Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Improve stamping resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

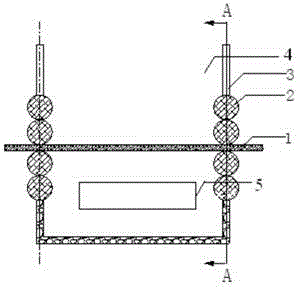

Method for carrying out one-side copper plating on wide stainless steel band and electroplating bath

ActiveCN103668374AImprove the bonding force of the coatingImprove complexation effectTanksCopper platingEnvironmental resistance

The invention discloses a method for carrying out one-side copper plating on a wide stainless steel band and an electroplating bath. The method comprises the following steps: carrying out oil removal and activation on the pre-plating surface of the stainless steel band of a substrate; carrying out nickel pre-plating and general nickel plating on the activated pre-plating surface of the stainless steel band of the substrate, and carrying out copper plating in an alkaline cyanide-free plating solution; passivating and drying the copper-plated stainless steel band. The improved electroplating bath is adopted in the copper plating process, at least two transmission rotary rollers are hermetically mounted on two groove walls at a transmission inlet and a transmission outlet of the electroplating bath respectively, and the electroplating bath can be used for guaranteeing the liquid level of the bath and preventing a plated layer of the stainless steel band from being scratched and is especially suitable for continuous one-side copper plating of the wide band-shaped stainless steel band. The method is safe, environment-friendly, low in cost and capable of carrying out high-speed one-side copper plating on the wide stainless steel band; the one-side plated layer of the stainless steel band, prepared by the method, is uniform, bright and compact in surface, good in corrosion resistance, high in electric conductivity and excellent in stamping resistance, meets the requirements of electronics and military industry, and can be industrially produced.

Owner:HUNAN YONGSHENG NEW MATERIALS

Epoxy self-leveling floor coating and preparation method thereof

InactiveCN103194136AImprove water resistanceGood oil resistanceEpoxy resin coatingsEpoxyPhysical property

The invention relates to the field of coatings, and particularly relates to an epoxy self-leveling floor coating and a preparation method thereof. The epoxy self-leveling floor coating mainly comprises a component 1 and a component 2, wherein the component 1 comprises the following ingredients by mass percent: 40-45 percent of epoxy resin, 5-15 percent of active diluent, 10-15 percent of pigment, 25-45 percent of packing, 0.5-1 percent of dispersant, 0.5-1 percent of deformer, 0.5-1 percent of flow promoter and 0.2-0.5 percent of anti-sedimentation agent; and the component 2 is a curing agent with equal equivalence to the epoxy resin. The epoxy self-leveling floor coating has good chemical properties of water resistance, oil resistance, acid resistance, alkali resistance and salt fog resistance as well as physical properties of abrasion resistance, punching resistance and washing resistance, is flat, beautiful, easily cleaned and easily repaired and maintained, and can meet all the requirements of modern industrial floor; the coating and the preparation method are coincident with the environmental protection ideas and have no harm on human bodies; and the construction is simple, the curing time does not exceed 24 hours, and the coating and the preparation method thereof have a wide application prospect.

Owner:XUZHOU HUARI CHEM IND

Thermosetting oil pollution resistant powdery paint

InactiveCN101143993AGuaranteed curingGuaranteed physical and chemical propertiesAntifouling/underwater paintsPaints with biocidesActive agentWear resistance

The invention discloses a thermosetting and anti-oil pollution powder coating, which includes 20-25 portion of polyester resin, 1-3 portion of triglycldyl isocyanuraate, 3-8 portion of barium sulfate, 2-4 portion of light calcium carbonate, 0.5-1 portion of titanium dioxide, 1.5-3.5 portion of aluminum powder, and 0.5-1 portion of active agent. Compared with the prior art, the invention has advantages of complete coating forming, thin thickness, good pigment dispersion, good flow and leveling, good appearance, and great anti-pressing, anti oil pollutant, wear resistance, washing resistance, no stain, which is widely used for steel door and window, metal surface decoration of appliances, and provide good protection for metal substrate.

Owner:ANHUI MEIJIA NEW MATERIAL

Nanometer solvent-free epoxy antirust paint and preparation method thereof

ActiveCN103709901AGood wear resistanceEasy to maintainAnti-corrosive paintsEpoxy resin coatingsSolventCardanol

The invention discloses nanometer solvent-free epoxy antirust paint and a preparation method thereof. The nanometer solvent-free epoxy antirust paint comprises the following raw material components in parts by weight: component A: 20-40 parts of E-44 epoxy resin, 5-15 parts of active diluent, 10-20 parts of zinc phosphate, 5-20 parts of mica powder, 10-20 parts of nanometer alumina, 10-20 parts of ferric oxide powder and 5-10 parts of aluminum triphosphate; component B: alicyclic amine or anacardol serving as a curing agent. The weight ratio of the component A to the component B is (6-8): 1. The nanometer solvent-free epoxy antirust paint disclosed by the invention is good in antirust property, environment-friendly, free of VOC emission, not harsh in construction conditions and low in requirements on base material, and the paint can be thickly coated once; the nanometer solvent-free epoxy antirust paint can be widely applied to a variety of fields, for example, bridge, guardrail steel structure, building material, machinery, etc.

Owner:FOSHAN GAOMING FULITE CHEM CO LTD

Conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature

ActiveCN105131881AGood coating effectImprove stamping resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseConductive polymer

The invention discloses a conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature. The conductive silver adhesive is prepared from 1%-2% of silver nanowires, 13%-29% of flake silver powder, 20%-30% of bisphenol A epoxy resin, 5%-10% of rapid medium and normal temperature curing agents, 0.5%-1% of rapid medium and normal temperature curing accelerant, 1%-3% of thinning agents, 1%-3% of K-570 or K-550, 0.5%-1% of terephthalic acid, 20%-56.3% of cellulose, 0.5%-1% of nano-silicon dioxide, 0.1%-0.5% of antifoaming agents and 0.1%-0.5% of ICAM8401 or ICAM8402. The conductive silver adhesive can be rapidly cured at medium and normal temperature and is low in silver content and low in cost, and therefore the application range of the conductive silver adhesive is greatly extended.

