Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Increase the production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten carbide catalysts, their preparation and application in synthesis of ethylene glycol from cellulose

ActiveUS20100255983A1Improve efficiencyHigh selectivityOxygen-containing compound preparationOrganic compound preparationHydrogen pressureCobalt

Tungsten carbide catalysts are used in preparation of ethylene glycol by hydrogenating degradation of cellulose. The catalyst includes tungsten carbide as main catalytic active component, added with small amount of one or more transition metals such as nickel, cobalt, iron, ruthenium, rhodium, palladium, osmium, iridium, platinum, and copper as the second metal, supported on one or more porous complex supports such as active carbon, alumina, silica, titanium dioxide, silicon carbide, zirconium oxide, for conversion of cellulose to ethylene glycol. The catalyst realizes high efficiency, high selectivity, and high yield in the conversion of cellulose to ethylene glycol at the temperature of 120-300° C., hydrogen pressure of 1-10 MPa, and hydrothermal conditions. Compared to the existing industrial synthetic method of ethylene glycol using ethylene as feedstock, the invention has the advantages of using renewable raw material resources, environment friendly process, and excellent atom economy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing starch-based carbon microsphere

The invention discloses a method used for preparing starch-based carbon microsphere, which pertains to the preparation technique of carbon microsphere. The procedure of the method comprises that cereal starch, tuber starch, bean starch and fruit starch of bananas and plantain are used as raw materials with a particle diameter of 2 to 120 micron; the raw materials are put into a heating furnace, heated to 62 to 300 DEG C at a certain heating rate in oxidizing atmosphere (for example, air, oxygen, ozone, etc.) and go through oxidation treatment under constant temperature for 2 to 72 hours. The starch after oxidation is put into a carbonization furnace, heated to 600 DEG C to 3000 DEG C at a certain heating rate under the protection of inert gas, treated for 0.5 to 48 hours at a constant temperature and then cooled to indoor temperature, and the starch-based carbon microsphere which keep original starch particle shape is obtained. The invention has the advantages of reproducible raw materials, wide source, low price, simple preparation process and low production cost, and being easy for large-scale production.

Owner:TIANJIN UNIV

Method for manufacturing soft-magnetic alloy powder

The production method of soft magnetic alloy powder includes the following steps: smelting soft magnetic mother alloy, making molten metal be quickly coagulated into crystalline sheet alloy, breaking the sheet alloy to obtain alloy powder, and making the alloy powder undergo the processes of activation, annealing treatment and passivation treatment. Said soft magnetic alloy powder is low in oxygen content, stable in property and good in magnetic powder core performance.

Owner:CENT IRON & STEEL RES INST

Honeycomb slightly convex grating, and preparation method and application thereof

InactiveCN105005106AIncrease the difficulty of copyingImprove clarityDiffraction gratingsPhotomechanical exposure apparatusGratingStereo imaging

The present invention discloses a honeycomb slightly convex grating, and a preparation method and an application thereof. The honeycomb slightly convex grating has a micro lens array layer formed by 360-degree continuous arrangement of orthohexagonal micro lenses, wherein a convex surface of each orthohexagonal micro lens is a spherical curved surface. Through adoption of a honeycomb slightly convex mode, the effect that slightly convex 3D stereo imaging has no blind angle and no blind spot is achieved. The material light transmittance of the slightly convex grating is more than 95%, thus the definition of the later stereo imaging is greatly improved. The surface of the material is coated with a UV light-cured layer so that the surface hardness of the material reaches more than 2H, and physical properties of base materials, such as PC, PET, PTU and PVC, which are used in cooperation with the grating, cannot change, toughness and tensile property can still maintain a good state, thus the honeycomb slightly convex grating can be widely applied to imd plastic product in-mold injection of a large number of industrial products for manufacturing optical anti-counterfeiting elements.

Owner:陈昭红 +1

Crocodile drinking liquid and production process thereof

The invention relates to crocodile drinking liquid and a production process thereof. The preparation process comprises the following steps: carrying out enzymolysis on crocodile meal for preparing crocodile extract liquid; simultaneously, carrying out water extraction on hawthorn, lemon and the like; and finally, proportionally mixing and uniformly stirring all ingredients to be prepared into finished drinking liquid products. The crocodile drinking liquid of the invention belongs to a pure natural biological product, the whole production process is simple and fast, the amino acid active nutrient content of the crocodile is completely maintained, and in addition, other harmful substances can not be brought into the crocodile drinking liquid. The amino acid composition of the crocodile is superior to that of other animal proteins, and belongs to the optimum selection of the amino acid absorption and utilization by human bodies. Products contain various amino acids necessary to human bodies, at the same time, auxiliary materials such as hawthorn, lemon and the like are reasonably added, and the crocodile drinking liquid has comprehensive and balanced nutritive effect.

Owner:黄学敏

Sandwich cake processing method

InactiveCN105123850AGreat tasteReduce the risk of contaminationDough treatmentBakery productsWhole milkCorn flour

The present invention discloses a sandwich cake processing method comprising the following steps: blending materials: the raw materials of the sandwich cake includes wrapping materials and stuffing materials, the wrapping materials consist of eggs, granulated sugar, sugar syrup, etc., and the stuffing materials is composed of vegetable oil, granulated sugar, water, whole milk powder, edible corn flour, etc.; whipping the wrapping materials: the eggs, granulated sugar, trehalose, sugar syrup, etc., are successively mixed and stirred in order; forming and steaming: the cake raw materials with an intermediate layer being the stuffing materials and an upper and a lower layer being the wrapping materials are put into a mold to be formed, and steamed at a temperature of 100-105 DEG C; and finally the cake materials are cooled, sterilized and packaged to obtain the finished products. The sandwich cake is unique in formulation, is scientific and closely examined in material use, is simple and practical in production method, and is high in nutrition ingredients, is soft, glutinous, fragrant and smooth, is excellent in mouthfeel, is mature in production equipment, and can realize large-scale production.

Owner:SHANGHAI SANHUIMAIFENG FOOD

Inner dump type strip mine pit bottom reservoir segmented construction method

ActiveCN110409359AIncrease the production processReduce manufacturing costExcavationsMarine site engineeringWater storageIsolation layer

The invention discloses an inner dump type strip mine pit bottom reservoir segmented construction method comprises the following steps of S1, processing end slopes, wherein clay is discarded at the lowest step of the inner waste dump of the strip mine, so that a waste dump isolation layer is formed; S2, discharging concrete to the lowest step slope faces of the end slopes on the two sides of the pit bottom to form end slope isolating layers; S3, sealing the bottom to form a pit bottom isolating layer; S4, discarding gravel into the pit of the strip mine; S5, laying a geotechnical cloth to forma top slab isolation layer so as to complete capping work; S6, re-adopting clay on the lowest steps of the end slopes of the inner waste dump to form a reservoir seal isolating layer; S7, building multiple reservoirs stepwise in the advancing direction of the strip mine; S8, conducting water resource storage work and completing installation of water storage wells; S9, completing installation of water fetching wells; S10, conducting water resource storage. The inner dump type strip mine pit bottom reservoir segmented construction method achieves local deep storage of water resources and provides water resource guarantee for environmental governance of the strip mine.

