Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Increase surface free energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst used for preparation of hydrogen through water electrolysis, and preparation method thereof

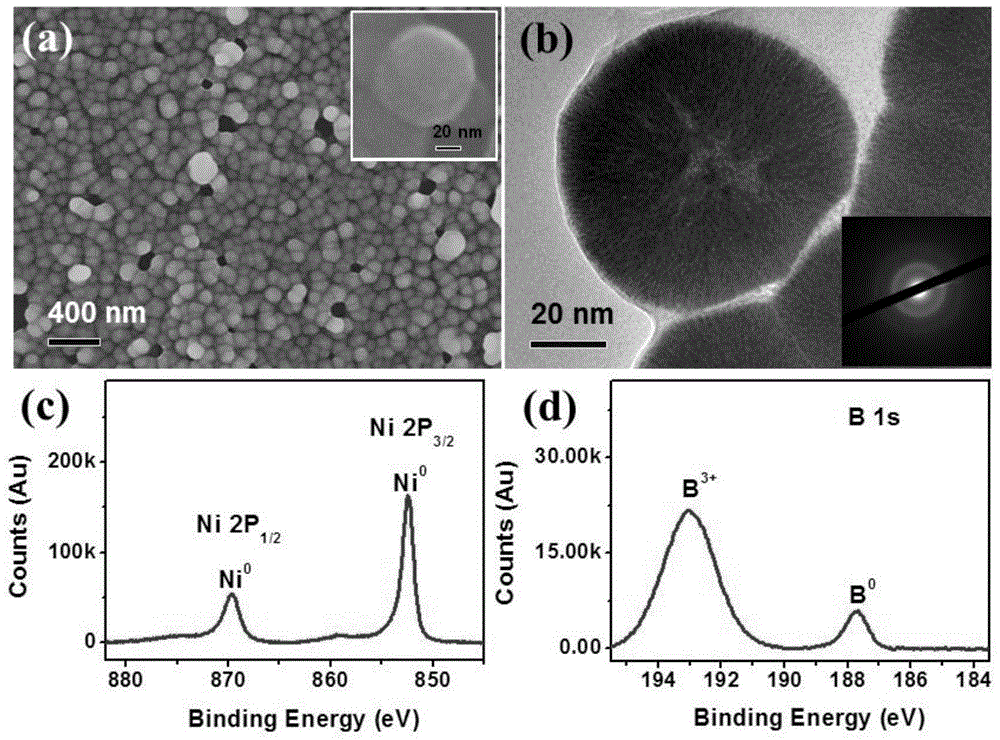

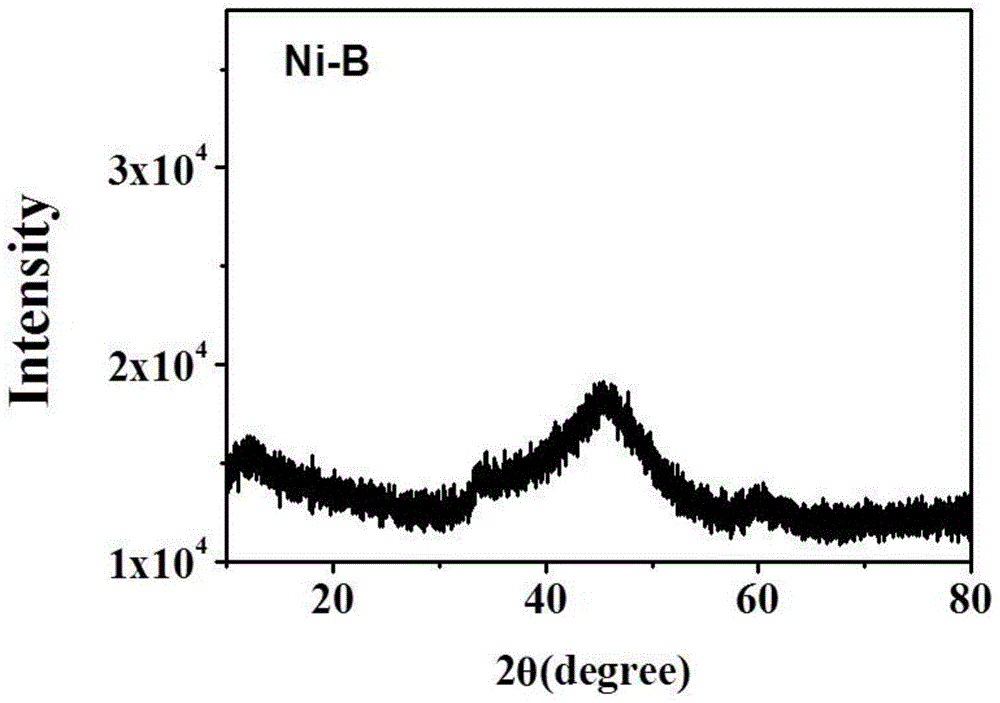

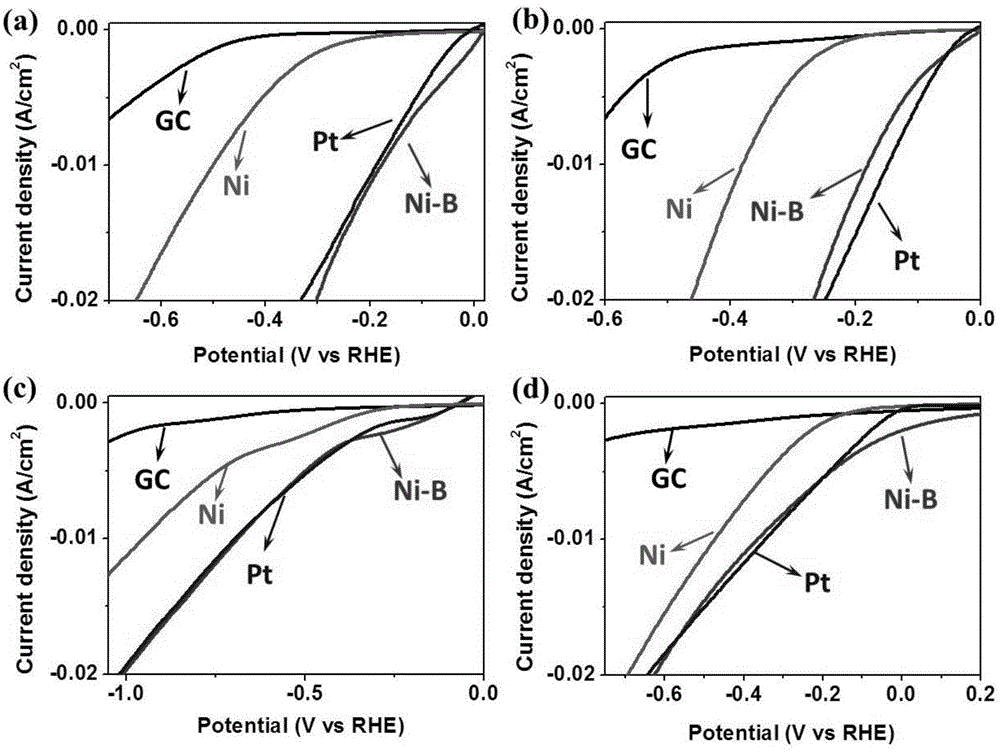

ActiveCN103952719AReduce hydrogen evolution overpotentialHigh activityLiquid/solution decomposition chemical coatingMetal/metal-oxides/metal-hydroxide catalystsPlatinumElectrolysis

The invention provides a catalyst used for the preparation of hydrogen through water electrolysis. The catalyst is amorphous Ni-B, and an atom ratio of Ni to B is 1.0-5.0. The invention also provides a preparation method for the catalyst. The method is characterized in that Ni-B is loaded on the surface of a carrier through a chemical plating method, and the feeding atom ratio of B to Ni in a chemical plating liquid is 3.0-10.0. The amorphous Ni-B is successfully applied in the catalysis of a hydrogen evolution reaction through water decomposition, and the reaction activity of the amorphous Ni-B can be comparable with that of platinum. The amorphous Ni-B has the advantages of low hydrogen evolution over-potential, high catalytic efficiency, stable performances, low price and simple preparation, and becomes one of the most ideal catalysts for substituting the present noble metal Pt catalyst.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Surface modification method for medical grade silicon rubber

ActiveCN101880402ADoes not affect the natureImprove hydrophilicityProsthesisBeam densityIon implantation

The invention discloses a surface modification method for a medical grade silicon rubber. The surface modification method is an ion implantation method, the implanted ions are C ions, and the ion-implanted material to be modified is the medical grade silicon rubber; in the process of ion implantation, the ion energy is 5 to 10kev, the using amount of ions is 1.0*1,014 ions / cm<2> to 1.0*1,016 ions / cm<2>, the beam density is no more than 0.6 mA / cm<2>, and the residual gas pressure is no more than 1*10<-3>Pa; and in the surface modification method, the C ions serving as the major elements of the human body are selected as the implanted ions, so that the hydrophily of the surface of the silicon rubber, namely the affinity with an organism, is enhanced, and the silicon rubber after being implanted into the human body can be comparable with histocytes, and the deformation and displacement of a medical silicone rubber implant are avoided. Meanwhile, the surface modification method of the invention overcomes the defects of poor peeling, poor stability and complicated processing steps, and the like existing in conventional plasma treatment, graft copolymerization and bionic coating, and the like.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

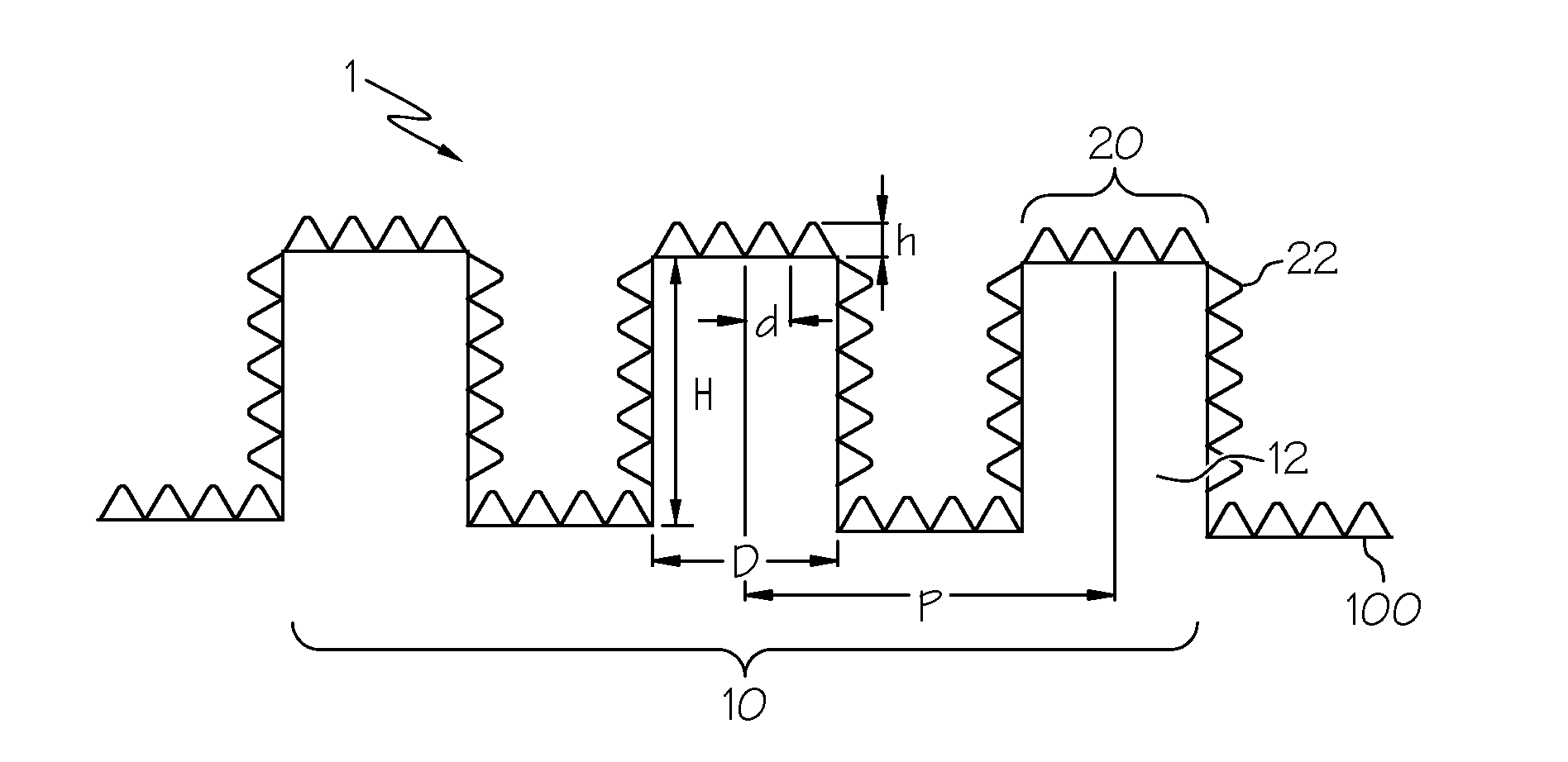

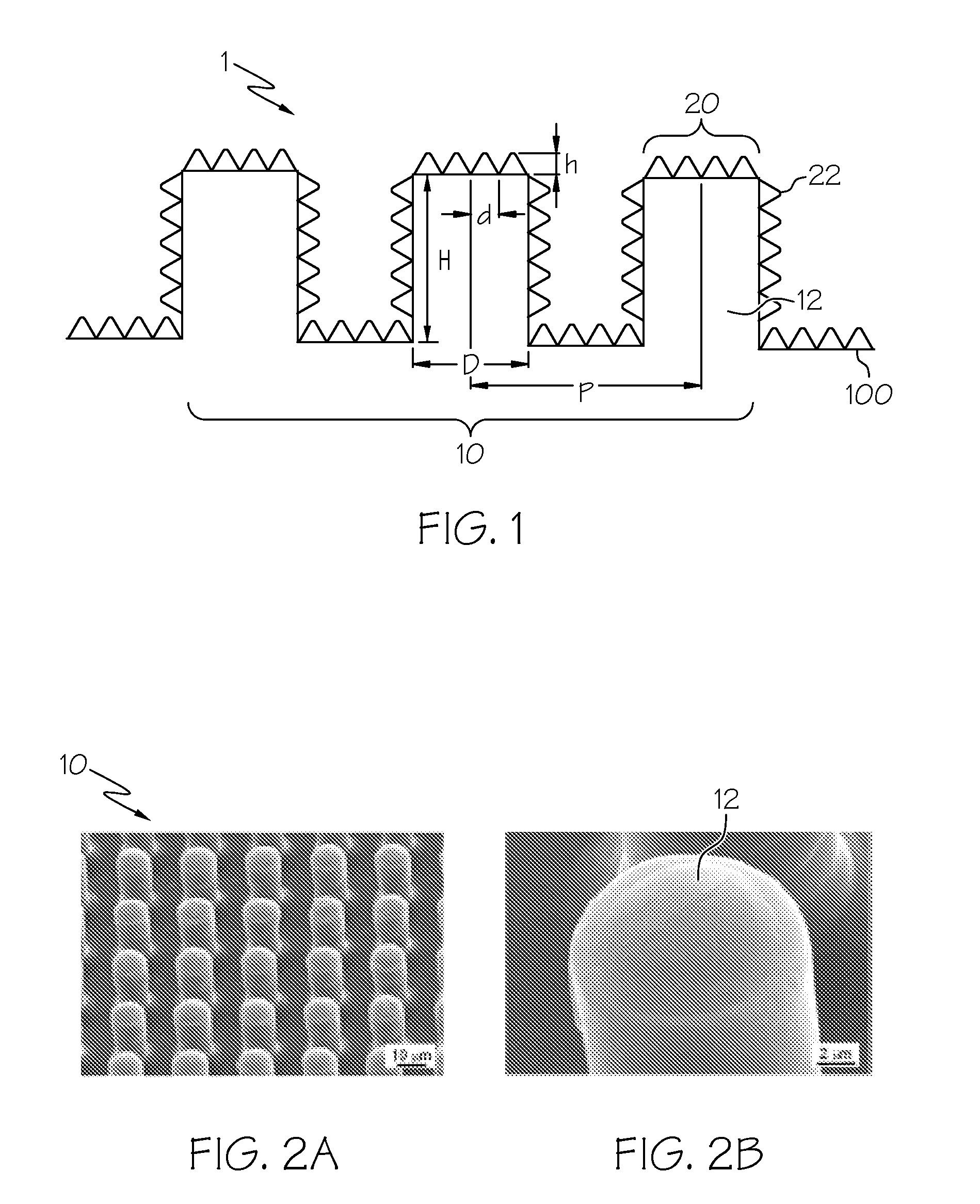

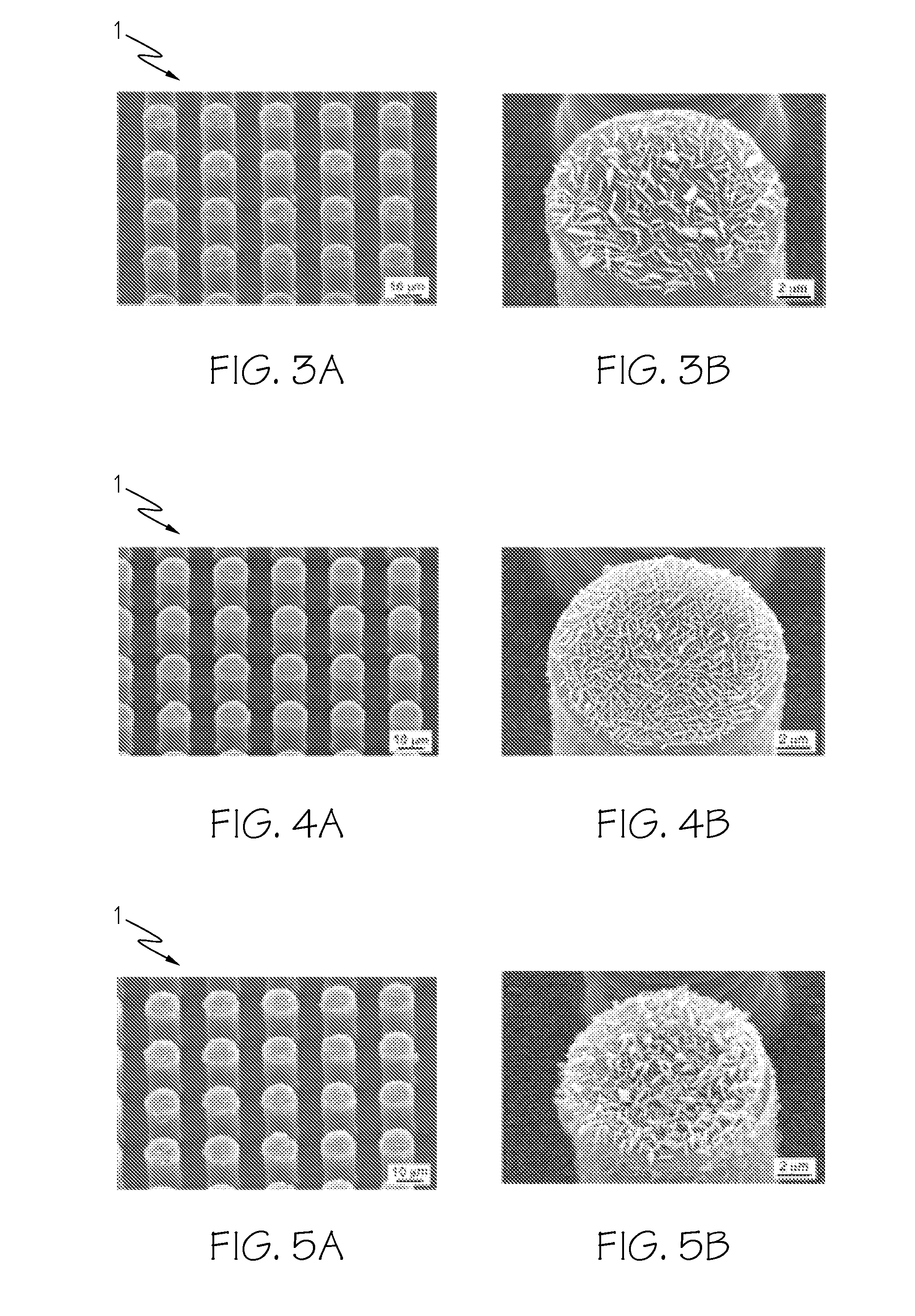

Hierarchical structures for superhydrophobic surfaces and methods of making

ActiveUS20110177288A1Increase contact angleStrong self-cleaningFouling preventionSynthetic resin layered productsEpoxySolvent vapor

Embodiments of methods of making superhydrophobic structures comprise depositing a polymer mold onto a silicon surface comprising a plurality of microasperities, removing the polymer mold after the polymer mold has hardened, depositing a liquid epoxy resin into the polymer mold, forming a microstructure with a plurality of microasperities by separating the epoxy resin from the mold after the epoxy resin has solidified, and forming a superhydrophobic structure by depositing a plurality of alkane nanoasperities on the microstructure in the presence of solvent vapor.