Owner:上海巨尔希电子科技有限公司

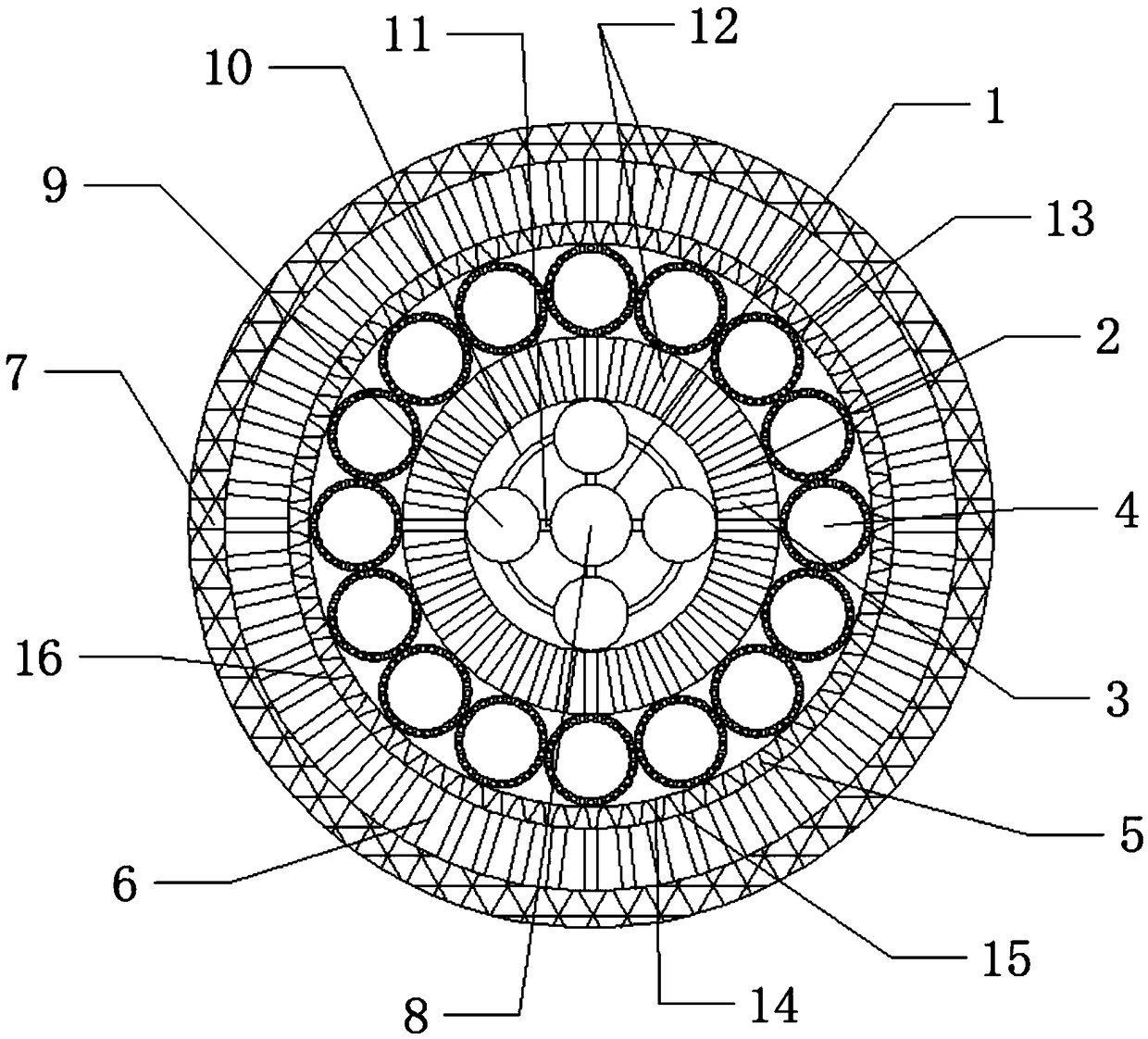

Flexible cable with heat dissipation effect

InactiveCN108735353ASafeguard ResilienceImprove toughnessFlexible cablesFlexible conductorsEngineeringElectric cables

The invention discloses a flexible cable with a heat dissipation effect, belongs to a multifunctional cable in the technical field of cables and aims at providing the flexible cable with the heat dissipation effect. According to the technical scheme, the flexible cable comprises a flexible cable core group arranged in the middle, wherein a first heat dissipation grid tube group is arranged outsidethe flexible cable core group; the length directions of grid tubes in the heat dissipation grid tube group are set along the radial direction of the flexible cable core group; a plurality of elasticcables are arranged outside the first heat dissipation grid tube group and are uniformly distributed along the external circumferential direction of the first heat dissipation grid tube group; a spring coil is arranged outside the elastic cables; a second heat dissipation grid tube group is arranged outside the spring coil; and a heat absorption layer is arranged outside the second heat dissipation grid tube group. The flexible cable with the heat dissipation effect has a good heat dissipation function while the flexibility of the cable is strengthened, and can be widely applied to a relatively harsh environment.

Owner:ZHENGZHOU JIZHI TECH CO LTD

Ceramic metal material

InactiveCN105420581AImprove wear resistanceImprove corrosion resistanceLithium oxidePolyvinyl alcohol

The invention provides a ceramic metal material. The ceramic metal material is composed of, by weight, 15-30 parts of iron oxide, 5-15 parts of zirconium oxide, 10-20 parts of aluminum oxide, 15-35 parts of silicon nitride, 5-15 parts of silicon dioxide, 3-8 parts of calcium borate, 2-5 parts of lithium oxide, 5-10 parts of paraffin, 2-5 parts of zinc stearate, 1-10 parts of copper powder, 1-6 parts of zinc oxide and 3-8 parts of polyvinyl alcohol. Compared with the prior art, the ceramic metal material has good abrasion resistance, corrosion resistance and impact resistance; meanwhile, the defect that ceramic is poor in flexibility is overcome, and good characteristics of alloy metal are kept; besides, heat resistance is high, ductility is high, and the service life of a product is prolonged.

Owner:TAICANG JIEGONG PRECISION METAL MATERIALS CO LTD

Epoxy floor coating

InactiveCN103305091AExcellent chemical corrosion resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses an epoxy floor coating, which is characterized by comprising a host and a curing agent, wherein the mixing ratio of the host to the curing agent is 2: 1, and wherein the host comprises the following components in parts by weight: 22-50 parts of epoxy resin, 10-30 parts of filler, 1-8 parts of thickener, 4-7 parts of auxiliaries, 18-35 parts of pigment or color cream and 6-20 parts of plasticizer, and wherein the curing agent is fatty amine and / or polyamide. The epoxy floor coating provided by the invention has excellent chemical corrosion resistance, high hardness, and excellent physical characteristics such as impact resistance, scrub resistance, abrasive resistance and the like; the epoxy floor coating is simple to prepare and convenient for construction; the epoxy floor coating is prepared from environment-friendly, solvent-free good-quality epoxy resin; the epoxy floor coating is wearproof and insulating, and hard and fine in surface; the epoxy floor coating is excellent in resistance to acid, to alkali, to salt, to oil, to esters, and to drugs; the epoxy floor coating is waterproof and non-absorbent, easy to flush, and simple and easy to clean and maintain; besides, the epoxy floor coating is bright and comfortable, smooth and beautiful in appearance with mirror face effect.