Owner:CHINA UNIV OF MINING & TECH

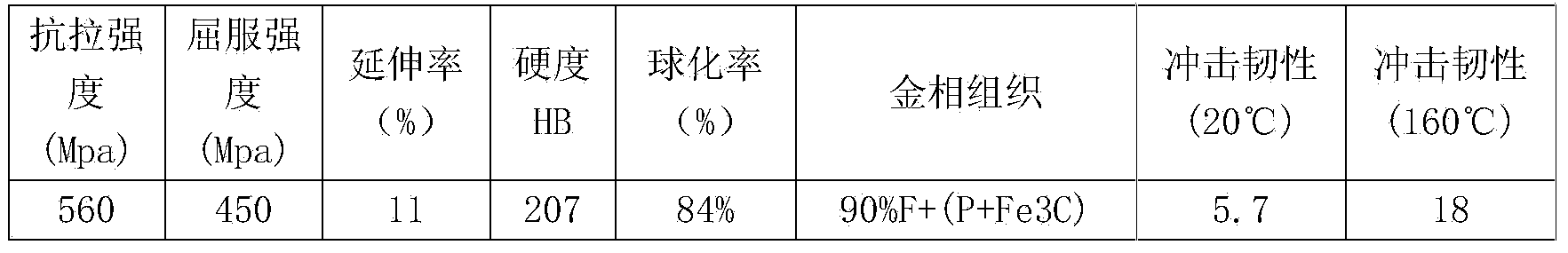

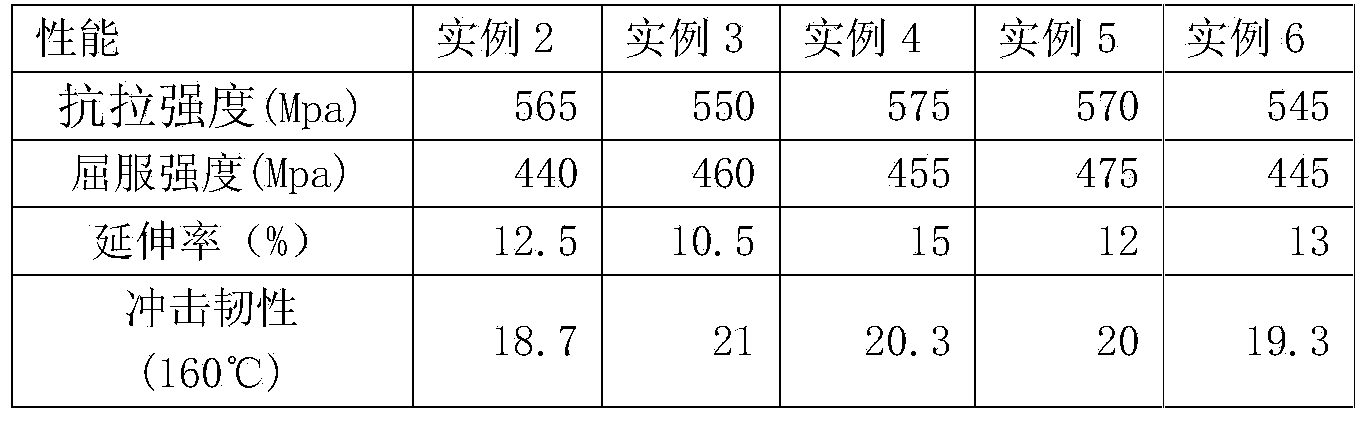

Manufacturing method of heat-resistant high-silicon-molybdenum nodular cast iron

ActiveCN104141088AImprove creep resistanceImprove durabilityProcess efficiency improvementRare-earth elementEnvironmental resistance

The invention relates to a manufacturing method of nodular cast iron for high-temperature parts of combustion engines, in particular to a manufacturing method of heat-resistant high-silicon-molybdenum nodular cast iron. The method comprises the following steps that chemical parameters, raw materials and weight percentage compositions are determined, wherein the nodular cast iron comprises, by weight, 30 percent-40 percent of pig iron, 20 percent-30 percent of scrap steel, 30 percent-40 percent of foundry returns, 1.5 percent-2.0 percent of silicon iron and 1 percent-1.2 percent of ferromolybdenum, and smelting, modification treatment, aging stress relieving technologies are performed. The method is unique, the creep resistance and endurance property of the material are improved, the intensity of the material is enhanced, and the service life of the material is prolonged; the influence on the graphite form by rare earth elements is relieved, the graphite roundness is improved, the fragmentation effect of graphite is relieved, the manufacturing cost and processing costs are reduced, and environmental friendliness and energy saving are facilitated.

Owner:KOCEL EQUIP

Carbon dioxide cured prefabricated water-permeable concrete and preparation method thereof

ActiveCN109824321ALow alkalinity requirementLow Pre-Care RequirementsEnvironmental resistanceCellulose

The invention discloses a carbon dioxide cured prefabricated water-permeable concrete and a preparation method thereof. The water-permeable concrete is composed of following components in parts by weight: 55 to 80 parts of regenerated aggregate, 7 to 30 parts of nickel slag sand, 18 to 40 parts of cementing material, 5 to 25 parts of water, 0.01 to 2 parts of naphthalene water reducer, 0 to 0.02 part of cellulose ether, and 0 to 0.01 part of welan gum. The cementing material is composed of following components in parts by weight: 70 to 90 parts of common silicate cement, 5 to 15 parts of fly ash, 10 to 30 parts of steel slag, 5 to 15 parts of lime or lime slag, and 0.02 to 1 part of nano calcium carbonate. The technology is simple, the structure advantage of water-permeable concrete and the properties of industrial byproducts such as nickel slag, steel slag, fly ash, and the like are fully utilized; carbon dioxide curing is utilized to realize rapid, efficient and environmentally friendly production; high strength, durable and water permeable concrete is obtained, the energy consumption is reduced, the industrial tail gas, metallurgy slag, and building waste are effectively utilized, and good economic benefits, social benefits, and environmental benefits are generated.