Owner:THE OHIO STATES UNIV

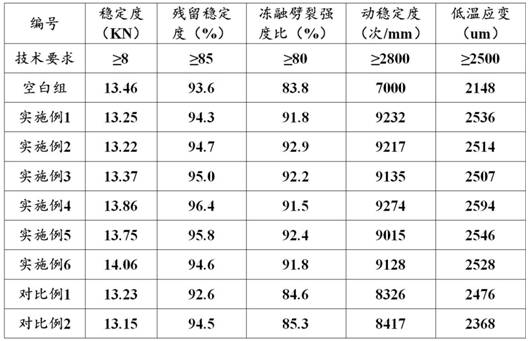

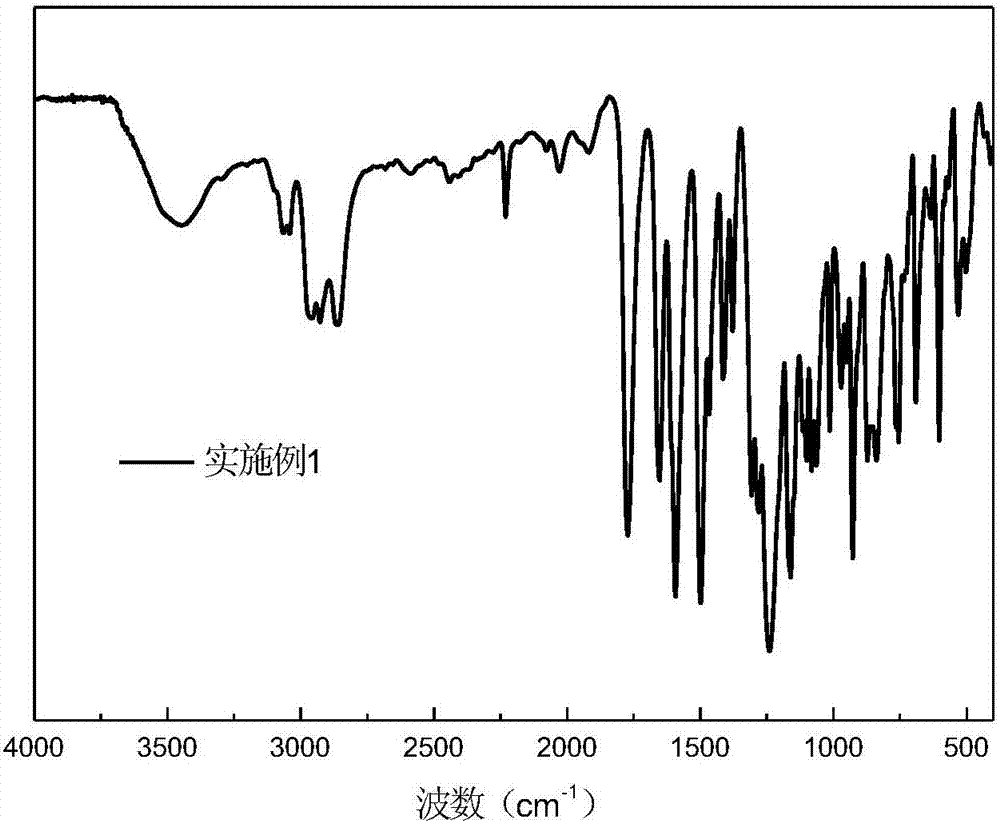

Chemically-modified hard asphalt and preparation method thereof

ActiveCN104559232AImprove low temperature performanceHigh viscosityBuilding insulationsCrack resistancePhosphoric acid

The invention discloses chemically-modified hard asphalt and a preparation method thereof. The chemically-modified hard asphalt comprises the following components in parts by weight: 100 parts of basic asphalt, 0.5-3.0 parts of polyphosphoric acid, 2-12 parts of ductility increasing agent mother liquor and 0.2-0.4 part of a surfactant. The preparation method comprises the following steps: adding polyphosphoric acid into the melted basic asphalt for chemically-modified reaction, then adding the ductility increasing agent mother liquor for further reaction, and finally adding the surfactant for further reaction for a period of time to prepare the chemically-modified hard asphalt. The whole process is implemented under a high-speed stirring condition. The chemically-modified hard asphalt prepared by the preparation method disclosed by the invention is high in flow resistance, high in softening point, high in low-temperature ductility, high in bonding property with aggregate, and excellent in high temperature stability, low temperature cracking resistance, fatigue resistance and water invasion resistance; the chemically-modified hard asphalt is particularly suitable for areas with high temperature, wet areas and areas with large diurnal temperature difference and can be used for paving a pavement of a traffic road, so that common pavement damage phenomena such pavement rutting, upheaval, fatigue cracking, low-temperature cracking and water invasion of the pavement are effectively prevented, and the service life of the pavement is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of aqueous fluorine-modified phosphorus-containing acrylate emulsion

InactiveCN103833888AWith fine grainFlash corrosion resistantFibre treatmentCoatingsEnvironmental resistanceFunctional monomer

The invention discloses a preparation method of an aqueous fluorine-modified phosphorus-containing acrylate emulsion. The preparation method comprises the steps of firstly preparing a pre-emulsion, then preparing a seed emulsion, and carrying out emulsion polymerization, so as to obtain the milky-white and slightly-blue aqueous fluorine-modified phosphorus-containing acrylate emulsion. According to the preparation method, a phosphate emulsifier is taken as an anionic emulsifier, meanwhile, phosphate is added as a functional monomer, phosphate groups are intruded into the emulsion, so that the emulsion has the characteristics of fine granularity and flash rusting resistance, and a coating has high adhesive force and certain salt water resistance; by adding a fluorine-containing modified monomer having good effects in the reduction of surface free energy and the improvement of surface dewatering and oleophobic performance, the water resistance of the coating of the emulsion is enhanced, and the pollution resistance of the coating of the emulsion is improved; meanwhile, the utilized fluorine-containing modified monomer is a fluorine-containing acrylic monomer, so that the problems of environment friendliness and biological harm of a long-fluorocarbon-chain compound are avoided, and the prepared emulsion is environmental friendly; the utilized nonionic emulsifier does not contain APEO (alkylphenol ethoxylate) and is environmental friendly.

Owner:西安佳龙油漆新技术发展有限公司

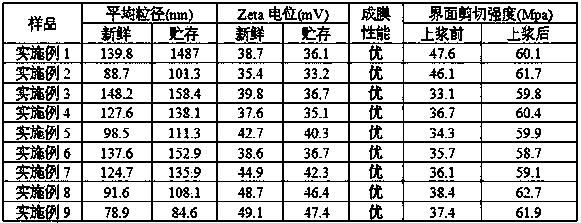

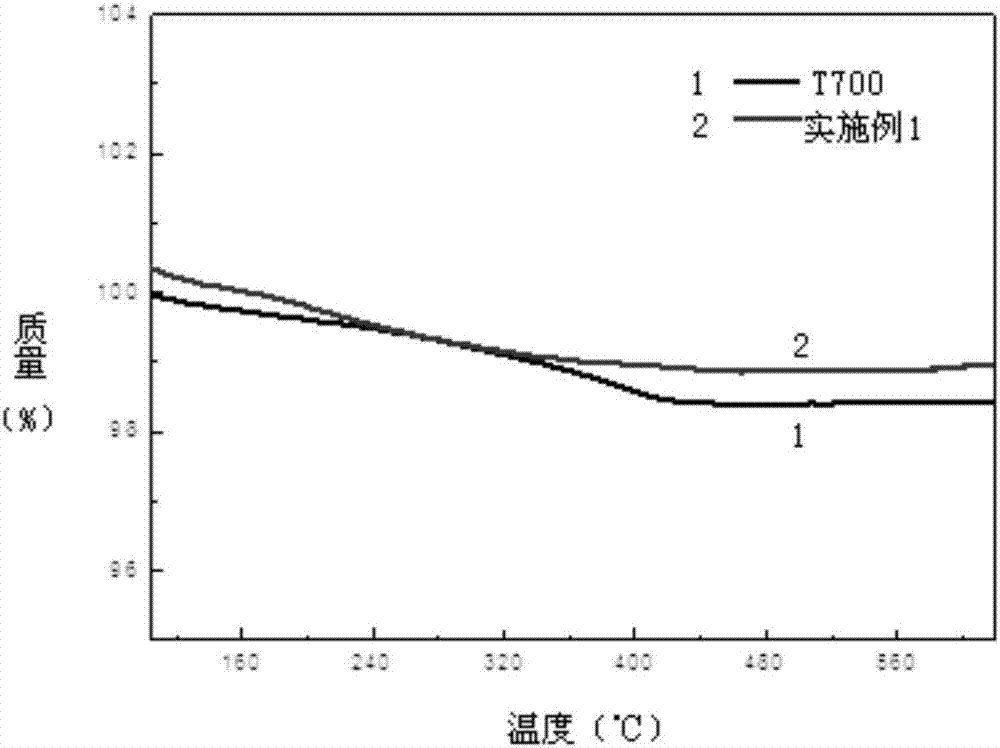

Polyetherimide aqueous emulsion type carbon fiber sizing agent as well as preparation method and application thereof

ActiveCN103757927ARealize the manufacturing processEase of industrial productionCarbon fibresPolyetherimideCarbon fibers

A polyetherimide aqueous emulsion type carbon fiber sizing agent contains the following components by weight percent: 20%-35% of main slurry, 2%-7% of an emulsifier, and 58%-78% of deionized water. The polyetherimide aqueous emulsion type carbon fiber sizing agent provided by the invention has the advantages of safety and non-pollution, and the interface bonding strength between carbon fiber and special engineering plastics can be improved.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