Owner:杭州宝力物资再生利用有限公司

Abrasion-resistant taper-shank twist drill and preparation method thereof

InactiveCN105886947AImprove hardenabilityImprove temper stabilitySolid state diffusion coatingFurnace typesNiobiumManganese

The invention discloses an abrasion-resistant taper-shank twist drill and a preparation method thereof. The abrasion-resistant taper-shank twist drill comprises, by weight, 0.88%-1.36% of carbon, 3.8%-5.6% of chromium, 4.5%-6.2% of tungsten, 1.65%-3.55% of vanadium, 11.6%-13.6% of manganese, 0.37%-0.72% of titanium, 0.02%-0.08% of niobium, 2.6%-4.2% of molybdenum, 0.003%-0.008% of zirconium, 0.86%-1.37% of aluminum, 0.0015%-0.0048% of boron, 0.02%-0.028% of nitrogen and the balance iron. The hardness, the strength and the abrasion resistance of the surface of steel are further improved through nitriding treatment. Proportions of the elements are adjusted to make the elements achieve the synergistic effect, the strength, the hardness and the abrasion resistance of the drill are remarkably improved, and the hardness and the abrasion resistance of the drill are further improved through quenching, moderate-temperature tempering and nitriding, so that the service life of the drill is greatly prolonged.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

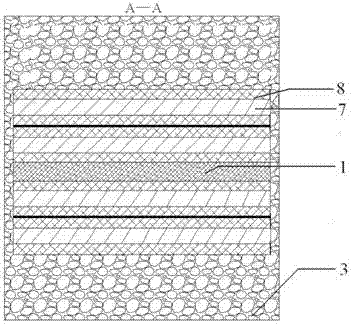

Hollow internal-model steel plate mesh cement anti-seismic splitting wall for heat-insulating wall

InactiveCN102653962ASimple structureEasy constructionWallsClimate change adaptationSteel tubeMoisture

The invention discloses a hollow internal-model steel plate mesh cement anti-seismic splitting wall for a heat-insulating wall. A front steel plate mesh and a rear steel plate mesh which are symmetrical are arranged in an outer layer formed by mixing ceramsite, fly ash and cement mortar; the two steel plate meshes are symmetrical with each other and fixedly connected, a plurality of prism channels, of which the cross sections are of rhombus, are formed between the two steel plate meshes, and glass wool is arranged in the channels; and vertical keel square steel tubes are arranged at outer sides of inner grooves of concave grooves located at the middle parts of steel mesh plates. According to the hollow internal-model steel plate mesh cement anti-seismic splitting wall, due to the unique hollow characteristic, the excellent characteristics of fire protection, moisture protection, sound insulation, heat insulation, cold insulation, low carbon, energy saving and environmental protection of the glass wool, and the anti-impact force and compression-resisting, anti-cracking and anti-seismic performances of a wall structure, the consumption of the ceramsite, the fly ash and the cement mortar can be minimized, the construction procedures are simplified to a greater extent, the labor intensity of construction workers is lightened, and the material cost is saved. Nowadays, the hollow internal-model steel plate mesh cement anti-seismic splitting wall is one of the most potential building materials in lightweight compartment wall materials and is an indispensable novel safe, low-carbon, energy-saving and environment-friendly lightweight building material in compartment wall building material products of high-rise building frame architectures.

Owner:韦作友

Internal parting wall for hollow internal template steel screen type cement anti-seismic thermal insulation wall

InactiveCN102733508ASimple structureEasy constructionWallsClimate change adaptationThermal insulationKeel

The invention discloses an internal parting wall for a hollow internal template steel screen type cement anti-seismic thermal insulation wall. Connectors are symmetrically arranged at the both ends of steel screens; the connectors are fixedly connected with convex surfaces through convex edges; a plurality of the convex surfaces are fixedly connected with a plurality of outer grooves; inner grooves are arranged at the middle part of the outer grooves; the two steel screens which are symmetrical front and back are tied and fixedly connected with each other through a plurality of zinc-plated iron wires, so as to form a steel screen plate; a plurality of prism channels with a diamond cross section are formed between the two steel screens, and anti-flaming glass cotton is arranged in the channels; vertical keel square steel tubes are arranged at the outer sides of the outer grooves at the middle parts of the steel screens, which are tightly adhered to the inner grooves; and the vertical keel square steel tubes are fixedly bound and connected with the two steel screens which are symmetrical front and back through the zinc-plated iron wires. The internal parting wall provided by the invention has the advantages of simple structure, convenience in construction, high security and reliability, and reasonable manufacturing cost. The internal parting wall meets the strict standard requirements of a national construction design and detection department, and has the characteristics of rapidness of construction, energy conversation and environmental friendless, crack and earthquake resistance, fire and moisture prevention, sound, thermal and cold insulation and the like. The properties of a wall body can meet the highest construction design standard requirements. The internal parting wall has wide popularization and application in a construction industry.

Owner:韦作友

Thermoset oil-rub-resistant powder paint

InactiveCN103509445AGood dispersionImprove the level ofAntifouling/underwater paintsPaints with biocidesJojoba oilTriallyl isocyanurate

A disclosed thermoset oil-rub-resistant powder paint is composed of the following raw materials in parts by weight: 50-55 parts of polyester resin, 5-15 parts of triglycidyl isocyanurate, 10-13 parts of light calcium carbonate, 1-2 parts of jojoba oil, 2-3 parts of aluminium powder, 1-2 parts of 4, 5-dichloro-2-octyl-3(2H)-isothiazolone, 12-15 parts of mica powder, 2-3 parts of triallyl isocyanurate and 10-20 parts of a composite filling material. Compared with the prior art, the coating of the powder paint of the invention is complete, thin in thickness, good in pigment dispersibility, good in leveling property and good in appearance, has the characteristics of impact resistance, oil stain resistance, wear resistance, cleaning resistance and no stains, is widely applicable to decoration on metal surfaces such as steel door and window, furniture and the like, and provides good protection for metal base materials.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Pre-phosphated electrogalvanized automobile outer panel with friendly coating and manufacturing method thereof

InactiveCN111349867AImprove mechanical propertiesImprove stamping resistanceMetallic material coating processesElectrogalvanizationManganese

The invention discloses a pre-phosphated electrogalvanized automobile outer panel with a friendly coating. The pre-phosphated electrogalvanized automobile outer panel is characterized by being formedby performing electrogalvanizing treatment and pre-phosphating treatment on the surface of an Nb-containing ultra-low carbon steel panel; the Nb-containing ultra-low carbon steel panel comprises the following chemical components in percentage by mass: less than or equal to 0.0012% of C, less than or equal to 0.010% of Si, 0.08-0.18% of Mn, less than or equal to 0.010% of P, less than or equal to 0.008% of S, 0.02-0.04% of Nb, 0.02-0.05% of Als, less than or equal to 0.003% of N, and the balance Fe and inevitable impurities; and the content of nickel and the content of manganese in a phosphating film obtained through pre-phosphating are 0.7-1.5% and 3-8% respectively. The pre-phosphated electrogalvanized automobile outer panel can show good coating performance on the premise of ensuring good application performance such as stretching and stamping, and a manufacturing method is simple and suitable for being used and popularized.

