Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

114results about How to "Improve adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

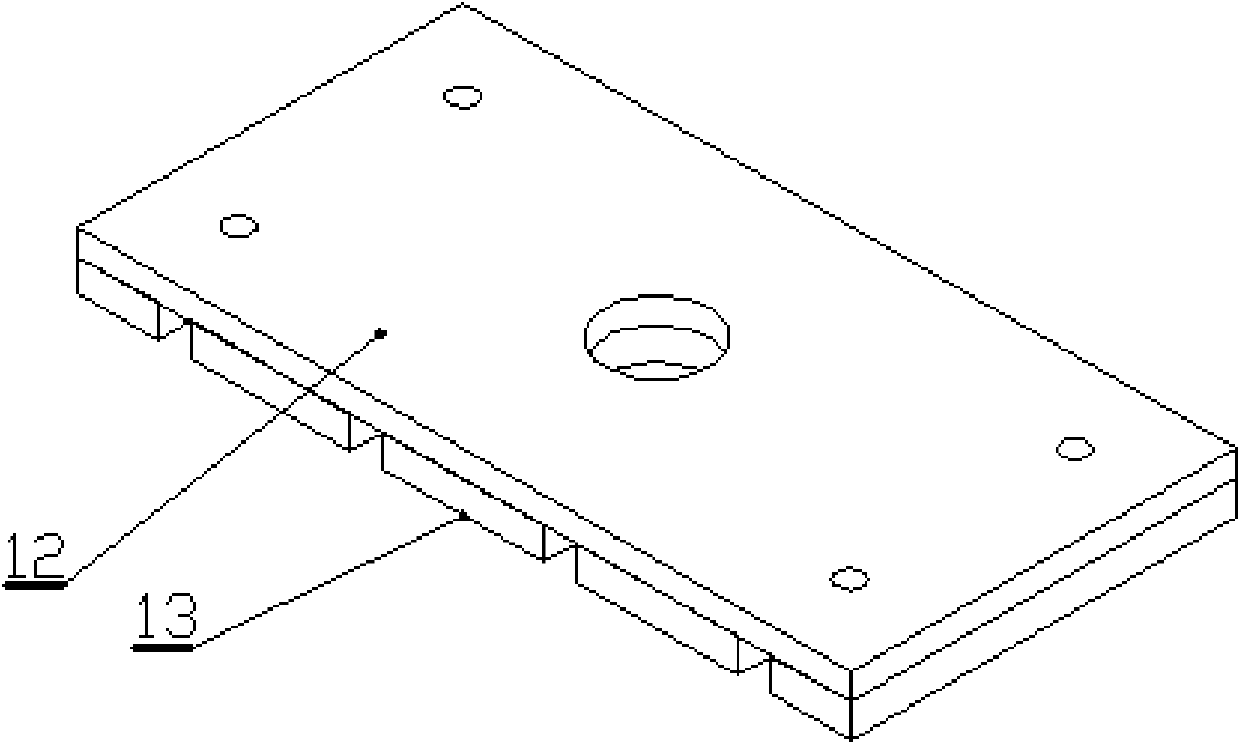

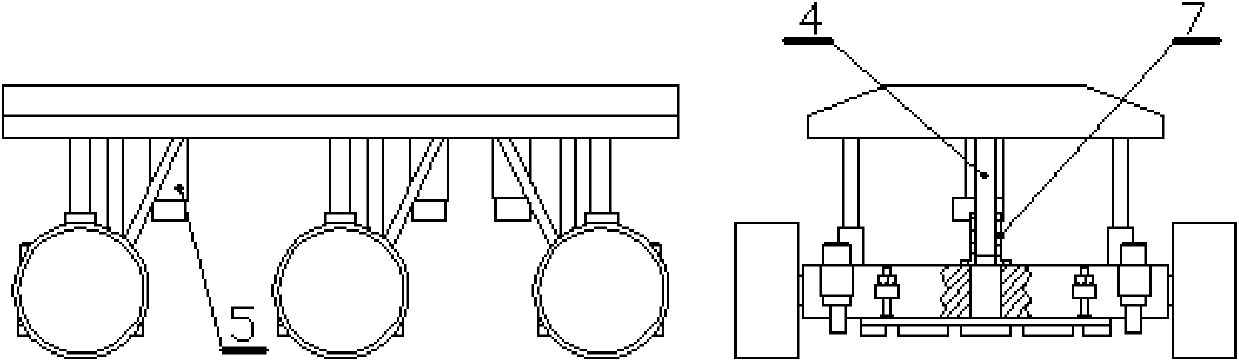

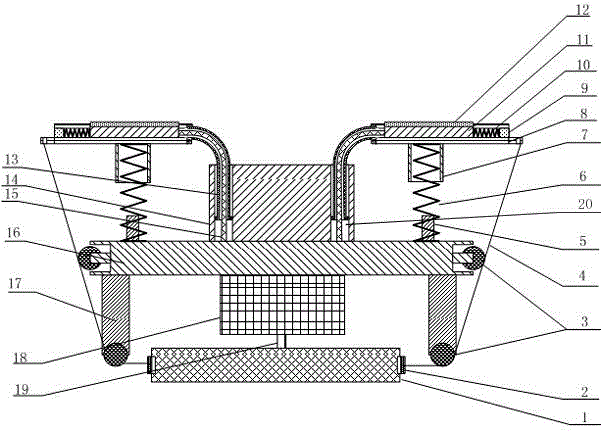

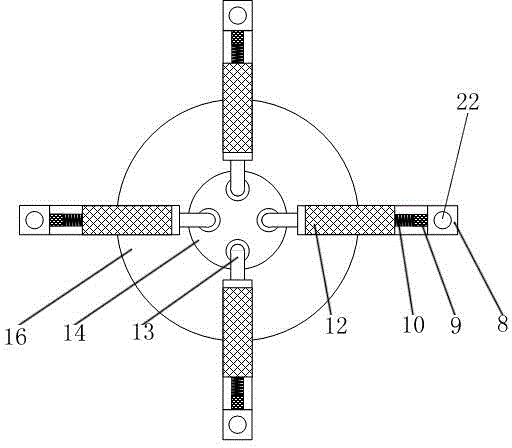

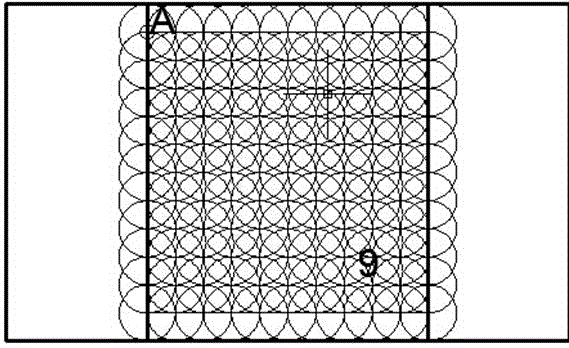

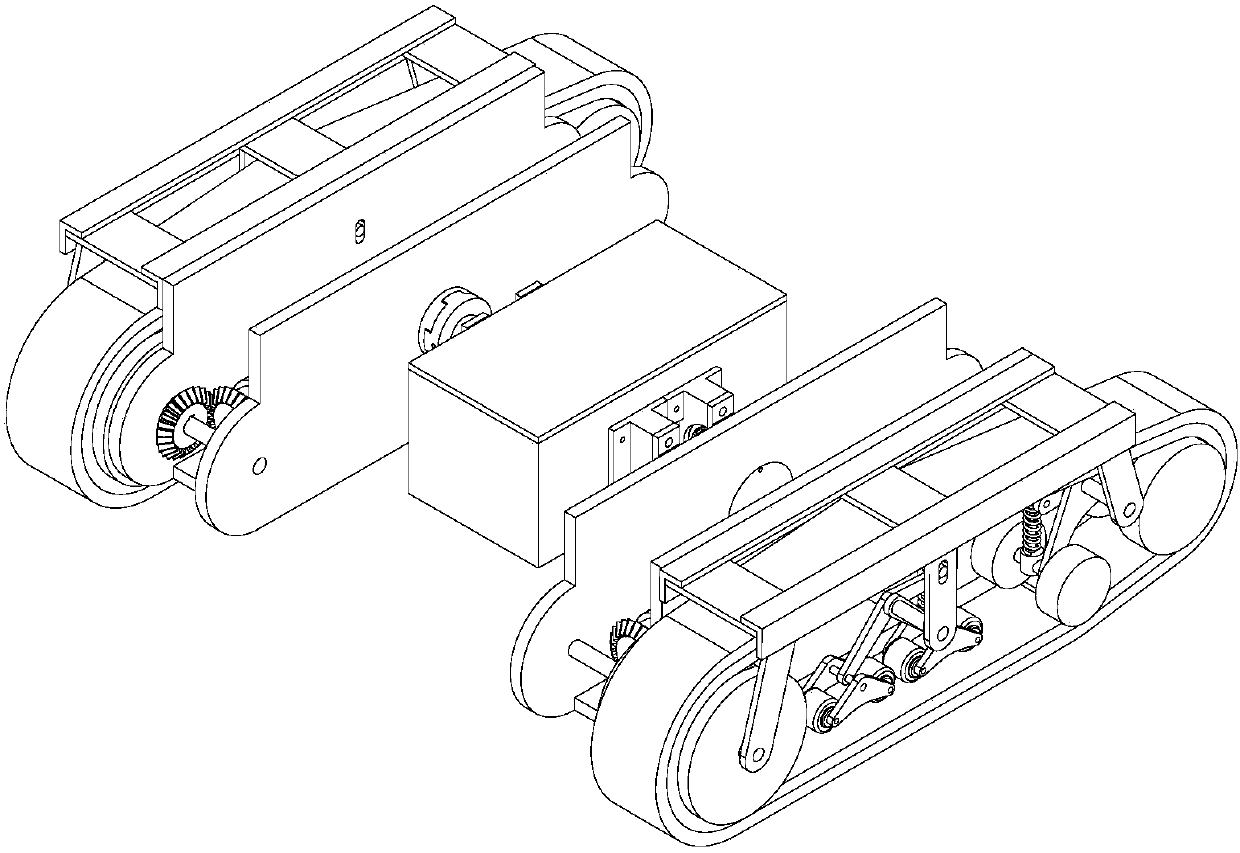

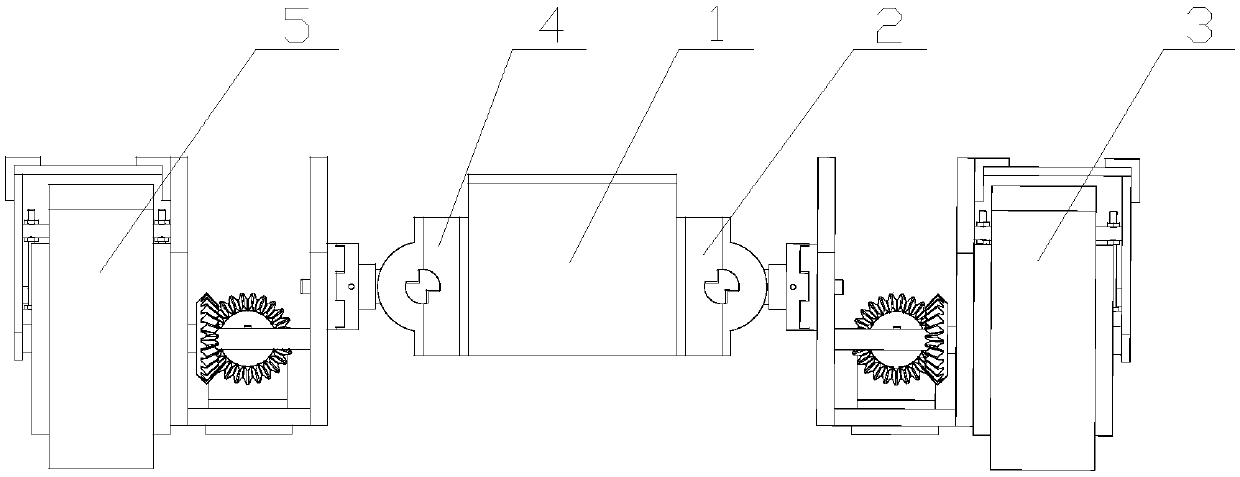

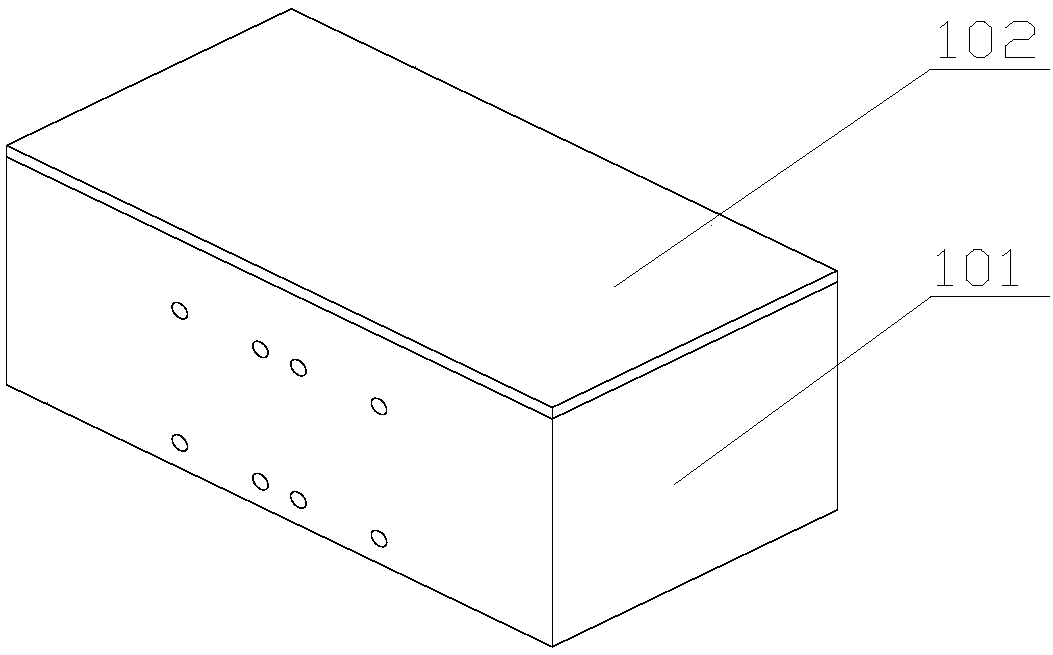

Wheel type barrier-crossing wall-climbing robot

ActiveCN101947776AImprove adsorptionGood ability to overcome obstaclesManipulatorDrive motorMobile robot

The invention relates to a wheel type barrier-crossing wall-climbing robot in the technical field of robot, comprising a robot frame, three groups of mobile adsorption mechanisms and linear slide rails, screw rods and drive motors corresponding to the three groups of mobile adsorption mechanisms, the three groups of linear slide rails and the screw rods are vertically arranged below the robot frame and the two ends thereof are respectively connected with the robot frame and the mobile adsorption mechanism, and the drive motors are fixedly connected with the mobile adsorption mechanisms. The robot of the invention solves the problem of the existing wall-climbing robot in vertical wall surface operation, has the characteristics of fast speed and flexible steering of the wheel type mobile robot and large magnetic adsorption force of the crawler-type mobile robot, features good barrier-crossing capacity and can meet the demands of motion and operation in complex environments.

Owner:SHANGHAI JIAO TONG UNIV

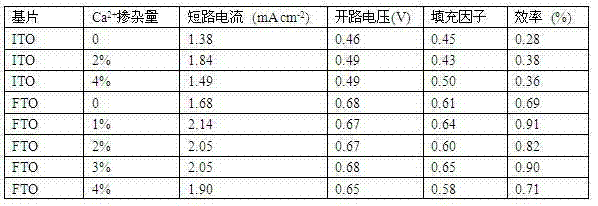

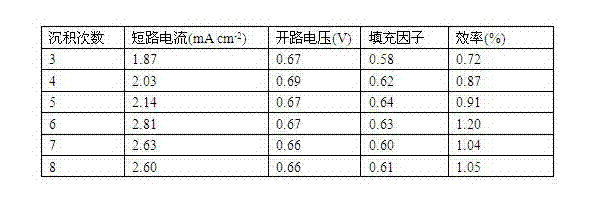

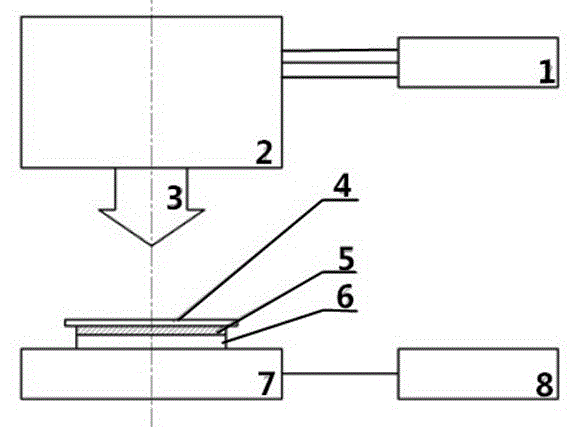

Method for increasing performance parameter of quantum dot sensitized solar battery

InactiveCN102163502ARaise conduction bandImprove adsorptionLight-sensitive devicesConduction bandElectronic energy