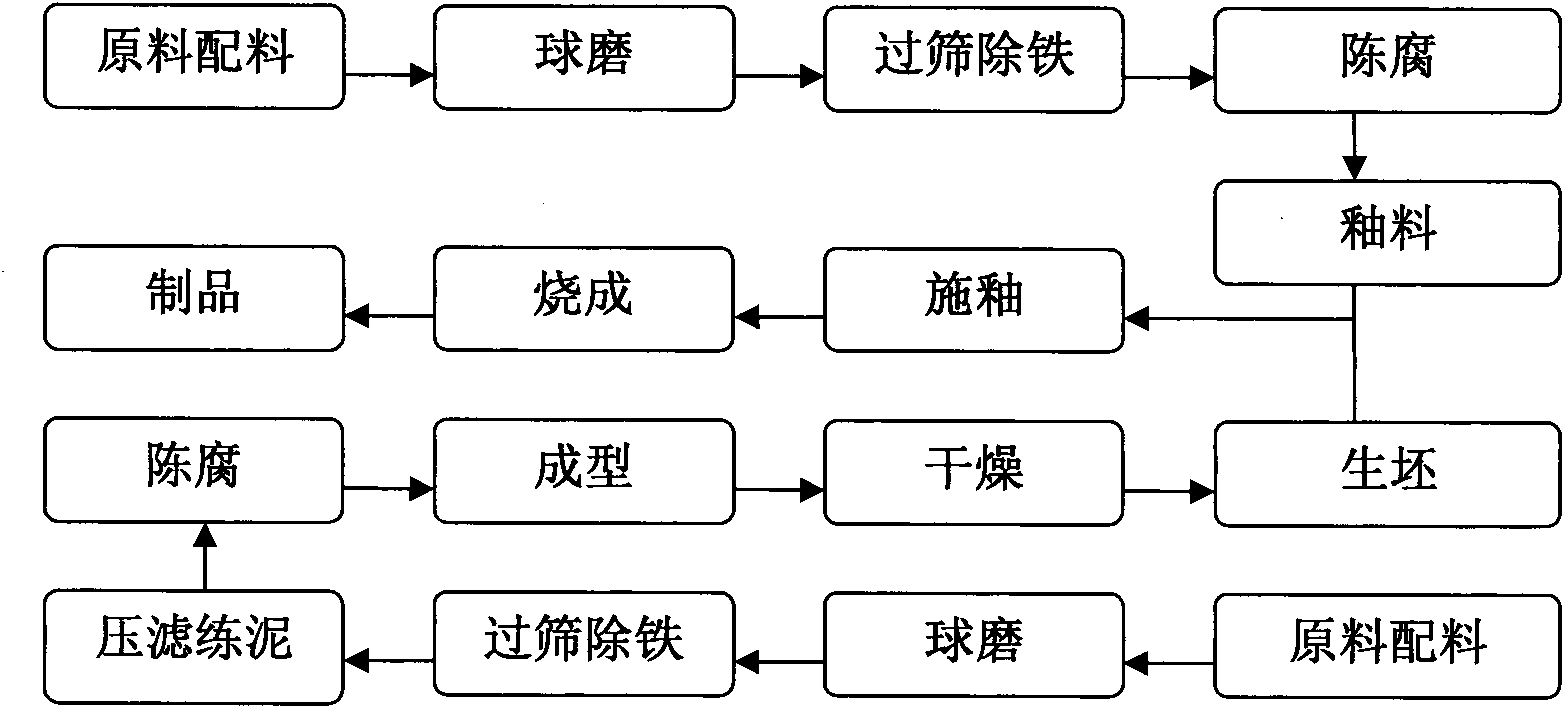

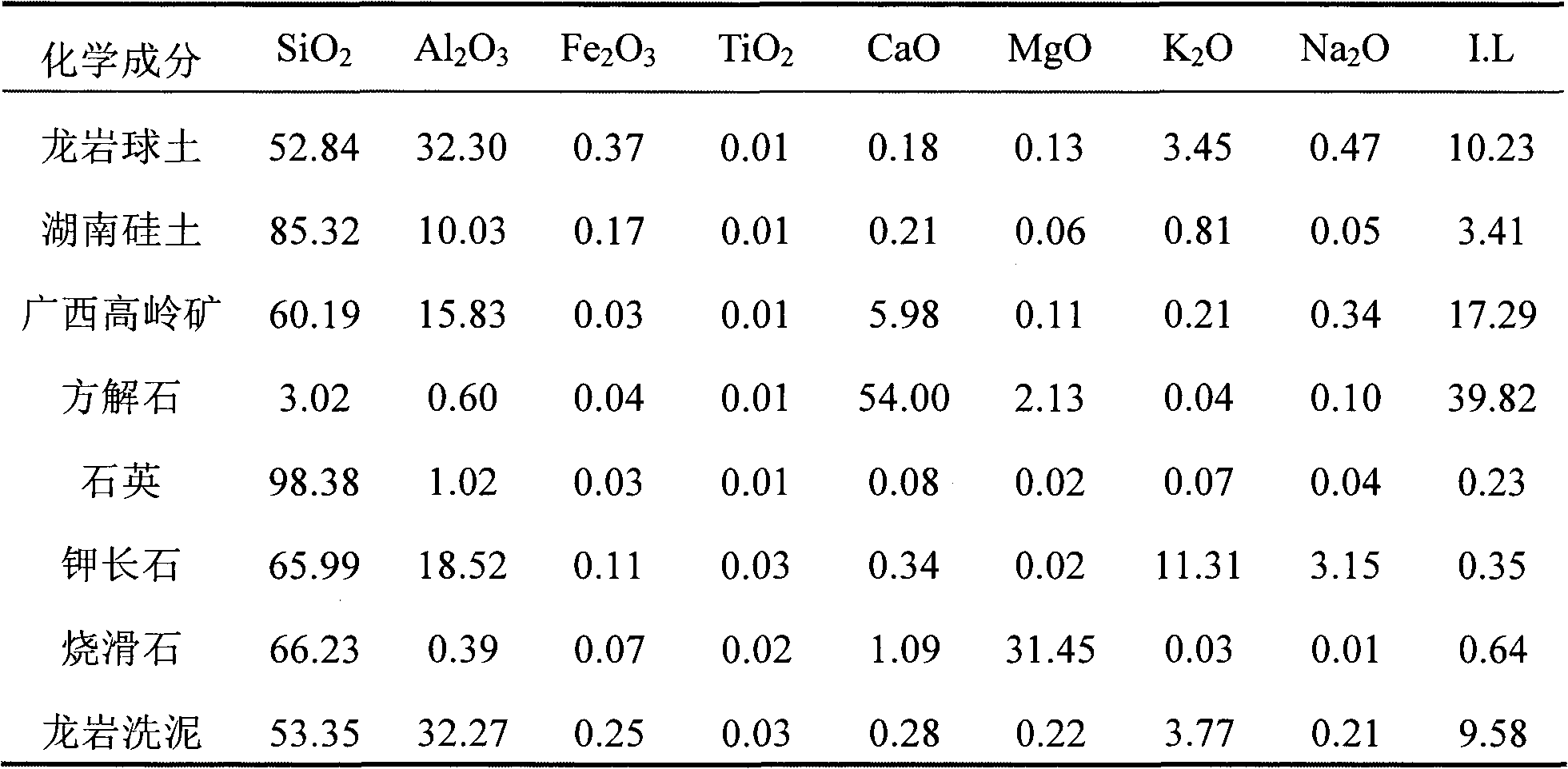

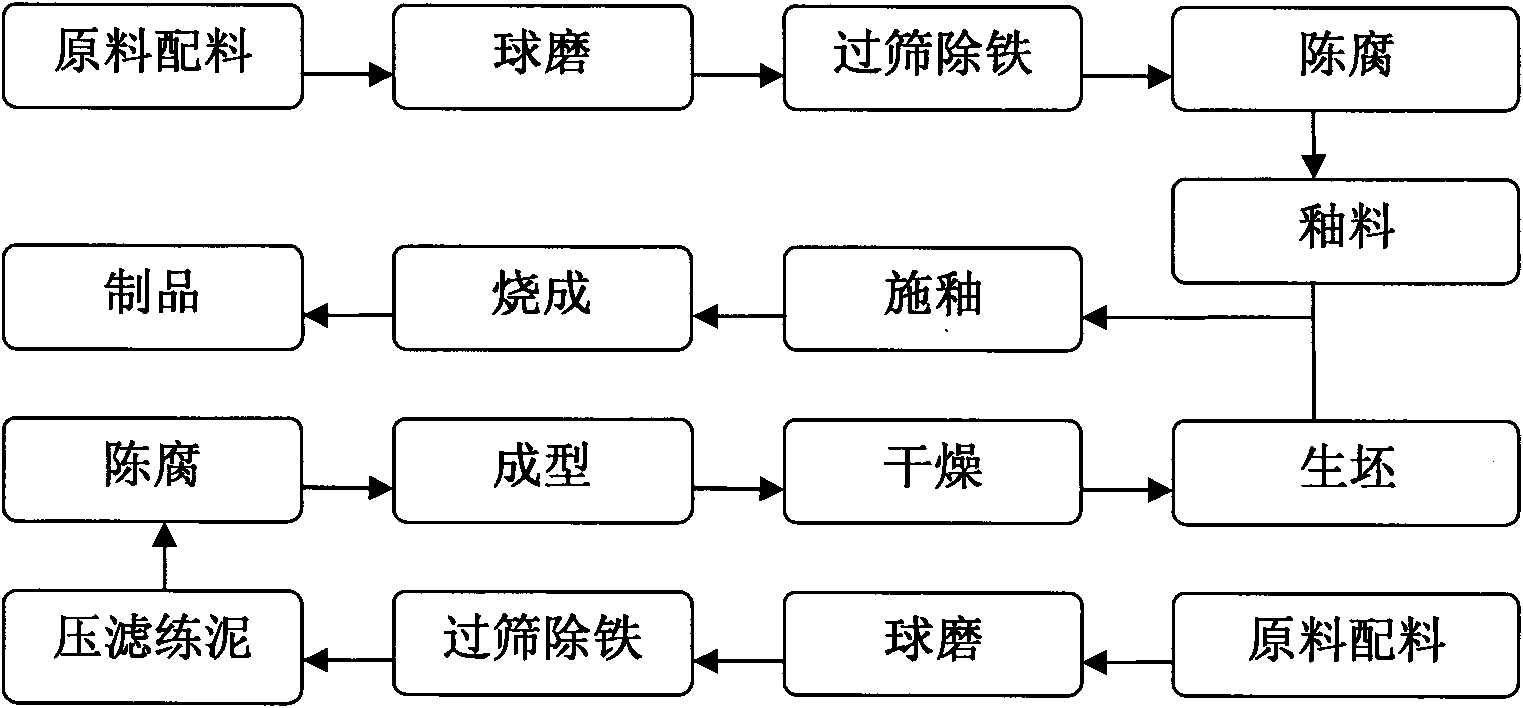

Preparation method of emerald ceramic

The invention discloses a preparation method of emerald ceramic, which comprises the steps of: (1) weighing raw materials according to a formula, mixing quartz, Guangxi Kaolinite and calcite for carrying wet-method ball-grinding, adding high-plasticity clay and low-plasticity clay for carrying out wet-method ball-grinding; (2) sieving and dewatering, ageing mud for 4-6 days, drying at a temperature of 80-110 DEG C after carrying out plastic forming; and (3) glazing, insulating the temperature at a temperature of 1240-1280 DEG C for 1-1.5h in an oxidizing atmosphere, and then cooling. The prepared emerald ceramic has the advantages of better permeability, light green color, emerald texture, high strength, good heat stability, lower production cost and better application value.

Owner:SOUTH CHINA UNIV OF TECH

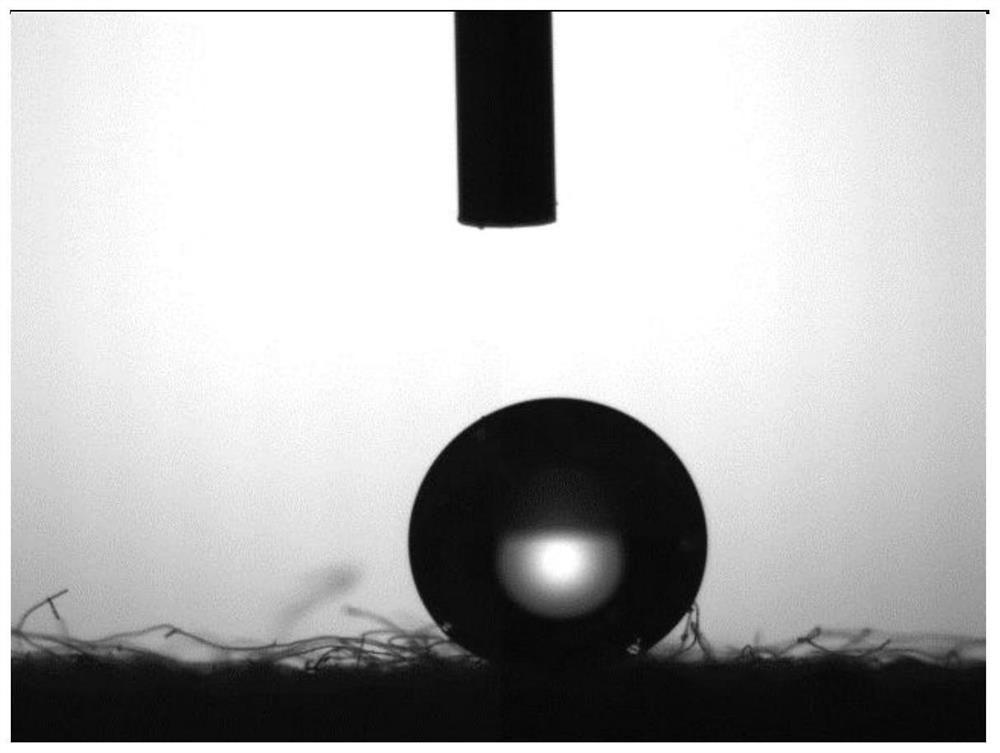

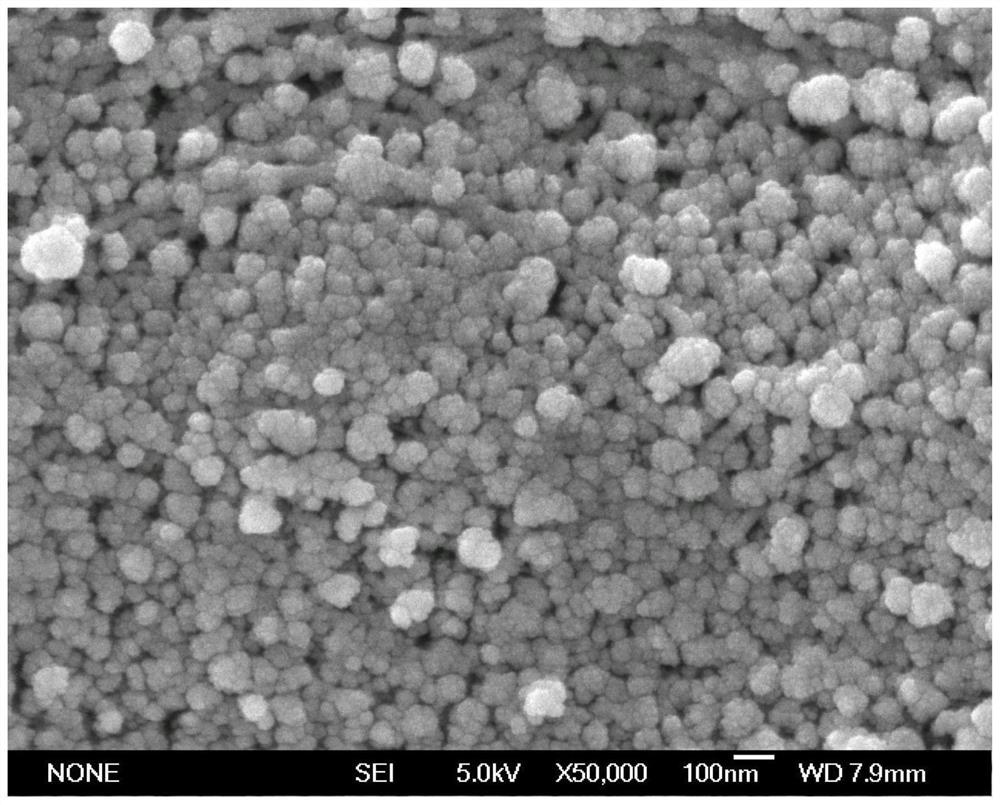

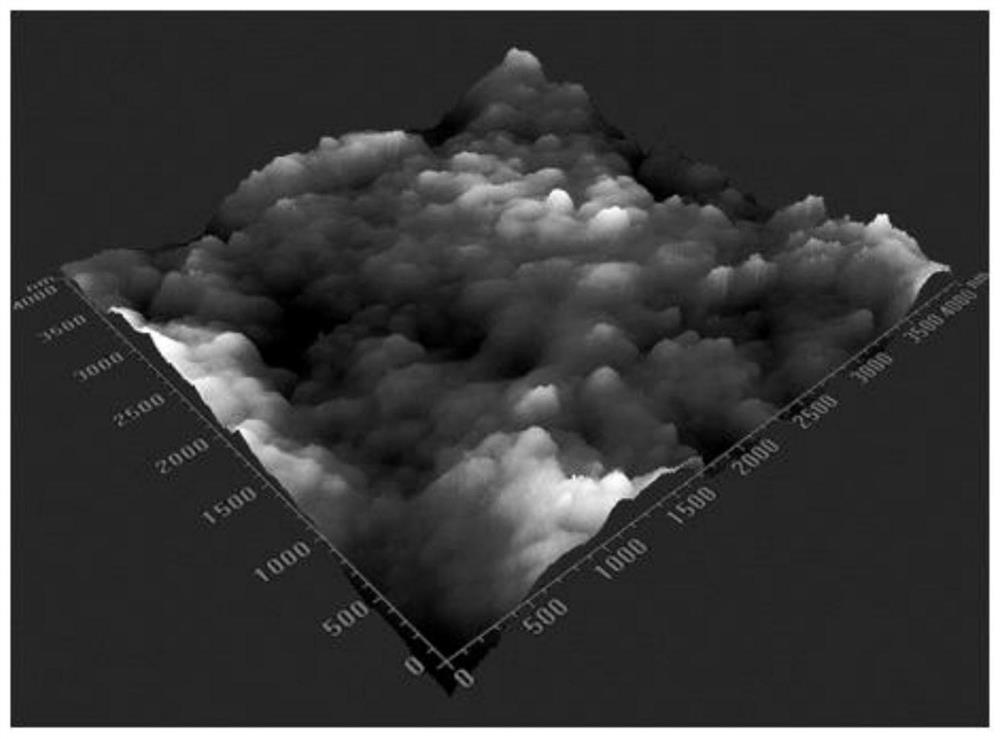

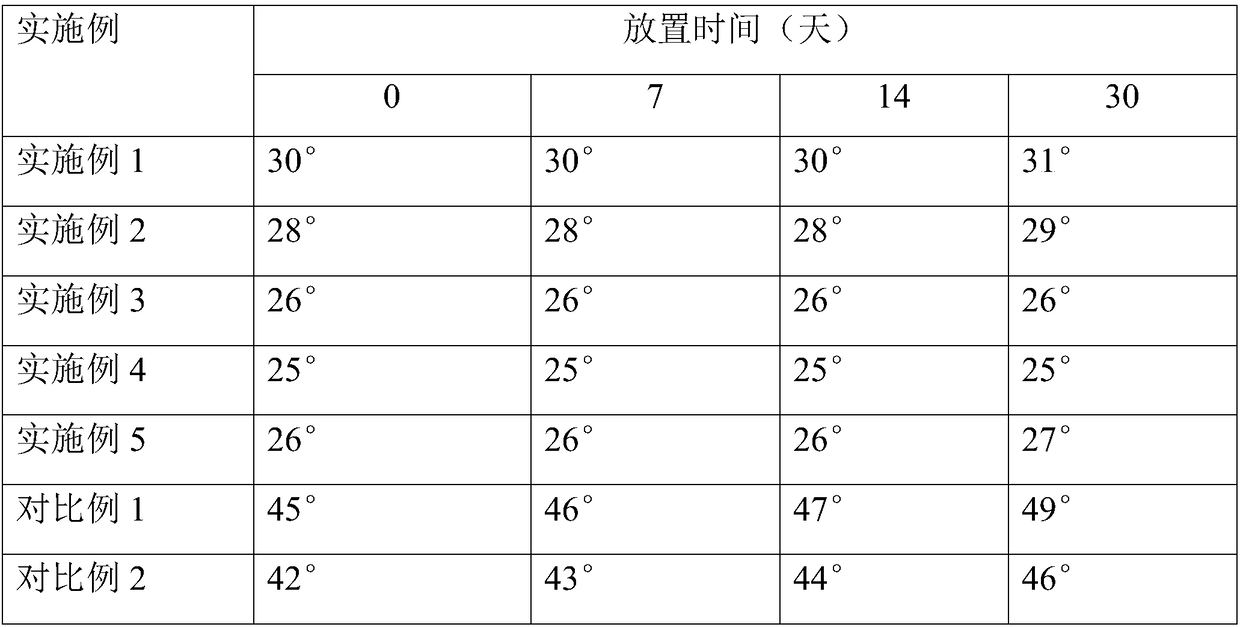

Super-hydrophobic material with hierarchical coarse structure and preparation method and application thereof

ActiveCN112647287AIncrease surface free energyStain/soil resistant fibresLiquid repellent fibresMicrospherePollution prevention

The invention relates to a super-hydrophobic material with a hierarchical coarse structure. The super-hydrophobic material is characterized in that metal oxide microspheres with a secondary coarse structure are arranged on the surface of a substrate material, and the outer surfaces of the microspheres are modified with a low-surface-energy substance layer. The invention further relates to a preparation method and application of the material. The super-hydrophobic material with the hierarchical coarse structure is simple in preparation process and good in material stability, and has excellent effects in the fields of self-cleaning, water prevention, pollution prevention, drag reduction, noise reduction, oil-water separation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method utilizing microwave technique to induce modified ardealite

The invention provides a method utilizing a microwave technique to induce modified ardealite. The method comprises the following steps of: ball-milling the ardealite to 160-200meshes; according to the mass ratio of the ardealite and an amorphous dielectric material being 1-2: 0.05-0.1, adding the amorphous dielectric material to be mixed; putting the mixture under the conditions of 2350MHz of microwave frequencies, 750-950W of power and 100-150 DEG C of temperature to carry out microwave processing for 10-15 minutes, and then naturally cooling to the room temperature; and finally obtaining microwave induced modified ardealite. According to the method, the surface free energy, the electric potential, the average pore size and the specific surface area of the ardealite can be significantly increased. The prepared microwave induced modified ardealite can be used for adsorption of heavy metal wastewater. The method has the advantages of simple operation, low cost and high efficiency, a lot of energy sources are saved, and the secondary pollution is avoided.

