Positive electrode slurry and preparation method thereof and lithium-ion battery

A technology of positive electrode slurry and sizing material, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor stability, poor cycle performance of lithium cobalt oxide, and easy damage to the structure of deep deintercalation lithium materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention also provides a method for preparing positive electrode slurry, comprising the following steps:

[0073] A) After the binder and the solvent are mixed by rotation and revolution, the rubber compound is obtained;

[0074] B) The conductive agent, nano-alumina and solvent are mixed by rotation and revolution for the second time, and then the rubber material and lithium cobaltate material prepared in the above steps are added for the third rotation and revolution, stirred and mixed to obtain the positive electrode slurry.

[0075] The selection and ratio of the raw materials in the present invention are consistent with the selection and ratio of the raw materials for the positive electrode slurry, unless otherwise specified, and will not be repeated here.

[0076] In the present invention, firstly, the binder and the solvent are stirred and mixed by rotation and revolution to obtain the glue material.

[0077] In the present invention, there is no sp...

Embodiment 1

[0133] According to the solid content (m 1 +m 2 +m 3 +m 4 ) / (m 1 +m 2 +m 3 +m 4 +m NMP )=70%, according to LCO: (SP+KS-6): PVDF: Nano Al 2 o 3 =(96.5:1.4:1.8:0.3) weighed, its LCO, SP+KS-6, PVDF, nano Al 2 o 3 The mass of each is denoted as m 1 、m 2 、m 3 、m 4 .

[0134] 1. Glue making

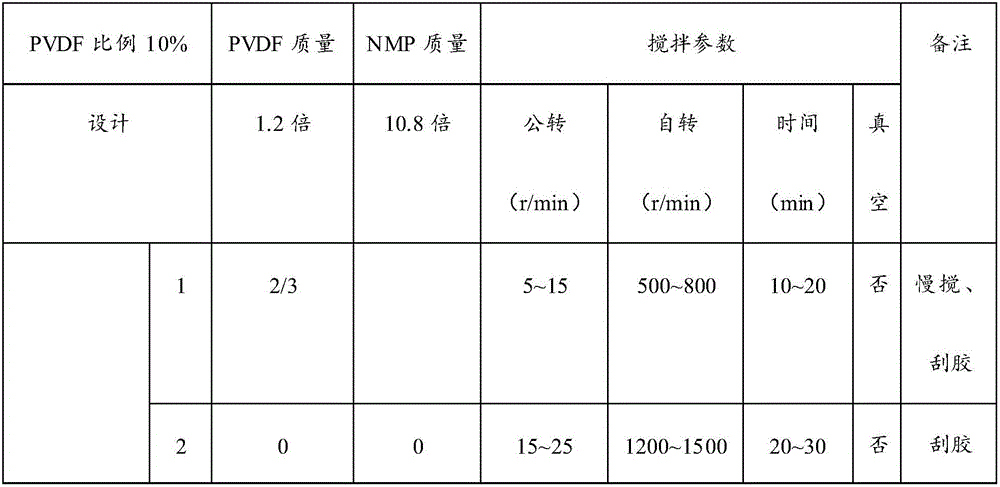

[0135] According to the content of PVDF in the rubber compound is 10% to make rubber

[0136] Consider process loss, weigh PVDF mass 1.2m 3 , the mass of NMP is required to be 10.8m 3 , see Table 3.

[0137] table 3

[0138]

[0139]

[0140] 2. Stirring

[0141] Adding method of conductive agent and other additives:

[0142] Take out 10% of the above rubber (containing PVDF:NMP=1:9), LCO, SP, KS-6, nano-Al 2 o 3 The mass of each is denoted as m 1 、m 2 、m 4 , weigh the NMP to be supplemented, and record the mass as m 5 , see Table 4.

[0143] Table 4

[0144]

[0145]

[0146] The slurry was prepared by the above process of Example 1, and a batch of lit...

Embodiment 2

[0150] According to the solid content (m 1 +m 2 +m 3 +m 4 ) / (m 1 +m 2 +m 3 +m 4 +m NMP )=70%, according to LCO:(SP+KS-6):PVDF:nano Al 2 o 3 =(96.5:1.7:1.8:0) weighed (i.e. do not add nanometer Al 2 o 3 ), its LCO, SP+KS-6, PVDF, nano Al 2 o 3 The mass of each is denoted as m 1 、m 2 、m 3 、m 4 . Stirring steps are consistent with Example 1.

[0151] According to Example 2: the maximum difference in the internal resistance of the prepared battery is within 3%, and the maximum difference in the first discharge specific capacity of the battery under 1C is 2.4mAh / g (about 1.45%), and the battery has shown good consistency, thus indicating The slurry obtained under this stirring scheme has good stability and uniformity.

[0152] In this way, the first average discharge capacity of the prepared battery at 1C is 166mAh / g (charging cut-off voltage 4.35V, discharge cut-off voltage 3V), and after 100 cycles, the capacity retention rate is 90.3%. The capacity of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com