The invention relates to a method for increasing performance parameters of a quantum dot sensitized solar battery. In the method, Ca<2+> is doped into CdS and serves as a sensitizing agent to assemble the quantum dot sensitized solar battery; the conduction band of Cds is enhanced, so electronic energy can be injected into TiO2 more effectively; meanwhile, the absorption state of the Cds quantum dot on the surface of an electrode material is improved, the dark current is restrained, and short circuit current and photoelectric conversion efficiency of the solar battery are improved. The processing method is simple, easy to operate, and low in cost.

Owner:FUZHOU UNIVERSITY

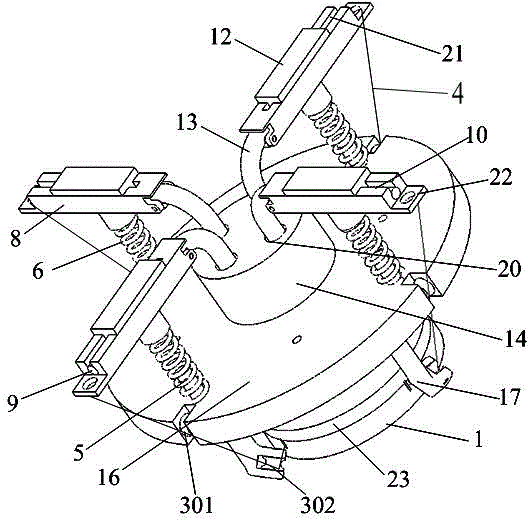

Gecko-like bionic dry adhering device

The invention provides a gecko-like dry adhering device. The gecko-like dry adhering device comprises a main structure, wherein the upper end of the main structure is coaxially connected with an upper structure, the upper end surface of the upper structure is uniformly provided with four sliding holes in the circumferential direction, each sliding hole is connected with an adhering structure which comprises a guide pipe, a base, a steel wire and an adhering part, one end of the guide pipe stretches into the sliding hole, the other end of the guide pipe is connected with the base, the lower end of the base is arranged on the main structure through an elastic supporting structure in parallel, the adhering part is arranged on the upper end surface of the base, and the steel wire penetrates through two ends of the guide pipe and is connected with the adhering part and the bottom part of the sliding hole; the lower end surface of the main structure is provided with a rotating motor and a rotating disc which are connected, and the rotating disc is connected with the bases through bracing wires. According to the gecko-like bionic dry adhering device disclosed by the invention, requirements on preload and relative sliding between the preload and an adhering surface in adhering are realized, a requirement that an angle between an adhering material and the adhering surface reaches 30 degree is realized in absorption removing, and the gecko-like bionic dry adhering device has the advantages that the adsorption force is larger, the adhering effect is good, repeated use can be realized, and the using range is wide.