Owner:武汉钢铁有限公司

A method and electroplating tank for single-sided copper plating of wide-width stainless steel strip

The invention discloses a method for carrying out one-side copper plating on a wide stainless steel band and an electroplating bath. The method comprises the following steps: carrying out oil removal and activation on the pre-plating surface of the stainless steel band of a substrate; carrying out nickel pre-plating and general nickel plating on the activated pre-plating surface of the stainless steel band of the substrate, and carrying out copper plating in an alkaline cyanide-free plating solution; passivating and drying the copper-plated stainless steel band. The improved electroplating bath is adopted in the copper plating process, at least two transmission rotary rollers are hermetically mounted on two groove walls at a transmission inlet and a transmission outlet of the electroplating bath respectively, and the electroplating bath can be used for guaranteeing the liquid level of the bath and preventing a plated layer of the stainless steel band from being scratched and is especially suitable for continuous one-side copper plating of the wide band-shaped stainless steel band. The method is safe, environment-friendly, low in cost and capable of carrying out high-speed one-side copper plating on the wide stainless steel band; the one-side plated layer of the stainless steel band, prepared by the method, is uniform, bright and compact in surface, good in corrosion resistance, high in electric conductivity and excellent in stamping resistance, meets the requirements of electronics and military industry, and can be industrially produced.

Owner:HUNAN YONGSHENG NEW MATERIALS

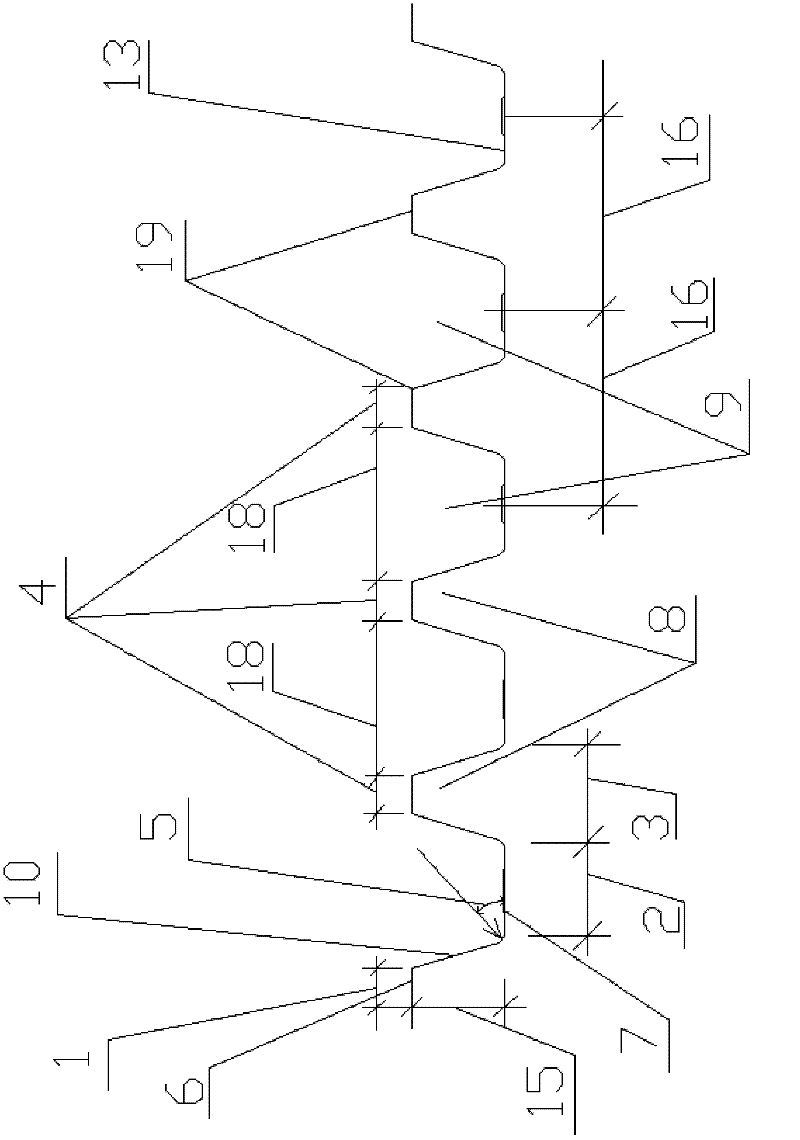

High-strength impact-resistant composite sleeve

PendingCN110410616AImprove stress resistanceImprove impact resistancePipe protection against damage/wearTubular articlesEngineeringHigh intensity

The invention relates to the technical field of sleeves, in particular to a high-strength impact-resistant composite sleeve. The high-strength impact-resistant composite sleeve comprises a main pipe,wherein the main pipe comprises a pipe body and a plurality of reinforcing blocks arranged on the periphery of the pipe body in a sleeved mode, the reinforcing blocks are arranged in sequence along the axial direction of the pipe body, the cross section of each reinforcing block is rectangular, and grooves are formed in the corners of the reinforcing blocks. According to the high-strength impact-resistant composite sleeve, the grooves are formed in the corners of the reinforcing blocks so as to improve the compression resistance of the corners of the reinforcing blocks, so that the fracture condition of the sleeve is reduced, and the impact resistance of the sleeve is further improved.

Owner:SHENZHEN ANPOWER ELECTRIC

Ceramic metal material

InactiveCN107778000AImprove stabilityOvercome the disadvantage of poor flexibilityLithium oxideParaffin wax

The invention discloses a ceramic metal material, which is composed of the following raw materials in parts by weight: 30-35 parts of iron oxide, 15-20 parts of zirconia, 12-18 parts of aluminum oxide, 7-15 parts of silicon nitride, 9-15 parts of silicon oxide, 2-7 parts of lithium borohydride, 8-9 parts of lithium oxide, 7-10 parts of paraffin, 1-5 parts of quartz sand, 1-4 parts of copper powder, 10-16 parts of aluminum nitride, 23 to 28 parts of polyvinyl alcohol. The composition of the material proposed by the invention is reasonably adjusted, and has good wear resistance, corrosion resistance and stamping resistance, and also overcomes the disadvantage of poor flexibility of ceramics. the service life of the product.

