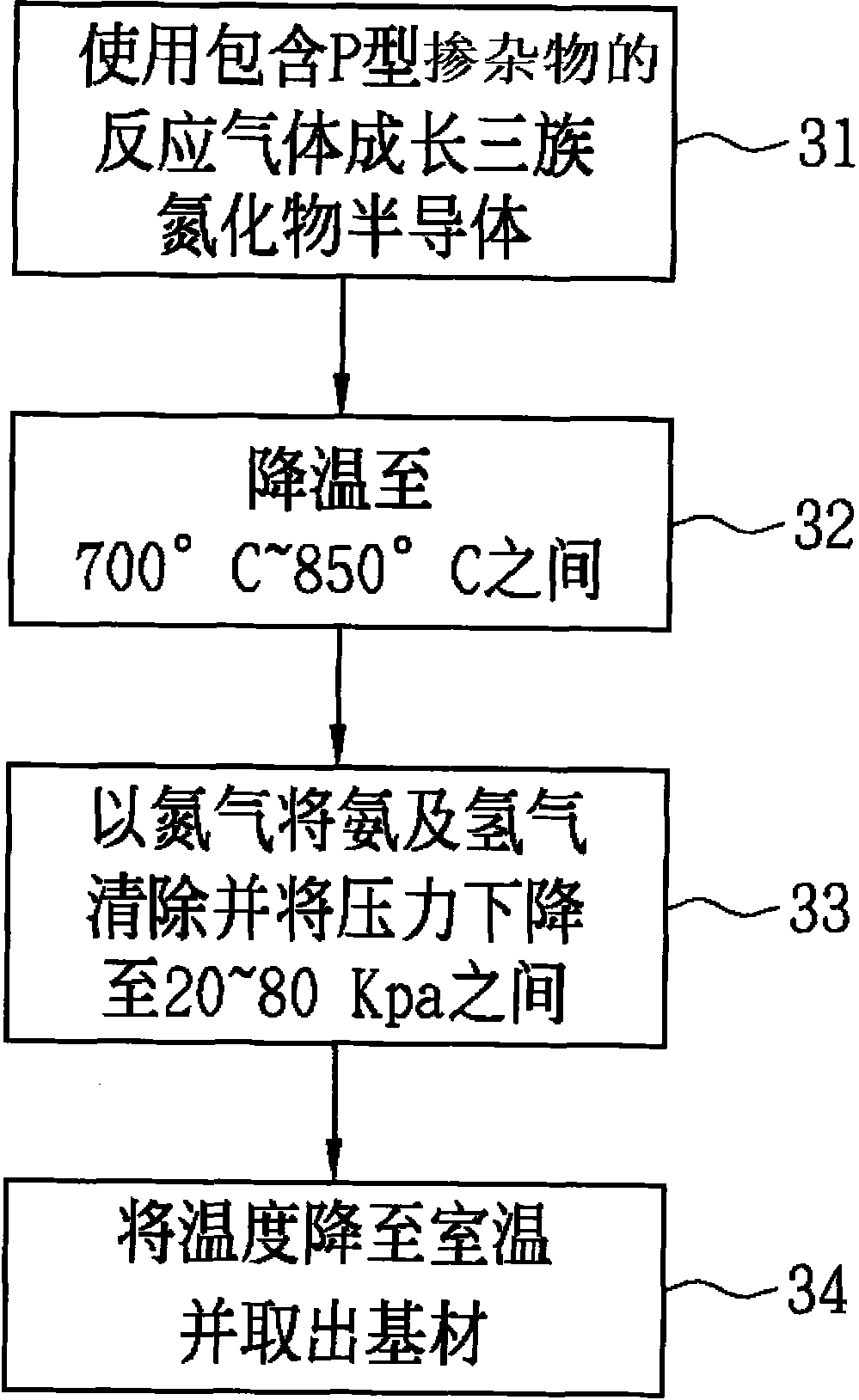

InactiveCN101325230ALattice stabilizationSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogen gasChemistry

A manufacturing method of a photoelectric semiconductor element containing a P-type group III nitride semiconductor comprises allowing a reacting gas containing a P-type dopant to grow on a substrate to obtain a group III nitride semiconductor; reducing the temperature in a reaction chamber to 700-850 DEG C, introducing nitrogen gas or an inert gas to discharge ammonia and hydrogen out of the reaction chamber, and reducing the pressure in the reaction chamber to 20-80 KPa; keeping for a sufficient time until the residual ammonia and hydrogen are completely discharged, reducing the temperature in the reaction chamber to room temperature, and taking out the substrate.