Owner:SHANGHAI AEROSPACE SYST ENG INST

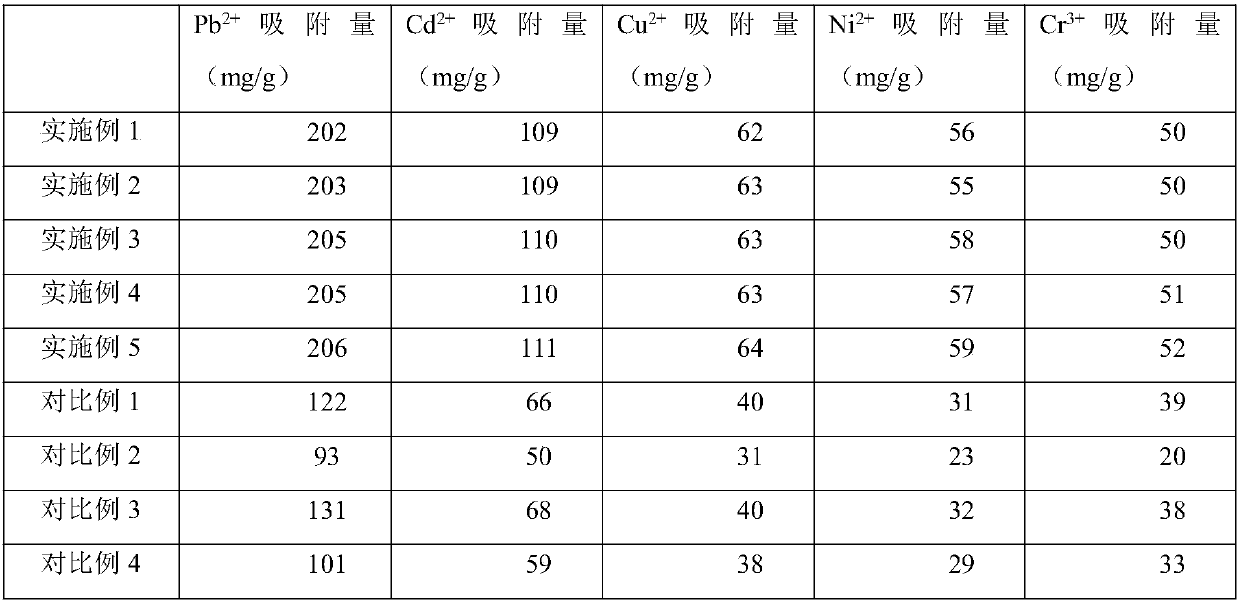

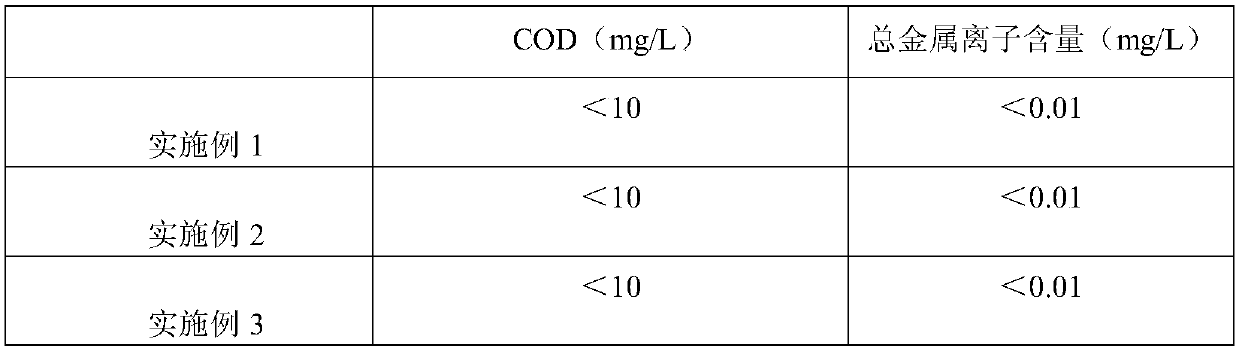

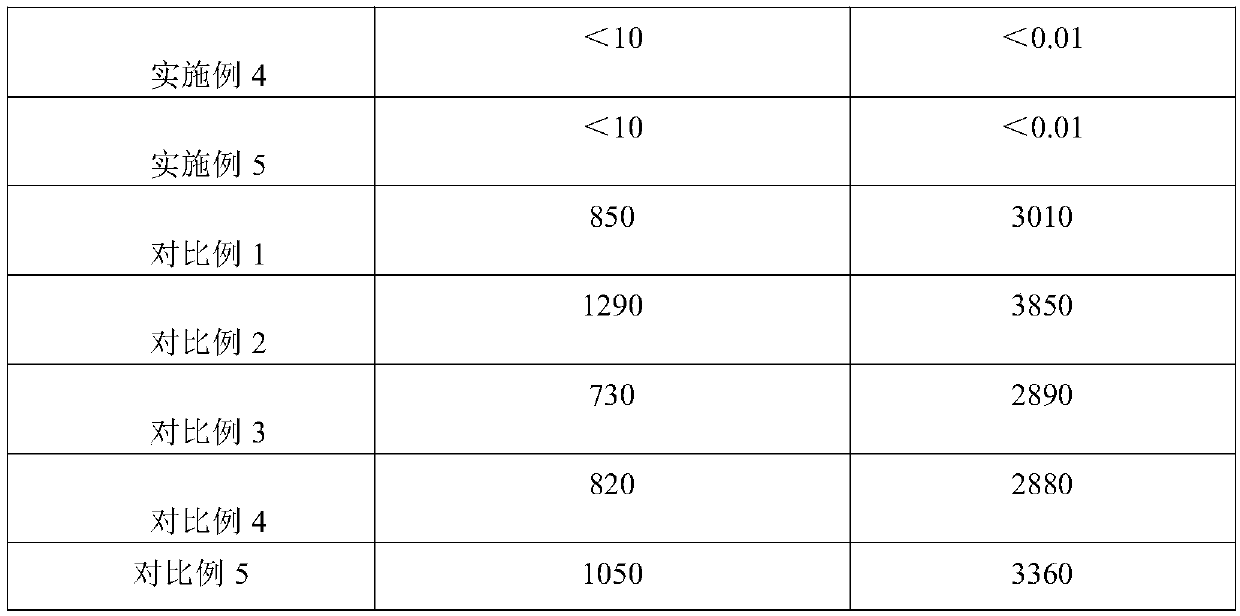

Preparation method for straw hydrogel composite material special for sewage treatment

InactiveCN105618006AImprove adsorptionLow costOther chemical processesWater contaminantsIonHeavy metals

The invention discloses a preparation method for a straw hydrogel composite material special for sewage treatment of metal ion adsorption. A hydrogel comprises the following components in parts by weight: 86 to 92 parts of polyvinyl alcohol, 0.5 to 4.0 parts of bentonite, 1.5 to 8 parts of straw and 1.0 to 2.0 parts of boric acid. Straw cellulosic fibers are adopted and added in the form of micro / nano fibrils; a nano cellulose hydrogel is an intelligent hydrogel, is a porous material, is small in pore diameter, is endowed with high water retaining capacity by the porosity, is a multifunctional adsorption material, has the characteristics of rapidness, high efficiency, high adsorption capacity and high selectivity, and has a remarkable effect on adsorbing heavy metal ions; meanwhile, the preparation process is simple, the cost is low and the operability is high, so that the hydrogel has a good application prospect in the field of sewage treatment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

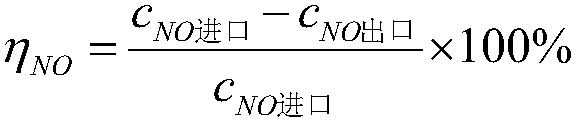

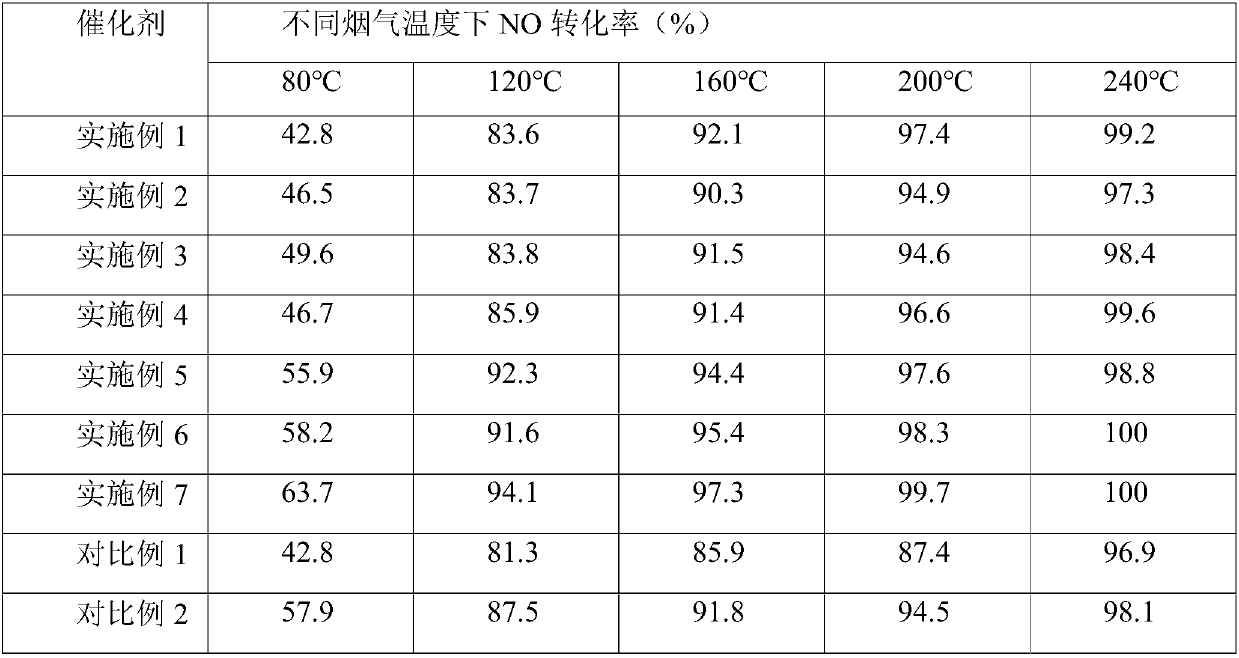

Manganese-based low-temperature flue gas denitration catalyst and preparation method thereof

PendingCN109569587AImprove adsorptionImprove denitrification activityGas treatmentDispersed particle separationFlue gasPulverised fuel ash

The invention provides a manganese-based low-temperature flue gas denitration catalyst and a preparation method thereof. The catalyst takes nitric acid modified fly ashes and TiO2 as a composite carrier, MnOx as an active component, one or more of CeO2, WO3, SnO2 and Fe2O3 as active additives, wherein the active component and the active additives are loaded on the surface of the carrier by an excess impregnation method; and the mass ratio of the catalytic active component, the catalytic additives, the fly ashes and the TiO2 is (0.05-0.15): (0.05-0.2): (0.3-0.6): (0.5-0.7). The catalyst has good low-temperature denitration activity, and thus serious environmental pollution caused by a vanadium denitration catalyst is avoided; and meanwhile, a cheap raw material of fly ashes with a wide range of sources is placed to partially replace TiO2 as the carrier, and thus the high-efficiency utilization of solid waste resources is realized, the specific surface area of the catalyst is increased,the low-temperature denitration performance is improved, and the production cost of the catalyst is reduced.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Temperature-sensitive hepatic cell culture support material and preparation method thereof

InactiveCN101914484AImprove adsorptionPromote proliferation and differentiationVertebrate cellsArtificial cell constructsCarboxylationChemistry

The invention discloses a temperature-sensitive hepatic cell culture support material and a preparation method thereof, and relates to an intelligent tissue engineering support material and technology, in particular to a temperature-sensitive hepatic cell culture support material, a method and technology. The support material is characterized in that: the surface of the material is relatively lyophobic at the temperature of 37 DEG C and is suitable for cell adherence / spreading and cell propagation, but the surface is hydrophilic at the temperature of 32 DEG C, so cells are desorbed from the surface automatically. The preparation method of the cell culture support material comprises the following steps of: (1) surface cleaning; (2) the temperature-sensitive carboxylation modification of a TCPS surface; (3) the preparation of amido lactobionic acid (L-NH2); and (4) the saccharifying modification of the TCPS surface. Through the preparation method, the biocompatibility and cell-bound loci of the support material are enhanced, the adsorption rate of the cells on the material surface is increased, and the intelligent support material which is suitable for hepatic tissue engineering is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

Smoke-content-reducing fragrant base paper of tipping paper with addition of nano kieselguhr and preparation method thereof

ActiveCN104213460AReduce smokeImprove adsorptionSynthetic cellulose/non-cellulose material pulp/paperInorganic compound additionAnhydrous sodium pyrophosphateChemistry

The invention discloses a smoke-content-reducing fragrant base paper of a tipping paper with addition of nano kieselguhr and a preparation method thereof. The base paper is prepared from following raw materials comprising, by weight, 125-140 parts of softwood pulp, 68-80 parts of bleached straw pulp, 1-2 parts of polylactic acid fiber, 0.3-0.5 parts of anhydrous sodium pyrophosphate, 3-4 parts of cinnamomum camphora leaves, 2-3 parts of kiwi leaves, 0.6-1 part of lignin, 1.5-2 parts of the nano kieselguhr, 1-2 parts of charophyte essential oil, 1.5-2 parts of spirulina platensis powder, 0.9-1.2 parts of seaweed glue, 0.8-1 part of an alkyl-ketene dimer and 3-4 parts of a mixed spice. In the invention, the nano kieselguhr is added to the raw materials of the base paper, wherein the nano kieselguhr has important functions in reduction of smoke and increase of adsorption. By means of the mixed spice, the base paper is refreshing, pungent smoke and odor of a cigarette is improved, and mouth is maintained to be refreshing. The base paper of the tipping paper is uniform in coating, is good in waterproof performance and breathability, is high in tensile strength and is suitable for high-quality cigarettes.

Owner:浙江恒成高分子材料股份有限公司

Preparation method of modified montmorillonite adsorbent for treating zinc-bearing wastewater

InactiveCN106423045AImprove adsorptionWide range of raw materialsOther chemical processesWater/sewage treatment by sorptionIonPre treatment

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Capacitor impregnant containing modified argil and preparation method thereof

The invention discloses a capacitor impregnant containing modified argil and a preparation method thereof. The capacitor impregnant comprises the following raw materials by weight: 103-108 parts of salad oil, 4-6 parts of modified argil, 2-4 parts of modified tree ash, 0.8 part to 1.2 parts of siliceous shale, 0.7-0.9 part of attapulgite and 0.1-0.3 part of stearic acid monoglyceride. The capacitor impregnant adopts the salad oil as a main material and is low in cost. Simultaneously, the modified argil, the modified tree ash, the siliceous shale the attapulgite and the stearic acid monoglyceride are added. Adsorption performance of moisture in the impregant is improved by modifying the argil and the tree ash. The capacitor impregant has good flowability and heat resistance, is free of corrosion and impurity, and is capable of effectively improving electric performance of a capacitor and prolonging service life of the capacitor.