Owner:南通龙池金属材料有限公司

Thermosetting water wave powdery paint

InactiveCN101143990AChange changeChange rheologyEpoxy resin coatingsPolyester coatingsEpoxyPolyester resin

The invention discloses a thermosetting water streak coating, which includes 15-20 portion of epoxy resin, 15-20 portion of polyester resin, 5-10 portion of barium sulfate, 2-4 portion of light calcium carbonate, and 0.3-0.5 portion of water streak agent. Compared with the prior art, the invention completely forms coating without any loss, and decrease the pollution to environment. The required thickness just needs one time spaying, and the coating has good mechanical property, good pressure resistance and wear resistance, which is widely used for steel door and window, metal surface decoration of appliances, and provide good protection for metal substrate.

Owner:ANHUI MEIJIA NEW MATERIAL

Ceramic metal material

InactiveCN108675760AImprove wear resistanceImprove corrosion resistanceClaywaresPotassium borohydridePolyvinyl alcohol

The invention discloses a ceramic metal material. The ceramic metal material is composed of, by weight, 20 to 25 parts of iron oxide, 5 to 10 parts of zirconia, 10 to 15 parts of alumina, 8 to 15 parts of silicon nitride, 5 to 8 parts of nanometer silica, 50 to 60 parts of kaolin, 3 to 8 parts of zinc oxide, 1 to 5 parts of lithium borohydride, 5 to 10 parts of paraffin, 5 to 8 parts of titanium,3 to 5 parts of potassium borohydride, 1 to 5 parts of quartz sand, 2 to 6 parts of copper powder, and 20 to 25 parts of polyvinyl alcohol. The ceramic metal material is excellent in wear resistance,corrosion resistance, and impact resistance, is capable of avoiding defect of ceramic that the flexibility is poor, is excellent in performance and stability, and is capable of prolonging product service life.

Owner:HUZHOU WUSHI TECH CO LTD

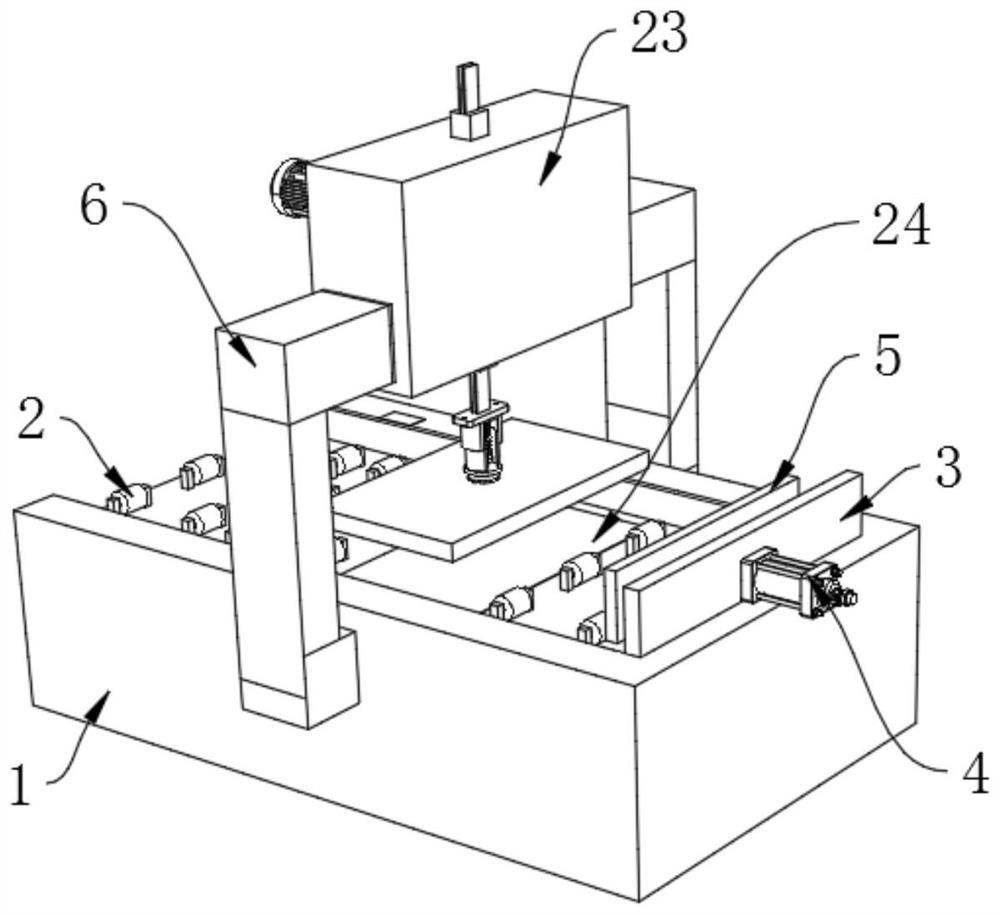

Reciprocating quick production and processing device of square plates

InactiveCN111889555AGuaranteed uniformityStable up and down frequencyShaping safety devicesStampingGear wheel

The invention belongs to the technical field of metal plate processing, and relates to a reciprocating quick production and processing device of square plates. The reciprocating quick production and processing device comprises a processing platform, wherein a plurality of feed auxiliary wheels are fixed to the top end of the processing platform, a positioning plate is welded on one end of the upper surface of the processing platform, and a hydraulic push rod cylinder is fixed to one end of the positioning plate by virtue of a screw. According to the reciprocating quick production and processing device, a reciprocating stamping forming structure is designed, so that the device conveniently reaches the stable lifting frequency through gear fit conduction; a counterforce offset fit design isused, so that the stamping forming efficiency of the forming production, the uniformity of a forming outer pipe and long service life are guaranteed; the combined design of a protective support structure under partial pressure and a matching top plate is adopted, so that good stamping can be formed on the device during use, and a bottom plate is prevented from being damaged by excessive pressure in a stamping forming process; and the forming of bottom counterforce is reduced by utilizing the design advantages of the structure, and the use effect of the device is increased.

