Automatic welding equipment for plastic barrel cover and oil nozzle

An automatic welding and barrel lid technology, which is applied in the destacking of objects, stacking, transportation and packaging of objects, etc. It can solve the problem of inability to further increase the feeding and discharging system, increase the diameter and size of the dividing turntable system, equipment operation and control. Cumbersome and other problems, to achieve the effect of reducing the number of manual feeding, increasing the production process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

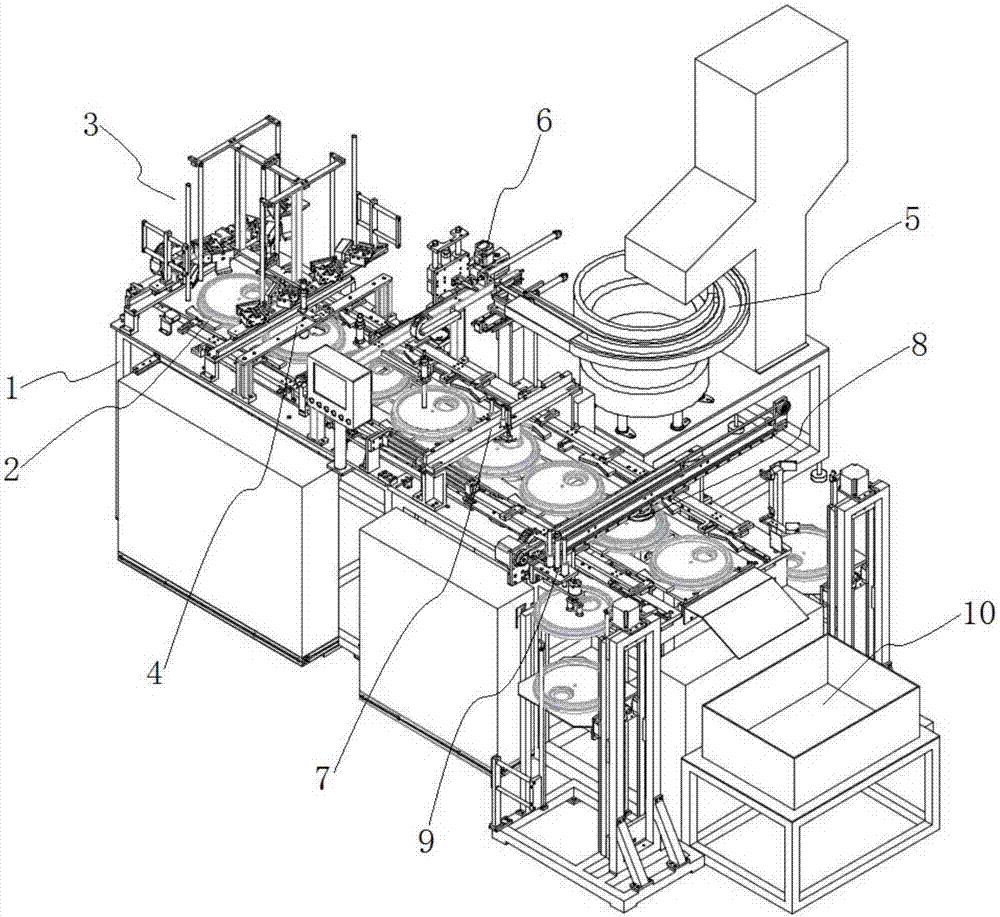

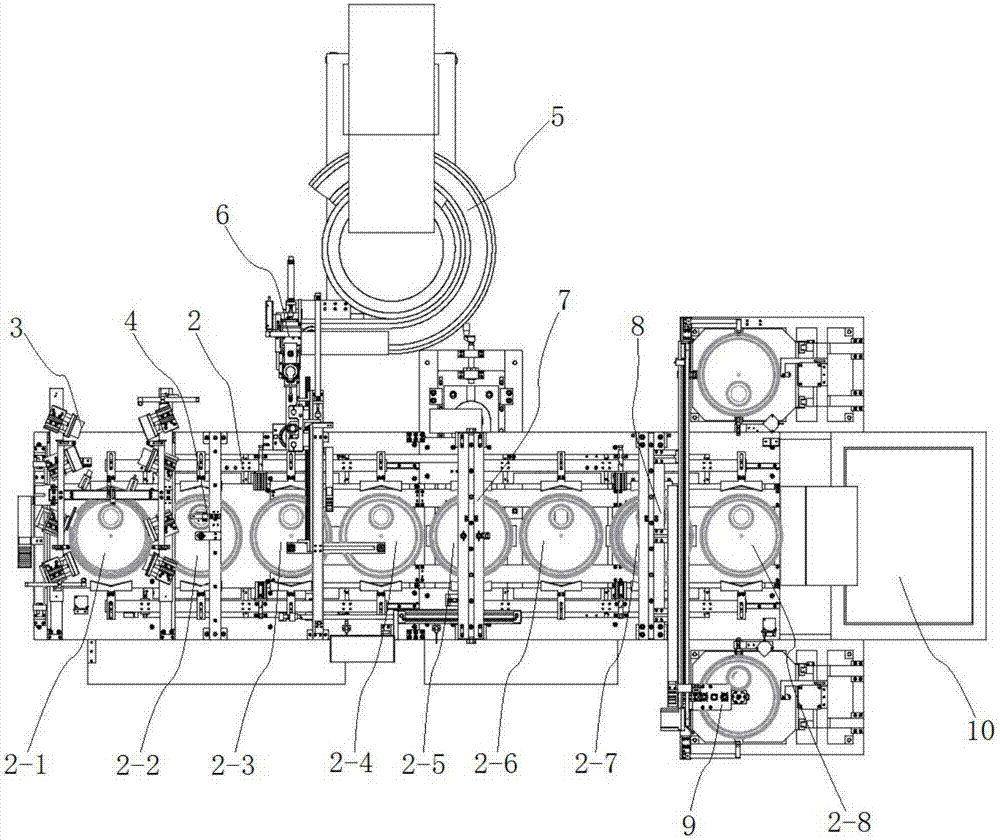

[0045] Combine figure 1 with figure 2 As shown, the automatic welding equipment for plastic bucket lids and oil nozzles of this embodiment includes a frame 1 and a lid clamping and conveying device 2 arranged on the frame 1 for synchronously conveying the lid. Conveying device 2 is provided with barrel lid loading station 2-1, barrel lid positioning station 2-2, nozzle installation station 2-3, welding station 2-5, and inspection station 2-7 in a straight line. And unloading stations 2-8, the lid gripping and conveying device 2 is equipped with reciprocating jaws on each station, these jaws can simultaneously grasp the lid on each station and transport it to the front At one station. The specific structure and working principle of the barrel lid gripping and conveying device 2 can be found in the patent ZL201521003343.X. The name of the invention is: an application for a clamping jaw mechanism of a plastic oil barrel lid welding machine, which will not be repeated here.

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com