Owner:KUNMING UNIV OF SCI & TECH

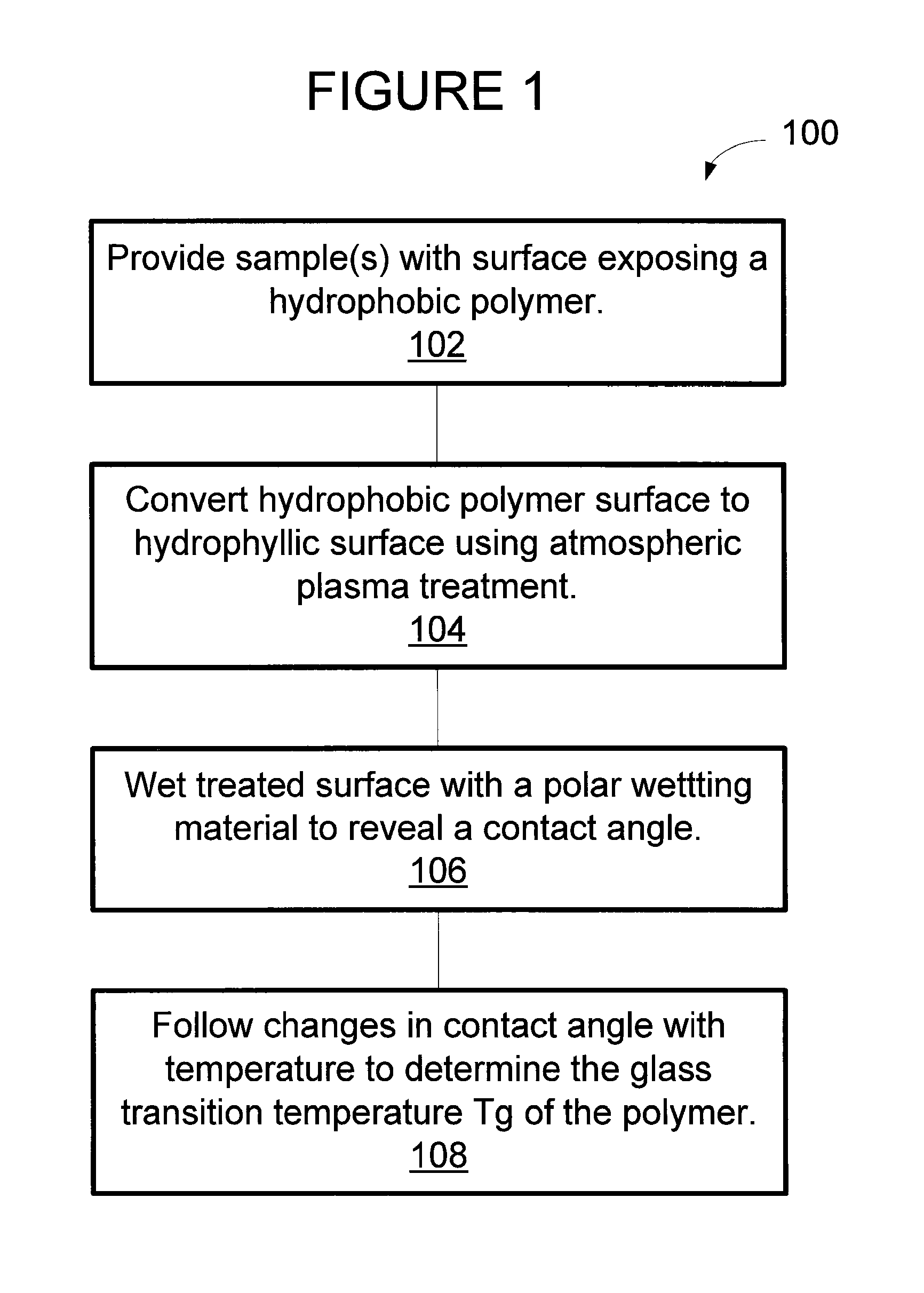

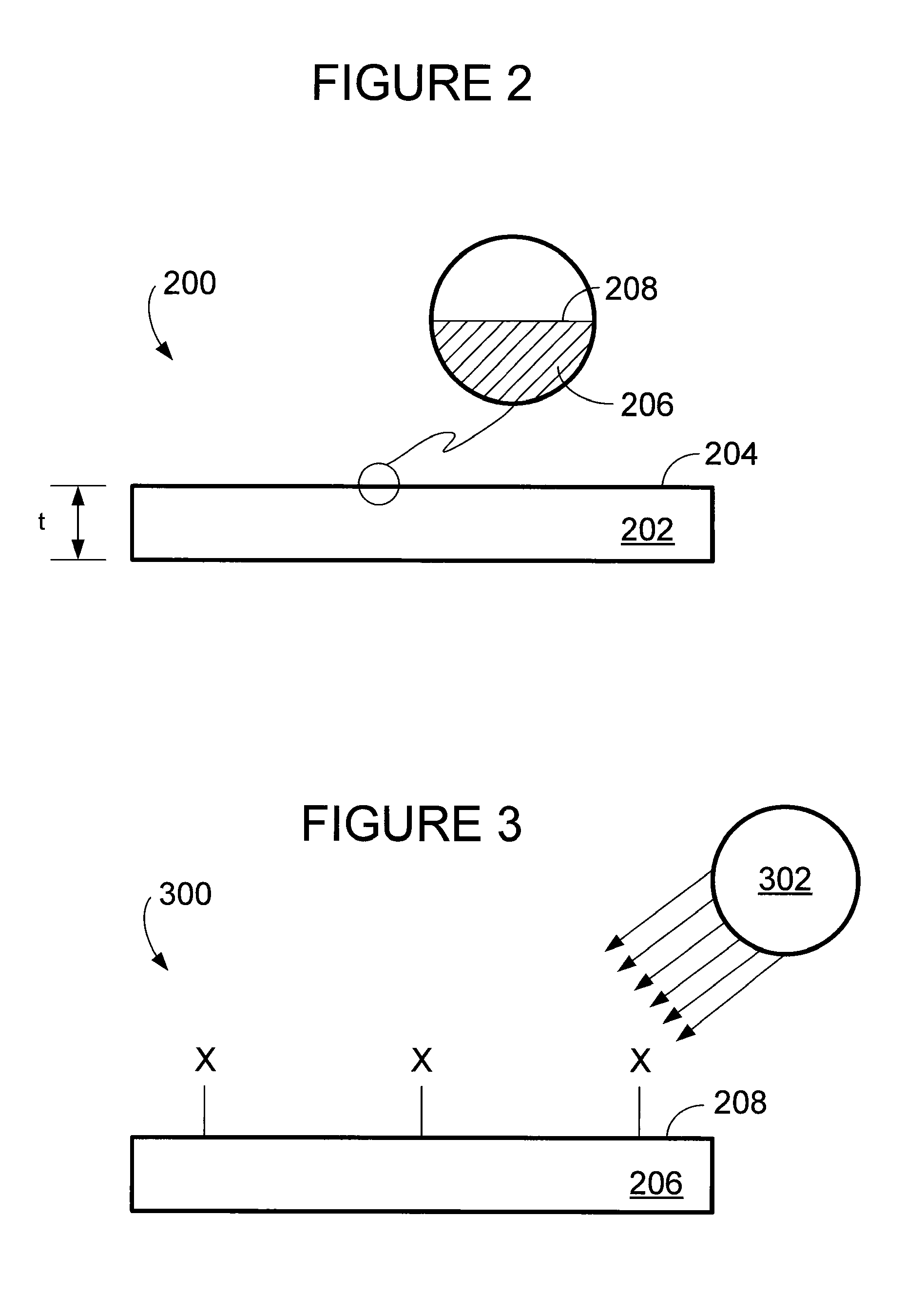

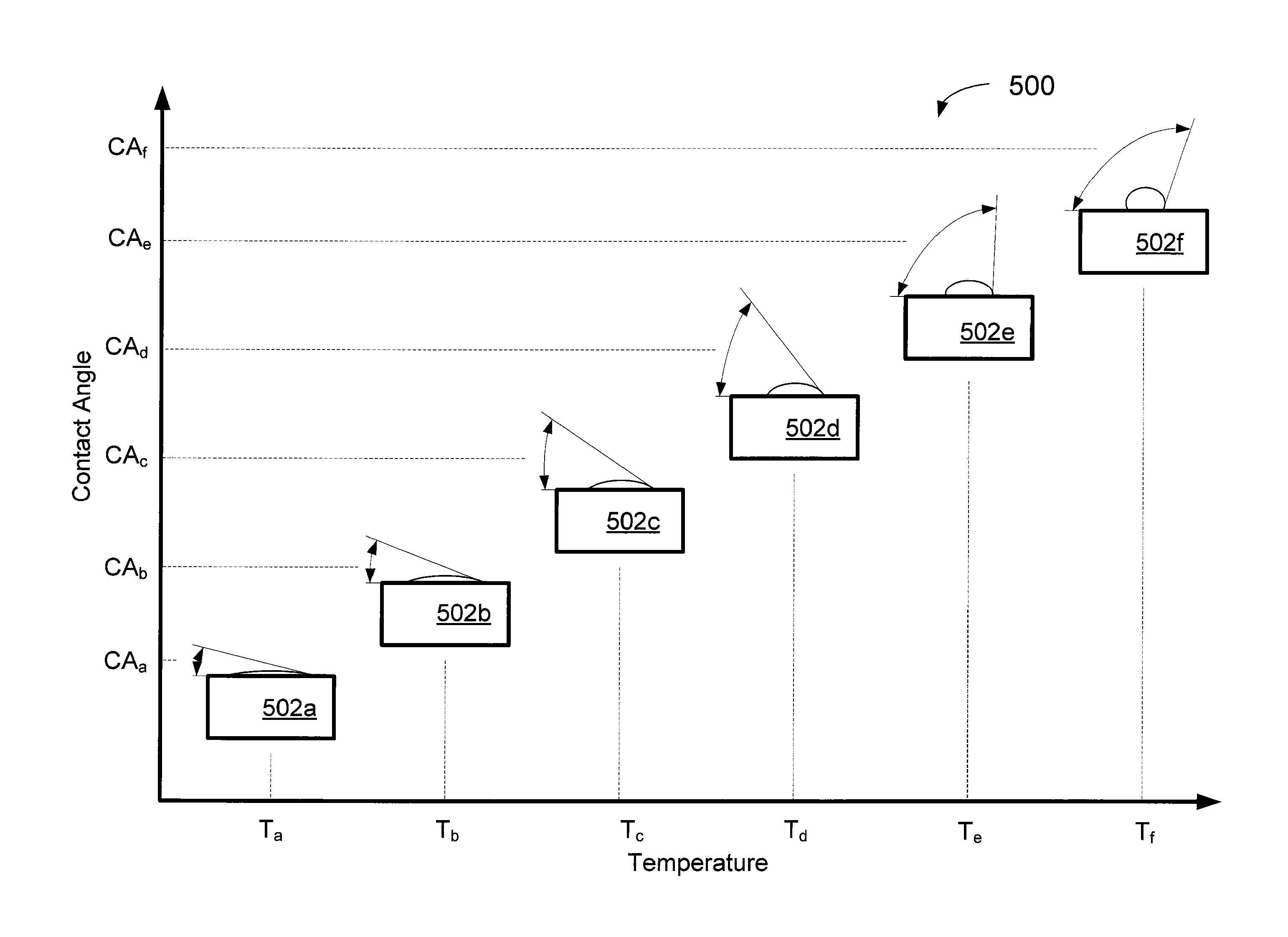

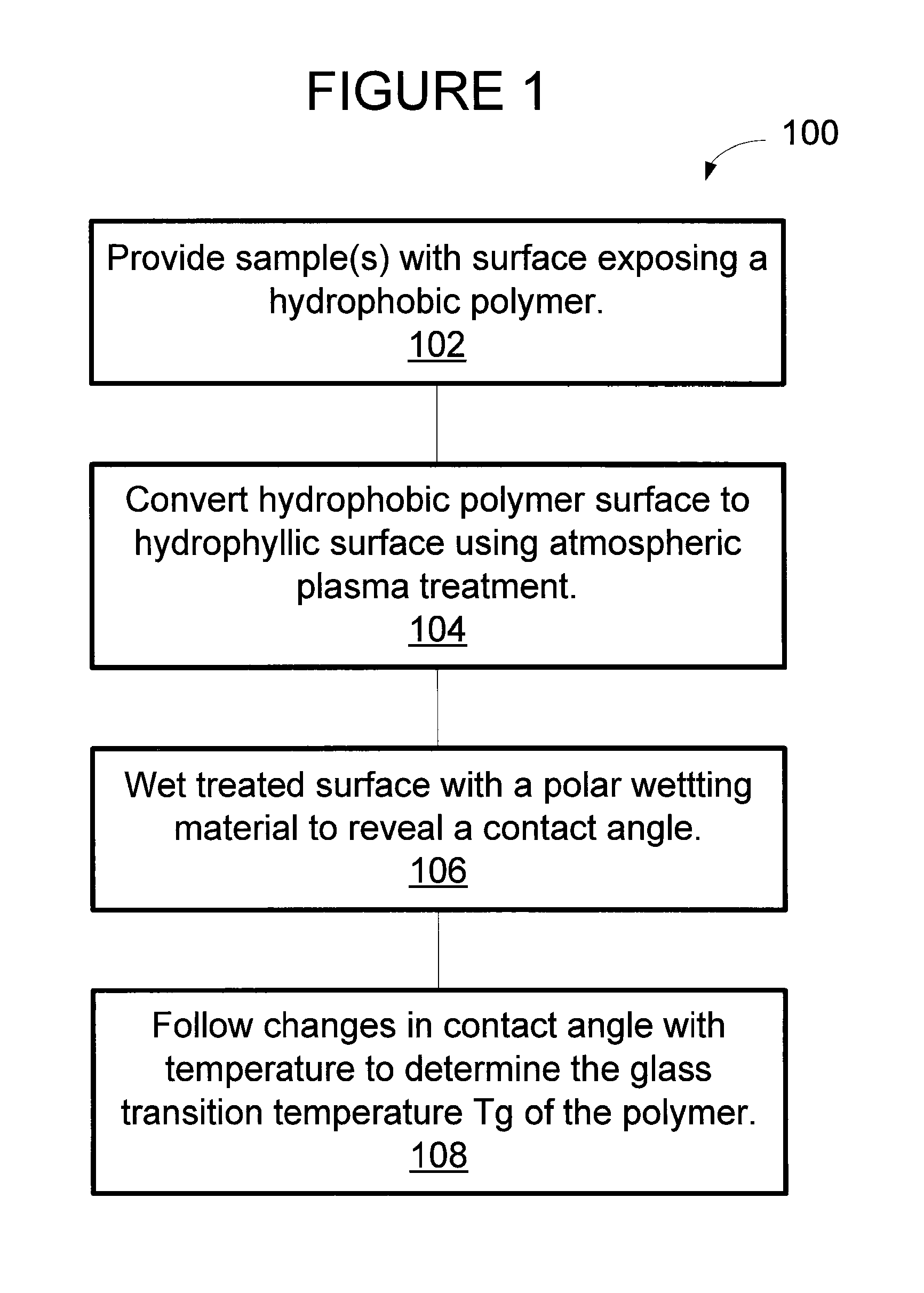

System and mehtod for measuring glass transition temperature

ActiveUS20120307860A1Improve wetting propertiesAccurate assessmentSurface/boundary effectInvestigating phase/state changeVitrificationHydrophobic polymer

A system and method for measuring a glass transition temperature of a hydrophobic polymer having a surface tagged with an atmospheric plasma.

Owner:THE AEROSPACE CORPORATION

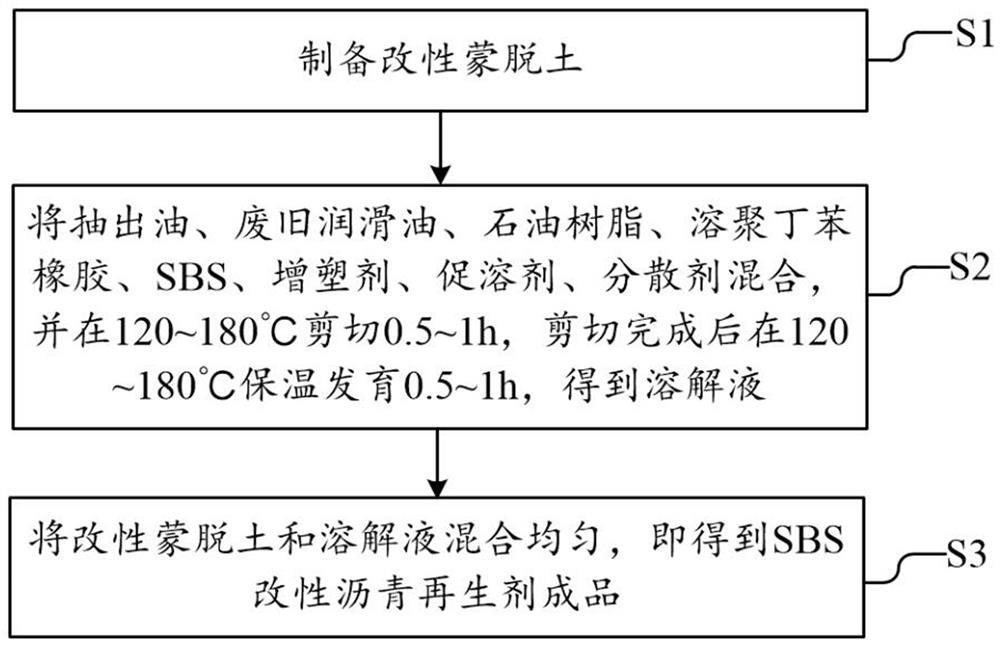

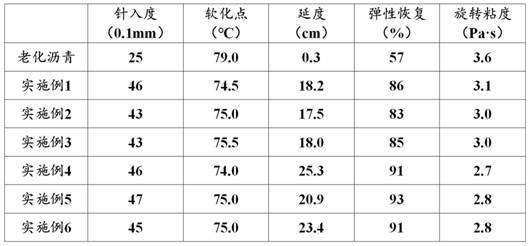

SBS modified asphalt regenerant and preparation method thereof

ActiveCN112094505AGood compatibilityStrong mutual solubilityBuilding insulationsPolymer sciencePlasticizer

The invention discloses an SBS modified asphalt regenerant and a preparation method thereof. The SBS modified asphalt regenerant comprises the following raw materials in parts by weight: 60-80 parts of extract oil, 10-20 parts of waste lubricating oil, 15-25 parts of petroleum resin, 2-10 parts of solution polymerized styrene-butadiene rubber, 3-10 parts of SBS, 5-10 parts of a plasticizer, 1-15 parts of a dissolution promoter, 0.5-3 part of a dispersing agent and 1-5 parts of modified montmorillonite. The modified montmorillonite is prepared by the following method comprising steps of uniformly mixing nano montmorillonite with an aqueous solution, carrying out low-temperature treatment at -30 to -10 DEG C, and then carrying out intercalation treatment by adopting an intercalating agent, so as to obtain the modified montmorillonite. By implementing the method, the high-temperature performance and the low-temperature performance of the old asphalt can be recovered simultaneously, and the cost of the regenerant is low.

Owner:FOSHAN TRANSPORTATION SCI & TECH CO LTD +2

System and method for measuring glass transition temperature

ActiveUS8858070B2Improve wetting propertiesAccurate assessmentInvestigating phase/state changeSurface tension analysisVitrificationHydrophobic polymer

Owner:THE AEROSPACE CORPORATION

Preparation method of shell and shell prepared by method

InactiveCN102076185ABeautiful appearanceImprove surface propertiesDecorative surface effectsVacuum evaporation coatingMetalInorganic sulfide

The invention provides a preparation method of a shell and the shell prepared by the method. The preparation method of the shell comprises the following steps: providing a plastic substrate which is prepared from polyphenylene sulfide; performing plasma surface treatment to the surface of the plastic substrate; and formed a non-conductive metal film on the treated surface of the plastic substrate. The shell contains the plastic substrate and the non-conductive metal film formed on the surface of the plastic substrate, wherein the plastic substrate prepared from polyphenylene sulfide and the adhesive strength of the non-conductive metal film on the surface of the plastic substrate is above 3B.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Emulsion type thermoplastic sizing agent for carbon fiber and preparation method of sizing agent

ActiveCN107385918AIncrease surface free energyStable storageCarbon fibresPhenolphthaleinCarbon fibers

The invention firstly provides an emulsion type thermoplastic sizing agent for carbon fiber and a preparation method of the sizing agent and belongs to the technical field of carbon fiber sizing agents. The sizing agent is prepared from components in percentage by mass as follows: 0.1%-2% of thermoplastic resin, 0.05%-2% of an emulsifier, 0.05%-1% of a coupling agent, 0.4%-8% of an organic solvent and 87.0%-99.4% of deionized water, wherein the thermoplastic resin is polyarylether resin adopting a phenolphthalein structure. The invention further provides the preparation method of the emulsion type thermoplastic sizing agent for the carbon fiber. The emulsion type thermoplastic sizing agent is mainly prepared from the polyarylether resin adopting the phenolphthalein structure and having higher temperature tolerance, the sized carbon fiber can be composited with thermoplastic resin with higher thermal resistance for preparation of a composite, an emulsion is stored stably and dispersed uniformly, and the interface shearing strength of the carbon fiber and the thermoplastic resin is remarkably improved.

