Preparation method of quickly-releasing compounded paracetamol and amantadine hydrochloride tablet

A compound paracetamol tablet and immediate-release technology, which can be applied to medical preparations containing active ingredients, pharmaceutical formulations, amine active ingredients, etc., can solve problems such as limited effects, and achieve good immediate-release effects and great clinical significance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

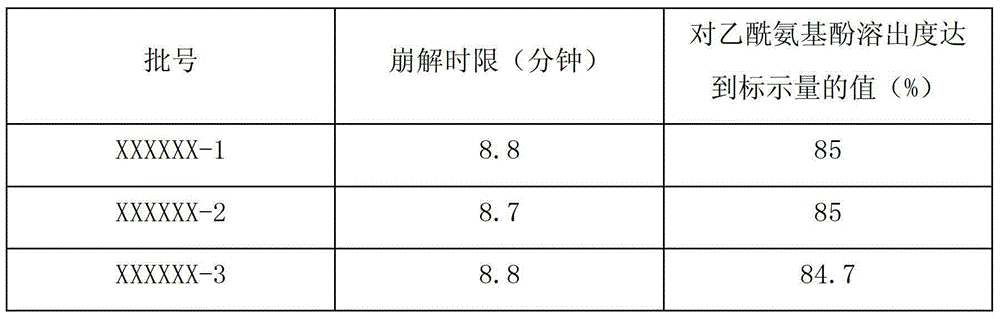

example 1

[0018] 1. Pulverize all the raw and auxiliary materials and pass through a 100-mesh sieve, in which silicon dioxide passes through a 50-mesh sieve;

[0019] 2. Mix 15 parts by weight of caffeine, 2 parts by weight of chlorpheniramine maleate and 10 parts by weight of artificial bezoar. During the mixing process, the materials need to pass through a 50-mesh sieve for 3 times;

[0020] 3. Put 100 parts by weight of acetaminophen, 250 parts by weight of amantadine hydrochloride, pre-mixed materials, 40 parts by weight of silicon dioxide and 20 parts by weight of sodium carboxymethyl starch into a wet mixer, and mix for 5 minutes , then add the binder, mix for 3 minutes, and then granulate.

[0021] 4. Move the granules into the boiling dryer, control the temperature of the material at 30-80°C, ventilate and dry for 20-60 minutes, cool the granules to room temperature, carry out sizing, and then move the granules into the mixing machine, add 3 parts by weight of carboxyl Sodium s...

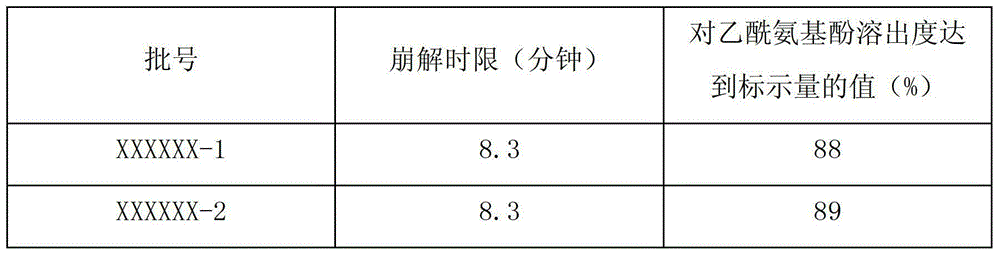

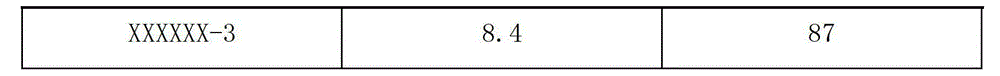

example 2

[0026] 1. Crush all the raw and auxiliary materials and pass through a 120-mesh sieve, among which calcium phosphate passes through a 80-mesh sieve.

[0027] 2. Mix 15 parts by weight of caffeine, 2 parts by weight of chlorpheniramine maleate and 10 parts by weight of artificial bezoar. During the mixing process, the materials need to pass through an 80-mesh sieve for 3 times;

[0028] 3. Put 100 parts by weight of acetaminophen, 250 parts by weight of amantadine hydrochloride, pre-mixed materials, 40 parts by weight of calcium phosphate and 30 parts by weight of sodium carboxymethyl starch into a wet mixer, and mix for 5 minutes , then add the binder, mix for 3 minutes, and then granulate.

[0029] 4. Move the granules into the boiling dryer, control the temperature of the material at 30-80°C, ventilate and dry for 20-60 minutes, cool the granules to room temperature, carry out sizing, and then move the granules into the mixing machine, add 3 parts by weight of carboxyl Sodi...

example 3

[0035] 1. Pulverize all the raw and auxiliary materials and pass through a 120-mesh sieve, in which silicon dioxide passes through a 80-mesh sieve.

[0036] 2. Mix 15 parts by weight of caffeine, 2 parts by weight of chlorpheniramine maleate and 10 parts by weight of artificial bezoar. During the mixing process, the materials need to pass through a 100-mesh sieve for 3 times;

[0037] 3. Put 100 parts by weight of acetaminophen, 250 parts by weight of amantadine hydrochloride, pre-mixed materials and 50 parts by weight of silicon dioxide and 50 parts by weight of sodium carboxymethyl starch into a wet mixer, and mix for 5 Minutes, then add the binder, mix for 3 minutes, and then granulate.

[0038] 4. Move the granules into the boiling dryer, control the temperature of the material at 70°C, ventilate and dry for 20-60 minutes, cool the granules to room temperature, carry out granulation, and then move the granules into the mixing machine, add 7 parts by weight of carboxymethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com