Owner:许惠

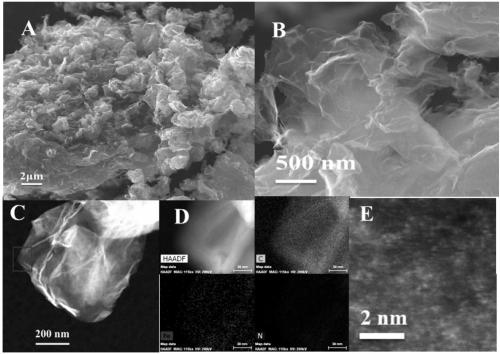

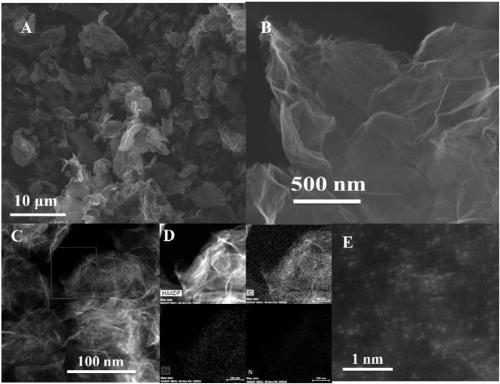

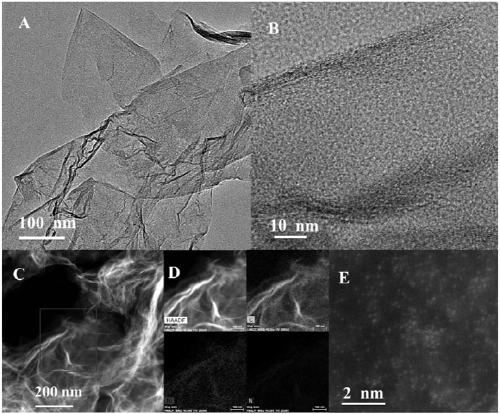

Metal single atom doped graphene preparation method

The invention relates to the field of metal single atom doped carbon materials, in particular to a controllable-supporting-amount metal single atom doped graphene preparation method. Surface functionalized graphene serves as a matrix, organic atomic dispersion metal salts including carbon nitride, melamine, amino acid, thiourea, urea, dicyandiamide, polyvinylpyrrolidone and the like serve as intermediates, and pyrolysis is performed in a protective atmosphere to obtain a series of metal single atom doped graphene structures. The method has advantages that graphene serves as the matrix, atomicmonodispersion of metal salts is realized by organics, and metal single atom doped graphene controllable in content and type is finally obtained through secondary pyrolysis. By the method, problems oflow doping amount, proneness to aggregation, uncontrollability and the like of metal single atoms are effectively solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

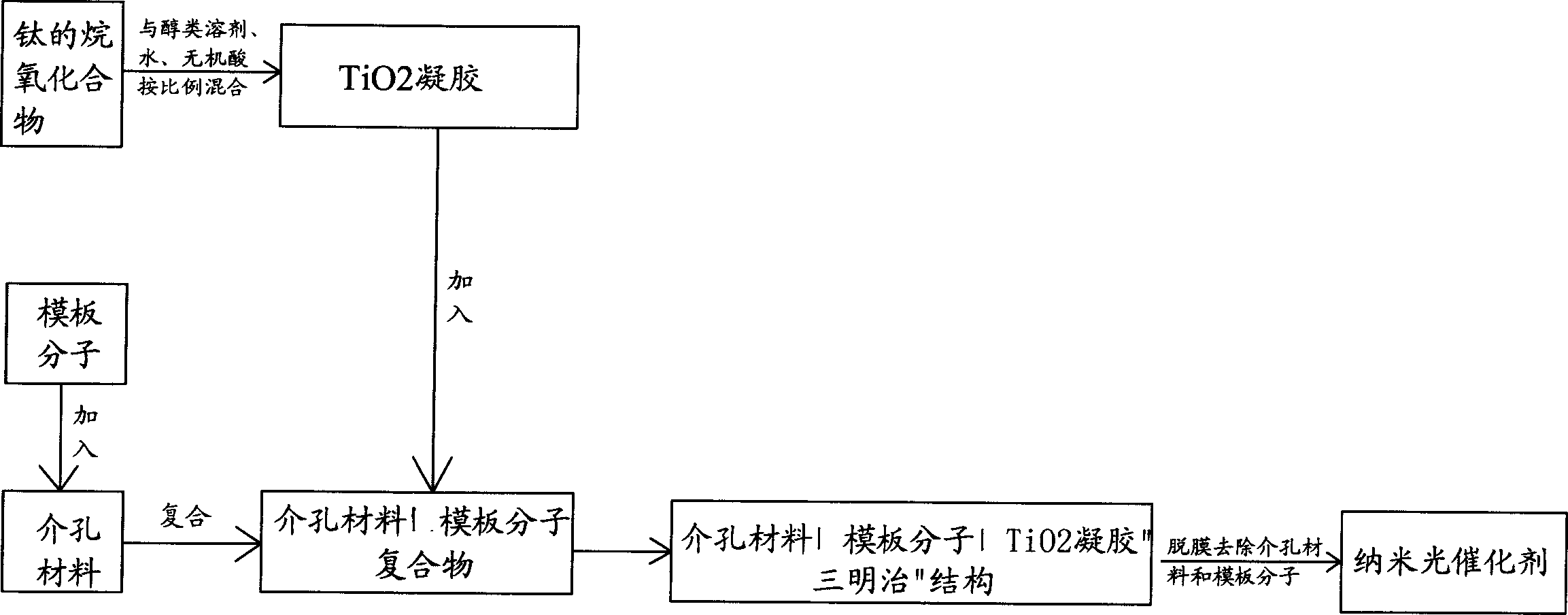

Nano photocatalyst of possessing function of molecular engram, preparation method and usage

InactiveCN1915487AImprove adsorptionReduce the concentration of gaseous pollutantsCatalyst carriersDispersed particle separationStereochemistryIndoor air quality

A nano-photocatalyst with molecular engram function has a 3D pore structure matched fully with the space structure of the compounds in formaldehyde or benzene system and combined specifically with them. It can be used to improve indoor air by adsorbing and degradating said compounds. Its preparing process is also disclosed.

Owner:ZHEJIANG UNIV

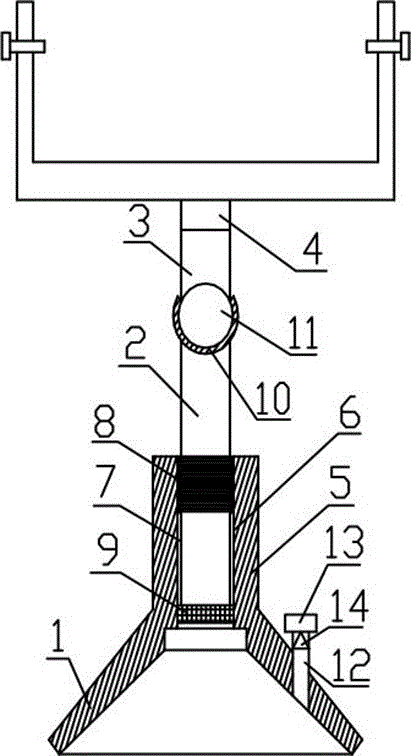

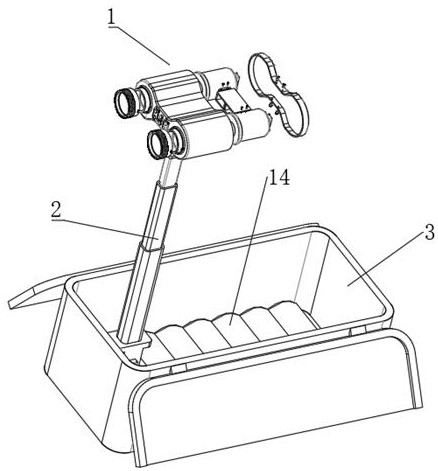

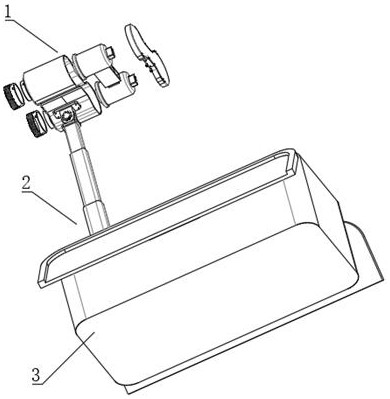

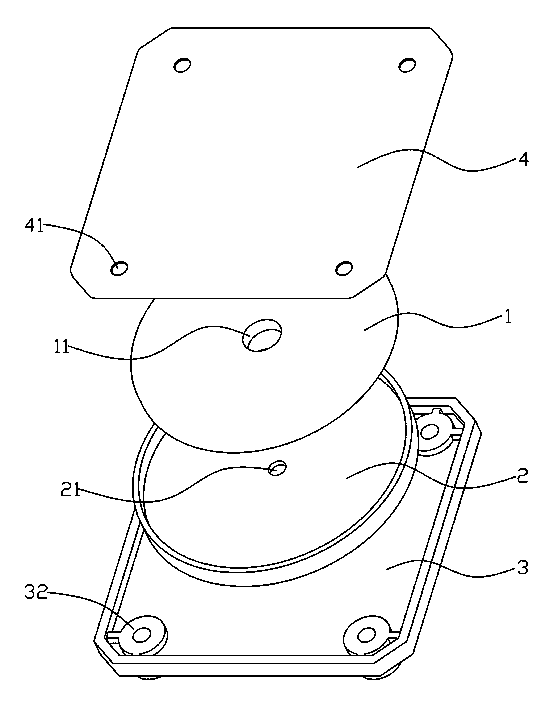

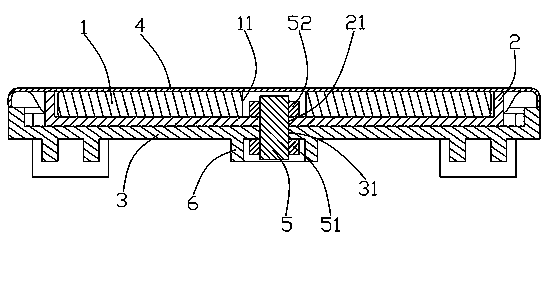

Navigator bracket adopting vacuum sucker

InactiveCN106143337AImprove adsorptionSimple and efficient operationVehicle componentsPistonReciprocating motion

The invention discloses a navigator bracket adopting a vacuum sucker. The navigator bracket comprises the vacuum sucker, a sucker connecting rod, a navigator connecting rod and a fixation support used for fixing a navigator, wherein the vacuum sucker, the sucker connecting rod, the navigator connecting rod and the fixation support used for fixing the navigator are sequentially connected. A flange is vertically arranged on the surface, opposite to an absorption end face, of the vacuum sucker, a through hole is formed in the flange, the through hole is communicated with an absorption concave face, a sucker duct is arranged in the through hole, and a thread is arranged at an inlet end of the sucker duct; one end of the sucker connecting rod is inserted into the sucker duct by being matched with the thread, and is fixedly connected; a piston is arranged at the tail end, inserted into the sucker duct, of the sucker connecting rod; the piston makes reciprocating motion in the sucker duct. According to the navigator bracket adopting the vacuum sucker, the air in the vacuum sucker can be discharged outside by means of the reciprocating motion of the piston in the sucker duct, so that the adsorption capacity of the sucker is effectively improved; the navigator bracket adopting the vacuum sucker is simple in structure and convenient to operate, and can be repeatedly disassembled, thus being economical and practical.

