Low-threshold yellow light solid laser based on energy transfer

A solid-state laser and energy transfer technology, which is applied in the direction of active dielectric materials, can solve the problems of low laser output power and inability to meet the needs of practical applications, and achieve the effects of high-efficiency yellow laser output, stable crystal lattice, and improved energy level loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

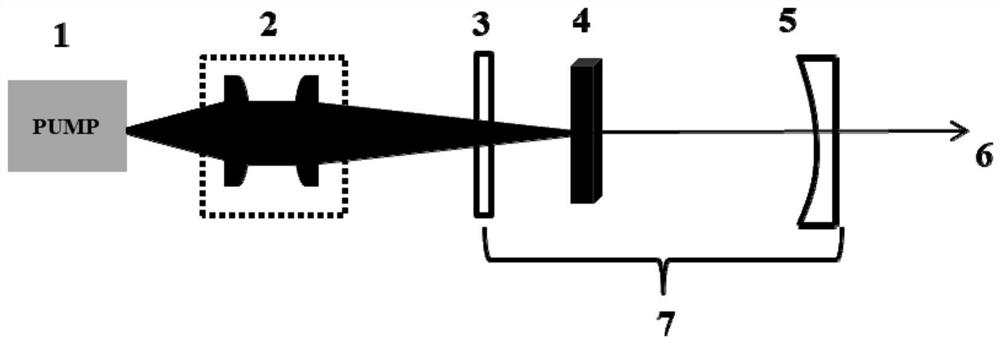

Method used

Image

Examples

Embodiment 1

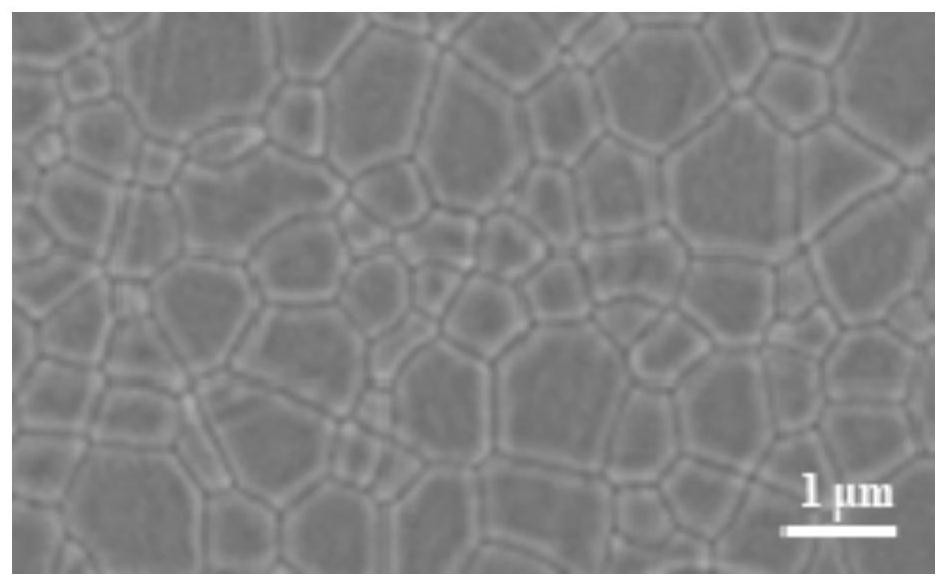

[0034] Example 1: When the chemical formula of the laser gain medium used is (Gd 0.18 Lu 0.5 Dy 0.3 Ce 0.02 ) 3 Al 5 O 12 , that is, when the values of x, y, and z are x=0.500, y=0.30, and z=0.02, respectively, 450nm GaN is used as the LD pump source. 2 O 3 , Lu 2 O 3 , Eu 2 O 3 and Gd 2 O 3 Raw material dissolved in dilute HNO 3 , respectively formulated into Dy(NO 3 ) 3 , Gd(NO 3 ) 3 , Eu(NO 3 ) 3 and Lu(NO 3 ) 3 solution, using the calibrated nitrate solution as a raw material, according to the stoichiometric proportion (Gd 0.18 Lu 0.5 Dy 0.3 Ce 0.02 ) 3 Al 5 O 12 , respectively measure a certain volume of nitrate solution, mix the above five nitrates together, and continue to vigorously stir and mix. In order to improve the powder properties, the concentration of 98.5% (NH 4 ) 2 SO 4 The solution is a dispersant, which is added dropwise to the continuously stirred mixed nitrate solution, using 1.4mol / L NH 4 HCO 3 The solution was used as ...

Embodiment 2

[0037] Example 2: When the chemical formula of the laser gain medium used is (Gd 0.44 Lu 0.4 Dy 0.15 Ce 0.01 ) 3 Al 5 O 12 , that is, when the values of x, y, and z are respectively x=0.40, y=0.15, and z=0.01, 450nm GaN is used as the LD pump source. 2 O 3 , Lu 2 O 3 , Eu 2 O 3 and Gd 2 O 3 Raw material dissolved in dilute HNO 3 , respectively formulated into Dy(NO 3 ) 3 , Gd(NO 3 ) 3 , Eu(NO 3 ) 3 and Lu(NO 3 ) 3 solution, using the calibrated nitrate solution as a raw material, according to the stoichiometric proportion (Gd 0.44 Lu 0.4 Dy 0.15 Ce 0.01 ) 3 Al 5 O 12 , respectively measure a certain volume of nitrate solution, mix the above five nitrates together, and continue to vigorously stir and mix. In order to improve the powder properties, the concentration of 99.0% (NH 4 ) 2 SO 4 The solution is a dispersant. Add dropwise to a continuously stirred mixed nitrate solution using 1.5 mol / L NH 4 HCO 3 The solution was used as a precipitan...

Embodiment 3

[0040] Example 3: When the chemical formula of the laser gain medium used is (Gd 0.45 Lu 0.5 Dy 0.03 Ce 0.02 ) 3 Al 5 O 12 , that is, when the values of x, y, and z are respectively x=0.500, y=0.03, and z=0.02, 450nm GaN is used as the LD pump source. 2 O 3 , Lu 2 O 3 , Eu 2 O 3 and Gd 2 O 3 Raw material dissolved in dilute HNO 3 , respectively formulated into Dy(NO 3 ) 3 , Gd(NO 3 ) 3 , Eu(NO 3 ) 3 and Lu(NO 3 ) 3 solution, using the calibrated nitrate solution as a raw material, according to the stoichiometric proportion (Gd 0.45 Lu 0.5 Dy 0.03 Ce 0.02 ) 3 Al 5 O 12 , respectively measure a certain volume of nitrate solution, mix the above five nitrates together, and continue to vigorously stir and mix. In order to improve the powder properties, the concentration of 99.5% (NH 4 ) 2 SO 4 The solution was used as a dispersant and was added dropwise to the continuously stirred mixed nitrate solution, using 1.6mol / L NH 4 HCO 3 The solution was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com