Owner:ZHANJING TECH SHENZHEN +1

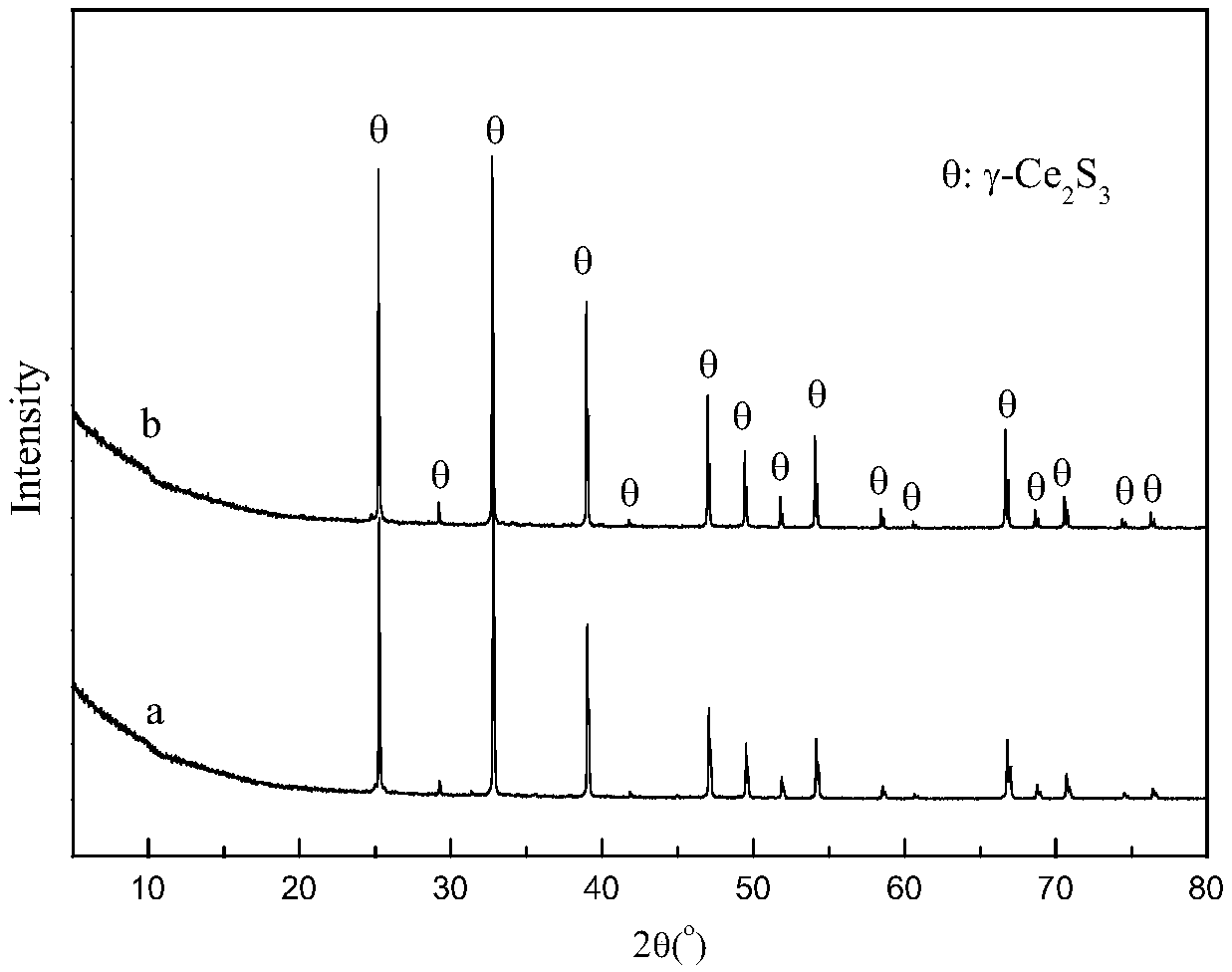

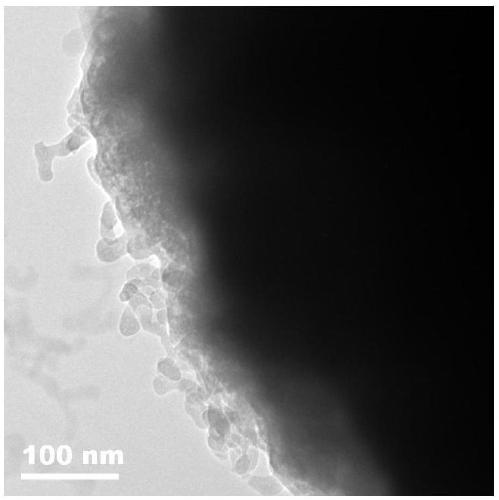

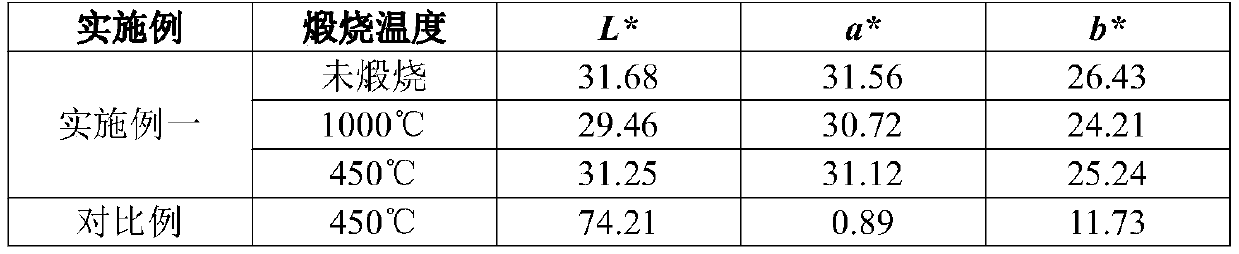

A zirconium silicate-encapsulated low-valent ion composite doped gamma-ce2s3 red pigment and its preparation method

ActiveCN107758720BImprove high temperature stabilityExtended temperature