Owner:SOUTHEAST UNIV

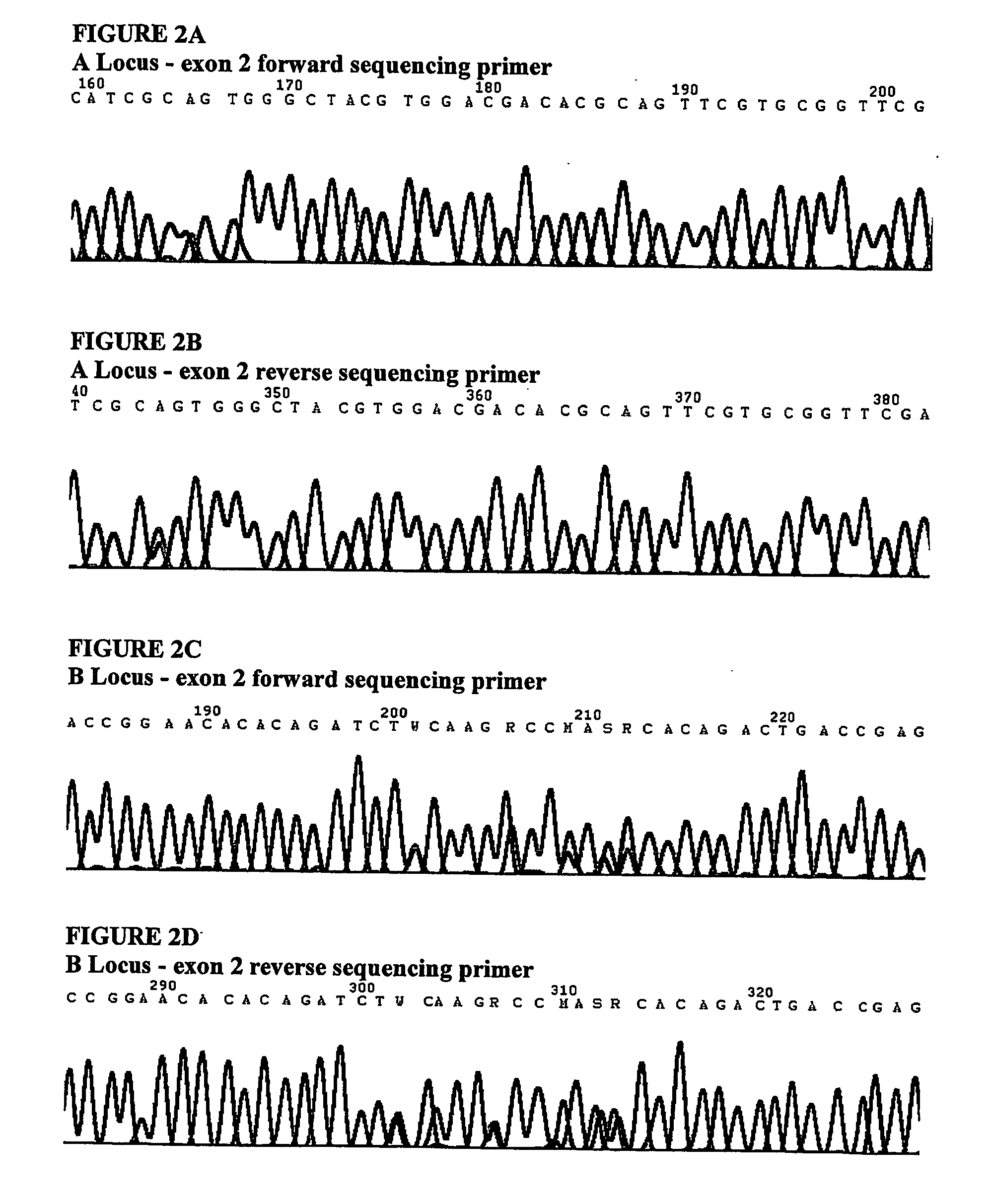

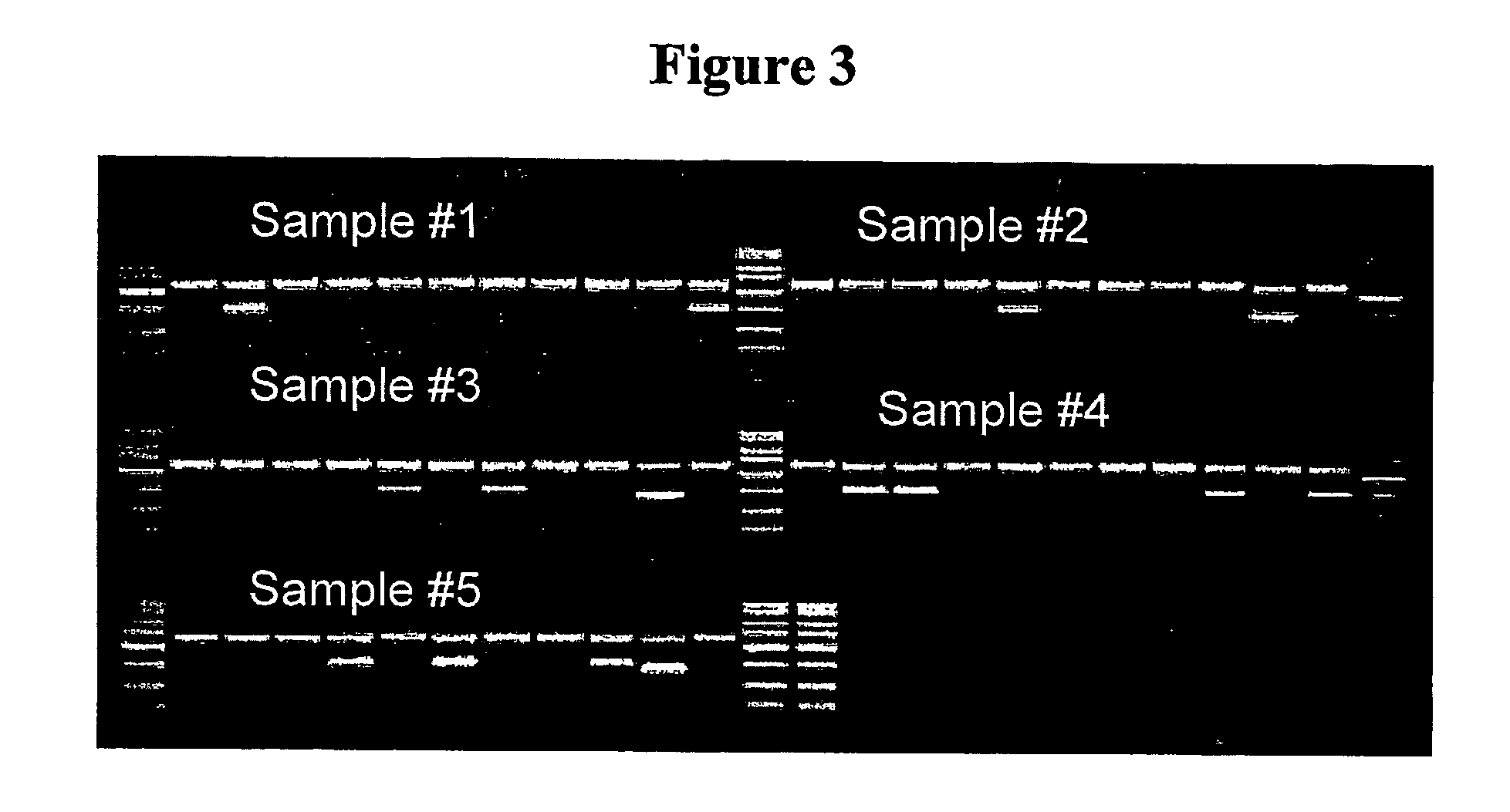

Primers, methods and kits for amplifying or detecting human leukocyte antigen alleles

InactiveUS20060078930A1Strong specificityMore abundant productsSugar derivativesMicrobiological testing/measurementMultiplexWhite blood cell

The present invention describes primers, methods and kits for amplifying and identifying HLA alleles. Using these primers, all HLA alleles at a single locus can be amplified using either a multiplex or non-multiplex PCR approach. Within sets of the primers, control primer pairs may be used to produce control amplicons of a predetermined size from an HLA allele only if a particular HLA locus is present in the sample. The present invention further describes primers for sequencing HLA alleles following amplification. Methods and kits for using the primers are also disclosed.