Owner:成都康普斯北斗科技有限公司

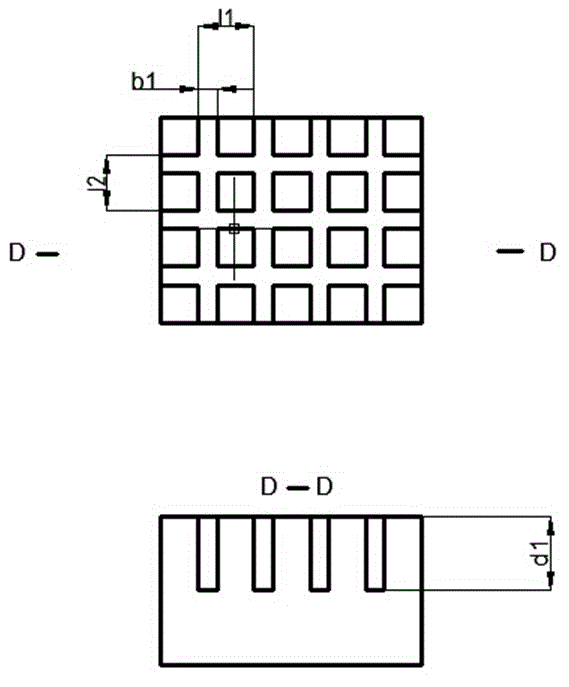

Method for preparing non-smooth surface of alloy substrate

InactiveCN104878189AImprove adsorptionHigh hardnessMetallic material coating processesAlloy substrateCorrosion resistant

The invention relates to the field of laser processing, and particularly relates to a method for preparing a non-smooth surface of an alloy substrate. According to the adopted scheme, the method comprises the following steps: carrying out laser engraving on the surface of the alloy substrate in advance to prepare a micrometer groove with certain depth-to-width ratio; injecting carbide nano-particles into the micrometer groove, closely adsorbing the nano-particles into the groove by utilizing the size effect of the surface adsorption of nano-particles, i.e., an equilibrium adsorption constant is increases with the reduction of size; and impacting the surface of the alloy substrate by using strong pulse laser to generate a plasma shock wave on an absorption layer. According to the method, the adsorption effect of the nano-particles is further enhanced under the action of a strong shock wave, and a part of the nano-particles are implanted into the surface of the alloy substrate, so that the rigidity, friction and abrasion resistant property, corrosion resistant property and the like of the surface of the alloy substrate are greatly enhanced.

Owner:JIANGSU UNIV

Automobile exhaust detecting and treating system

InactiveCN106894863AAvoid harming human healthImprove adsorptionInternal combustion piston enginesExhaust apparatusExhaust gasAutomotive engineering

The invention discloses an automobile exhaust detecting and treating system. The automobile exhaust detecting and treating system comprises an automobile exhaust detector, wherein the automobile exhaust detector is arranged at a gas inlet; the gas inlet is connected with an exhaust treating device; a flushing device and a gas return pipe are respectively arranged on two sides of the exhaust treating device; a gas outlet is formed in the other side of the exhaust treating device; filter screens are respectively arranged on the gas inlet and the gas outlet; each filter screen is filled with activated carbon; the filter screens are arranged on the inner side of the flushing device; by the exhaust treating device, HC, CO and nitrogen oxide in exhaust are converted into non-toxic gas and then discharged; by the filter screens and the activated carbon, solid micro-particles in the exhaust can be adsorbed; and by the gas return pipe and the automobile exhaust detector on an opening of the gas return pipe, the automobile exhaust can be discharged if the automobile exhaust is qualified, and if the automobile exhaust is not qualified, the automobile exhaust continues being treated by the exhaust treating device; and finally, by the flushing device, impurities in the activated carbon can be flushed away, and soot particles adhered to the exhaust treating device can also be flushed away.

Owner:HANGZHOU POLYTECHNIC

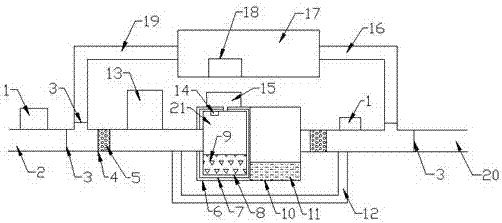

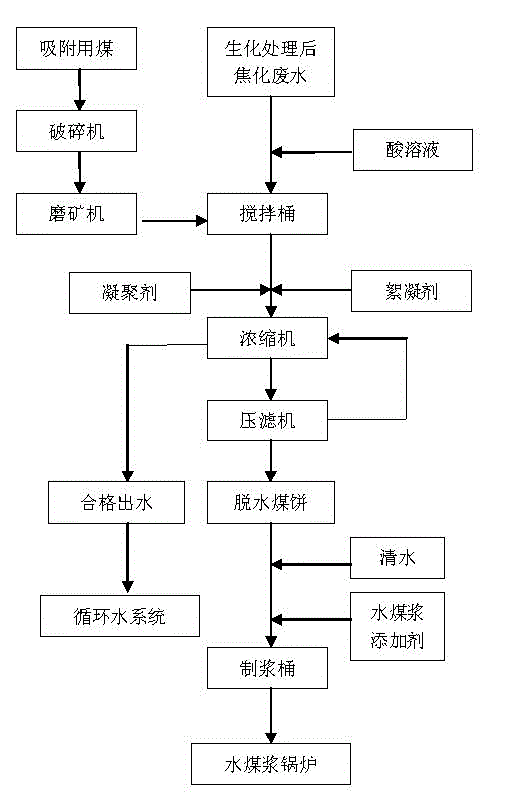

Method for deep treatment of biochemical tail water of coking wastewater

ActiveCN104556483AImprove adsorptionReduce dosageMultistage water/sewage treatmentChemical industryChemistry

The invention discloses a method for deep treatment of biochemical tail water of coking wastewater. The method comprises the following steps: 1, pulverizing and grinding coal for absorption to obtain coal powder; 2, adding an acid solution into biochemically treated coking wastewater, regulating the pH value of a water body to 2-6, then adding the coal powder, and agitating and mixing to obtain agitating products; 3, separating the solid agitating product from the liquid agitating product to obtain a dehydrated coal cake and effluent; preferably, adding polyaluminium sulfate and polyacrylamide into the agitating products, carrying out concentrating treatment by a concentrator to obtain overflow water and concentrated bottom flow, carrying out filter pressing and dehydration on the concentrated bottom flow to obtain filtrate and the dehydrated coal cake, returning the overflow water back to the concentrator, and obtaining final effluent by the concentrator. Through the change of the existing forms of complexing macromolecules in the waste water in an acid environment, the coal powder absorbing function is improved, and the use quantity of the coal powder is reduced. The effluent indexes reach the requirements of Emission Standards of Pollutants for Coking Chemical Industry (GB16171-2012).

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Activation of brown coal humic acid and preparation method of slow-release coated organic fertilizer thereof

InactiveCN107337510AImprove adsorptionImprove sustained release performanceOrganic fertilisersLayered/coated fertilisersIonAmmonium hydroxide

The invention discloses activation of brown coal humic acid and a preparation method of slow-release coated organic fertilizer thereof. Oxidation of brown coal is conducted through nitric acid, so that the content of the brown coal humic acid, the number of carboxy group on the surface and the adsorptivity to ammonium ion are improved; biological activation of the brown coal humic acid is conducted through zymin, so that the the brown coal humic acid is degraded into small molecular; by means of ammonium hydroxide, a series of reactions such as condensation, oxidation and degradation are conducted, so that nitridation and dissolution of the brown coal humic acid are conducted; proportioning of the brown coal humic acid after nitridation and dissolution, organic composted fertilizer and inorganic fertilizer are conducted to obtain granules, and the granules are coated by a coating agent made from gelatin, CMC-Na, zeolite powder and soybean oil. According to the method, not only is the slow-release performance of the organic fertilizer improved, but the fertilizer granules are stable, moisture-resistant, easy to transport and of low cost; the use ratio of the brown coal is effectively improved, the brown coal humic acid is degraded into small molecular, the hydrophilia is improved, the fertilizer efficiency is significantly improved, technology is simple, the cost is low, and large-scale production can be conducted.

Owner:安徽省瑞森生物科技有限责任公司

Wastewater treatment agent prepared from ceramic wastes

InactiveCN108126668APore structure is stableImprove adsorptionOther chemical processesWater/sewage treatment by sorptionMuffle furnaceScrap

The invention discloses a wastewater treatment agent prepared from ceramic wastes. Raw materials for preparing the wastewater treatment agent prepared from the ceramic wastes include the ceramic wastes and an organic carbon source. A preparation method of the wastewater treatment agent includes the following steps: using the organic carbon source to prepare an aqueous organic carbon source solution; adding the ceramic wastes into the aqueous organic carbon source solution, performing uniform stirring, transferring the obtained mixed solution into a hydrothermal kettle, carrying out a hydrothermal reaction, and washing, drying, grinding and sieving the obtained product to obtain a preliminary wastewater treatment agent; and transferring the preliminary wastewater treatment agent into a muffle furnace, sintering the preliminary wastewater treatment agent, and grinding, crushing and sieving the obtained product to obtain the wastewater treatment agent. The novel wastewater treatment agentand the preparation method thereof are provided on the basis of secondary recycling of the ceramic wastes, so the wastewater treatment efficiency is improved, the production cost of the wastewater treatment agent is reduced, and no new pollution sources are introduced.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

