High-wear-resistance polyurethane shoe material and manufacturing method thereof

A manufacturing method, polyurethane technology, applied in footwear, applications, clothing, etc., can solve the problem of insufficient wear resistance of ordinary polyurethane shoe materials, achieve good wear resistance, improve dispersion effect, and improve the effect of interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

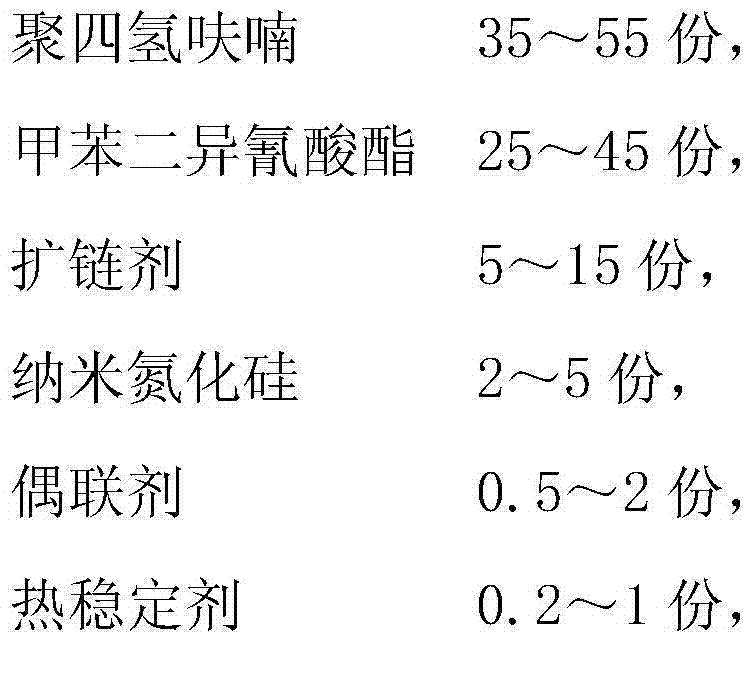

[0024] A kind of highly wear-resistant polyurethane shoe material, its parts by weight consist of:

[0025]

[0026] Its manufacturing method comprises the following steps:

[0027] (1) dissolving nano-silicon nitride in propanol, nitrogen protection, adding a coupling agent under high-speed stirring, taking it out after refluxing at 70°C for 2 hours, and obtaining modified nano-silicon nitride after drying;

[0028] (2) Toast and dry polytetrahydrofuran and toluene diisocyanate respectively, and set aside;

[0029] (3) other components in the formula and the modified nano-silicon nitride obtained in the step (1) are added to the polytetrahydrofuran after drying, and mixed uniformly to form a mixture;

[0030] (4) mixing the mixture obtained in step (3) with the dried toluene diisocyanate and casting to obtain a highly wear-resistant polyurethane shoe material.

Embodiment 2

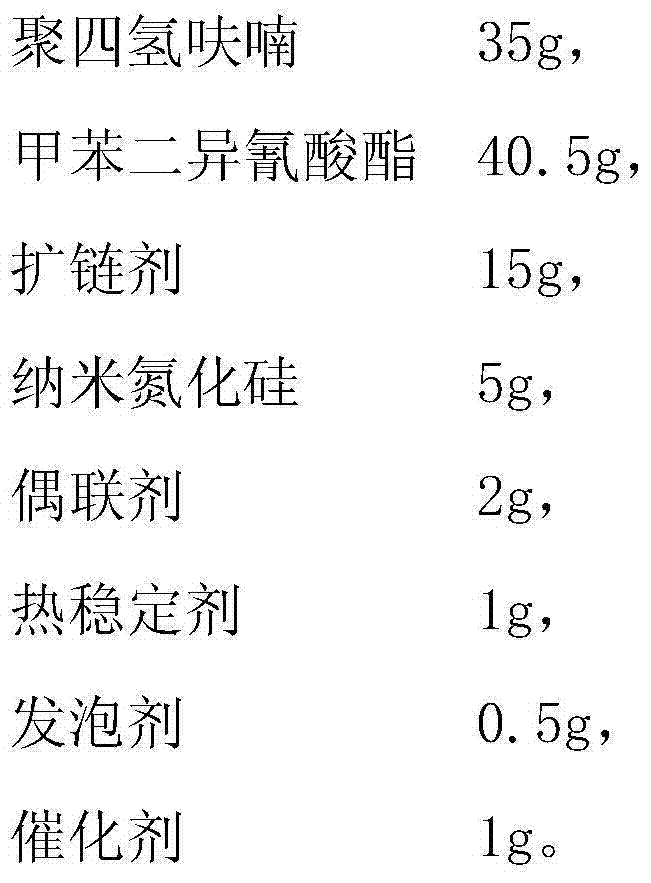

[0032] A kind of highly wear-resistant polyurethane shoe material, its parts by weight consist of:

[0033]

[0034]

[0035] Its manufacturing method comprises the following steps:

[0036] (1) dissolving nano-silicon nitride in propanol, nitrogen protection, adding a coupling agent under high-speed stirring, taking it out after refluxing at 70°C for 2 hours, and obtaining modified nano-silicon nitride after drying;

[0037] (2) Toast and dry polytetrahydrofuran and toluene diisocyanate respectively, and set aside;

[0038] (3) other components in the formula and the modified nano-silicon nitride obtained in the step (1) are added to the polytetrahydrofuran after drying, and mixed uniformly to form a mixture;

[0039] (4) mixing the mixture obtained in step (3) with the dried toluene diisocyanate and casting to obtain a highly wear-resistant polyurethane shoe material.

Embodiment 3

[0041] A kind of highly wear-resistant polyurethane shoe material, its parts by weight consist of:

[0042]

[0043] Its manufacturing method comprises the following steps:

[0044] (1) dissolving nano-silicon nitride in propanol, nitrogen protection, adding a coupling agent under high-speed stirring, taking it out after refluxing at 70°C for 2 hours, and obtaining modified nano-silicon nitride after drying;

[0045] (2) Toast and dry polytetrahydrofuran and toluene diisocyanate respectively, and set aside;

[0046] (3) other components in the formula and the modified nano-silicon nitride obtained in the step (1) are added to the polytetrahydrofuran after drying, and mixed uniformly to form a mixture;

[0047] (4) mixing the mixture obtained in step (3) with the dried toluene diisocyanate and casting to obtain a highly wear-resistant polyurethane shoe material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com