Emulsion type thermoplastic sizing agent for carbon fiber and preparation method of sizing agent

An emulsion type, thermoplastic technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problem of low heat resistance of sizing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing an emulsion-type thermoplastic sizing agent for carbon fibers, the method comprising:

[0038] Step 1: Dissolving the polyarylether resin in an organic solvent, adding an emulsifier, stirring to mix evenly, and obtaining the main slurry; the stirring time is preferably 10 minutes to 30 minutes;

[0039]Step 2: Add the coupling agent into the deionized water, stir and mix evenly to obtain modified deionized water; the stirring time is preferably 5 minutes to 10 minutes;

[0040] Step 3: Select a high-speed shear emulsifier, preferably at 6000rpm-20000rpm, drop the modified deionized water obtained in step 2 into the main slurry in step 1, and continue stirring at a temperature of 30°C-60°C to disperse the system Uniformity means that an emulsion-type thermoplastic sizing agent is obtained; the dropping speed is preferably 0.01ml / s-1ml / s, and the stirring time is preferably 1h-2h.

Embodiment 1

[0043] The sizing agent is calculated by mass fraction, including: PPK-CN: 1.5%, KH-560: 1%, NP-10: 2%, dichloroethane: 7%, deionized water: 88.5%.

[0044] The thermoplastic resin PPK-CN (the number average molecular weight is 8.0×10 3 g / mol) was dissolved in ethylene dichloride, stirred for 15min to make it evenly mixed, then added NP-10, stirred for 5min to obtain the main slurry;

[0045] Add KH560 into deionized water and stir for 5 minutes to make it evenly mixed to obtain modified deionized water;

[0046] Use a high-speed shear emulsifier, slowly add the modified deionized water to the main slurry at 10000rpm, the dropping speed is 0.05ml / s, control the system temperature at 60°C, increase the phase inversion stirring speed to 12000rpm, drop Accelerate at 1ml / s, and continue stirring at 8000rpm for 1h after the dropwise addition to obtain an emulsion-type sizing agent.

[0047] The structural formula of the PPK-CN is as follows:

[0048]

