Method for recovering mica and feldspar quartz from rare metal beneficiation tailings

A rare metal, flotation tailings technology, applied in chemical instruments and methods, flotation, wet separation, etc. The effect of resource utilization efficiency, strengthening adsorption, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

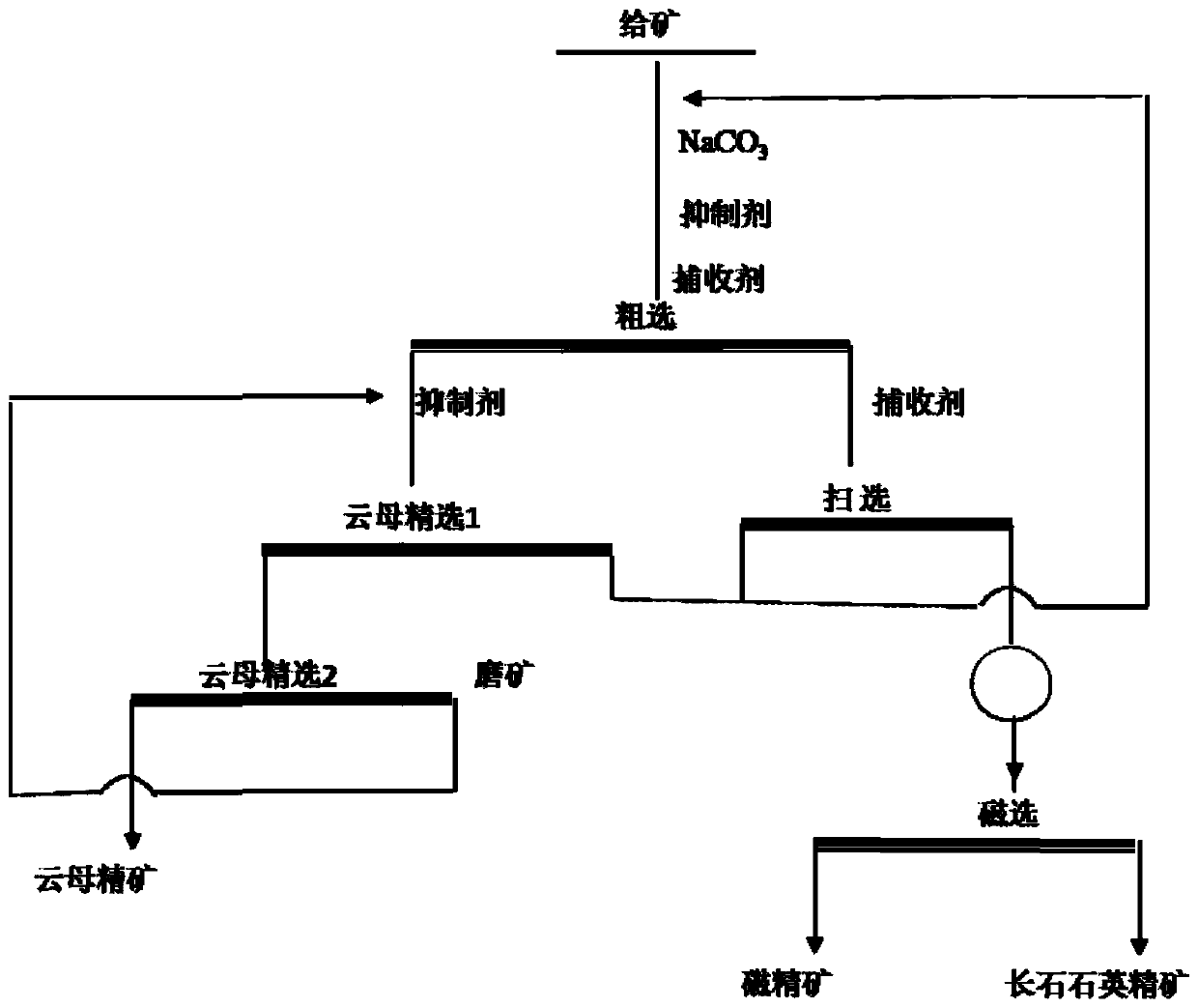

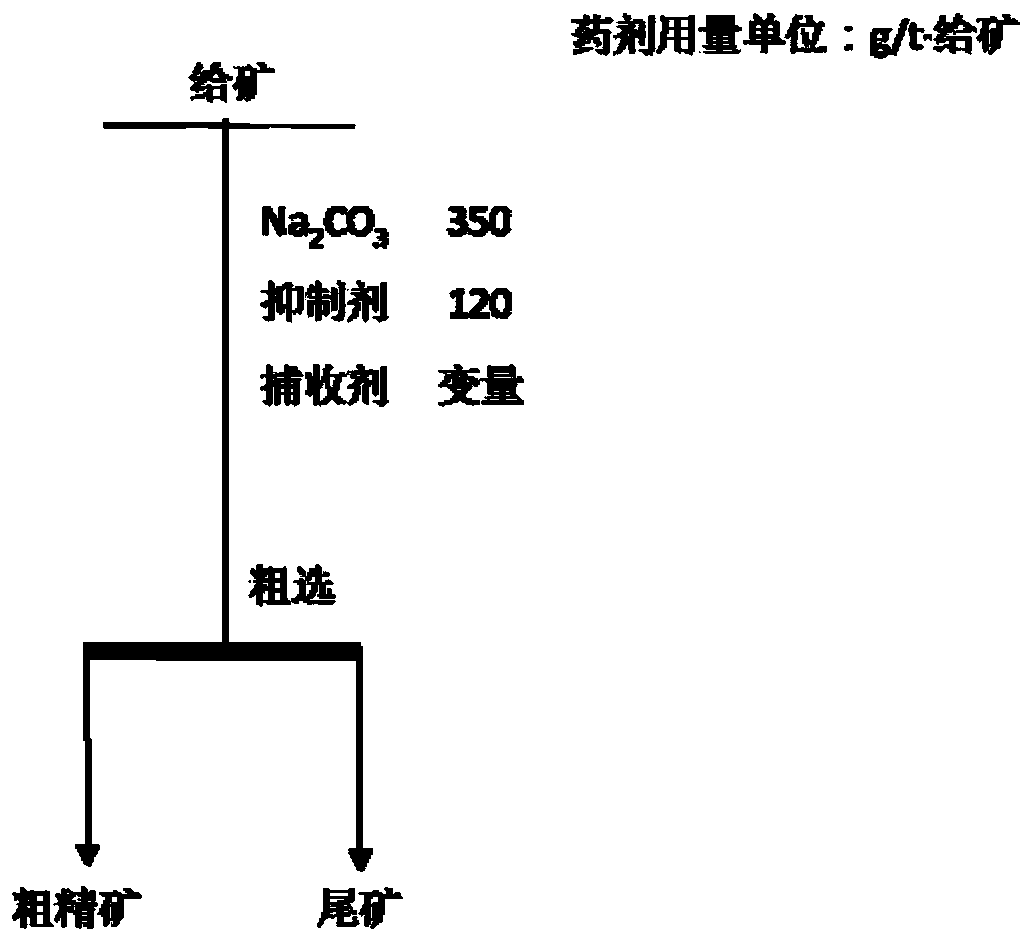

Method used

Image

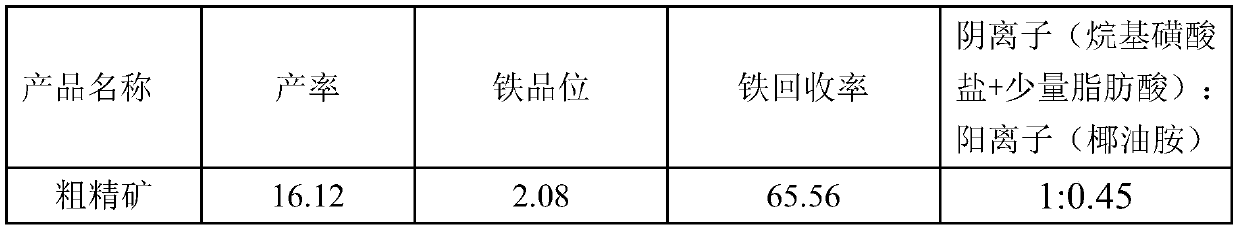

Examples

Embodiment 1

[0037] 1. Raw materials

[0038] The composition of rare metal (tantalum and niobium) beneficiation tailings in a certain place in Guangdong is shown in Table 1.

[0039] Table 1 tailings multi-element analysis results (%)

[0040] ingredients CaO MgO K 2 o

Na 2 o

al 2 o 3

SiO 2

S Fe content 0.61 0.12 4.61 2.69 15.64 63.62 0.2 1.07

[0041] The mineral composition of tailings is mainly feldspar, quartz, mica and so on. The tailings fineness -0.074mm accounts for 52.35%, the relative content of mica minerals is about 10% to 15%, the relative content of feldspar minerals is about 45% to 50%, and the relative content of quartz minerals is about 35% to 40%. The mineral content of the three minerals in the mine exceeds 95%.

[0042] 2. Key equipment: (all existing equipment)

[0043] Flotation cell, ball mill, high gradient strong magnetic separator, disc vacuum filter, 101 electric oven.

[0044] Three, the specific ...

Embodiment 2

[0055] 1. Raw materials

[0056] The composition of rare metal tailings (tantalum and niobium) in a certain place in Hunan is shown in Table 2.

[0057] Table 2 tailings multi-element analysis results (%)

[0058] ingredients CaO MgO K 2 o