Owner:王普照

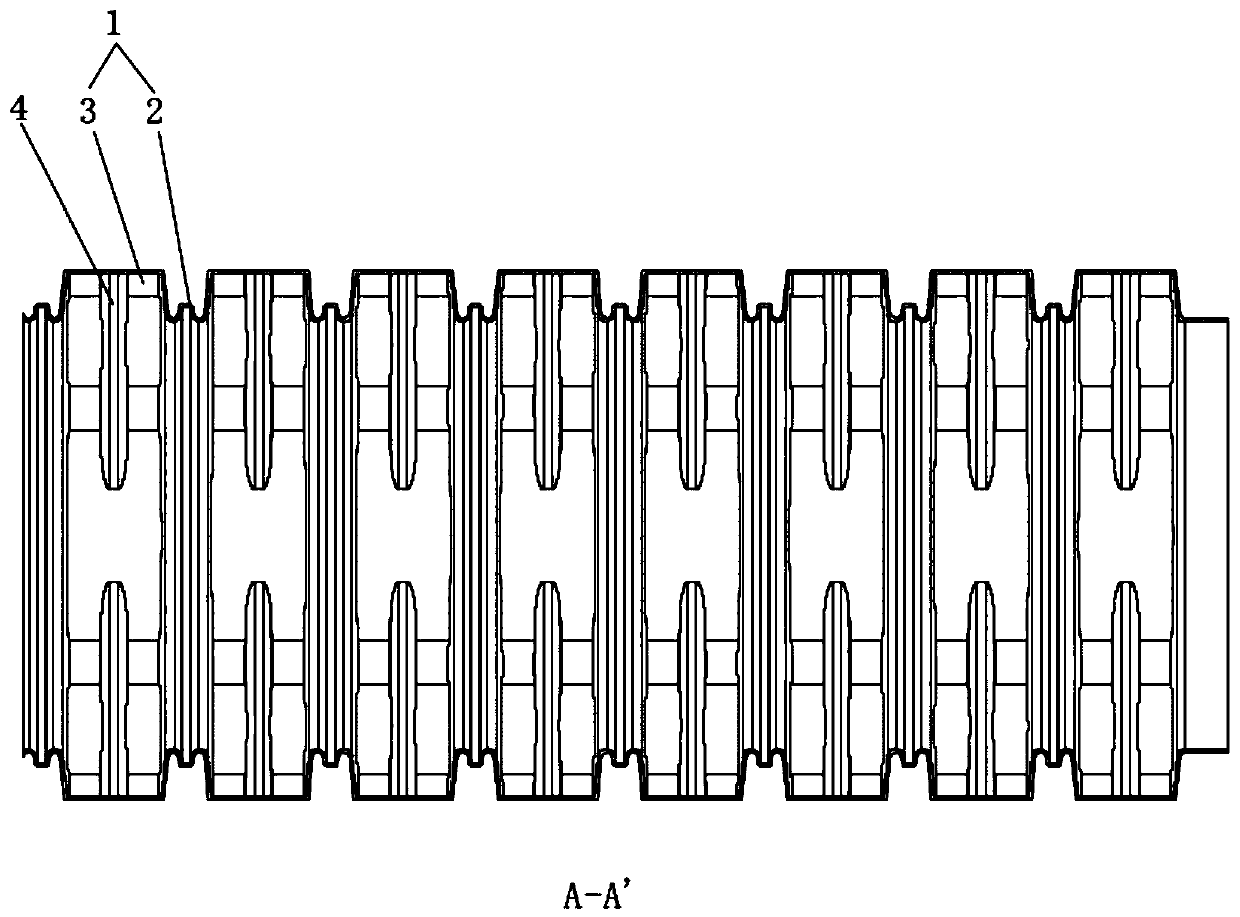

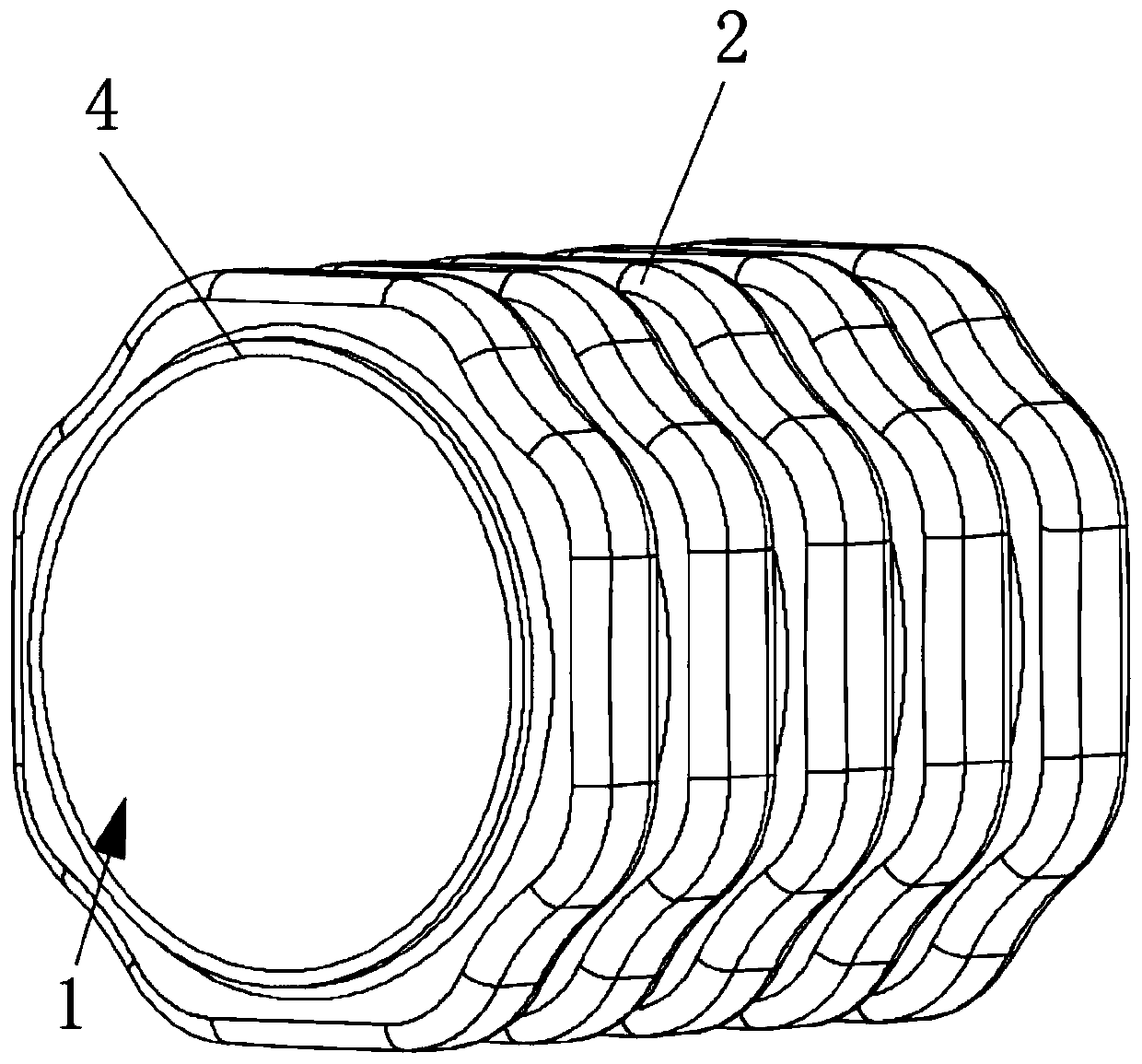

High-impact-resistance pillow-shaped composite sleeve and sleeve assembly

ActiveCN110649538AHigh compressive strengthIncreased ring stiffnessCable installations in surface ductsCable installations in underground tubesEngineeringStructural engineering