rangeRare earth metal sulfidesSilicon compoundsCrystal structurePhysical chemistry

Owner:JINGDEZHEN CERAMIC UNIV

A kind of preparation method of tin oxide coated cobalt magnesium lithium material

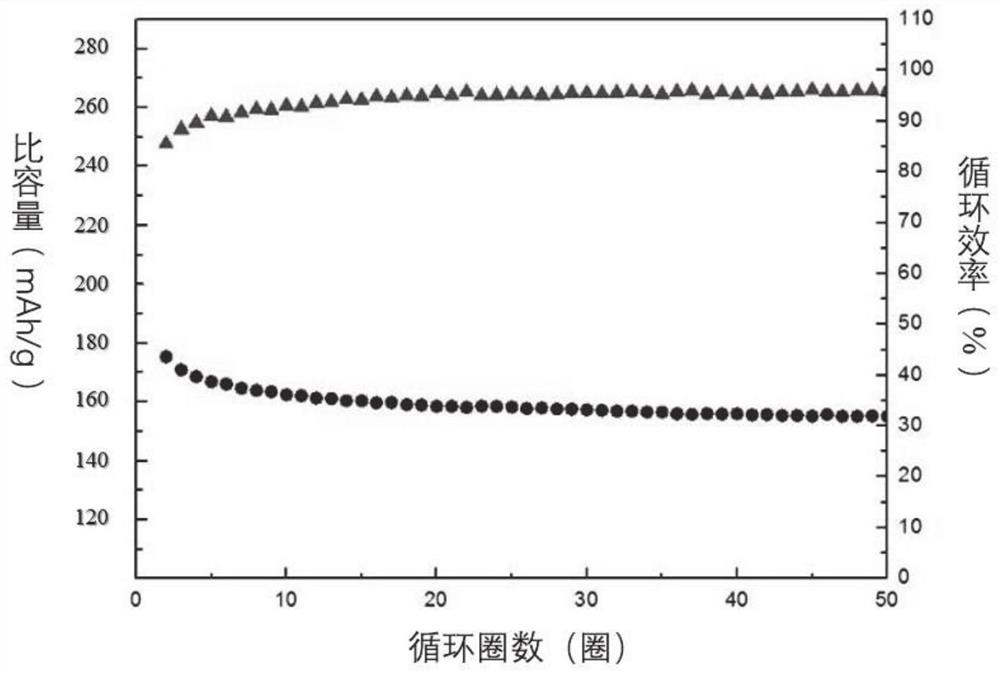

ActiveCN105006567BLattice stabilizationCoated evenlyCell electrodesSecondary cellsLithiumMagnesium salt