Owner:芜湖万隆新材料有限公司

Polytetrafluoroethylene grafted membrane and preparation method thereof

ActiveCN109161046AImprove surface activityIncrease surface free energyPolymer sciencePolytetrafluoroethylene

The invention discloses a polytetrafluoroethylene grafted membrane and a preparation method thereof. The preparation method comprises the following steps: (1) performing plasma treatment on a polytetrafluoroethylene thin film; (2) under the protection of nitrogen, putting the polytetrafluoroethylene thin film subjected to plasma treatment into mixed liquid composed of anhydrous tetrahydrofuran, N-(benzocyclobutene-4-radical) maleimide and acrylic acid, and generating reaction under ultraviolet irradiation, thus obtaining the polytetrafluoroethylene grafted membrane. According to the polytetrafluoroethylene grafted membrane disclosed by the invention, surface grafting is realized by adopting an ultraviolet initiation mode, so that the step of introducing peroxy radicals is omitted; furthermore, the N-(benzocyclobutene-4-radical) maleimide is a light initiator and a polymerization monomer, so no extra light initiator is needed, and the reaction system is simpler and the post-treatment steps are simpler and more convenient; the surface of the polytetrafluoroethylene thin film is grafted to form a three-dimensional meshed high polymer, so that the surface activity of the polytetrafluoroethylene thin film is further improved, and the surface free energy of the polytetrafluoroethylene thin film is enhanced.

Owner:ZHEJIANG DEQING CONCEPTFE PLASTIC PROD

Metal organic framework material HKUST-1 and preparation method thereof

ActiveCN107793309AGood dispersionIncrease surface free energyOrganic compound preparationCarboxylic acid salt preparationMetal-organic frameworkSlurry

The invention discloses a metal organic framework material HKUST-1 and a preparation method thereof. The preparation method comprises: (1) adding HKUST-1 crystal seed to a first solvent, and performing first ultrasonic treatment to obtain a crystal seed-containing mixed slurry A; (2) adding trimesic acid and a copper salt to a second solvent, and dissolving to obtain a solution B; and (3) mixing the solution B and the mixed slurry A, carrying out a synthesis reaction under heating reflux and stirring, filtering after the synthesis reaction, washing, and drying to obtain the metal organic framework material HKUST-1. According to the present invention, with the method, the crystallization reaction can be accelerated, the crystal nucleus growth period of the product is shortened, the relativecrystallinity of the product can be improved, the generation of the miscellaneous crystals can be reduced, the yield of the metal organic framework material HKUST-1 can be substantially improved, andthe production cost of the product can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

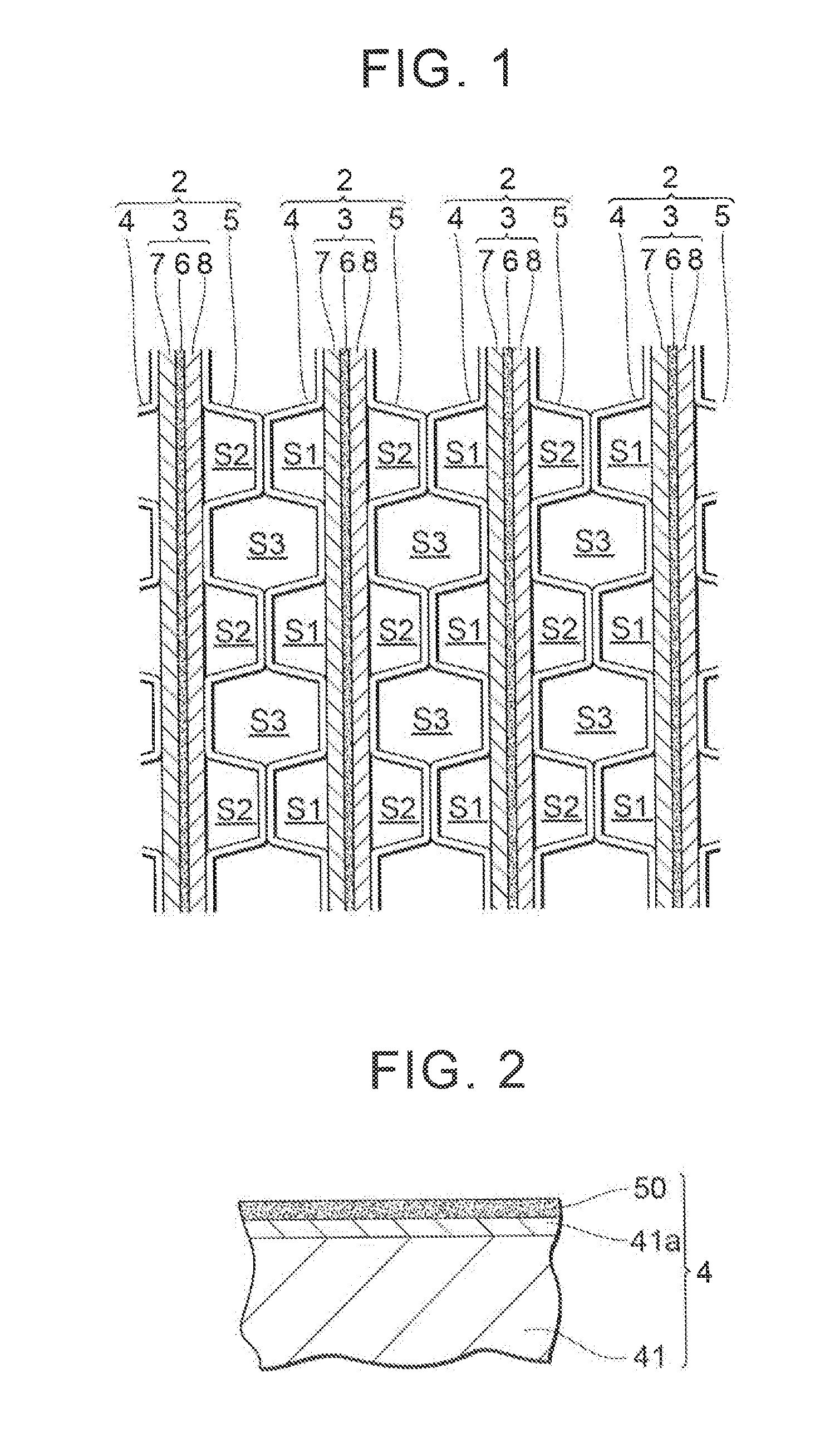

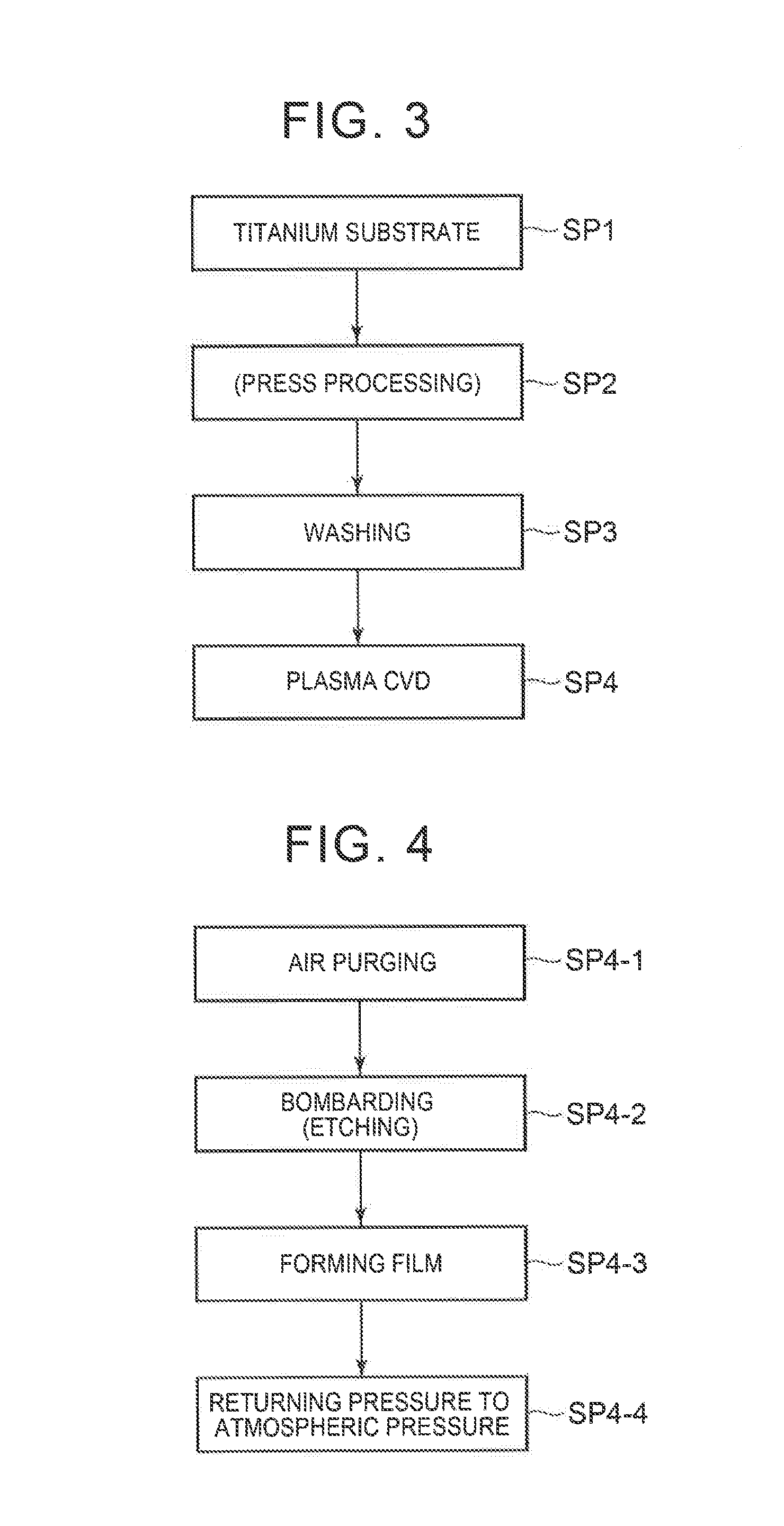

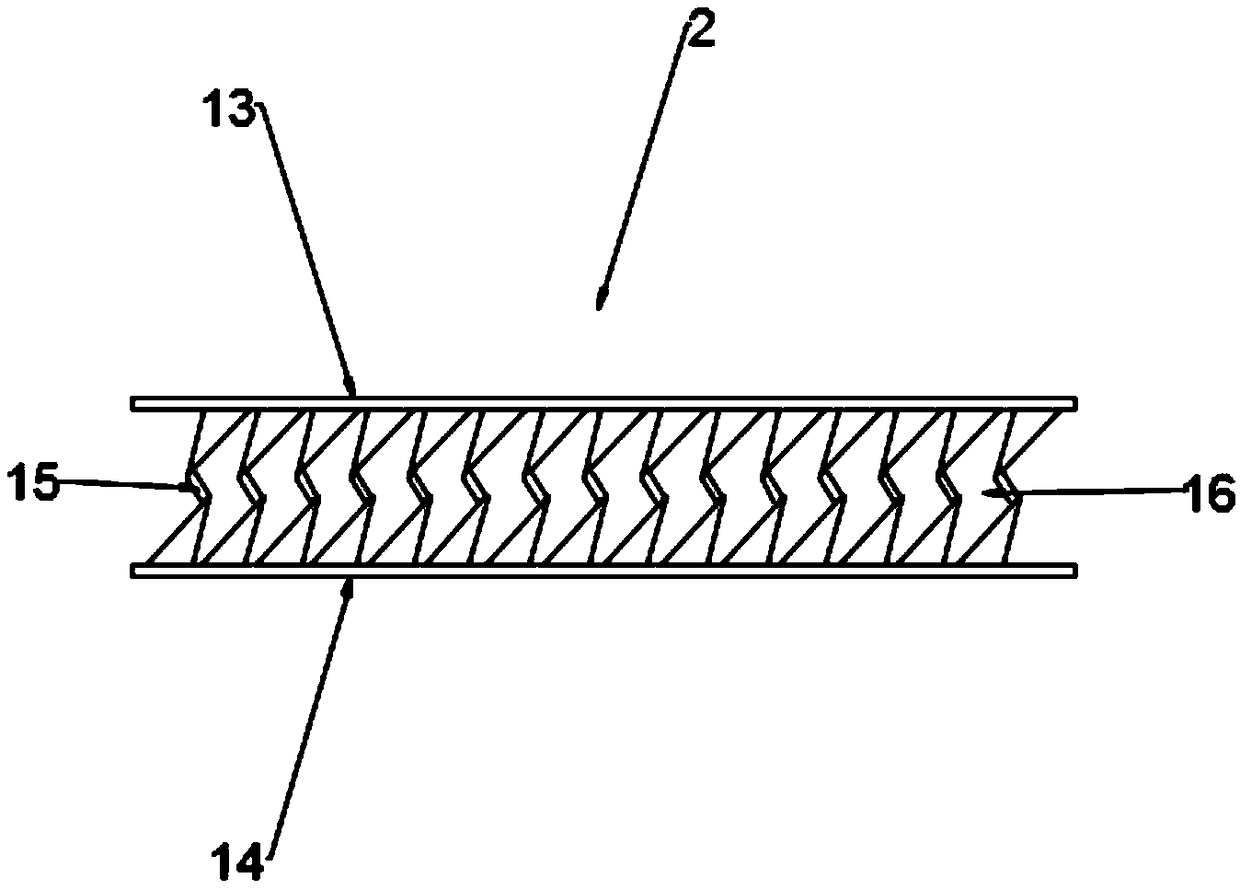

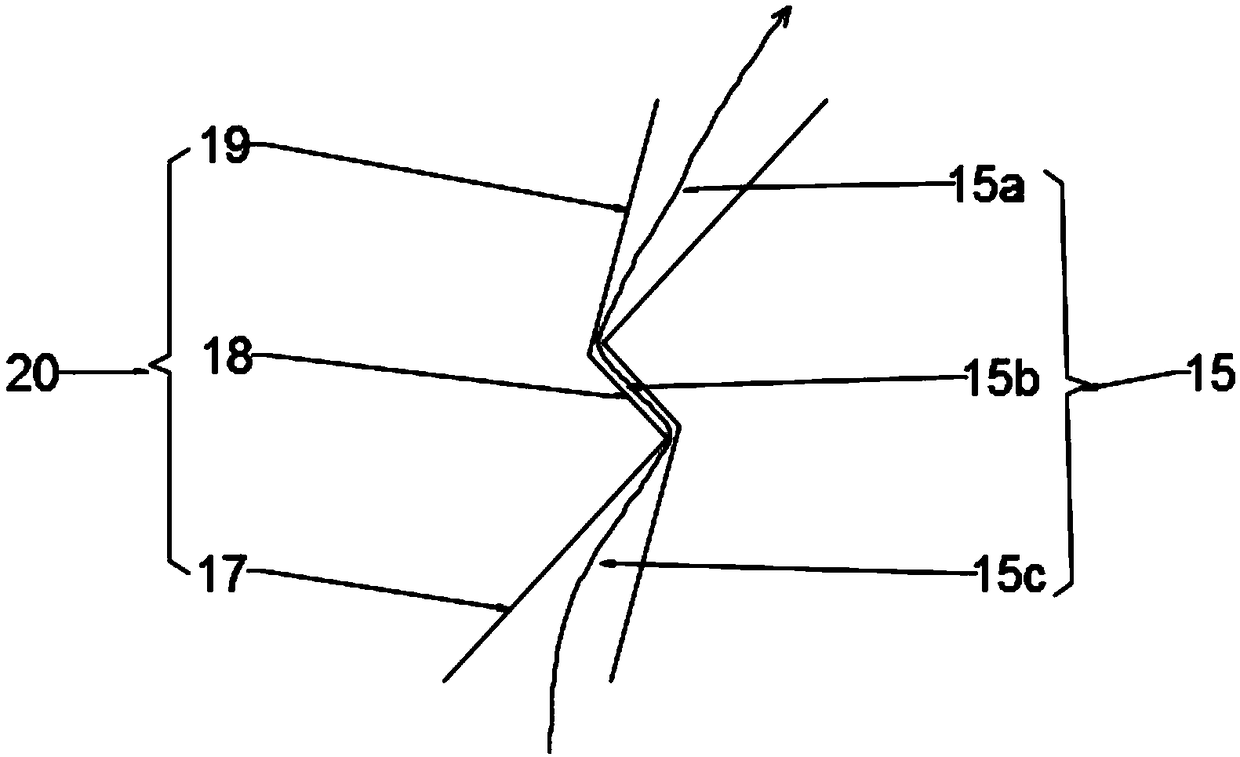

Manufacturing method of separator for fuel cell

ActiveUS20160087287A1Reduce manufacturing costReduce manufacturing stepsRadiation applicationsFinal product manufactureFuel cellsTitanium

Owner:TOYOTA JIDOSHA KK

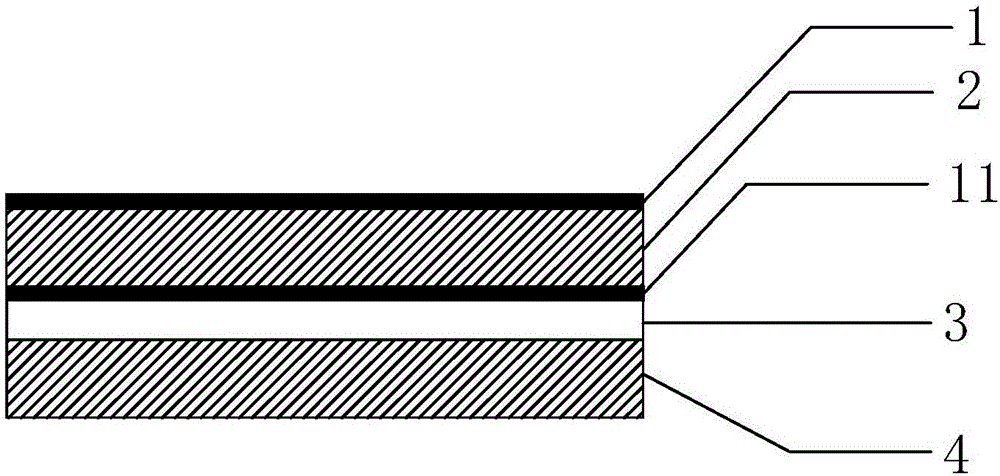

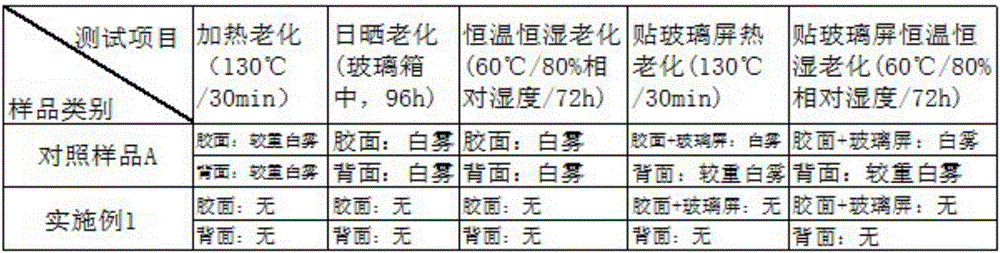

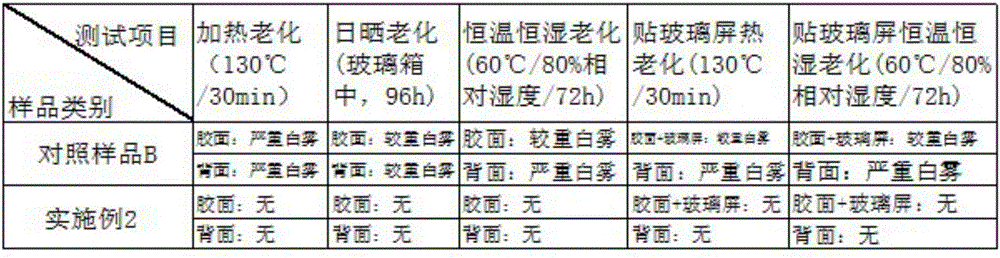

Polyester-based protective film for preventing oligomer preparation and manufacturing method thereof