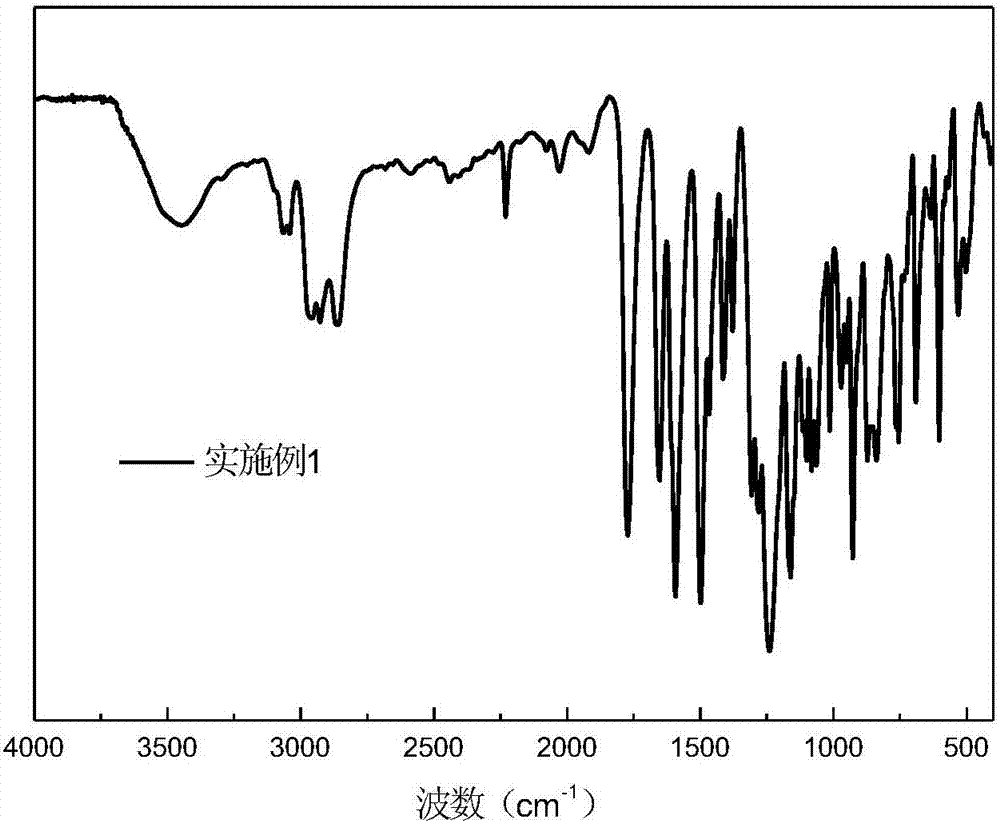

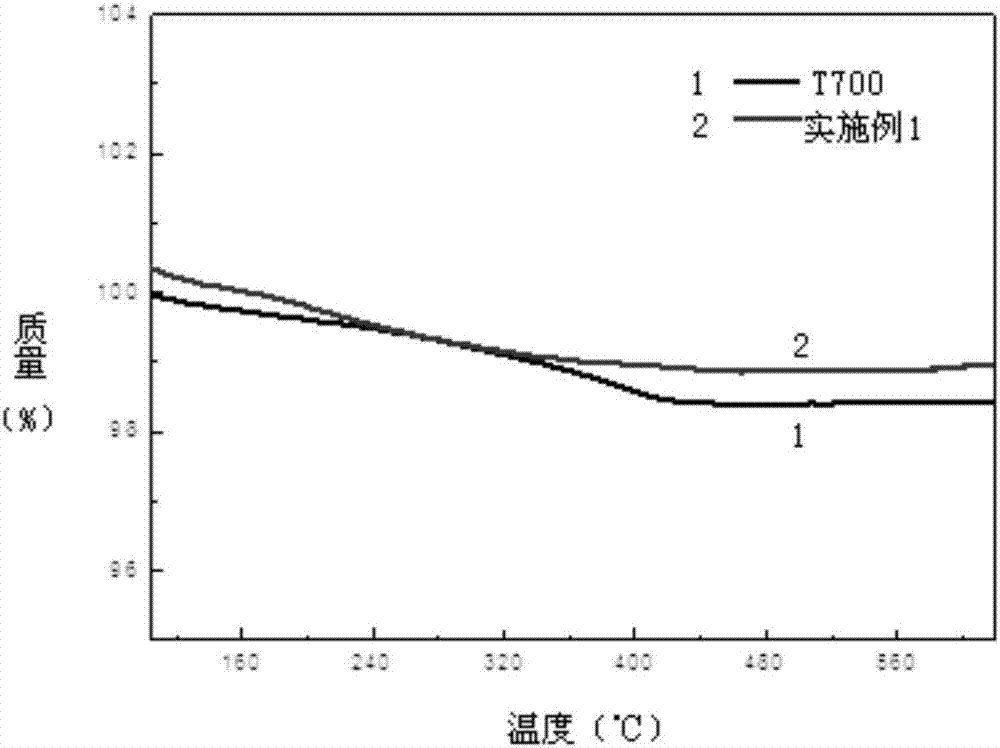

[0049] figure 1 It is ...

Embodiment 2

[0051] The sizing agent is calculated by mass fraction, including: PES-C: 0.8%, KH-402: 0.5%, EL-40: 1%, N,N-dimethylacetamide: 7%, deionized water: 90.7%.

[0052] The thermoplastic resin PES-C (the number average molecular weight is 3.0×10 4 g / mol) was dissolved in N,N-dimethylacetamide, stirred for 15 minutes to make it evenly mixed, then added EL-40, stirred for 5 minutes to obtain the main slurry;

[0053] Add KH-402 into deionized water and stir for 5 minutes to make it evenly mixed to obtain modified deionized water;

[0054] Use a high-speed shear emulsifier, slowly add the modified deionized water into the main slurry at 6000rpm, the dropping speed is 0.03ml / s, control the system temperature at 50°C, increase the phase inversion stirring speed to 15000rpm, drop Accelerate at 1ml / s, and continue stirring at 12000rpm for 1h after the dropwise addition to obtain an emulsion-type sizing agent.

[0055] The structural formula of the PES-C is as follows (n=0; a, b>0):

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com