White light LED (light-emitting diode) blue fluorescent powder, preparation method thereof and application

A blue fluorescent powder and fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of weakened luminous intensity of fluorescent materials, difficult control of synthesis process, easy imbalance of component matching, etc., and achieve production The preparation process is energy-saving and environmentally friendly, inhibits the formation of impurity phases, and is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of blue fluorescent powder for white light LED of the present invention, concrete steps are as follows:

[0042] (1) According to the chemical formula Ba 2-m A m Lu 5-x-n L n Ce x B 5 o 17 The stoichiometric ratio of each element in the 2+ Compounds containing Ca 2+ Compounds containing Sr 2+ Compounds containing Sc 3+ Compounds containing Lu 3+ Compounds containing Ce 3+ compounds containing Y 3+ Compounds containing La 3+ Compounds containing Gd 3+ Compounds containing Yb 3+ Compounds containing Er 3+ compounds and those containing B 3+ compound, ground in an agate mortar and mixed well to obtain a mixture;

[0043] In step (1), preferably, containing Ba 2+ , Ca 2+ 、Sr 2+ The compound is one or more of oxides, carbonates, nitrates and halides containing corresponding ions; containing Lu 3+ , Y 3+ 、Ce 3+ , La 3+ 、Gd 3+ 、Sc 3+ , Yb 3+ 、Er 3+ The compound is one or more of oxides, carbonates, nitrates and halides contain...