Owner:LIFE TECH CORP

Simple brewage method of strawberry wine

ActiveCN103555546AThe production process steps are simpleIncrease incomeAlcoholic beverage preparationFragariaBiology

The invention discloses a simple brewage method of a strawberry wine, which comprises the following steps: A. raw material preparation: screening mature fresh strawberries to obtain original strawberry fruits; B. natural fermentation: putting the original strawberry fruits and white granulated sugar into a fermentation tank in a weight ratio of 10:1-10:1.5, sealing the opening of the fermentation tank, and carrying out natural fermentation at room temperature under atmospheric pressure, thereby obtaining a strawberry juice; C. distillation: distilling the strawberry juice in a distilling apparatus to obtain a distilled unblended wine; and D. putting the distilled unblended wine in a storage tub, storing in a sealed state, and aging to obtain the strawberry wine finished product. The production procedure is simple, and is suitable for large-scale production for wineries and more suitable for domestic workshop production. The strawberry wine prepared by the method has the advantages of thick natural fragrance of strawberries, clear and transparent vinosity, sweet and soft mouthfeel, high fragrance endurance and long aftertaste.

Owner:王志岳

Induction cooker wire coil and wire coil winding technology

ActiveCN102548076ACompact structureEasy to installCoil arrangementsTransformers/inductances coils/windings/connectionsWinding machineEngineering

The invention relates to a wire coil, in particular to an induction cooker wire coil and a wire coil winding technology. The induction cooker wire coil is characterized in that a wire coil bottom base is of a plane structure, a wire clamping framework and the wire coil bottom base are respectively matched with corresponding strengthening ribs, the strengthening ribs on the wire clamping framework are provided with clamping grooves for clamping a coil at intervals, and the clamping grooves in the wire clamping framework are in clamping match with the wire coil bottom base after clamping the coil. When the wire coil is wound, a winding mould can be arranged on a winding machine first, the winding machine can be started, and the winding for the coil of which the shape is corresponding to the shape of the winding mould can be finished on the winding mould; then, the wire clamping framework can be clamped into the winding mould, an aluminum coil which is wound and formed on the winding mould can be clamped firmly through the wire clamping framework, and then the wire clamping framework clamping the coil firmly can be pushed out of the winding mould through a coil pushing-out groove arranged at the bottom part of the winding mould; and finally, the wire clamping framework clamping the coil firmly can be arranged in the wire coil bottom base. According to the induction cooker wire coil and the wire coil winding technology which are disclosed by the invention, on the premise without influencing the whole strength of the wire coil, a large amount of materials are saved, the winding technology is simplified, and the winding efficiency is increased.