The invention relates to the technical field of protective sleeves, in particular to a high-impact-resistance pillow-shaped composite sleeve and a sleeve assembly. The high-impact-resistance pillow-shaped composite sleeve comprises a sleeve body and a plurality of impact-resistant reinforcing ribs arranged on the outer wall of the sleeve body. Every two adjacent impact-resistant reinforcing ribs are arranged at intervals. The periphery of each impact-resistant reinforcing rib is square, and the four corners of each impact-resistant reinforcing rib are sunken to form filleted corners. The two ends of the sleeve body extend outwards to form connecting parts. By utilizing the structure, the impact resistance can be improved. The outer wall of the sleeve body is sleeved with a plurality of impact-resistant reinforcing ribs. Because of the structure of the impact-resistant reinforcing ribs and the filleted corners formed by sinking the corners of the reinforcing ribs, the compression resistance of the impact-resistant reinforcing ribs is improved, and the compressive strength of the high-impact-resistance pillow-shaped composite sleeve in the vertical direction is also improved. Meanwhile, if the pressures borne by the multiple impact-resistant reinforcing ribs are different, the pressures can be transmitted to the sleeve body and evenly dispersed and counteracted, and therefore, the ring stiffness and the impact strength of the high-impact-resistance pillow-shaped composite sleeve are improved.

Owner:SHENZHEN ANPOWER ELECTRIC

Wet silicon paper for stamping paper cup

InactiveCN112900132ALow costEasy to preparePulp bleachingPaper coatingPaper sheetManufacturing engineering

Owner:JIAXING FENGLAI SANGDABEI PAPER CO LTD

A metal ceramic preparing method

The invention relates to a metal ceramic preparing method, belonging to the technical field of ceramic. The method includes separately feeding raw materials weighed according to weight parts into a ball mill and performing ball milling; feeding products into a high-speed mixer and performing high-speed mixing; feeding a mixture into a high-temperature sintering furnace, and performing vacuum high-temperature sintering; and cooling a product to obtain metal ceramic. The raw materials include 55-65 parts of ceramic powder, 10-15 parts of cobaltous oxide, 10-15 parts of aluminum carbide, 5-10 parts of magnesium silicate, 5-8 parts of cobalt silicide, 5-8 parts of oxidized ferrochromium, 5-8 parts of a compound named as Chinese characters 'eryanghuaqin' by the inventor, 1-5 parts of manganesesilicide, 7-10 parts of silicon nitride, 20-30 parts of flux, 15-23 parts of assistant flux and 8-10 parts of a waterproofing agent. The assistant flux is one or more selected from limestone, calcite,diopside, wollastonite, dolomite, talc and industrial waste slag. The production process is simple and the production cost is low. The prepared metal ceramic material is excellent in performance andhigh in stability.

Owner:淄博新金亿陶瓷科技有限公司

Metal ceramic material

The invention relates to a metal ceramic material, and belongs to the technical field of ceramics. The metal ceramic material is prepared from the following components in parts by weight: 55-65 partsof ceramic powder, 20-30 parts of ferric oxide, 10-15 parts of alumina, 1-5 parts of quartz sands, 7-10 parts of silicon nitride, 20-30 parts of flux, 15-23 parts of a fluxing agent and 8-10 parts ofa water-proofing agent, wherein cupric oxide and aluminate are embedded in the alumina substrate, and the aluminate exists in a mode of small flaky particles and flakes. The ceramic metal material hasexcellent performance and good stability, can be used for prolonging the service life of products, and can meet the requirement of various industries.

Owner:淄博新金亿陶瓷科技有限公司

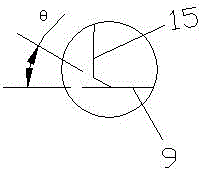

High-voltage transformer shell end socket stamping die

ActiveCN105855386ARealize stamping shock absorptionGood pressure and impact resistanceShaping toolsInductances/transformers/magnets manufactureMechanical engineeringHigh voltage transformer

The invention relates to a high-voltage transformer shell end socket stamping die comprising a lower die holder, an upper die head, a die cover and a bolt. A cavity is formed in the lower die holder and is internally provided with a plurality of baffle plates; one side of the lower die holder is provided with a cooling water inlet, and the other side of the lower die holder is provided with a cooling water outlet; the top of the lower die holder is provided with a pressing groove and damping mechanisms; the side wall of the pressing groove sequentially comprises a first vertical face, a first inwards-concave face, an inclined face, a second outwards-convex face and a second vertical face from top to bottom; each damping mechanism comprises a guiding column, a pressing spring and a top plate; the upper die head comprises a die core, a guiding plate and a lifting shaft; a rotating gear, a first pull plate and a second pull plate are arranged outside the lifting shaft; and a self-aligning bearing disk is arranged between the lifting shaft and the guiding plate. By means of the high-voltage transformer shell end socket stamping die, the end socket forming performance is good, the service life of the die can be prolonged easily, and the anti-breakthrough pressure bearing performance, the quality stability and the machining efficiency of an end socket are high.