InactiveCN106366962AImprove cleanlinessGuaranteed Optical PerformanceFilm/foil adhesivesCoatingsPolyesterOligomer

The invention relates to a polyester-based protective film for preventing oligomer preparation and a manufacturing method thereof. The polyester-based protective film comprises a multi-layer composite polyester-based base material and a pressure-sensitive adhesive coating coated on the surface of the composite base material; a crosslinking polyacrylate sealing agent upper surface layer and a crosslinking polyacrylate sealing agent lower surface layer are coated on the upper surface and the lower surface of the multi-layer composite polyester-based base material respectively. The manufacturing method includes the following steps that 1, a crosslinking polyacrylate sealing agent is synthesized; 2, the multi-layer composite polyester-based base material is prepared; 3, the polyester-based protective film for preventing oligomer preparation is prepared. The fogging problem caused by oligomer emigration in the polyester-based base material in the storage, processing and using processes of a conventional protective film is solved, when long-term exposure to sunlight, constant-temperature constant-humidity artificial aging and heating ageing are carried out on the polyester-based protective film for preventing oligomer preparation, the fogging phenomenon on the film face due to oligomer emigration is avoided, and use requirement of high-end glass films is ensured.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

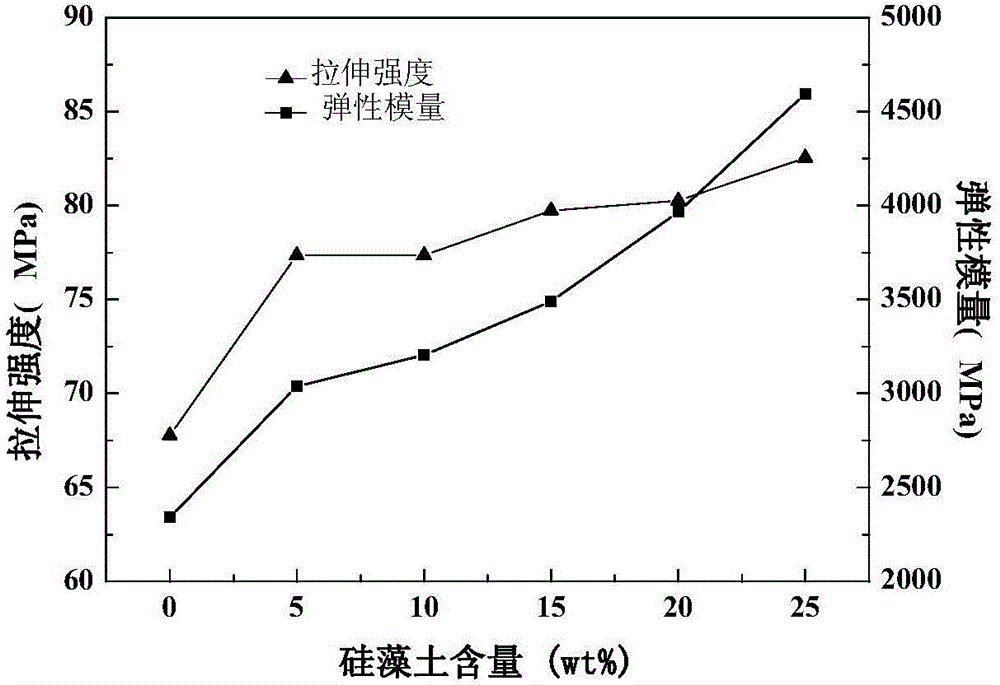

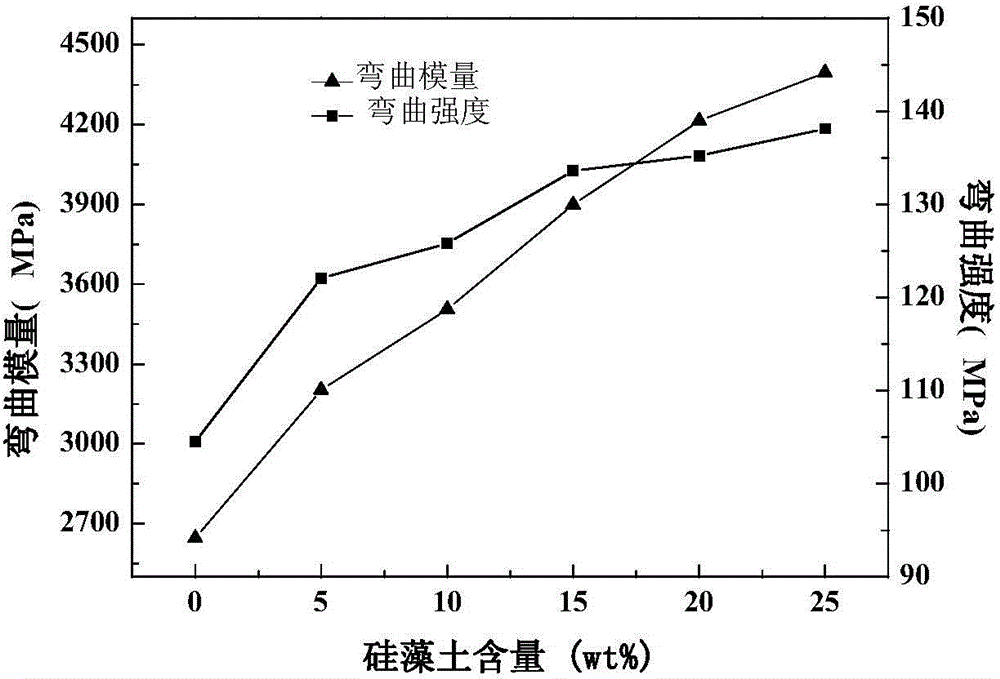

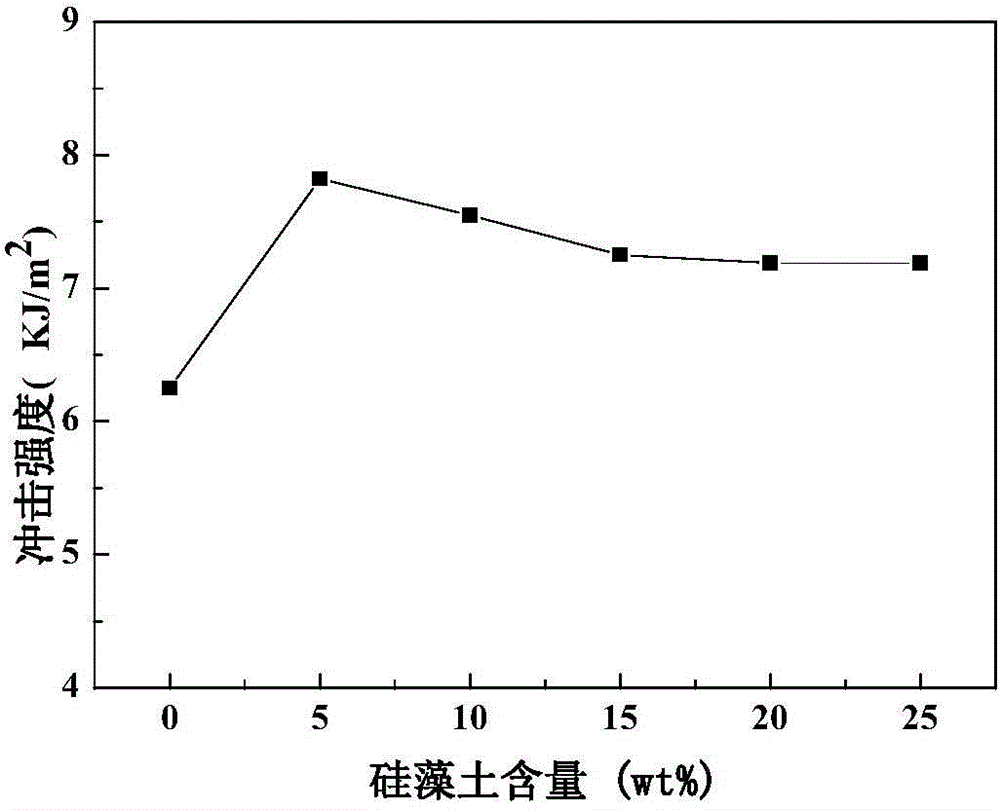

Diatomite/nylon-6 composite material and preparation method thereof

The invention discloses a diatomite / nylon-6 composite material and a preparation method thereof, and belongs to the field of plastic filling modification. The composite material is composed of 70 to 95% of nylon-6 and 5 to 30% of diatomite; wherein the particle size of diatomite is 5 to 40 [mu]m, and the diatomite is processed by a surfactant. The preparation method comprises the following steps: drying diatomite, processing the dried diatomite by a surfactant through a dry-process technology, wherein the surfactant accounts for 0.2 to 1 wt% of the weight of diatomite; pre-mixing nylon-6 and processed diatomite according to a certain formula, adding the premix into a double screw extruder, mixing, cooling by water, and granulating to obtain the composite material. The nylon-6 is modified by filling diatomite, the strength, modulus, toughness, and thermal deformation temperature of nylon-6 are all enhanced, the cost is reduced, the using amount of nylon-6 is reduced, the energy is saved, and the environment is protected. Moreover, the application range of diatomite is enlarged, and the utilization value of diatomite is increased.

Owner:BEIJING UNIV OF CHEM TECH +1

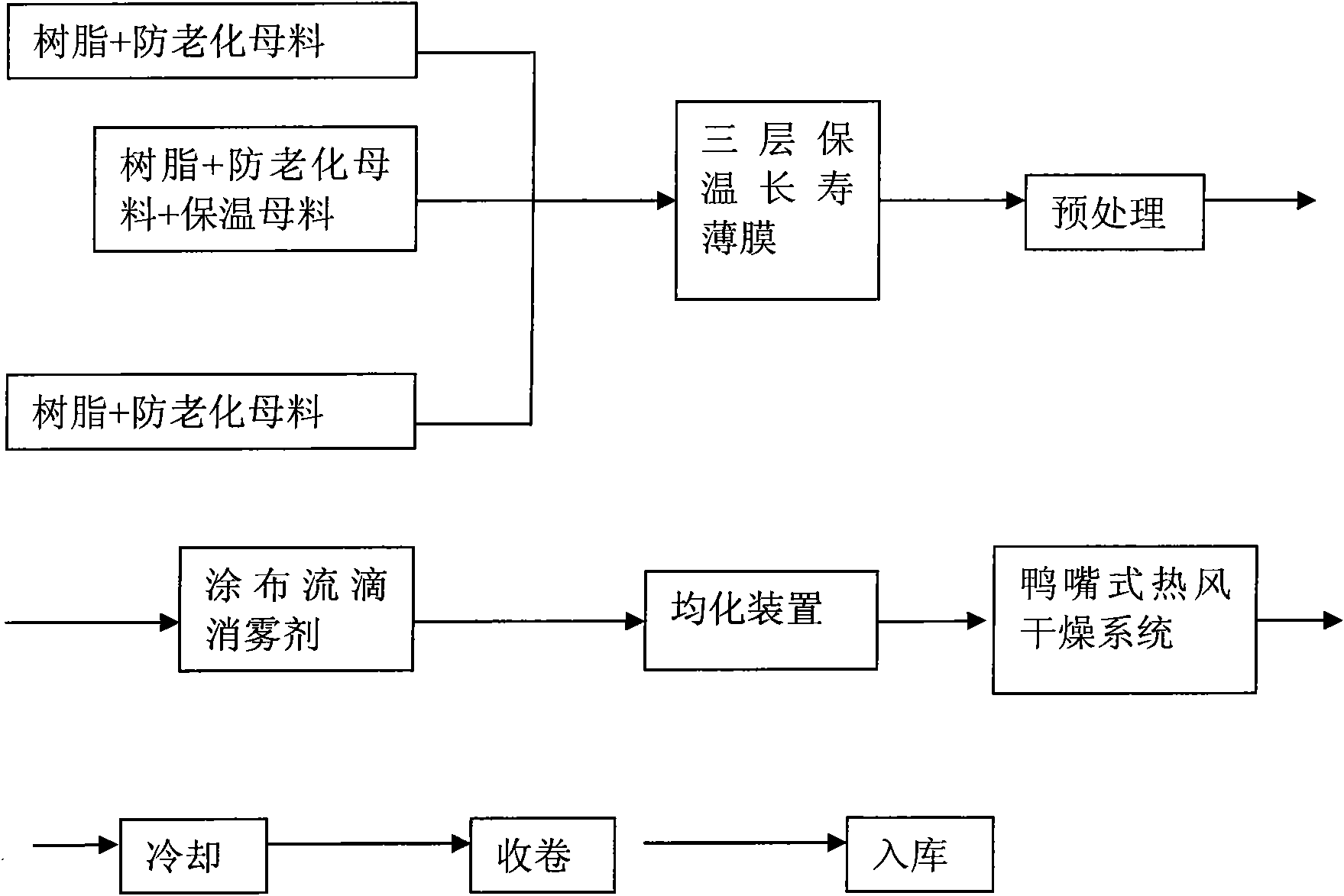

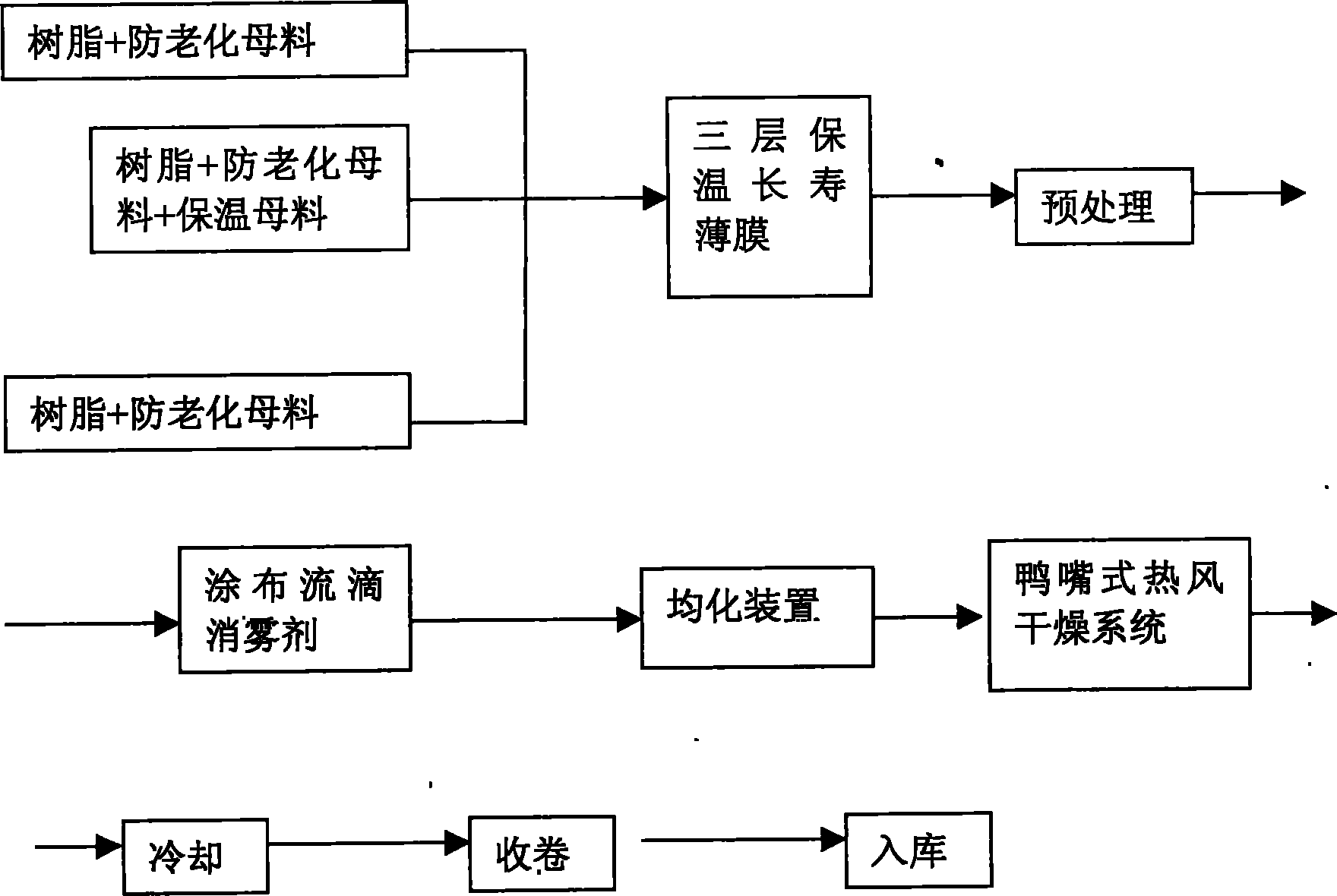

Long-acting dripping fog-dissipating aging-resistant agricultural film

ActiveCN102653140AStrong adhesionIdeal scratch resistanceFlat articlesCoatingsContinuous useAntioxidant

A long-acting dripping fog-dissipating heat-insulating aging-resistant agricultural film produced by externally-coated inorganic nanometer water-soluble dripping fog-dissipating liquid through a one-step method has a continuous service life of 2-5 years. The production process of the film comprises the following steps: well mixing resins, a light stabilizer, and an antioxidant, preparing an aging-resistant master batch by a twin-screw extruder; well mixing the resins and a heat-insulating agent, preparing a heat-insulating master batch by a internal mixer and a single-screw extruder; well mixing the resins, the aging-resistant master batch, and the heat-insulating master batch, blowing to prepare a cylindrical film; clamping the film by an upper drawing roller to obtain a flat film, performing surface treatment of the film by a corona treatment machine, coating the dripping fog-dissipating liquid on the film in a liquid-coating device, performing homogenization and drying, rolling to prepare the long-acting dripping fog-dissipating heat-insulating aging-resistant film.