Owner:杭州信多达电子科技有限公司

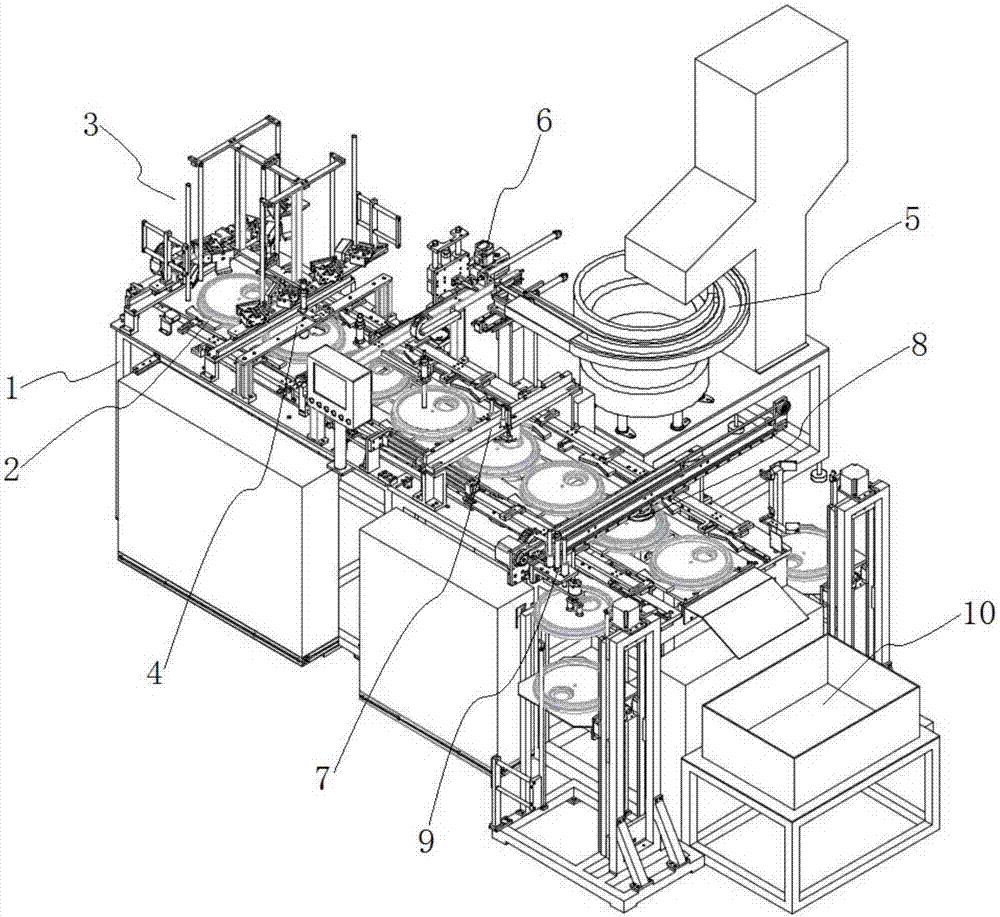

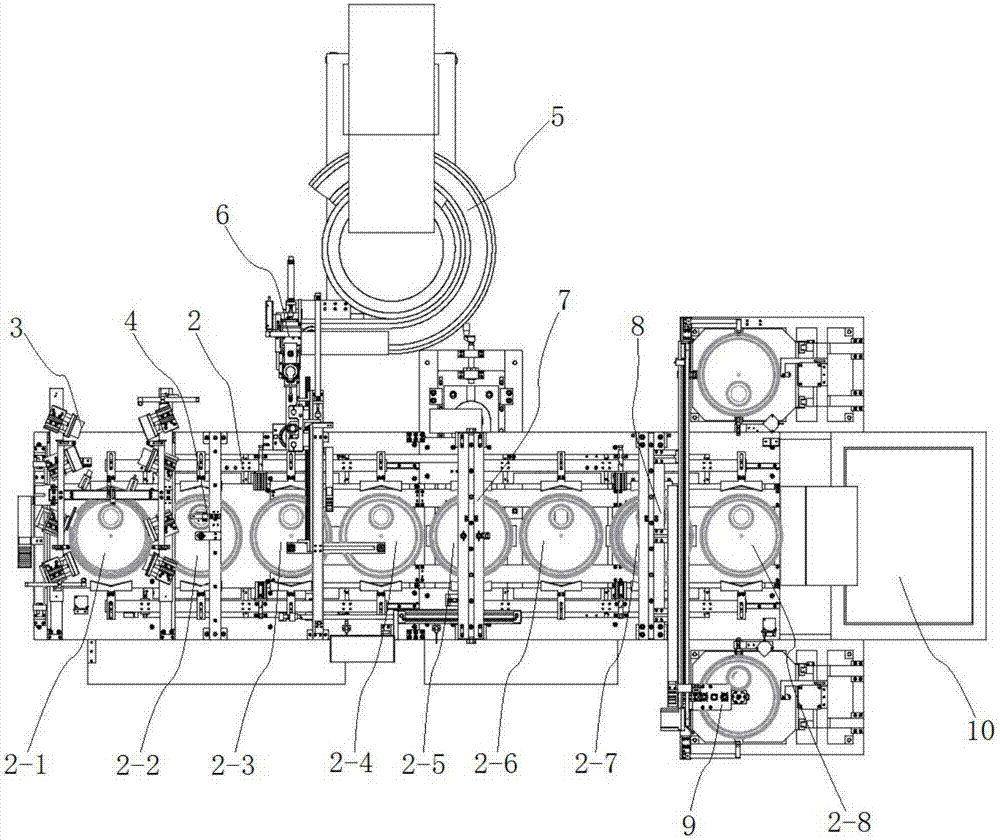

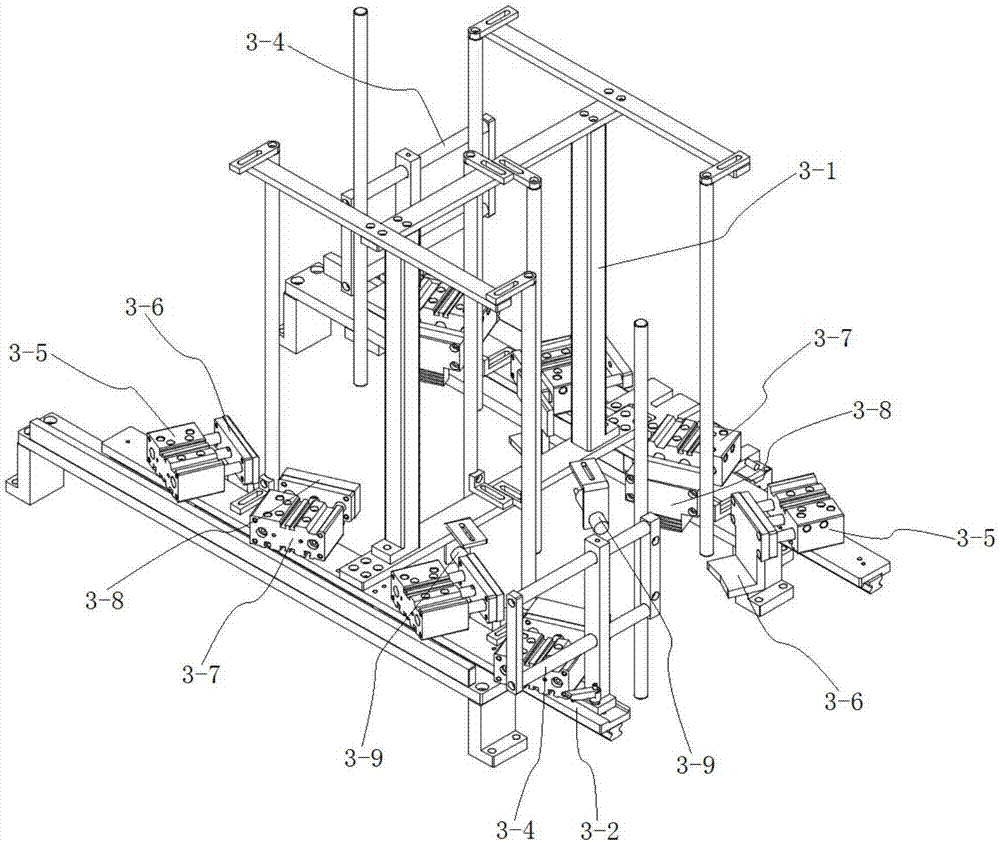

Automatic welding equipment for plastic barrel cover and oil nozzle

ActiveCN107139488ARealize continuous automatic welding productionCompact structureStacking articlesDe-stacking articlesUltrasonic weldingStructural engineering

The invention discloses automatic welding equipment for a plastic barrel cover and an oil nozzle and belongs to the field of automatic equipment. The automatic welding equipment disclosed by the invention comprises a frame and a barrel cover clamping and conveying device; a barrel cover feeding station, a barrel cover positioning station, an oil nozzle mounting station, a welding station, a detecting station and a discharging station are arranged in sequence on the barrel cover clamping and conveying device and along a rectilinear direction; a barrel cover feeding device is arranged at the barrel cover feeding station; a barrel cover rotary positioning device is arranged at the barrel cover positioning station; an oil nozzle positioning and mounting device is arranged at the oil nozzle mounting station; an ultrasonic welding device is arranged at the welding station; an air tightness detecting device is arranged at the detecting station; and a discharged material stacking device and an inferior-quality product recycling device are arranged at the discharging station. The automatic welding equipment disclosed by the invention can sequentially automatically accomplish the work of barrel cover feeding, barrel cover positioning, oil nozzle positioning and mounting, welding, air tightness detection and discharged material stacking, and is simple and compact in structure, stable and reliable in operation, flexible and convenient to control, high in production efficiency and good in welding quality.

Owner:CHANGZHOU CENTRWAY PLASTICS

Printing device for surfaces of lithium batteries

ActiveCN112265361APrevent looseningAvoid deformationPrimary cell manufactureNon-aqueous electrolyte cellsEngineeringMechanical engineering

The invention relates to a printing device, in particular to a printing device for the surfaces of lithium batteries, and aims to solve the technical problem of how to provide a printing device capable of adapting to the surfaces of various types of lithium batteries. The printing device for the surfaces of the lithium batteries comprises a rack, a mounting plate, a driving assembly and a printingassembly, wherein sliding grooves are formed in the two sides of the rack; the mounting plate is mounted on the rack; the driving assembly is mounted on the mounting plate; and the printing assemblyis mounted on the rack. The printing device is provided with a clamping assembly, a new template can be replaced and clamped, so that the template cannot loose, and deformation caused by printing is prevented; the printing device is provided with a pushing assembly, and damage to a printing plate due to the fact that the printing plate makes contact with the rack when moving to the edge can be prevented; and the printing device is provided with an adjusting assembly, so that the device can adapt to different types of batteries, and enterprises can carry out diversified production.