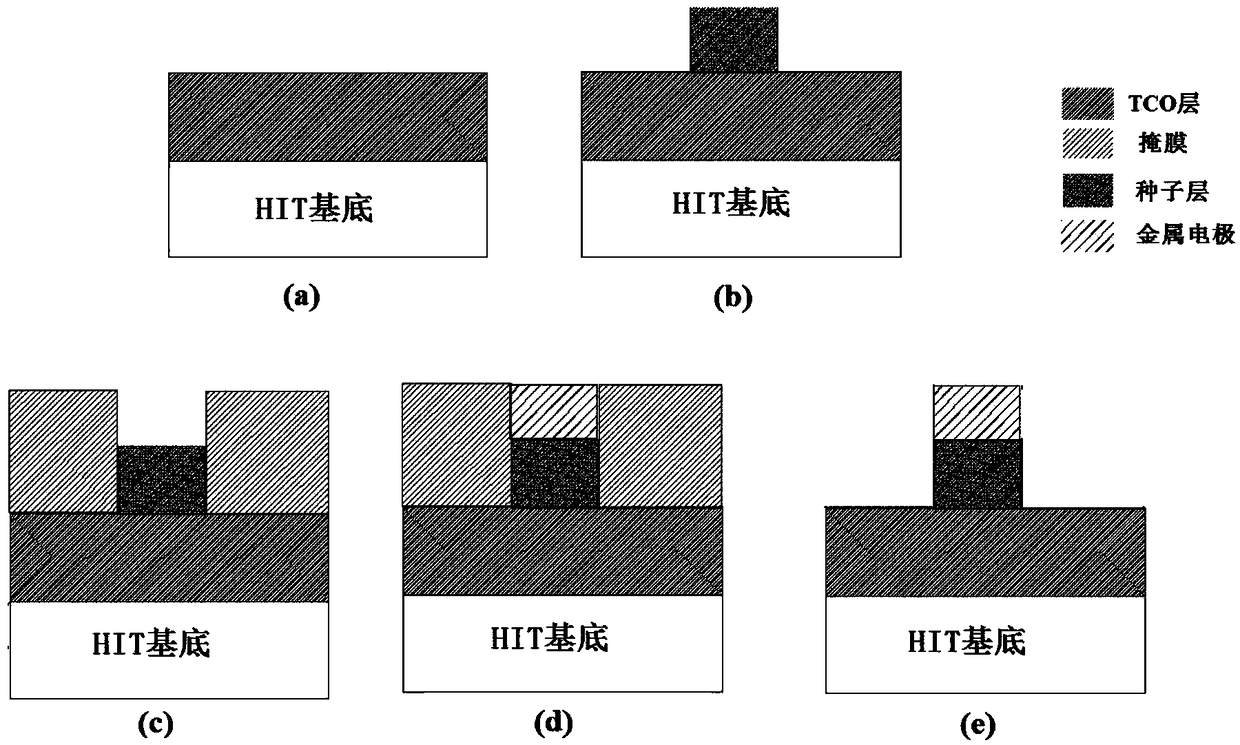

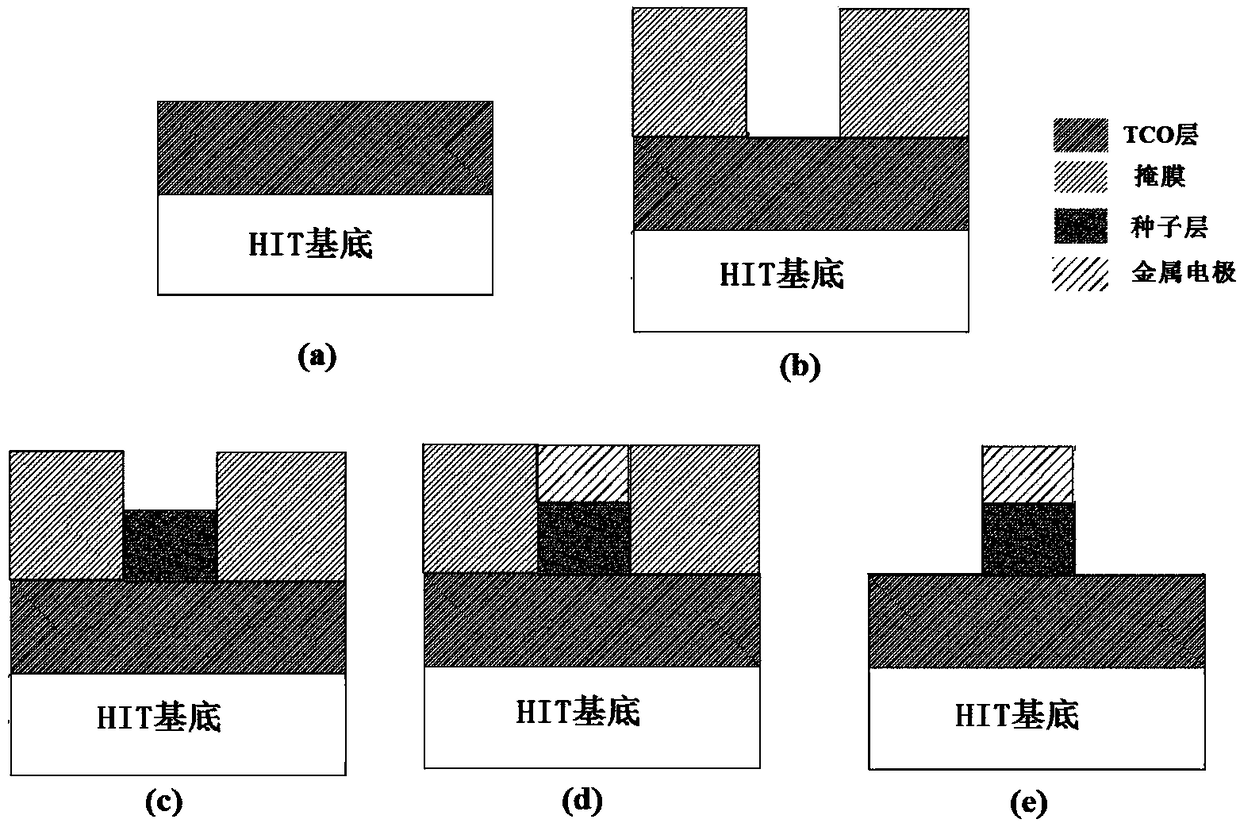

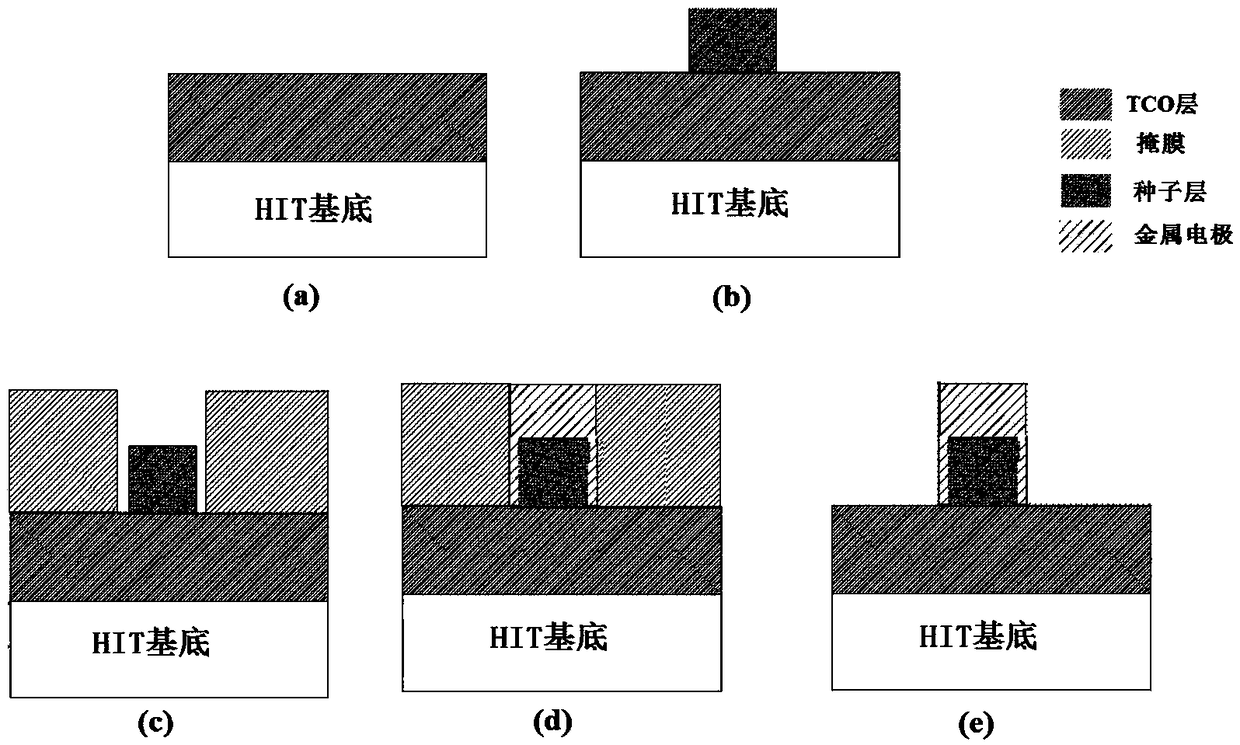

Heterojunction solar cell having electroplated electrode and preparation method thereof

InactiveCN108400175AImprove adsorptionReduce process difficultyFinal product manufacturePhotovoltaic energy generationHigh absorptionSolar cell

The invention discloses a preparation method of a heterojunction solar cell having an electroplated electrode. The preparation method comprises steps that S01, a transparent conductive thin film layeris prepared on the substrate of the heterojunction solar cell; S02, a metal seed layer is formed on a part of the transparent conductive thin film layer, and graphical masks are formed on the two sides of the metal seed layer; S03, metal is electroplated on an opening between the graphical masks; S04, the masks are removed. The invention also discloses the heterojunction solar cell having an electroplated electrode, which is prepared by adopting the above mentioned preparation method. The heterojunction solar cell having an electroplated electrode and the preparation method thereof are advantageous in that under a precondition of guaranteeing high absorption force between the electroplated metal and a TCO layer, the etching step of the seed layer is saved, and the etching on the TCO layer is prevented, and therefore the technological difficulty of the batch production of the solar cells is reduced, and liquid waste emission is reduced.

Owner:SUZHOU SUNWELL NEW ENERGY CO LTD

Mineral cotton fiber filter paper for fuel filter and preparation method for mineral fiber filter paper

ActiveCN102912679AImprove adsorptionImprove adsorption performanceNon-macromolecular organic additionReinforcing agents additionActivated carbonLignosulfonates

The invention discloses mineral cotton fiber filter paper for a fuel filter and a preparation method of the mineral fiber filter paper. The mineral fiber filter paper comprises, by weight, 50-60 parts of bamboo pulp, 40-50 parts of mineral cotton fiber, 10-20 parts of glass fiber, 2-5 parts of zeolite molecular sieve, 1-3 parts of sodium bentonite, 2-4 parts of modified calcium carbonate, 1-2 parts of modified activated carbon, 2-3 parts of polyvinyl acetate emulsion, 1-2 parts of nanometer aluminum oxide, 0.5-0.8 part of triphenyl phosphate, 3-4 parts of coumarone resin, 0.5-1 part of lignosulfonate, 0.5-1 part of silane coupling agent DL602, 0.4-0.8 part of sodium lauryl sulfate, 0.5-1 part of antioxygen DLTP, and 4-6 parts of wet strength agent PAE (polyamide epichiorobydrin resin). The mineral cotton fiber filter paper prepared is good in water permeability, large in filtering area, small in maximum hole diameter, high in filtering precision, strong in bursting strength, high in temperature resistance and water resistance and the like, has stable performance index under normal-temperature and high-temperature working conditions and is provided with good temperature resistance and filtering effects, and filtering efficiency of the mineral cotton fiber filter paper can reach to 99.95%.