The invention discloses a method for preparing a stannic-oxide-wrapped cobalt magnesium lithium material. The method includes the following steps: cobalt salt and magnesium salt are dissolved into water, stabilizers are added to be mixed, a solution A is obtained, the solution A and precipitators are added into a reaction container at the same time for carrying out co-precipitation, purifying processing, heat nature determining processing and sub-high temperature processing are carried out on sediment to obtain cobalt magnesium oxide; the cobalt magnesium oxide is mixed with LiOH.H2O, absolute ethyl alcohol is added, ball milling is carried out in a planetary ball mill, filtering and drying are carried out, the obtained powder material is loaded into a porcelain boat, the porcelain boat with the powder material is pushed into a resistance furnace to be sintered, and a cobalt magnesium lithium material is obtained after cooling is carried out; the obtained cobalt magnesium lithium material is mixed with SnCl2.2H2O and deionized water, the mixture is evenly stirred, ultrasonic processing, filtering and drying are carried out, and the stannic-oxide-wrapped cobalt magnesium lithium material is obtained after roasting is carried out in a muffle furnace. The prepared stannic-oxide-wrapped cobalt magnesium lithium material is stable in electrochemical performance, stable in crystal lattice, large in tap density and good in cycle performance and rate performance.

Owner:玉环市星光眼镜厂

A titanium-containing calcium hexaaluminate material and its preparation method

ActiveCN111377727BWide variety of sourcesSimple processProcess efficiency improvementEngineeringManganese oxide

The invention relates to a titanium-containing calcium hexaaluminate material and a preparation method thereof. The technical scheme is: using 60-80wt% of alumina micropowder, 5-20wt% of calcium-containing micropowder, 10-20wt% of titanium oxide micropowder and 1-10wt% of manganous oxide micropowder as raw materials; Mix evenly in a planetary ball mill to obtain a mixture. Then the mixture is machine-pressed at 100-200MPa to obtain a green body; then the green body is dried at 110-200°C for 12-36 hours, and kept at 1500-1800°C for 1-8 hours. Hours, that is, titanium-containing calcium hexaaluminate material. The particle size D of the alumina micropowder 50 1-8 μm; the particle size of the calcium-containing micropowder D 50 1 to 10 μm; the particle size D of the titanium oxide micropowder 50 1 to 10 μm; the particle size D of the manganese oxide micropowder 50 1 to 8 μm. The invention has low cost and simple process, and the manufactured product has the characteristics of good chemical stability, good thermal shock resistance and strong resistance to titanium-aluminum alloy melt.

Owner:YIXING MORGAN THERMAL CERAMICS CO LTD

Preparation method of rare earth sulfide pigment

ActiveCN113415818AThe synthesis process is simpleLow equipment requirementsRare earth metal sulfidesRare earth metal compounds preparation/treatmentPhysical chemistryProcess engineering

The invention discloses a preparation method of a rare earth sulfide pigment, which comprises the following steps: carrying out high-temperature solid-phase reaction on zinc sulfide as a sulfur source and rare earth oxide in a reducing atmosphere to obtain rare earth sulfide powder. The preparation steps are simple, toxic, flammable and explosive vulcanizing agents such as H2S, CS2 or elemental sulfur powder are not used, and the preparation method is a green preparation method suitable for the rare earth sulfide pigment.

Owner:HUNAN NORMAL UNIVERSITY

Salt-bath hardening treatment method for obtaining supersaturated solid solution from stainless steel surface

InactiveCN104060216AStrong reduction potentialLower salt bath melting pointSolid state diffusion coatingHydrogen fluorideCryogenic hardening

The invention discloses a salt-bath hardening treatment method for obtaining a supersaturated solid solution from a stainless steel surface, belonging to the field of surface treatment of stainless steel. The stainless steel is soaked and activated by using a 5V01.% HF (Hydrogen Fluoride) water solution and subjected to salt-bath hardening treatment for 8-10 hours below the temperature of 480 DEG C; the salt bath contains CNO<->, the mass concentration is controlled to be 50%-55%, and the salt bath also contains K2CO3, N2CO3, CO(NH2), Li2CO3 and other trace elements. As the salt bath adopted by the method disclosed by the invention has low melting point and good liquidity at a low temperature and the CNO<-> in the salt bath has relatively high reduction potential, the stainless steel is subjected to activation treatment and low-temperature hardening treatment below the critical temperature, and active nitrogen atoms have direct contact with the base body, thus a supersaturated solid solution hardened layer can be obtained, the hardened layer has an S-phase structural characteristic, the surface hardness of the hardened layer is three times the hardness of the base body; and the supersaturated solid solution hardened layer has higher corrosion resistance than austenitic stainless steel before the hardening treatment.