Na 2 o

al 2 o 3

SiO 2

S Fe content 0.26 0.023 3.72 3.09 13.05 72.45 0.063 1.04

[0059] The mineral composition of the tailings is mainly feldspar, quartz, mica, etc., and the tailings fineness -0.074mm accounts for 71.76%. The relative content of mica minerals is about 10% to 15%, the relative content of feldspar minerals is about 35% to 45%, the relative content of quartz minerals is about 35% to 45%, and the content of the three minerals in the tailings exceeds 90%.

[0060] 2. Key equipment: (all existing equipment)

[0061] Flotation cell, ball mill, high gradient strong magnetic separator, disc vacuum filter, 101 electric oven.

[0062] Three, the specific operation proces...

Embodiment 3

[0072] 1. Raw materials

[0073] The composition of rare metal tailings (tungsten) in a certain place in Hunan is shown in Table 3.

[0074] Table 3 tailings multi-element analysis results (%)

[0075] ingredients CaO MgO K 2 o

Na 2 o

al 2 o 3

SiO 2

S Fe content 0.32 0.02 1.65 6.12 14.35 76.18 0.021 0.51

[0076] The mineral composition of the tailings is mainly quartz, feldspar, mica, etc., and the tailings fineness -0.074mm accounts for 63.41%. The relative content of mica minerals is about 11% to 13%, the relative content of feldspar minerals is about 45% to 50%, the relative content of quartz minerals is about 30% to 35%, and the content of the three minerals in the tailings exceeds 95%.

[0077] 2. Key equipment: (all existing equipment) flotation cell, ball mill, high gradient strong magnetic separator, disc vacuum filter, 101 electric oven.

[0078] Three, the specific operation process:

[0079] In this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com