Owner:东营昆宇电源科技有限公司 +1

Heated vulcanizing device based on seal ring application

PendingCN111633887AIncrease the production processGuaranteed buffer timeDomestic articlesVulcanizationMechanical engineering

The invention discloses a heated vulcanizing device based on seal ring application. The device comprises an operation table, a pressurizing device and a control cabinet, wherein a lifting table is disposed on the top of the operation table, and a baseplate is fixedly connected to the top of the lifting table. The invention relates to the technical field of vulcanizing devices. The heated vulcanizing device based on seal ring application is characterized in that a structure which can realize rapid unloading is formed through configuration of a movable block, a fixation shaft and a first springin a lower mold; at this moment, a worker only needs to move a tool plate from the inner side of the top of the lower mold towards the front side and take out all the formed seal rings, so that all the seal rings can be unloaded at the same time, unloading time is greatly saved, working efficiency is further increased, and processing and production of the seal rings are accelerated; and when a production amount of the seal rings is large, the worker can have certain buffering time and does not need to keep a rapid working state, and thus the worker can make operations more easily and conveniently.

Owner:WUXI TEHENG TECH CO LTD

Smoking behavior real-time detection method based on deep learning

ActiveCN111507416AIncrease the production processRich varietyCharacter and pattern recognitionNeural architecturesSmoking behaviorData set

The invention is suitable for the technical field of artificial intelligence and behavior detection, and provides a smoking behavior real-time detection method based on deep learning. According to themethod, a data set is constructed through a data acquisition standard, and a set of smoking convolutional neural network for smoking behavior detection is constructed. The method promotes research ofdeep learning on smoking behavior detection, and has good detection accuracy, and by means of deep learning, the method has very high real-time performance and robustness and can adapt to the environmental change of an application scene.

Owner:湖北马斯特谱科技有限公司

PLA heat-resistant knife, fork and spoon and production method

A PLA material used by a PLA heat-resistant knife, fork and spoon of the invention comprises the following components in parts by weight: 40-80 parts of racemic polylactic acid; 10-30 parts of aliphatic polyester; 0.5-1 part of a nucleating agent; 5-30 parts of an inorganic filler; 0.3-3 parts of a dispersant; and 0.3-1 part of an antioxidant. The PLA heat-resistant knife, fork and spoon has effectively improved heat resistance, meets the high-temperature use requirement, can be stably formed, and is beneficial to efficient processing and production.

Owner:NANJING PRIDE PLASTIC TECH

Earphone wire forming method

ActiveCN106531349AIncrease the production processAvoid damage or wire contactInsulating conductors/cablesEngineeringHigh pressure

The invention is suitable for the technical field of an earphone. The invention discloses an earphone wire forming method which comprises a wire shaping step on a cut wire which comprises a wire middle layer that wraps an enameled stranded wire and a wire outer layer that wraps the wire middle layer. The wire shaping step comprises processes of performing pre-shaping on the wire with an appropriate length so that the wire is preset to a required shape; and performing heating forming, namely performing heating forming on the pre-shaped wire. Because pre-shaping is performed on the wire and the pre-shaped wire is placed into boiled water or a baking furnace for performing baking for further shaping, a controllable heating temperature is realized. Not only can secondary injection molding forming in a high-temperature high-pressure mold be saved for preventing production process increase, but also core wire damage or core wire contact caused by the high temperature and high pressure in secondary injection molding forming can be prevented. Furthermore the earphone wire forming method has advantages of improving quality of an earphone wire, reducing process difficulty, and improving product yield rate and production efficiency.

Owner:SHENZHEN CANNICE TECH

Ship production management system and management method thereof

InactiveCN102880946AReal-time understanding of order progressRealize rational utilizationResourcesManufacturing computing systemsRational usePurchasing

The invention discloses a ship production management system comprising a production workshop management system, a parts management system, an expert analysis platform, a technology management system, a finished workshop management system, a product purchasing system and a management platform, wherein the production workshop management system, the parts management system, the technology management system, the finished workshop management system and the product purchasing system are all connected with the management platform. The invention further discloses a management method of the ship production management system. According to the ship production management system and the management method of the ship production management system, the whole production process is connected together through an information system without manual management; through system circulating, the rational use of resources during the whole production process is realized; the labor cost is reduced; and meanwhile, the waste of the resources is reduced, the production task is rationally distributed and the production efficiency is improved.

Owner:JIANGSU HANTONG SHIP HEAVY IND

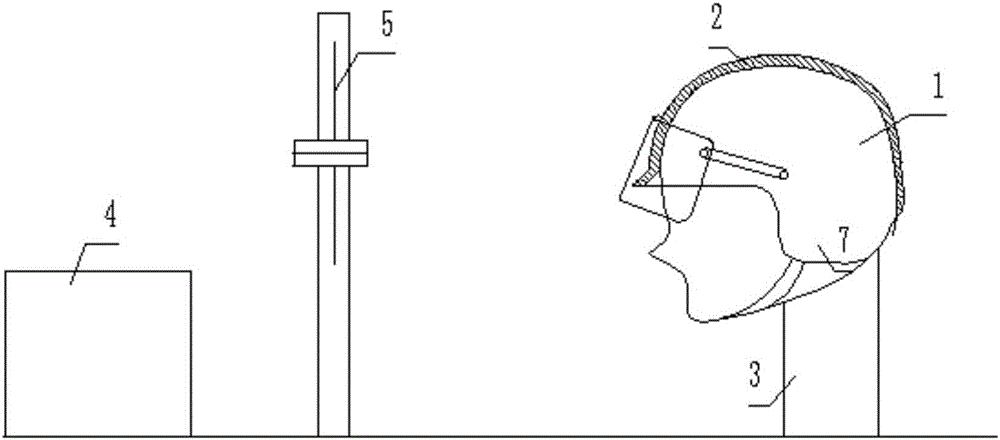

Helmet quality detection system

The invention discloses a helmet quality detection system and belongs to the technical field of quality detection. The helmet quality detection system comprises head model, a detection module, a controller and a fixed support. The head model is fixedly installed in the fixed support. The detection module is installed inside and outside the head model and is used for detecting the inner and outer temperatures of the head model, the humidity and the stress of the head model. An output end of the detection module is connected with the controller and outputs detection signals to the controller. The controller analyzes the data. According to the invention, the head model and the detection module for inner and outer detection are additionally arranged, the problems in helmet quality detection that the detection data is insufficient and the quality is ragged are solved, and the helmet quality detection system has the advantages that data of a plurality of aspects such as helmet comfort and heat dissipation is detected, and the quality parameters of a helmet are detected, such as the heat dissipation and the protection capability of the helmet.

Owner:安瑞装甲材料(芜湖)科技有限公司

PVC (polyvinyl chloride) board and production method thereof

InactiveCN104592687AImprove high temperature resistanceNo signs of deformation were foundPolyvinyl chlorideFire resistance

The invention discloses a PVC (polyvinyl chloride) board and a production method thereof. The PVC board is prepared from 91%-94% of PVC waste, 0.8%-1.4% of stabilizing agent, 3.5%-4.5% of foaming regulator, 0.15-0.3% of yellow foam, 0.4%-0.7% of white foam, 0.05%-0.25% of PE (polyethylene) wax, 0.2%-0.4% of OK60, 0.15%-0.3% of OA6 and 0.5%-1.7% of CPE (chlorinated polyethylene) or MBS (methyl methacrylate-butadiene-styrene). The production method comprises the following steps: low-temperature mixing, extrusion and cooling setting. The PVC board produced by the method has the advantages of high hardness, favorable fire resistance, favorable high temperature resistance, low water content, high static bending strength, favorable bending properties, favorable screw holding performance and favorable compression strength.