Owner:JIANGSU HAINA MECHANICAL & ELECTRIC EQUIP GRP +1

Aluminum-coated ternary zirconium-doped composite material, composite cathode material and its preparation and application in lithium ion battery

ActiveCN108428862BEvenly dopedImprove performanceCell electrodesSecondary cellsComposite cathodeElectrical battery

Belonging to the field of lithium ion batteries, the invention discloses an aluminum coated ternary zirconium-doped composite material. The aluminum coated ternary zirconium-doped composite material comprises a core and a shell coating the core surface. The material of the core is (Ni0.8-xCo0.15Al0.05Zrx)(OH)2, wherein x is 0.001-0.03, and the material of the shell is Al(OH)3. The invention also discloses a preparation method of the aluminum coated ternary zirconium-doped composite material and a composite cathode material obtained by sintering of the composite material with a lithium source.The preparation method provided by the invention is simple and low in cost, and can achieve macro preparation. The prepared lithium ion battery doped and coated ternary material has good sphericity, specific surface area, and excellent ionic conductivity and electrical conductivity, the material can be used for lithium ion batteries and exhibits excellent cyclic stability and rate performance, thus having industrial application prospect.

Owner:CENT SOUTH UNIV +1

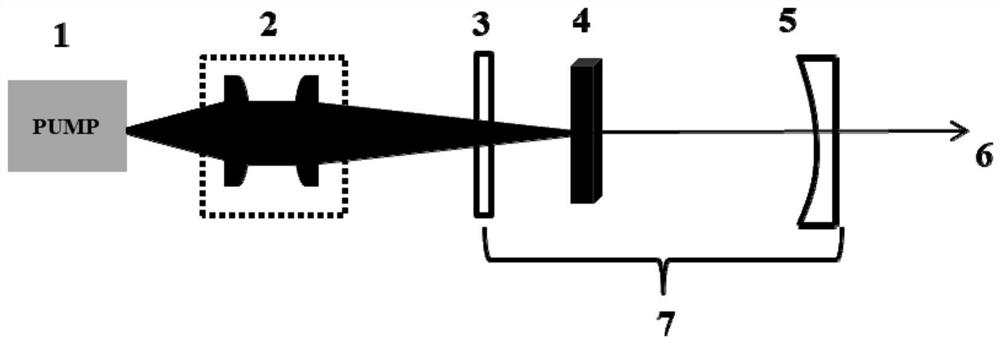

Low-threshold yellow light solid laser based on energy transfer

The invention discloses a low-threshold yellow light solid-state laser based on energy transfer. The low-threshold yellow light solid-state laser comprises a pumping source, a focusing coupling system and a resonant cavity, the resonant cavity comprises an input mirror, an output mirror and a laser gain medium, the input mirror and the output mirror are oppositely arranged in a resonant cavity body, the laser gain medium is Ce, Dy: LuGdAG transparent ceramic, the chemical formula of the laser gain medium is (Gd1-x-y-zLuxDyyCez) 3Al5O12, x is larger than or equal to 0.30 and smaller than or equal to 0.5, y is larger than or equal to 0.03 and smaller than or equal to 0.3, z is larger than or equal to 0.005 and smaller than or equal to 0.02, and the Ce, Dy: LuGdAG transparent ceramic is prepared through a coprecipitation method. Ce, Dy: LuGdAG transparent ceramic is adopted as a laser gain medium, Ce < 3 + > is co-doped, Dy < 3 + > can transmit absorbed photon energy of wavelength to Ce < 3 + >, so that 5d-4f transition of Ce < 3 + > is increased, doping of Gd < 3 + > improves energy level loss among ions, in addition, Gd < 3 + > is doped as ions with large radiuses, so that crystal lattices doped with multiple ions are more stable, and finally, efficient yellow laser output is realized.

Owner:XUZHOU NORMAL UNIVERSITY

Method for manufacturing photoelectricity semiconductor element of semiconductor containing P-type three-tribe nitrogen compound

InactiveCN101325230BLattice stabilizationSimple processSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogen gasChemistry

A manufacturing method of a photoelectric semiconductor element containing a P-type group III nitride semiconductor comprises allowing a reacting gas containing a P-type dopant to grow on a substrate to obtain a group III nitride semiconductor; reducing the temperature in a reaction chamber to 700-850 DEG C, introducing nitrogen gas or an inert gas to discharge ammonia and hydrogen out of the reaction chamber, and reducing the pressure in the reaction chamber to 20-80 kPa; keeping for a sufficient time until the residual ammonia and hydrogen are completely discharged, reducing the temperaturein the reaction chamber to room temperature, and taking out the substrate.

Owner:ZHANJING TECH SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com