Owner:华盾雪花塑料(固安)有限责任公司

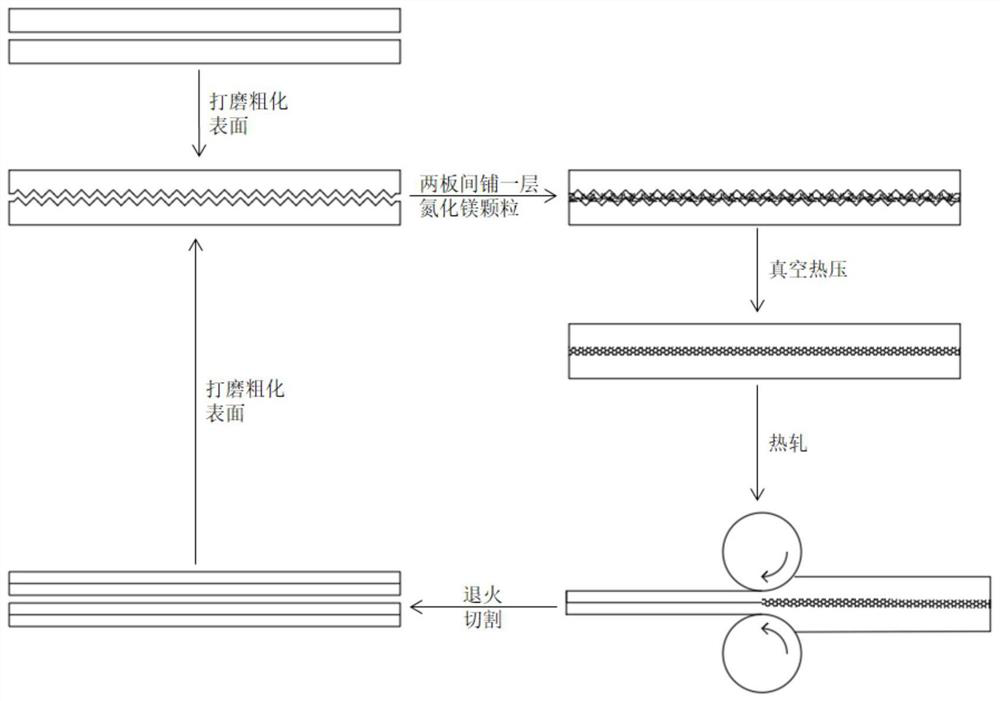

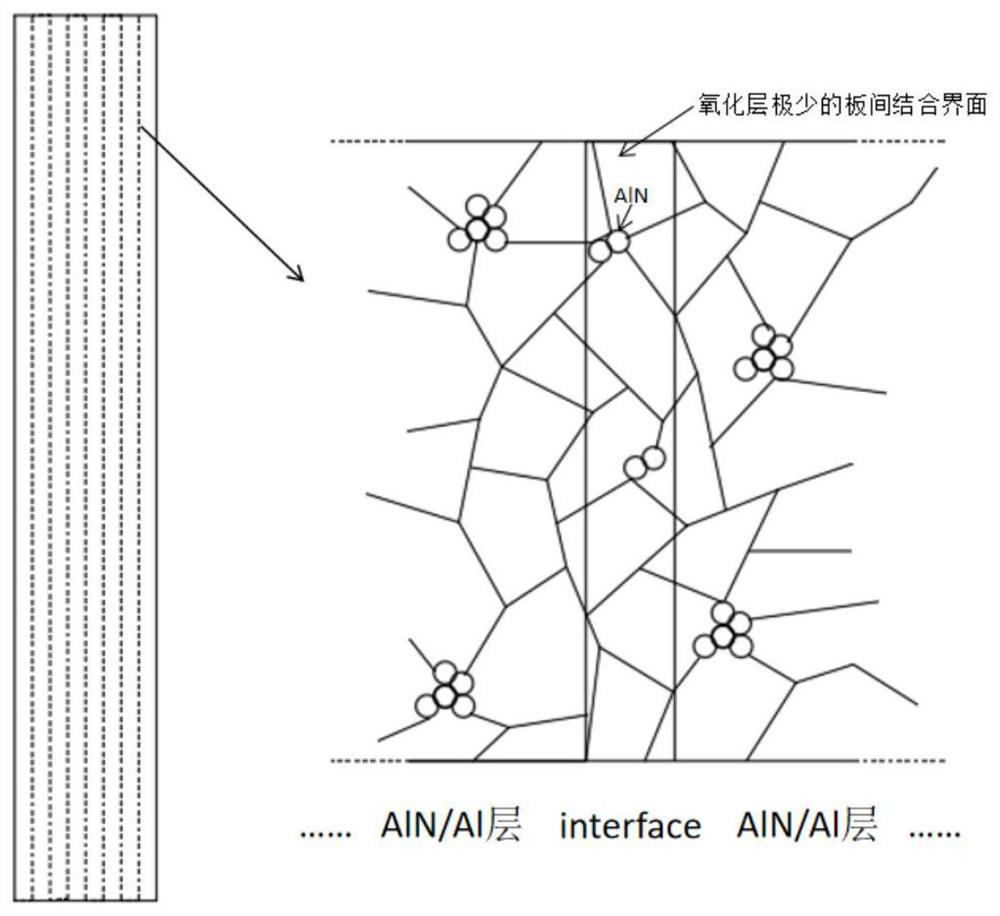

Layered aluminum alloy/aluminum-based composite board and preparation method thereof

PendingCN113385534AAvoid contact surface oxidationPromote bondingFurnace typesAuxillary arrangementsAluminum matrix compositesBonding strength

The invention belongs to the field of metal material preparation, and particularly relates to a layered aluminum alloy / aluminum-based composite board and a preparation method thereof. The preparation method specifically comprises the following steps that magnesium nitride powder is uniformly dispersed between aluminum alloy plates subjected to surface roughening treatment, the stacked plates are subjected to vacuum hot pressing to generate AlN in situ through a replacement reaction, the bonding strength and the bonding quality between the plates are improved, the plates are rolled to refine grains, the dislocation density and the grain boundary number in the materials are improved, the effect of improving the mechanical property of the material is achieved, and then low-temperature annealing is carried out to remove residual stress, so that the material has better comprehensive mechanical properties; and then the obtained plate is cut into two pieces with the same size. The prepared layered aluminum-based composite material plate is good in interface bonding, internal defects introduced in the rolling process are reduced to the maximum extent, and the material has good strength and plasticity.

Owner:NANJING UNIV OF SCI & TECH

Production process for preparing alkali cementing material from coal gangue

The invention relates to the field of solid waste resource utilization, and provides a production process for preparing an alkali cementing material from coal gangue, which comprises the following steps: (1) crushing, ball-milling and sieving coal gangue to obtain coal gangue powder; (2) putting the coal gangue powder into the mixed acid solution, uniformly stirring, standing for several days, carrying out suction filtration, and drying; (3) mixing the coal gangue powder obtained in the step (2) with salty mud, calcining at high temperature, cooling, carrying out secondary ball milling, and sieving to obtain mixed powder; (4) weighing the following raw materials in parts by weight: 50-80 parts of the mixed powder, 20-40 parts of slag powder, 4-8 parts of an exciting agent and 24-36 parts of water; (5) uniformly mixing the raw materials to obtain alkali gelling slurry; and (6) injecting the alkali gelling slurry into a mold, carrying out vibration molding, curing at normal temperature until demolding, and carrying out steam curing at 66-72 DEG C for 8 hours. According to the preparation method, the problems of resource waste and environmental pollution of the coal gangue waste are solved, and the alkali cementing material with excellent performance is prepared.

Owner:王庆乐

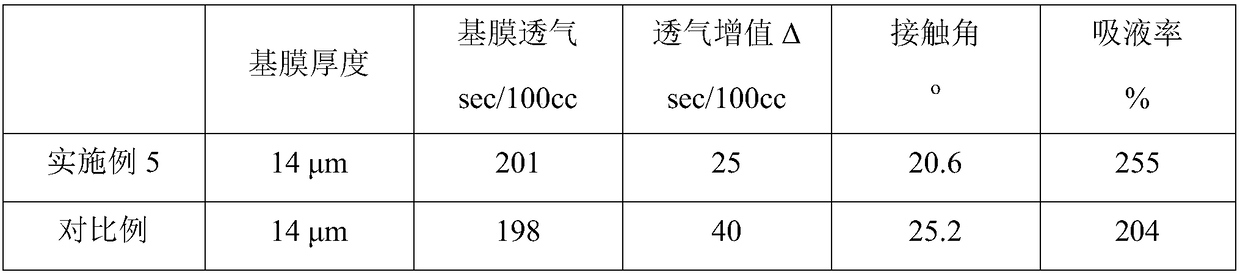

Self-stabilized P(VDF-HFP) (Poly(Vinylidene Fluoride-Hexafluoropropylene)) slurry as well as preparation and lithium-ion battery separator thereof

ActiveCN109161292AIncrease surface free energyGood dispersionCell component detailsCoatingsElectrolytic agentHexafluoropropylene

The invention discloses a preparation method of self-stabilized P(VDF-HFP) (Poly(Vinylidene Fluoride-Hexafluoropropylene)) slurry. The preparation method comprises the following steps: adding an acrylic monomer and a polymerization inhibitor into deionized water for mixing and dissolving, and further adding P(VDF-HFP) powder to obtain a mixed system; introducing an inert gas into the mixed systemto eliminate air in the mixed system, and sealing and preserving later; putting the mixed system which is sealed and preserved in the step b into a 60COgamma-ray radiation chamber for radiation to obtain dispersion liquid; centrifuging the dispersion liquid, washing with water, and re-dispersing the dispersion liquid into deionized water to obtain the self-stabilized P(VDF-HFP) slurry. According to the slurry prepared by the invention, no surfactant or adhesive is required to be added, performance degradation and hidden danger caused by dissolving of the surfactant or the adhesive in electrolyte can be avoided when coating a lithium-ion battery separator with the slurry, so that the performance and the security properties of a lithium-ion battery are substantially improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

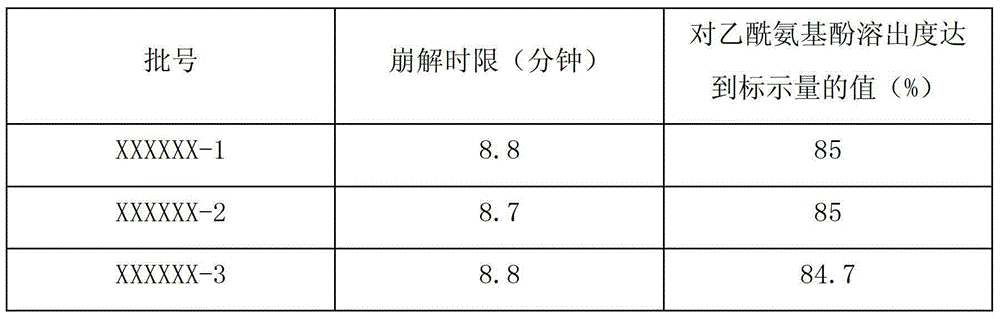

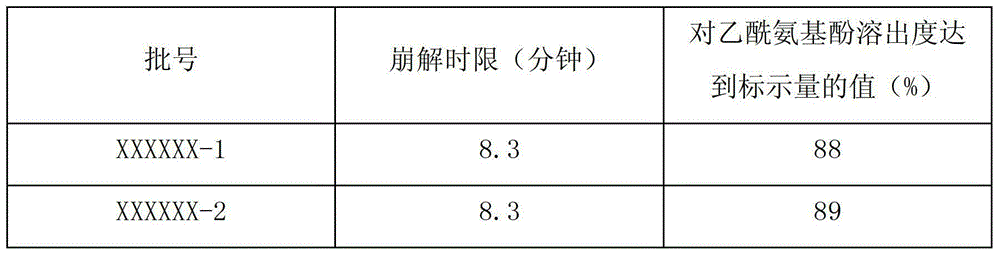

Preparation method of quickly-releasing compounded paracetamol and amantadine hydrochloride tablet

InactiveCN104415054APromotes quick releaseGood dispersionUnknown materialsPill deliveryMedicineDissolution

The invention provides a preparation method of a quickly-releasing compounded paracetamol and amantadine hydrochloride tablet. The preparation method mainly comprises following steps: pulverization, mixing, granulation, granule drying, granule shaping, totally blending and tablet pressing. In the steps of the pulverization, the mixing and the granulation, a preparation technology of a solid dispersing body is employed, wherein a carrier is an indissolvable hydrophilic material. After pulverizing the raw materials and the auxiliary materials into a certain degree, the raw materials and the auxiliary materials are dispersed with the carrier uniformly to prepare the solid dispersing body, and then the solid dispersing body is subjected to other processes and finally is subjected to the tablet pressing to obtain the tablet, which can achieve a good quickly-releasing effect with a dissolution rate being not less than 82% which is indicated. The invention has significant clinical significance in treatment of cold patients.

Owner:哈药集团人民同泰医药股份有限公司

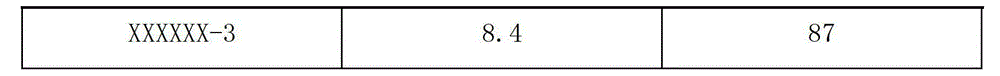

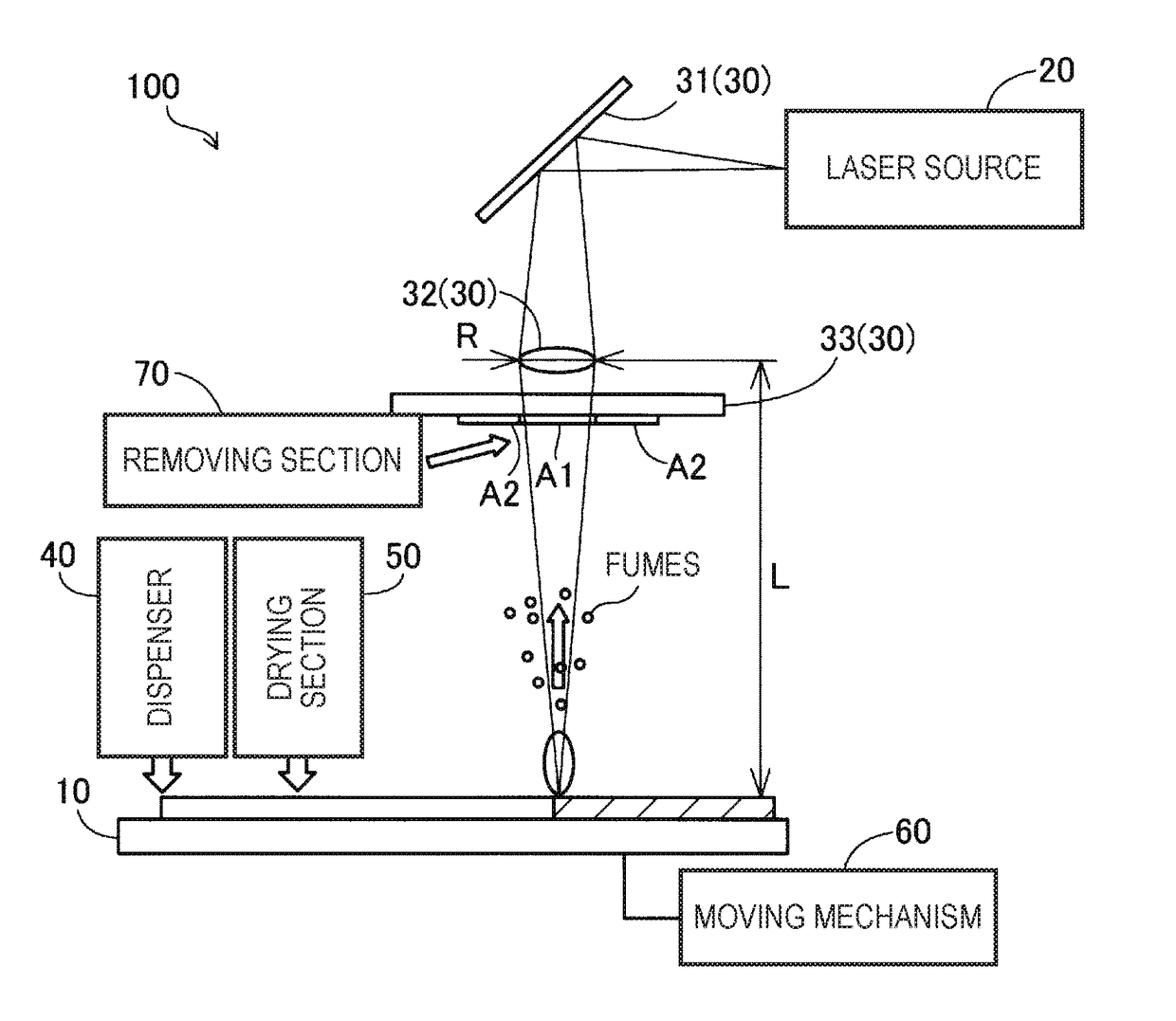

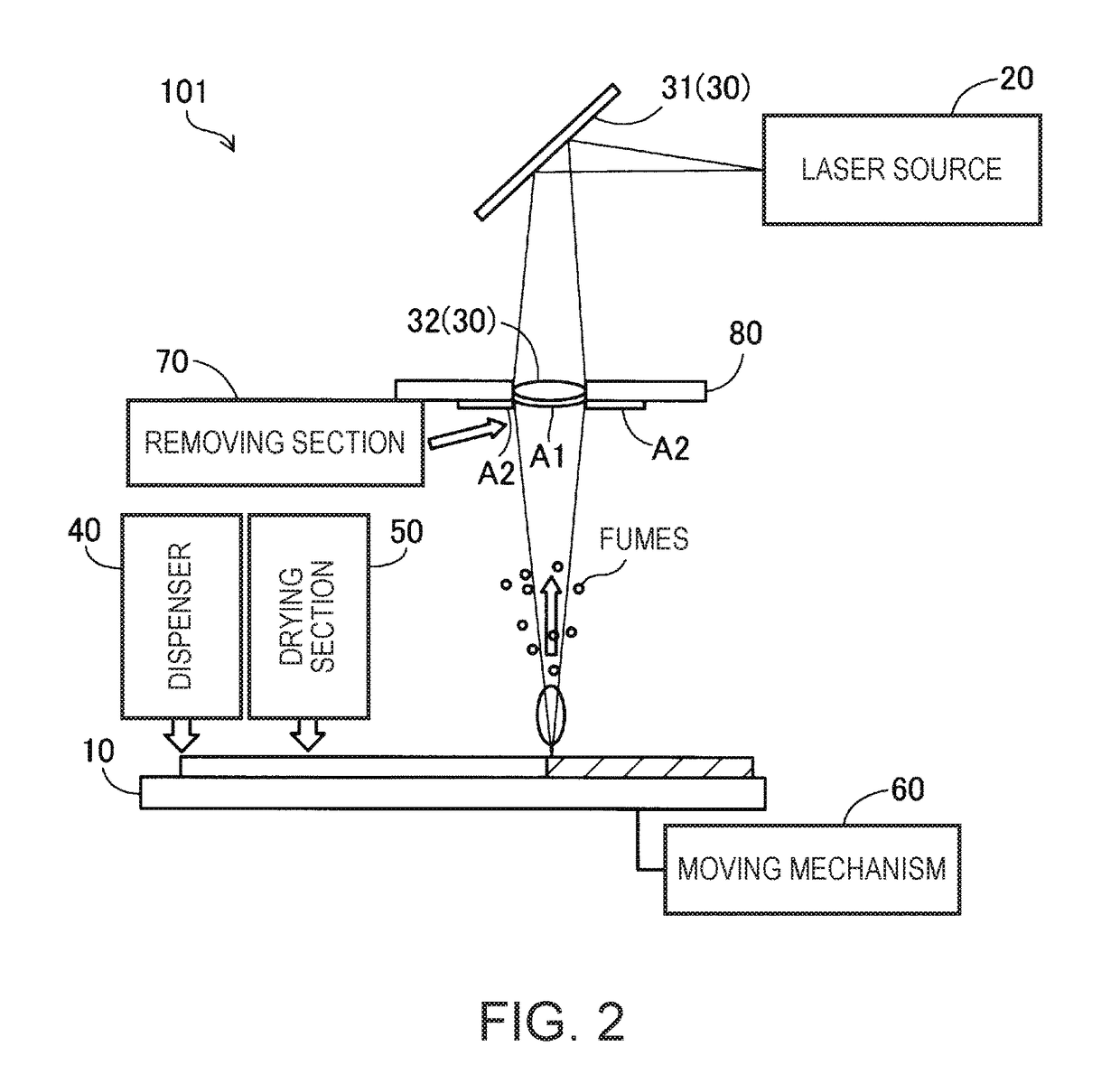

Three-dimensional modeling device

InactiveUS20180009064A1High surfaceImprove accuracyAdditive manufacturing apparatusTransportation and packagingFree energiesMaterials science

A three-dimensional modeling device includes a modeling section supplied with a material including a metal powder, a laser source adapted to emit a laser used to sinter or melt the metal powder, and an optical component through which the laser emitted from the laser source passes in the midway to the material on the modeling section. The optical component is provided with a first area, which faces to the modeling section, and through which the laser passes, and a second area higher in surface free energy than the first area is disposed in at least a part of a periphery of the first area.