Owner:梁伯行

Primers, methods and kits for amplifying or detecting human leukocyte antigen alleles

InactiveUS20070111213A1Strong specificityMore abundant productsSugar derivativesMicrobiological testing/measurementMultiplexWhite blood cell

The present invention describes primers, methods and kits for amplifying and identifying HLA alleles. Using these primers, all HLA alleles at a single locus can be amplified using either a multiplex or non-multiplex PCR approach. Within sets of the primers, control primer pairs may be used to produce control amplicons of a predetermined size from an HLA allele only if a particular HLA locus is present in the sample. The present invention further describes primers for sequencing HLA alleles following amplification. Methods and kits for using the primers are also disclosed.

Owner:LIFE TECH CORP

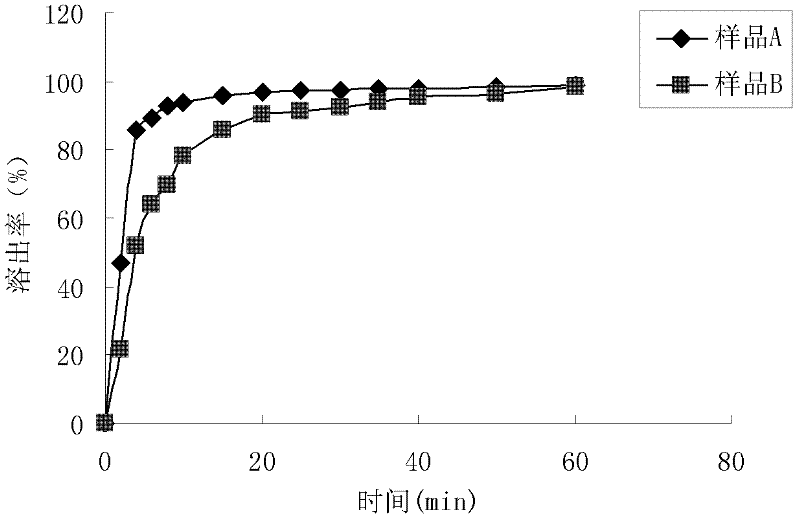

Ganciclovir tablet composition and its preparation method

ActiveCN102309463AImprove bioavailabilityGood dispersionAntiviralsPill deliveryCarboxymethyl starchActive component

A ganciclovir tablet composition. The ganciclovir tablet composition comprises the following components of: by weight, 1part of ganciclovir hydrate crystals, 0.1-0.5 part of lactose, 0.05-0.08 part of hydroxypropylcellulose, 0.008-0.014 part of carboxyl methyl starch sodium, a proper amount of polyvinylpyrrolidone K30 and 0.01-0.05 part of magnesium stearate, wherein the brief molecular formula of the ganciclovir hydrate crystals is C9H13N504.1.5H2O; the weight of the ganciclovir hydrate crystals is calculated according to the weight of ganciclovir; and major peaks in powder XRD of the crystals are shown at diffraction angles of 5.45+ / -0.1 degrees, 7.28+ / -0.1 degrees, 11.45+ / -0.1 degrees, 15.67+ / -0.1 degrees and the like. The preparation technology of the prepared ganciclovir tablets is simple; tablets have good stability; dosage is accurate; active components are easy to dissolve; and the bioavailability of the active components is raised.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +2

High performance printing equipment for anti-counterfeiting marks

InactiveCN107264009AImprove printing effectImprove printing qualityScreen printersFixed frameEngineering

The invention discloses high-performance printing equipment for anti-counterfeiting marks, which includes a screen fixing frame whose size matches that of the printing screen, and a plurality of horizontal bars are sequentially arranged on the inner side wall of the screen fixing frame. The paint spraying tube and the four corners of the fixed frame of the screen are connected with a fixed column respectively, and the outer wall of the fixed frame of the screen is slidably connected with the side wall of the fixed column. A height adjustment block is provided, and an inclined printing scraper is arranged above the fixed frame of the screen. The inclination angle of the printing scraper is 15-30°, and the printing scraper moves back and forth along the horizontal direction. The printing device of the present invention can improve the printing effect of the anti-counterfeit label and improve the uniformity of printing, thereby ensuring the normal use of the anti-counterfeit label, being convenient and quick to use, reducing manual labor, and improving work efficiency.

Owner:CHONGQING JOYA TECH DEV CO LTD

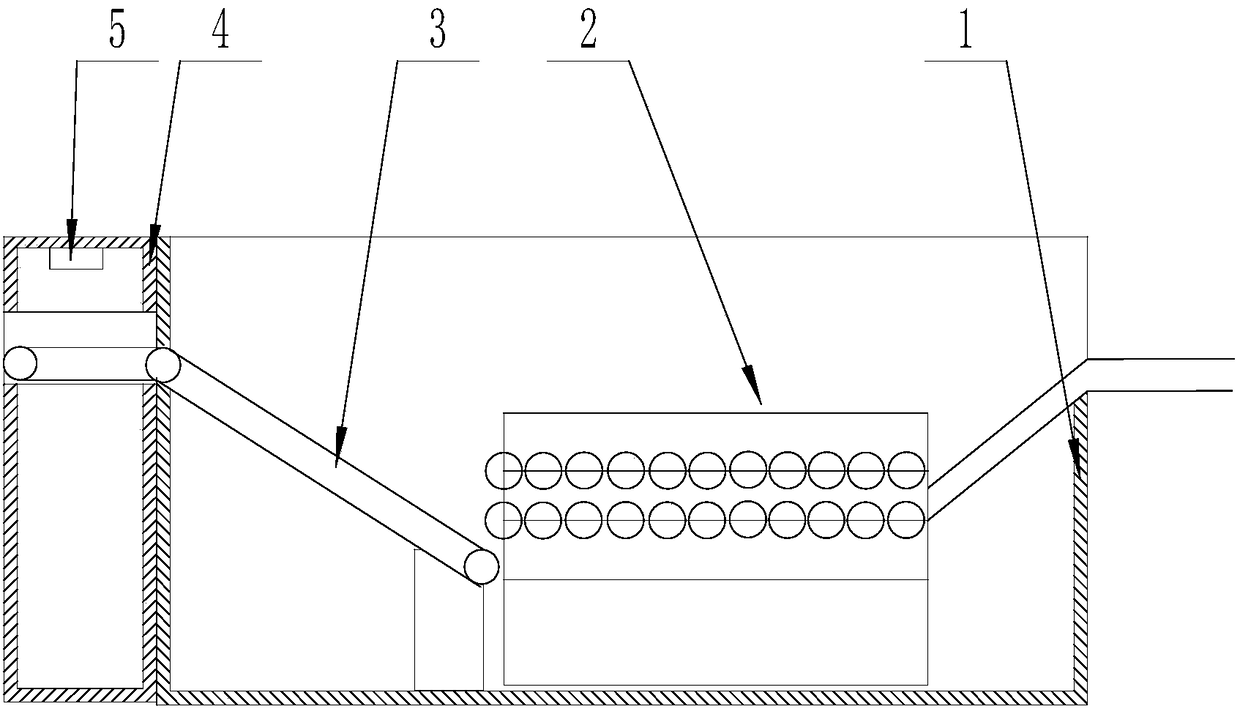

Date fruit washing equipment and date fruit washing system

PendingCN108244673AEasy to cleanIncrease the production processFood treatmentDate FruitTransmission belt