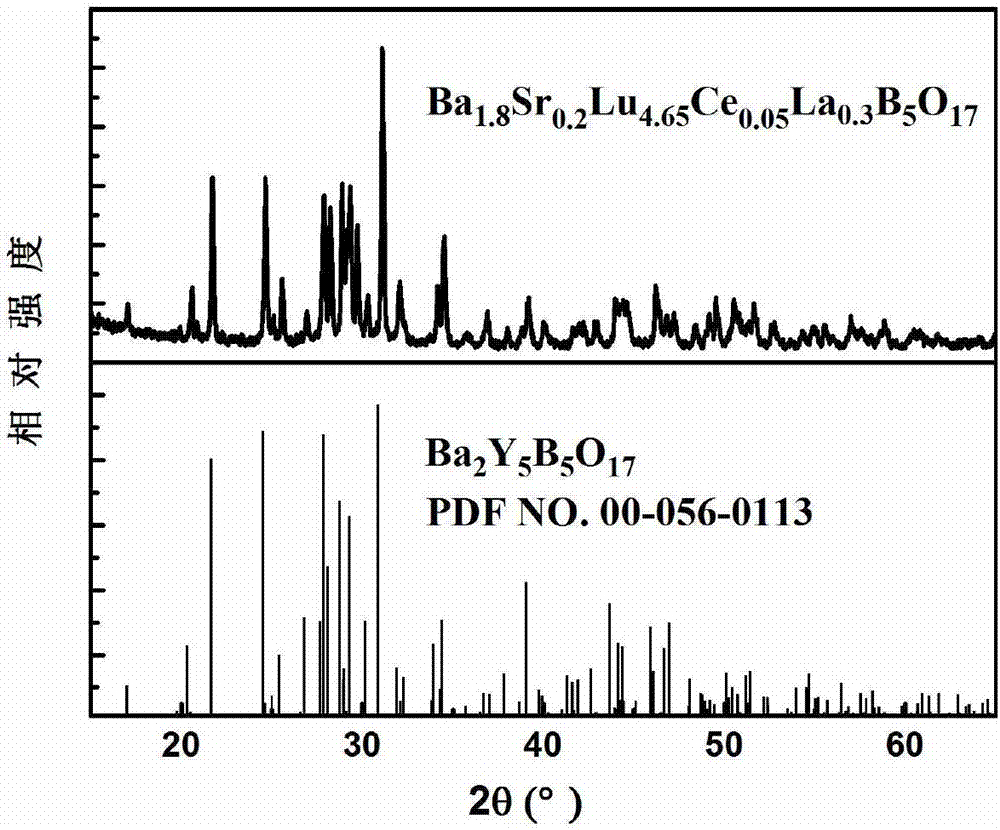

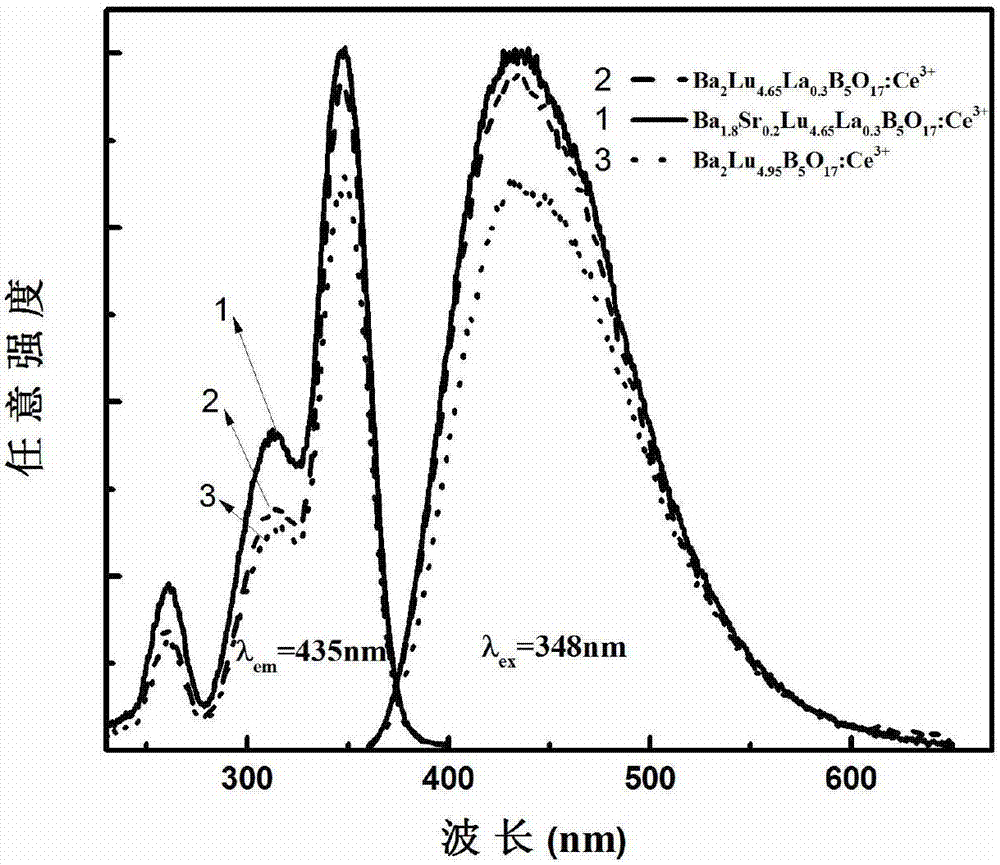

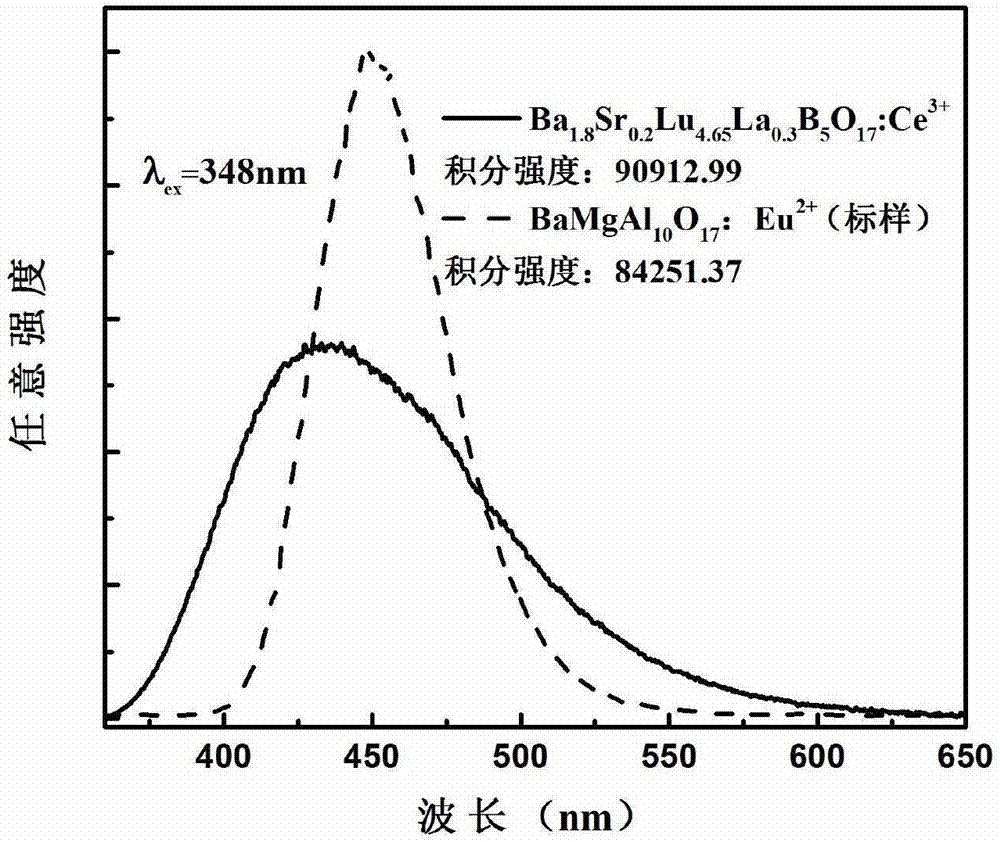

Embodiment 1

[0050] Ba 2 Lu 4.99 Ce 0.01 B 5 o 17 preparation of

[0051] Weigh BaCO according to stoichiometric ratio 3 : 0.3947 g, H 3 BO 3 : 0.3092 g, Lu 2 o 3 : 0.9928 g, CeO 2 : 0.0017 g. Grind and mix evenly in an agate mortar, put it into a corundum crucible, cover it, place it in a high-temperature furnace, pre-sinter at 400°C for 8 hours, take it out after cooling, and grind it for several minutes. Next, in carbon monoxide CO or hydrogen H 2 Under reducing atmosphere, sinter at 1100°C for 20 hours, after natural cooling, properly grind to obtain phosphor powder Ba 2 Lu 4.99 Ce 0.01 B 5 o 17 . Its crystal structure is similar to Example 3, but the excitation and emission intensity is weaker than that of Example 3.

Embodiment 2

[0053] Ba 1.9 Ca 0.1 Lu 4.98 Ce 0.02 B 5 o 17 preparation of

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com