Owner:ANHUI PHOENIX INT CO LTD

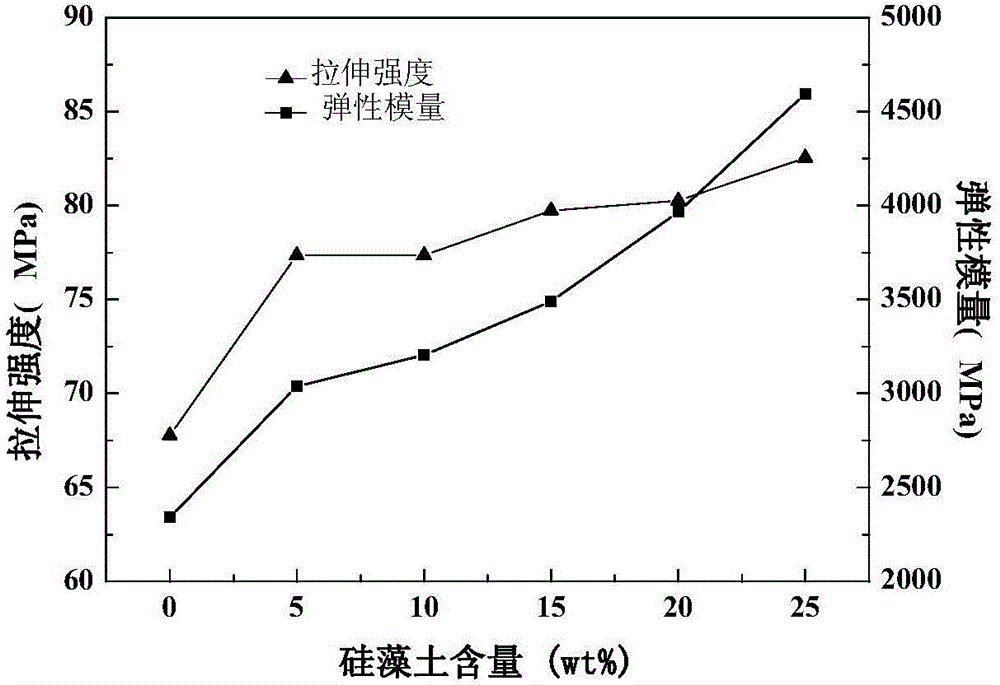

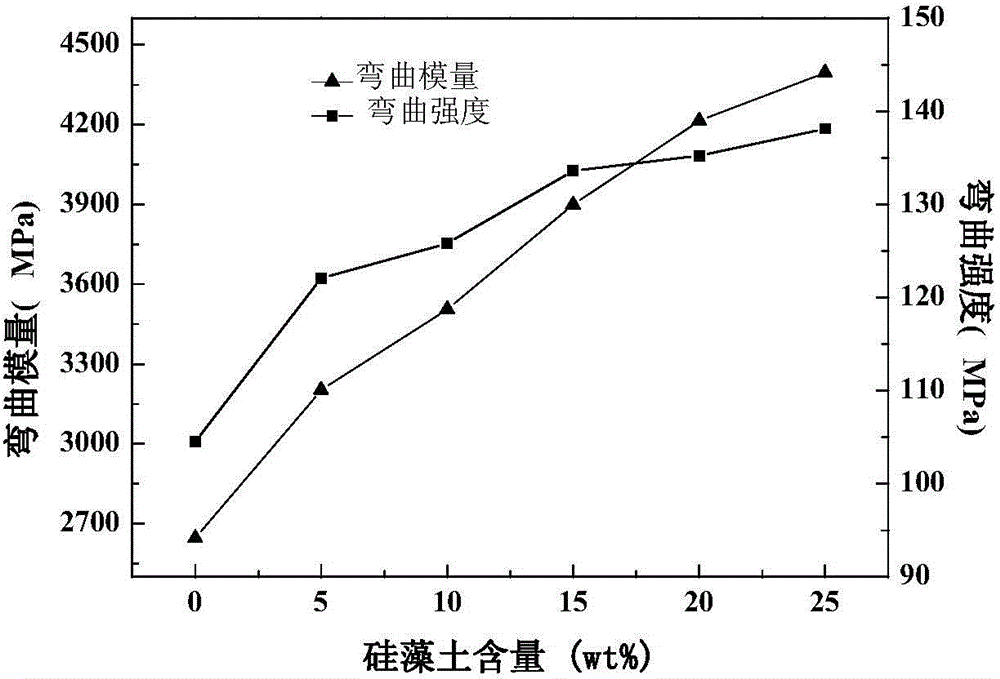

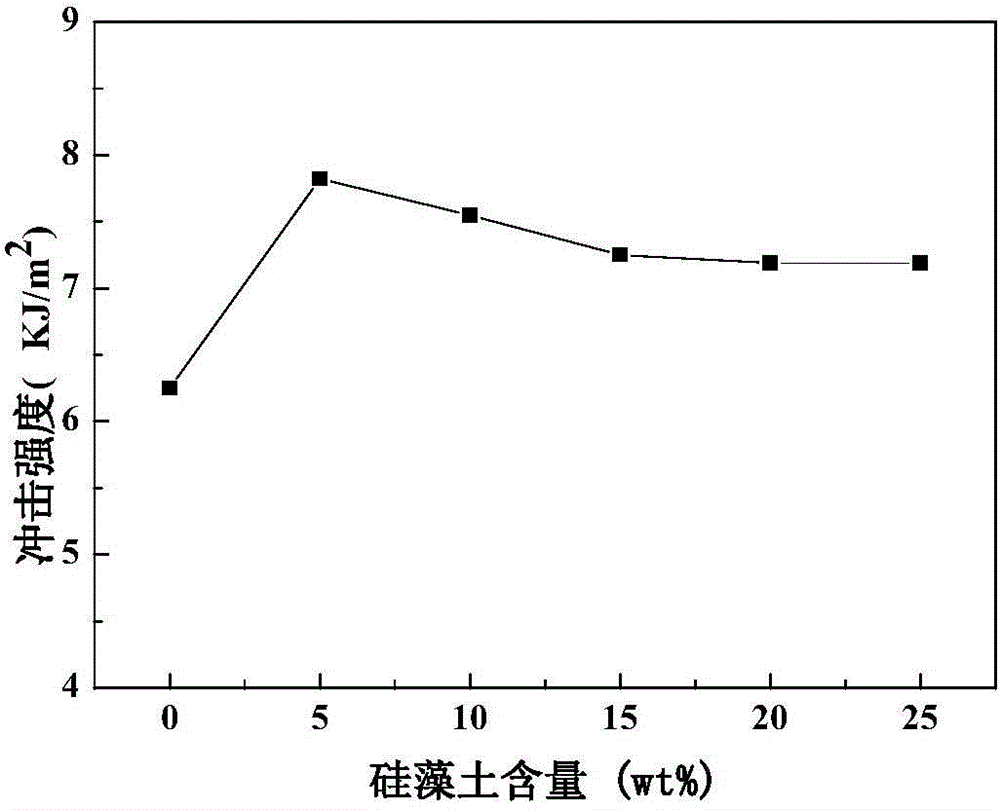

Diatomite/nylon-6 composite material and preparation method thereof

The invention discloses a diatomite / nylon-6 composite material and a preparation method thereof, and belongs to the field of plastic filling modification. The composite material is composed of 70 to 95% of nylon-6 and 5 to 30% of diatomite; wherein the particle size of diatomite is 5 to 40 [mu]m, and the diatomite is processed by a surfactant. The preparation method comprises the following steps: drying diatomite, processing the dried diatomite by a surfactant through a dry-process technology, wherein the surfactant accounts for 0.2 to 1 wt% of the weight of diatomite; pre-mixing nylon-6 and processed diatomite according to a certain formula, adding the premix into a double screw extruder, mixing, cooling by water, and granulating to obtain the composite material. The nylon-6 is modified by filling diatomite, the strength, modulus, toughness, and thermal deformation temperature of nylon-6 are all enhanced, the cost is reduced, the using amount of nylon-6 is reduced, the energy is saved, and the environment is protected. Moreover, the application range of diatomite is enlarged, and the utilization value of diatomite is increased.

Owner:BEIJING UNIV OF CHEM TECH +1

Method for extraction of bilirubin from bile

The invention provides a method for extraction of bilirubin from bile. The method includes: firstly taking fresh pig bile, adding sodium bisulfite and ammonium sulfate to conduct hydrolysis for 3-8h; then adding a certain amount of macroporous resin into the hydrolysate to conduct adsorption for 2-4h; then washing the resin subjected to adsorption treatment with a hot ethanol-chloroform mixed solution repeatedly, further adding a small amount of sodium bisulfite into the washing solution, conducting standing for 10-30min, and flushing the obtained mixture with a small amount of tepid 95% ethanol and distilled water repeatedly; and finally subjecting the filtrate to vacuum drying and crystallization, thus obtaining bilirubin crystal grains. The method provided by the invention utilizes the adsorption effect of macroporous resin to extract bilirubin and has no damage to bilirubin, the process is simple, and the extracted bilirubin product has high yield and high purity.

Owner:TIANYIYANG TIANJIN BIO SEPARATION ENG TECH CO LTD

Obstacle-crossing multifunctional wall-climbing robot

The invention relates to an obstacle-crossing multifunctional wall-climbing robot. The obstacle-crossing multifunctional wall-climbing robot is technically characterized in that the robot comprises amiddle platform, two vehicle bodies and two limiting knuckles, the two vehicle bodies are completely of the same structure and are symmetrically installed on the two sides of the middle platform through the limiting knuckles, and the two limiting knuckles are both two-freedom-degree limiting knuckles and allow the two vehicle bodies to have two rotation freedom degrees relative to the middle platform. The obstacle-crossing multifunctional wall-climbing robot is reasonable in design, the obstacle-crossing capacity is good, meanwhile, the load capacity is strong, the adaptability to the wall surface form and the curvature change is good, the robot can be quickly detached, transported and installed and easily and conveniently controlled to move and make a turn, and the requirements for motionand operation in the complicated environment can be met.