The invention relates to the technical field of washing equipment, in particular to date fruit washing equipment and a date fruit washing system. The date fruit washing equipment comprises a washing pond, a brush roller washing device, a transmission belt mechanism, a drying chamber and a drying device, wherein the washing pond, the brush roller washing device, the transmission belt mechanism andthe drying chamber are sequentially arranged in the transporting direction of date fruits; the drying device is arranged in the drying chamber; and the brush roller washing device is fixed in the washing pond. Through the adoption of the date fruit washing equipment provided by the invention, massive date fruits can be washed, and manual labor is avoided; through the washing of brush rollers in the brush roller washing device, the date fruits can be effectively washed, the washing effect is good, and the washing efficiency can be greatly improved; and besides, wet dates can be quickly dried bythe drying device, so that people can directly load dates in boxes and bags, the dates are further convenient for people to use, and processing and producing of the dates are improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Computer-based steelmaking logistics simulation system

InactiveCN109557881AVersatilitySimulate a wide range of steelmaking production processesTotal factory controlProgramme total factory controlComputer basedLocal area network

The invention discloses a computer-based steelmaking logistics simulation system and belongs to the technical field of metallurgical production simulation. The system is composed of a plan schedulingsimulator, a monitoring display device, a molten iron preprocessing simulator, a converter simulator, an LF refining furnace simulator, an RH refining furnace simulator, a continuous casting simulatorand a simulation result library, which are connected with an Ethernet local area network, wherein the plan scheduling simulator establishes a steelmaking production environment; the monitoring display device realizes display of a simulation content; the simulation result library realizes storage of the simulation result; the molten iron preprocessing simulator is used for simulating a molten ironpreprocessing process; the converter simulator is used for simulating a converter smelting production process; the LF refining furnace simulator is used for simulating a steel ladle refining production process; the RH refining furnace simulator is used for simulating a vacuum refining production process; and the continuous casting simulator is used for simulating a continuous casting pouring andcasting blank cutting process. The system has the advantage of being capable of supporting steelmaking production plan arrangement, steelmaking production process logistics balance research and steelmaking process path design.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

Vaccine and Therapeutic Delivery System

ActiveUS20130095131A1Increase the production processEliminate needPolypeptide with localisation/targeting motifBacterial antigen ingredientsVaccine deliveryGenomic DNA

The present invention relates to a new vaccine delivery system. In particular, the present invention includes compositions and methods of integrally transformed non-pathogenic, commensal bacteria that can express a nucleic acid molecule of a foreign polypeptide, wherein the nucleic acid molecule that encodes the foreign polypeptide is stably integrated into genomic DNA of the bacteria. The foreign polypeptide includes a vaccine antigen that elicits an immunogenic response, an inhibitor of a pathogen, or an immune booster or modulator.

Owner:FORSYTH DENTAL INFARY FOR CHILDREN

New method for liquid chlorine vaporization

InactiveCN103292154AReduce consumptionIncrease the production processPressure vesselsContainer discharging from pressure vesselsChemical industryWater chlorination

The invention discloses a new method for liquid chlorine vaporization. Cooling water which is generated in a phosphorus trichloride or phosphorus oxychloride production process is utilized to heat chlorine gas so as to vapourize the chlorine gas. Compared with the prior art, the new method provided by the invention has the advantages that (1), the energy consumption is greatly reduced; (2) the operational safety is greatly improved; (3), production adopting a chlorine productive unit (phosphorus trichloride and phosphorus trichloride production department) is smooth; (4) the environment of production field is greatly improved; (5) the service life of equipment is obviously prolonged. The new method is an environment-friendly chemical industry process, meets development direction of safe production and energy saving and emission reduction, and has good industrialized application prospect.

Owner:JIANGSU TIANYUAN CHEM

Health tea for enhancing memory, and production method thereof

InactiveCN106035831ALight tasteFragrant and pleasantPre-extraction tea treatmentSucroseAgrimonia eupatoria

The invention discloses a health tea for enhancing memory, and a production method thereof. The health tea comprises, by weight, 35-45 parts of black tea, 6-8 parts of radix and rhizome of Acanthopanax senticosus, 5-7 parts of Agrimonia eupatoria, 15-20 parts of wolfberry fruit, 15-20 parts of omega fish oil, 5-7 parts of blueberry fruit powder, 3-5 parts of Cortex Moutan, 6-8 parts of Gynostemma pentaphylla, 4-6 parts of raisin, 8-10 parts of litchi flesh, 3-4 parts of Radix Ophiopogonis, 5-7 parts of spine date seeds, 4-6 parts of walnut kernels, 8-12 parts of Seleno-k-carrageenan, 4-6 parts of needle mushroom powder, 6-8 parts of sucrose, 4-6 parts of lactalbumin powder and 7-10 parts of nutrition powder. The health tea has light taste and pleasant fragrance, reserves the natural and original taste of raw materials, has abundant nutrition values, simplifies the production process, and reduces the production cost; and various medicinal and edible materials added in the invention can improve sleep, enhance memory and delay ageing, so the health tea can be drunk for a long term to effectively improve the body functions.

Owner:BOZHOU YIZHONGTANG HEALTH FOOD CO LTD

A kind of simple brewing method of strawberry wine

ActiveCN103555546BIncrease aromaStrong natural fragranceAlcoholic beverage preparationFragariaDistillation

The invention discloses a simple brewage method of a strawberry wine, which comprises the following steps: A. raw material preparation: screening mature fresh strawberries to obtain original strawberry fruits; B. natural fermentation: putting the original strawberry fruits and white granulated sugar into a fermentation tank in a weight ratio of 10:1-10:1.5, sealing the opening of the fermentation tank, and carrying out natural fermentation at room temperature under atmospheric pressure, thereby obtaining a strawberry juice; C. distillation: distilling the strawberry juice in a distilling apparatus to obtain a distilled unblended wine; and D. putting the distilled unblended wine in a storage tub, storing in a sealed state, and aging to obtain the strawberry wine finished product. The production procedure is simple, and is suitable for large-scale production for wineries and more suitable for domestic workshop production. The strawberry wine prepared by the method has the advantages of thick natural fragrance of strawberries, clear and transparent vinosity, sweet and soft mouthfeel, high fragrance endurance and long aftertaste.

Owner:王志岳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com