Florfenicol soluble powder and preparation method thereof

A florfenicol and soluble technology, which is applied in the field of florfenicol soluble powder and its preparation, can solve the problems of difficult absorption in the digestive tract, uneven dispersion, and affecting solubility, etc., and achieves good quick release effect and high solubility Good, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

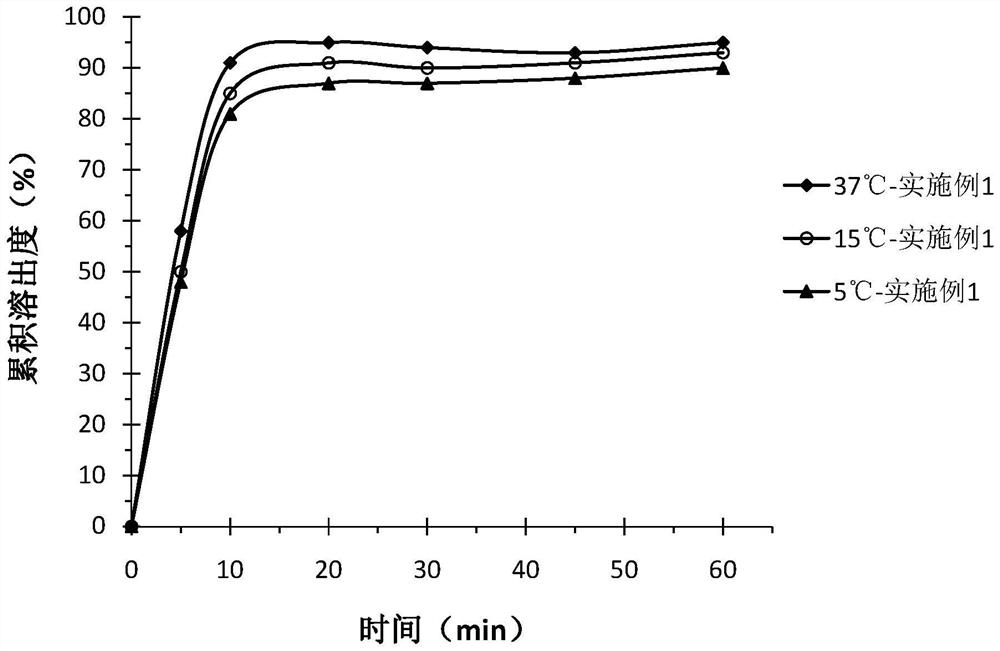

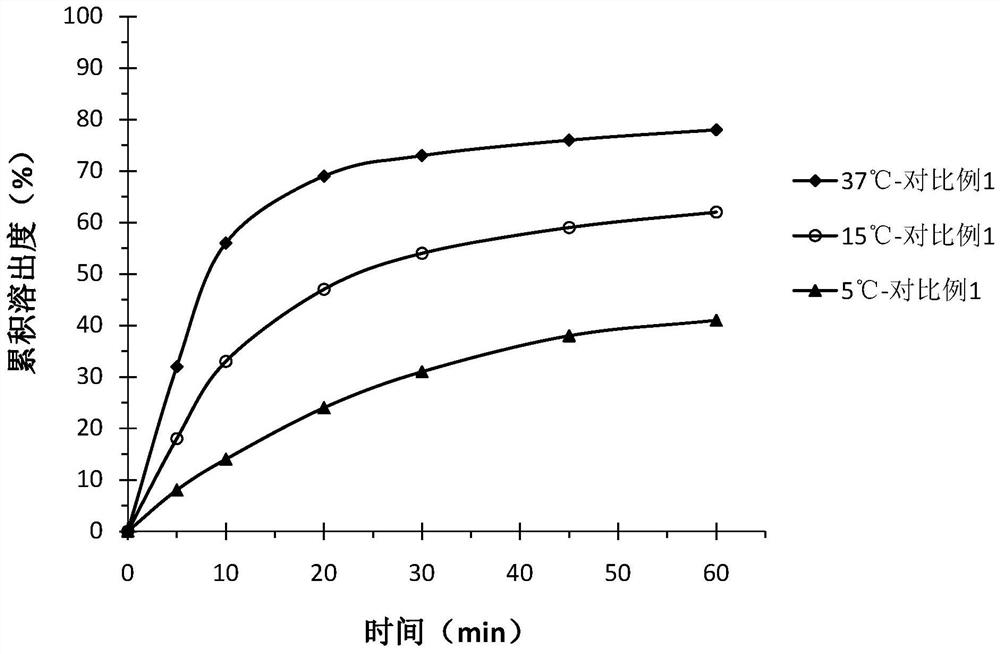

Embodiment 1

[0036] Raw material composition:

[0037]

[0038] Preparation:

[0039] (1) Take 300g of Florfenicol and 500g of 95% ethanol, stir at a temperature of 50°C, and dissolve to obtain solution 1;

[0040] (2) Take 150g of sodium starch octenyl succinate, 250g of β-cyclodextrin, 200g of sodium citrate and 100g of sodium alginate, add them to 1000g of purified water, stir at a temperature of 50°C, and dissolve to obtain solution 2;

[0041] (3) After mixing solution 1 and solution 2, turn on the high-speed shear emulsifier, set the rotating speed at 3000rpm for emulsification; turn on the high-pressure homogenizer, set the homogenization pressure at 50MPa, and carry out high-pressure homogenization of the emulsified liquid to obtain Lotion;

[0042] (4) Turn on the spray dryer, set the temperature at 180° C., and rotate at 600 rpm, and spray-dry the emulsion obtained in step (3) to obtain the florfenicol soluble powder.

Embodiment 2

[0044] Raw material composition:

[0045]

[0046] Preparation:

[0047] (1) Take 200g of florfenicol and 450g of 95% ethanol, stir at a temperature of 35°C, and dissolve to obtain solution 1;

[0048] (2) Take 100g of sodium lauryl sulfate, 200g of β-cyclodextrin, 150g of sodium citrate and 50g of sodium alginate, add them to 1000g of purified water, stir at a temperature of 35°C, and dissolve to obtain solution 2;

[0049] (3) After mixing solution 1 and solution 2, turn on the high-speed shear emulsifier, set the rotation speed at 5000rpm for emulsification; turn on the high-pressure homogenizer, set the homogenization pressure to 30MPa, and carry out high-pressure homogenization of the emulsified liquid to obtain Lotion;

[0050] (4) Turn on the spray dryer, set the temperature at 160° C., and rotate at 600 rpm, and spray-dry the emulsion obtained in step (3) to obtain the florfenicol soluble powder.

Embodiment 3

[0052] Raw material composition:

[0053]

[0054]

[0055] Preparation:

[0056] (1) Take 250g of florfenicol and 400g of 95% ethanol, stir at a temperature of 65°C, and dissolve to obtain solution 1;

[0057](2) Take 120g of sodium dodecylbenzenesulfonate, 220g of β-cyclodextrin, 300g of sodium citrate and 80g of sodium alginate, add them to 1000g of purified water, stir at a temperature of 65°C, and dissolve to obtain solution 2;

[0058] (3) After mixing solution 1 and solution 2, turn on the high-speed shear emulsifier, set the rotating speed to 4000rpm for emulsification; turn on the high-pressure homogenizer, set the homogenization pressure to 70MPa, and carry out high-pressure homogenization of the emulsified liquid to obtain Lotion;

[0059] (4) Turn on the spray dryer, set the temperature at 200° C., and rotate at 600 rpm, and spray-dry the emulsion obtained in step (3) to obtain the florfenicol soluble powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com