Owner:SEIKO EPSON CORP

Anticorrosive flame-retardant polyaspartic acid polyurea waterproof paint and preparation method thereof

InactiveCN109021797AExtended gel timeHigh tensile strengthFireproof paintsAnti-corrosive paintsToluene diisocyanateSilicon dioxide

The invention discloses an anticorrosive flame-retardant polyaspartic acid polyurea waterproof paint and a preparation method thereof. The anticorrosive flame-retardant polyaspartic acid polyurea waterproof paint consists of a component A and a component B. The component A is a prepolymer of polyisocyanate and anticorrosive flame-retardant blocked isocyanate, the prepolymer of the anticorrosive flame-retardant blocked isocyanate takes toluene diisocyanate and polyether polyol as basic monomers, a phosphorus-nitrogen synergistic flame-retardant is used as a hard segment chain extender, and therice husk silica is used as a synergistic flame retardant, and the component B is polyaspartic acid ester, polymeric modified polyaspartic acid ester, a filler and a small amount of additives. The paint has long gelation time, high tensile strength, high elongation at break, excellent water resistance, flame retardancy, anti-corrosion performance, good weather resistance, and environmental friendliness, at the same time, the paint can be applied with manual construction, and does not require special large-scale spraying equipment, and the application field is wide.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

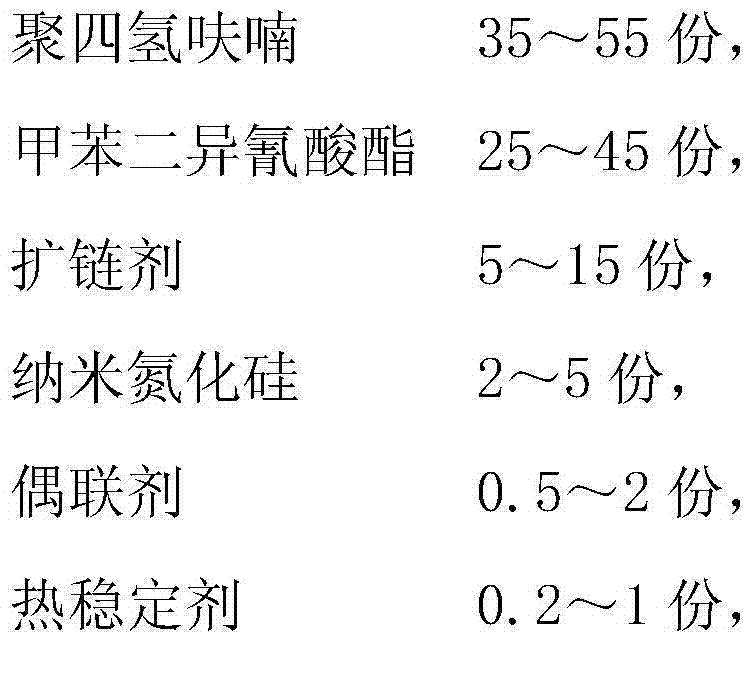

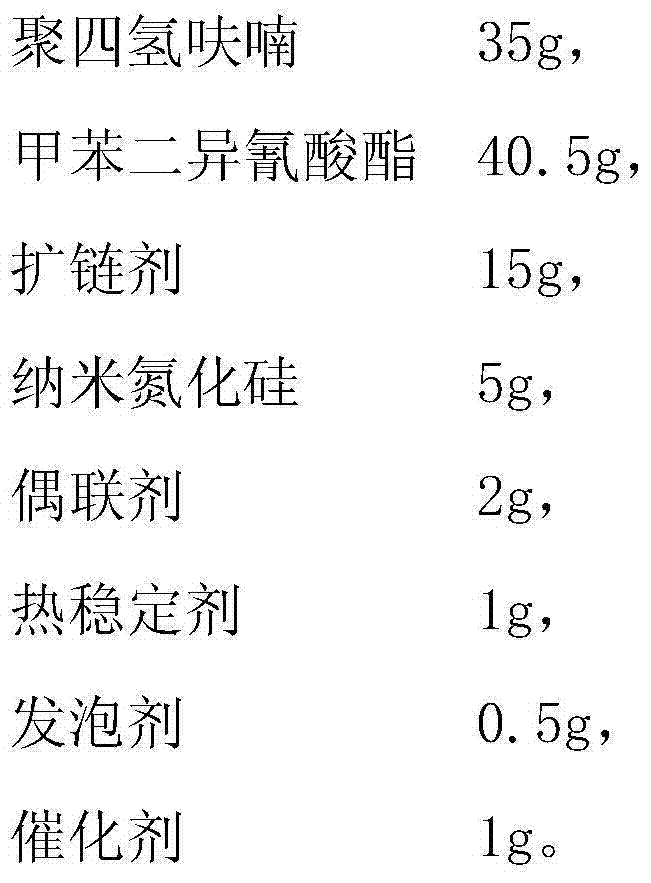

High-wear-resistance polyurethane shoe material and manufacturing method thereof

ActiveCN104262569AGood self-lubricationGood wear resistanceFootwearToluene diisocyanatePolytetrahydrofuran

The invention provides a high-wear-resistance polyurethane shoe material which is prepared from the following components in parts by weight: 35-55 parts of polytetrahydrofuran, 25-45 parts of toluene diisocyanate, 5-15 parts of chain extender, 2-5 parts of nano silicon nitride, 0.5-2 parts of coupling agent, 0.2-1 part of heat stabilizer, 0.1-0.5 part of foaming agent and 0.5-1 part of catalyst. The invention also provides a manufacturing method of the high-wear-resistance polyurethane shoe material. The polyurethane shoe material provided by the invention has favorable wear resistance.

Owner:SUZHOU JINGRO TECH

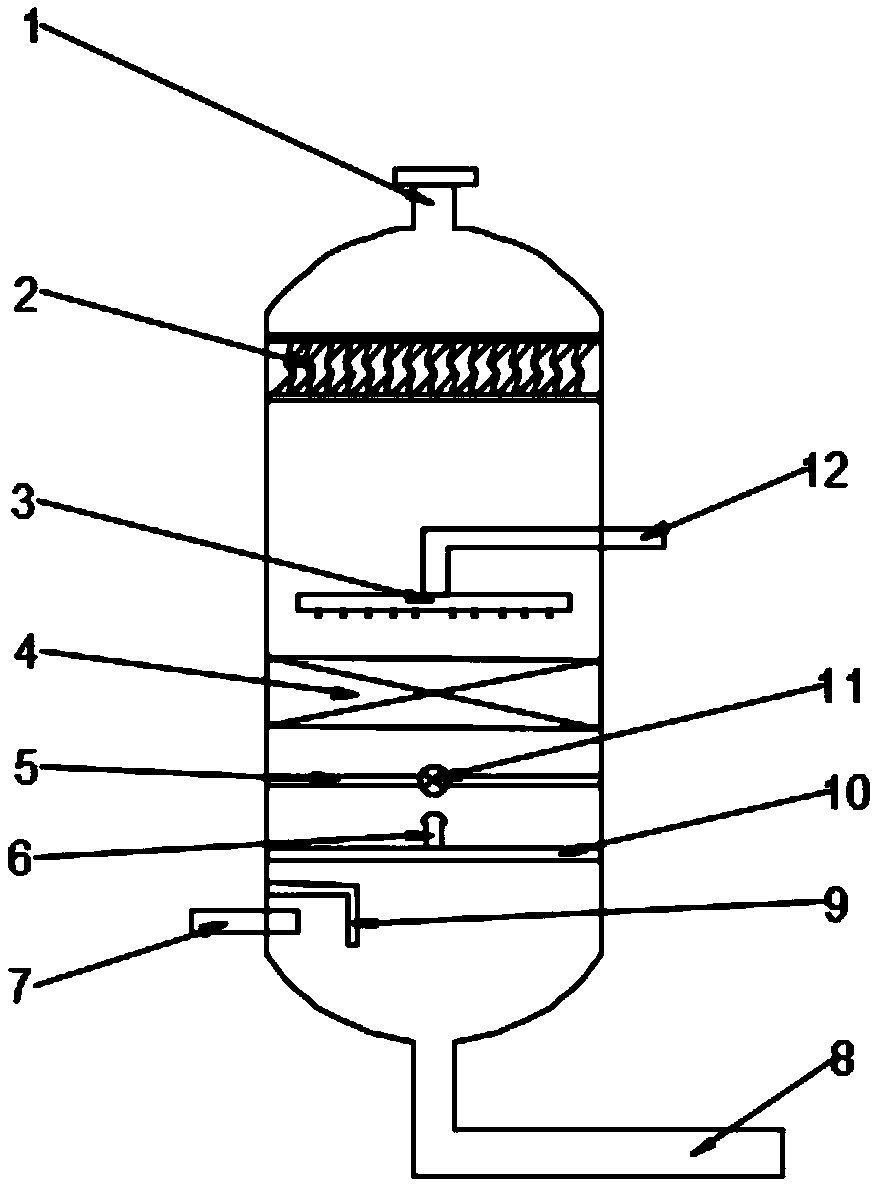

Waste gas absorption and purification equipment

InactiveCN109157951AStrong capture capacityIncrease the gas-liquid contact areaCombination devicesExhaust gasEngineering

The invention relates to the technical field of purification machinery equipment, in particular to waste gas absorption and purification equipment and solves the problem that liquid is carried in exhaust gas. The invention has the technical key points that the waste gas absorption and purification equipment comprises a gas outlet, a gas inlet, a liquid outlet and a liquid inlet; the liquid inlet is connected with a liquid distributor, and a gas-liquid separation device is arranged above the liquid distributor and is positioned between the gas outlet and the liquid inlet; the gas-liquid separation device comprises a first supporting piece and a second supporting piece, and first baffles, second baffles and third baffles are arranged between the first supporting piece and the second supporting piece; one first baffle, one second baffle and one third baffle form a baffle; the gas-liquid separation device comprises a plurality of baffles arranged in parallel, and a first overflow passage and a second overflow passage which are arranged in a staggered manner are formed between the adjacent baffles. As the waste gas absorption and purification equipment is provided with the gas-liquid separation device, the gas-liquid separation device can more thoroughly separate the gas from the liquid carried in the gas.

Owner:霸州市辉月网络技术有限公司

Self-cleaning and noise-reducing self-adhesive waterproof roll cementing material and preparation method thereof

ActiveCN112646547AHigh strengthWith noise reduction functionNon-macromolecular adhesive additivesBituminous material adhesivesPolymer scienceWaste rubber

A self-cleaning and noise-reducing self-adhesive waterproof roll cementing material and a preparation method thereof belong to the technical field of waterproof rolls. The self-cleaning and noise-reducing self-adhesive waterproof roll cementing material is prepared from the following raw materials in parts by weight: 38-47 parts of asphalt special for I-type waterproof rolls, 2-9 parts of styrene tar, 7-13 parts of rubber softening oil, 7-14 parts of SBS, 2-12 parts of waste rubber powder, 4-14 parts of tackifying resin, 9-22 parts of silane modified glass powder subjected to low-temperature plasma treatment and 7-18 parts of nano silicon dioxide. The preparation method comprises the following steps of: (1) heating and mixing the asphalt special for I-type waterproof rolls and the styrene tar; (2) adding the SBS, and carrying out heating and mixing; and (3) adding the tackifying resin and the waste rubber powder, carrying out heating and mixing, sequentially adding the silane modified glass powder subjected to low-temperature plasma treatment and silicon dioxide, and carrying out heating and mixing. The noise-reducing self-adhesive waterproof roll cementing material is high in strength, has self-cleaning and noise-reducing functions, and can realize self-adhesion without smearing cement or base oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

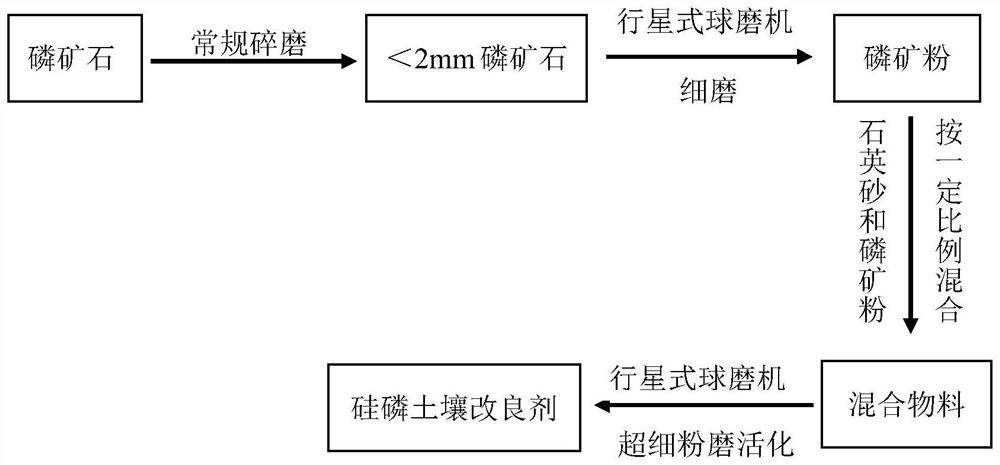

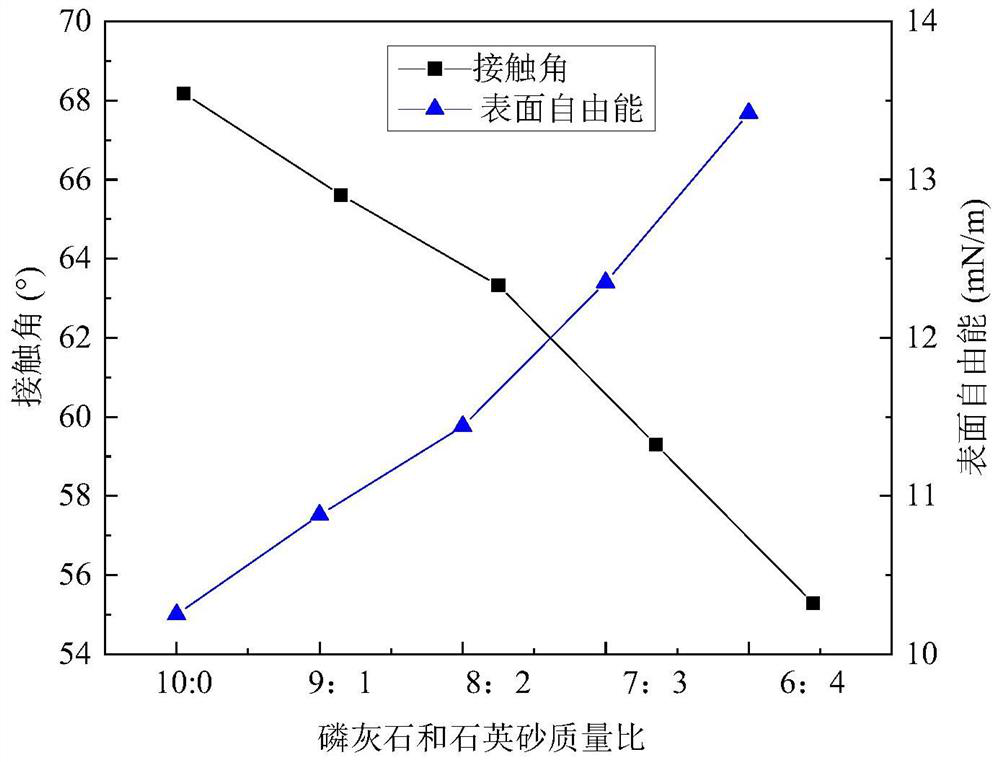

Silicon phosphorus soil conditioner

PendingCN114773106AEfficient activationIndustrial Application SecurityFertilizer mixturesPhosphoriteSoil conditioner

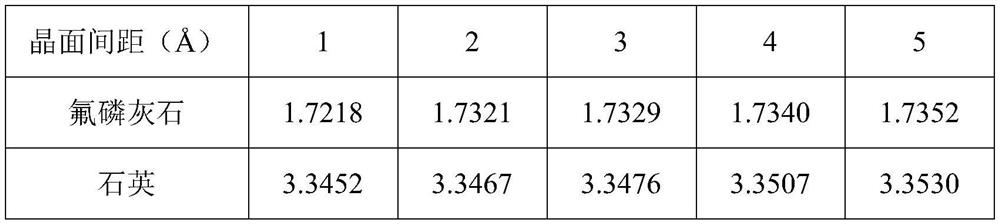

The invention discloses a silicon-phosphorus soil conditioner, which is obtained by finely grinding phosphate ore with phosphorus content of about 20% into phosphate rock powder and then adding quartz sand with silicon content of about 90% for ultrafine grinding treatment by means of mechanical activation. According to the invention, the mixture of the ground phosphate rock and the quartz sand is subjected to high-energy grinding, so that the activation of the ground phosphate rock is promoted while the quartz sand is activated, and the content of citric acid-soluble silicon and phosphorus which are easily absorbed by plants in the product is greatly increased. The crystal structures of the phosphorite powder and the quartz sand which are activated by superfine grinding are destroyed, the reaction activity is improved, in the production process, chemicals do not need to be added, pollution and redundant impurities are not generated, the production efficiency is high, the cost is low, the operation is simple, and the method plays an important role in improving the utilization rate of phosphorite resources.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com