Owner:HEBEI UNIV OF TECH

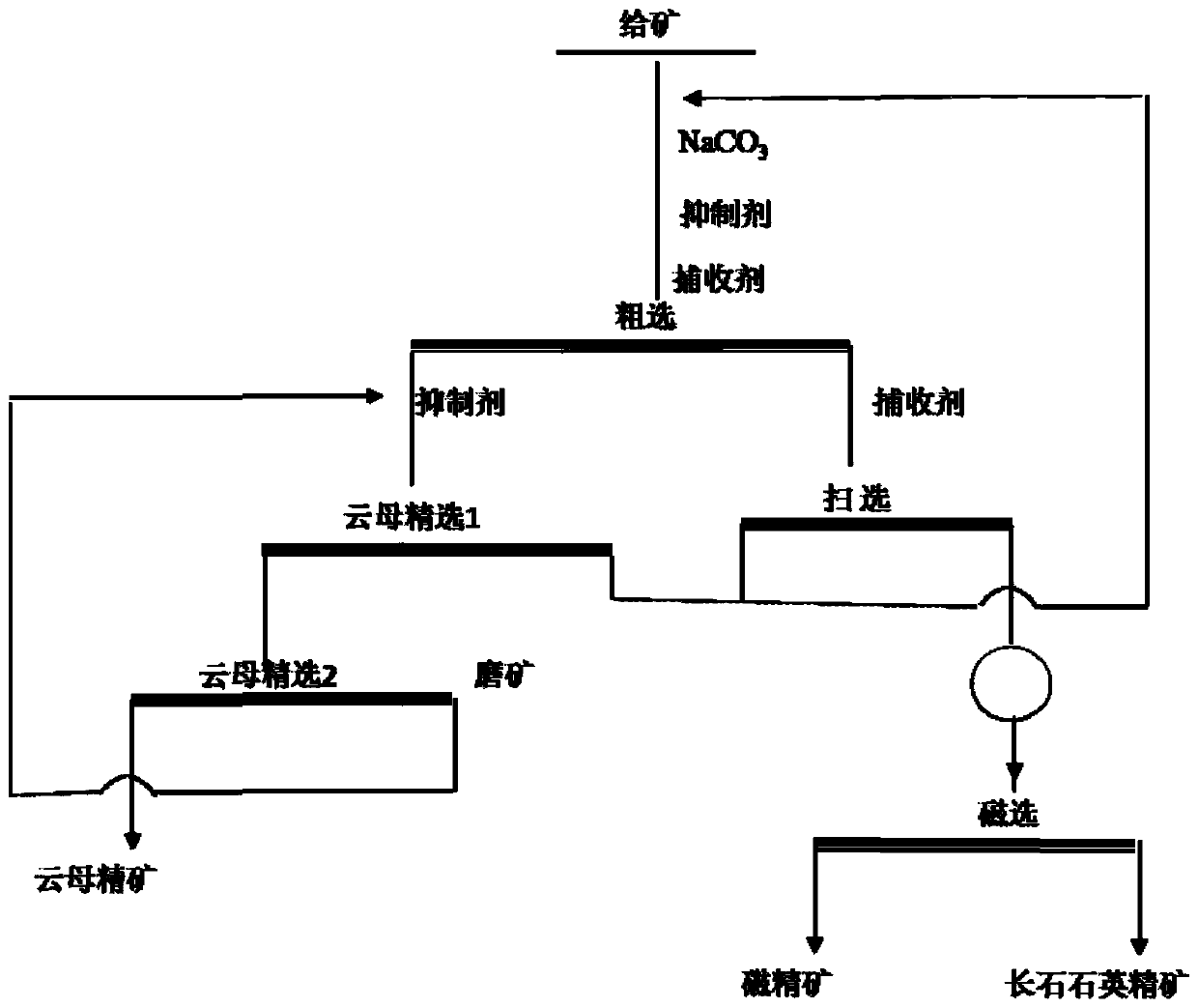

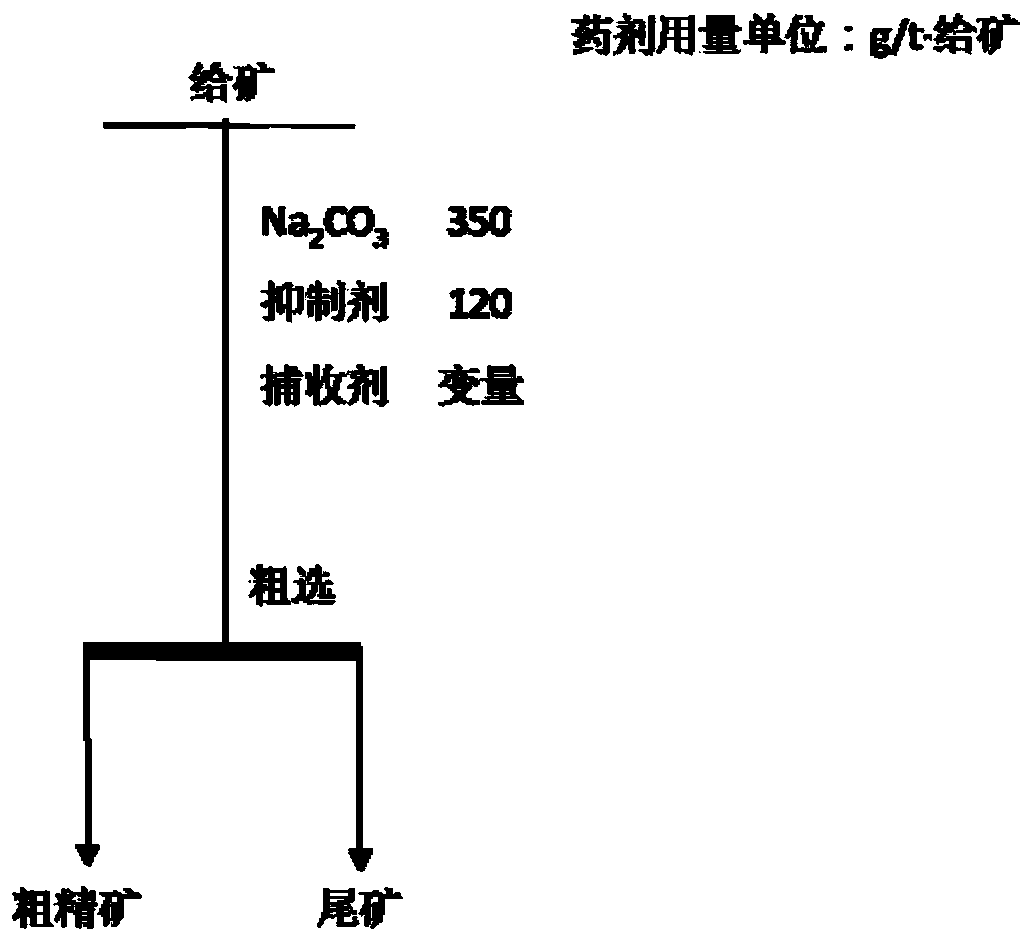

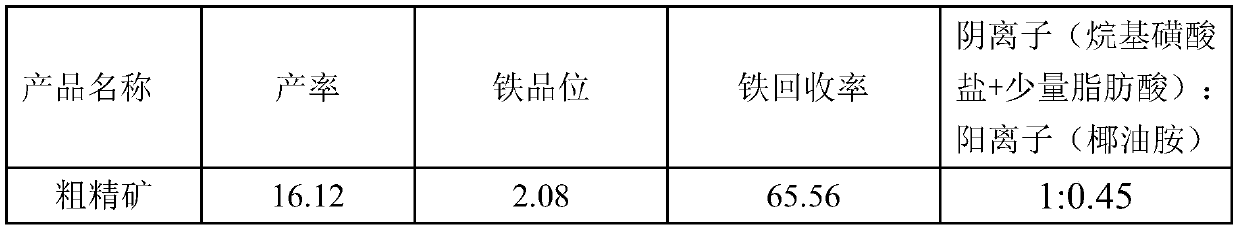

Method for recovering mica and feldspar quartz from rare metal beneficiation tailings

ActiveCN111389598AImprove adsorptionGood choiceFlotationWet separationOre concentrateBuilding material

The invention provides a method for recovering mica and feldspar quartz mixed minerals from rare metal beneficiation tailings, mica and feldspar quartz are floated and recovered by adopting a high-efficiency environment-friendly novel inhibitor and a collecting agent, the test process comprises roughing, scavenging, ore grinding and strong magnetic separation, and the magnetic separation tailingsare feldspar quartz minerals. The feldspar quartz mineral recovery rate can reach 90% or above, the iron content is smaller than 0.08%, the sintering whiteness is 65 or above, and the feldspar quartzmineral can be used as a high-quality raw material in ceramic and glass industries. The mica concentrate can be used as filler, and the magnetic concentrate can be applied to building materials. The method is simple in technological process, the wastewater can be recycled after being simply treated, and tailing-free mine tailings can be achieved.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Modified zeolite-iron oxide mixed soil in-situ repairing agent and preparation method thereof

InactiveCN107931317AImprove adsorption capacityImprove adsorptionContaminated soil reclamationBrown iron oxideHeavy metals

The invention discloses a modified zeolite-iron oxide mixed soil in-situ repairing agent and preparation method thereof. The modified zeolite-iron oxide mixed soil in-situ repairing agent is made of zeolite, organic matters, ferric chlorides, coal ashes and other raw materials and mixes with water to form nano-iron oxides, and further mixes with a mixed system of organic matters and zeolite whichare low in price and easy to get on this basis to shape multi-polymers; and interior microcellular structure can be retained to improve absorbability to soil pollutants, through cooperative combination of the interior microcellular structure and the absorbability, specific surface area is greatly increased, pollutant-absorbing species are enlarged, and the absorbing efficiency for heavy metals isimproved. The modified zeolite-iron oxide mixed soil in-situ repairing agent uses raw materials which are rich in reserves and cheap in price, finished products are high in reliability and has a goodgeneralizing potential at home and abroad, and particularly has a wide application prospect to composite type soil pollution of the heavy metals and the organics.

Owner:MAANSHAN JUNJUN FOOD TECH

Cement-based grouting material

The invention discloses a cement-based grouting material, and belongs to the technical field of building materials. The cement-based grouting material is prepared according to the following steps: melting asphalt powder, performing high-voltage electrostatic spinningto obtain asphalt raw threads, soaking the asphalt raw threads in a potassium permanganate solution, performing oxidation to obtain oxidized asphalt fibers, mixing nano magnesium oxide, a silane coupling agent and an ethanol solution, performing ultrasonic dispersion, adding the oxidized asphalt fibers, performing mixing under stirring, adding tetraethoxysilane dropwise, performing mixing under stirring, performing filtering, performing washing, performing drying, and performing carbonizing to obtain modified asphalt fibers; mixing aluminum powder and glycerol under stirring, adding wheat gluten powder, performing mixing under stirring, adding water, performing swelling, allowing the obtained material to stand, and performing ultrasonic dispersion to obtain a modified aluminum powder dispersion liquid; and mixing cement, quartz sand, water, a water reducing agent, fly ash, mineral powder, slag, a defoaming agent, a water retaining agent, the modified asphalt fibers and the modified aluminum powder under stirring to obtain the cement-based grouting material. The cement-based grouting material obtained by the technical scheme has the advantages of good fluidity, early-stage strength and expansion performance.

Owner:郭迎庆

Convenient-to-install computer vision protection device

ActiveCN112261278AImprove adsorptionReduce man-made damageTelevision system detailsColor television detailsEmbedded systemAcousto-optics

The invention discloses a convenient-to-install computer vision protection device in the technical field of computer vision. The convenient-to-install computer vision protection device comprises a protection mechanism for carrying out overall protection and anti-collision warning on computer vision equipment, the computer vision equipment is subjected to height adjustment and angle adjustment through the adjusting mechanism, the computer vision equipment is stored in the protection box to be stored, the camera is integrally protected through the protection mechanism outside the camera, directdamage to the camera due to external collision is avoided, the protection mechanism can be rapidly installed, and the protection effect is good. The lens cone of the camera can be rapidly maintained,and the anti-collision module carries out acousto-optic reminding on surrounding dangerous factors, so that the camera can be conveniently carried while protection is carried out.

Owner:HEFEI UNIV

Modification and reuse production method for floatation filter-pressed sludge of white manila board

The invention discloses a modification and reuse production method for floatation filter-pressed sludge of a white manila board and belongs to the field of sludge reuse. The modification and reuse production method for the floatation filter-pressed sludge of the white manila board includes the steps that the sludge is screened, heavy slag is removed, and light slag is recycled; activation adjusting is carried out, wherein poly aluminum chloride is added into the sludge, and anionic trash is removed; lotus powder is added into the sludge; retention and drainage are carried out, wherein Hansenula sinensis, poly aluminum chloride and cationic polyacrylamide are added into the sludge, and the sludge is dewatered and conditioned; paper making is carried out, wherein the sludge and pulp needing to be made into paper are mixed according to the ratio of 3:50, and paper is made with the pulp. In the whole process, the sludge is purified, residual fibers in the sludge are utilized to the maximum degree, and environmental friendliness and resource utilization maximization are achieved.

Owner:LIANSHENG PAPER IND LONGHAI

Process for treating heavy metal wastewater

InactiveCN109592738AShort timeImprove adsorptionWater contaminantsWater/sewage treatment by flocculation/precipitationTreatment effectHeavy metals

The invention provides a process for treating heavy metal wastewater, which can realize heavy metal wastewater treatment in a relatively short time by preparing a magnetic treatment preparation. By adopting the process, after solid and liquid are separated, effluent can achieve the national drainage standard and can be directly drained, sludge is electrolyzed to realize heavy metal reclamation, the used treatment preparation can be separated by utilizing a magnetic separation method, and the treatment preparation can be recycled after regeneration (the heavy metal wastewater treatment effect is not remarkably reduced when the treatment preparation is used repeatedly for more than 1000 times). The process is applicable to heavy metal wastewater treatment, has short time consumption, enableseffluent to accord with the national drainage standard, can realize heavy metal reclamation, and accords with the concept of environmental friendliness.

Owner:长沙如洋环保科技有限公司

Magnetic force enhancement structure

InactiveCN103700462AImprove adsorptionFixed firmlyPermanent magnetsInductances/transformers/magnets manufactureMagnetEngineering

The invention discloses a magnetic force enhancement structure, which comprises a magnet and a magnetic conducting barrel, wherein the magnet is arranged in the magnetic conducting barrel; the magnetic conducting barrel is made from a magnetic conducting material, and has a barrel-shaped structure of which the upper end is opened and the lower end is closed; the magnet and the magnetic conducting barrel are fixedly arranged on a base which is positioned below the magnetic conducting barrel. According to the magnetic force enhancement structure, the upper end of the magnetic conducting barrel is opened, the lower end of the magnetic conducting barrel is closed, the magnetic conducting barrel is made from the magnetic conducting material, and the magnet is arranged in the magnetic conducting barrel, so that a magnetic field generated by the lower end of the magnet can be conducted to an iron device above the magnet by the magnetic conducting barrel to endow the magnet with about twice magnetic attraction force and enhance the attraction force of the magnet on the iron device to more firmly fix the iron device, and the problem that the iron device falls due to insufficient attraction force of the magnet in the prior art is solved.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Green ecological foam glass and production method thereof

InactiveCN105384341AImprove adsorptionLow thermal conductivityGlass shaping apparatusCoalPulverised fuel ash

The invention provides green ecological foam glass prepared from the following raw materials in parts by weight: 75-80 parts of waste glass powder, 15-20 parts of shell powder and 0-5 parts of coal ash. The green ecological foam glass is produced by using a production method comprising the steps of 1, respectively crushing and grinding waste beer bottles and shells, and controlling the fineness, namely the screen residue of a 0.08mm square hole sieve, to be lower than 10%; 2, uniformly mixing the waste glass powder, the shell powder and the coal ash, placing the mixture into a mould in which alundum powder serving as a separant, calcining at 800-850 DEG C in a high-temperature furnace, preserving the heat for 0.8-1.2 hours, and annealing at the temperature of 500-600 DEG C; and 3, cooling the high-temperature furnace to 180-220 DEG C, taking out the mould, and demolding to obtain the green ecological foam glass. The foam glass produced by using the waste glass, shells serving as renewable resources and the coal ash has the advantages of high adsorptivity, bacterium inhibition, nontoxicity, no combustibility, small heat conductivity coefficient and energy saving so as to be a novel green ecological heat insulation material.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com