Long-acting dripping fog-dissipating aging-resistant agricultural film

An anti-aging and dripping technology, applied in applications, coatings, household appliances, etc., can solve problems such as the inability to guarantee the dripping and defogging function, the consumption of manpower and material resources, and poor control of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

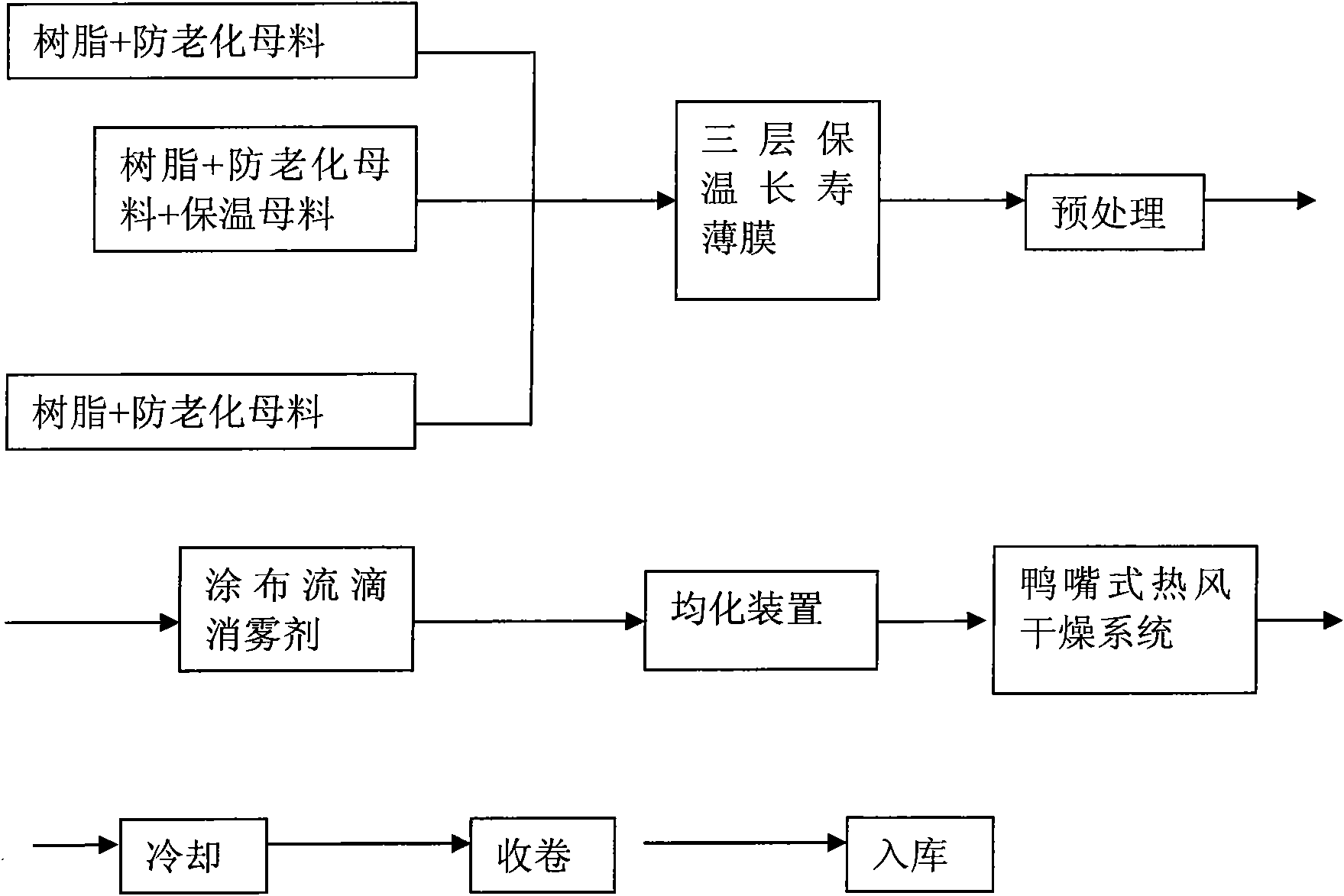

Image

Examples

Embodiment 1

[0031] The one-step method of externally-coated inorganic nanometer water-soluble dripping anti-fog liquid is used to produce long-term dripping anti-fog heat preservation and anti-aging film. The production steps are as follows:

[0032] The first step: Mix 15Kg of light stabilizer and antioxidant with 90Kg polyethylene resin, and make an anti-aging masterbatch through a twin-screw extruder; pass 50Kg of hydrotalcite and 80Kg polyethylene resin through an internal mixer and a single screw The extruder makes hydrotalcite insulation masterbatch.

[0033] Step 2: Mix 200Kg LLPE 2045 and about 20Kg anti-aging masterbatch evenly, and then add them to the inner and outer layer feeding ports of the three-layer co-extrusion blown film unit; mix 100Kg mLPE 2005, 100Kg mLPE 2010, 20Kg insulation masterbatch is evenly mixed and then added to the middle feeding port of the three-layer co-extrusion film blowing unit. A tubular film is made by a three-layer co-extrusion blown film unit, c...

Embodiment 2

[0035] Embodiment 2, using the one-step method of externally coated inorganic nanometer water-soluble dripping anti-fog liquid to produce long-term dripping anti-fog heat preservation and anti-aging film, the production process is as follows:

[0036] The first step: mix 10Kg of light stabilizer and antioxidant with 85Kg polyethylene resin, and make an anti-aging masterbatch through a twin-screw extruder; pass 20Kg of hydrotalcite and 50Kg polyethylene resin through an internal mixer and a single screw The extruder makes hydrotalcite insulation masterbatch.

[0037] Step 2: Mix 200Kg of mLLPE 2010 and about 20Kg of anti-aging masterbatch evenly and add them to the inner and outer layer feeding ports of the three-layer co-extrusion film blowing unit; mix 100Kg of mLLPE2005, 100Kg of LLPE 2045 and 15Kg of anti-aging masterbatch Materials, 25Kg insulation masterbatch are evenly mixed and then added to the middle feeding port of the three-layer co-extrusion blown film unit. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com