Owner:NINGBO RONGYU MACHINERY

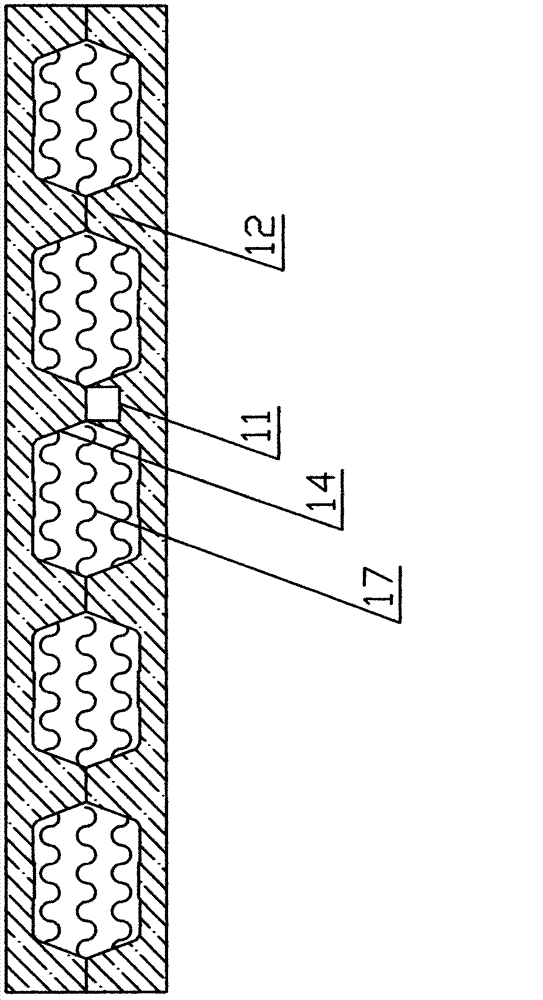

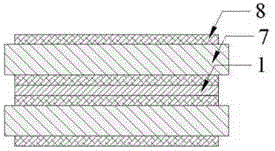

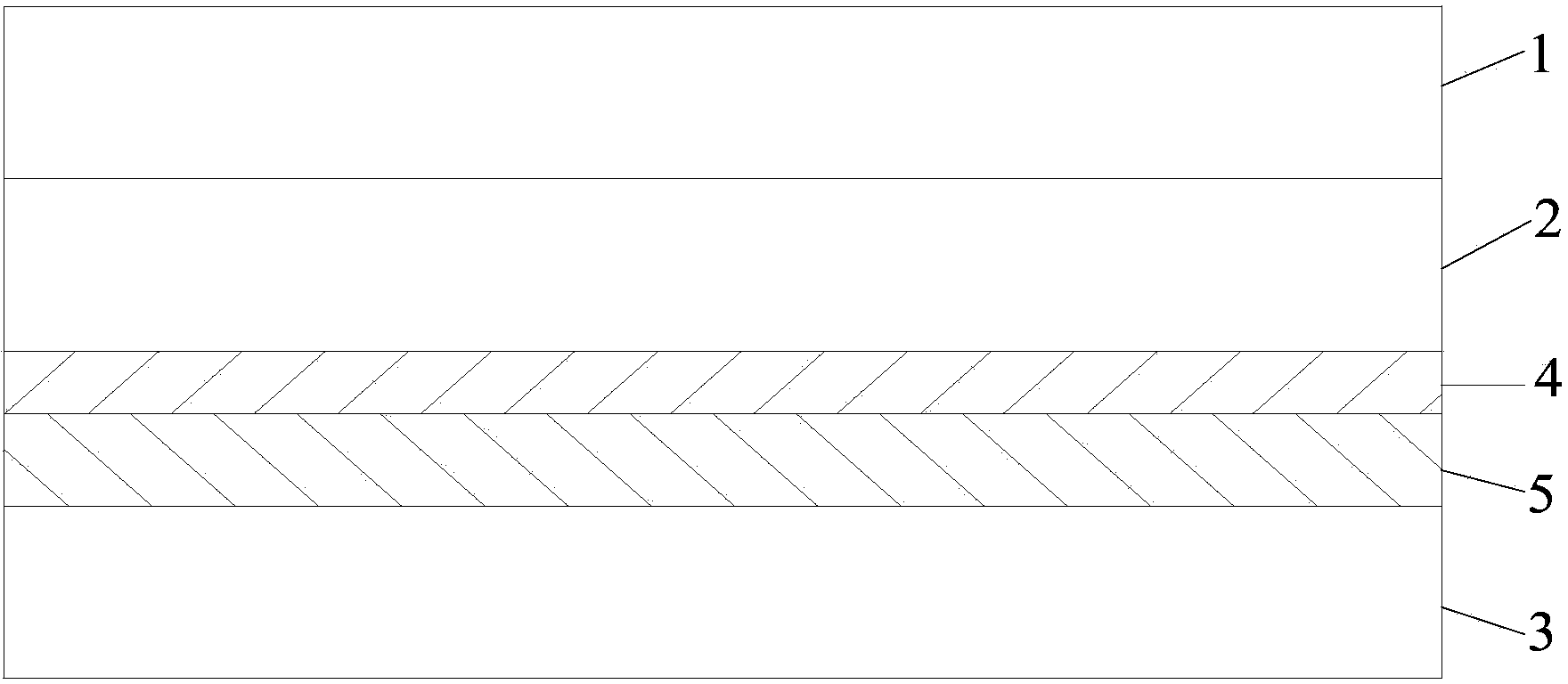

Lithium battery cell soft packaging membrane and battery

ActiveCN103840097AGuaranteed performanceExtended service lifeLi-accumulatorsCell component detailsEngineeringAluminum foil

The invention discloses a lithium battery cell soft packaging membrane and a battery, wherein the lithium battery cell soft packaging membrane comprises an isolating layer, an aluminum foil layer and a sealing compound layer which are arranged in sequence, and a protective layer is arranged between the aluminum foil layer and the sealing compound layer. Through the mode, the corrosive liquid of the battery can be prevented from infiltrating through the sealing compound layer and corroding the surface of the aluminum foil layer, the sealing compound layer on the surface of the aluminum foil layer can be prevented from falling, the battery does not leak liquid, and the service life of the packaging membrane can be prolonged; binder is not used between a heat seal layer and the aluminum foil layer, so that electrolyte is prevented from infiltrating the heat seal layer to contact with the binder and pollute the electrolyte, and the performance of the battery can be ensured.

Owner:深圳市安博瑞新材料科技有限公司

Ceramic metal material

InactiveCN108531800AImproved mechanical properties and usabilityGood wear resistancePliabilityMagnesium

The invention discloses a ceramic metal material. The ceramic metal material comprises the following raw materials including, by weight, 20-30 parts of ceramic micro mist, 6-8 parts of copper powder,6-8 parts of magnesium powder, 6-8 parts of iron powder, 3-5 parts of a dispersing agent, 2-6 parts of paraffin, 10-15 parts of kaolin, 8-12 parts of kieselguhr and the balance deionized water. By means of the ceramic metal material, the mechanical performance and the practicability of the metal material are improved, the good abrasive resistance, corrosion resistance and punching resistance are achieved, the defect of poor ceramic suppleness is overcome, the manufactured ceramic metal material is excellent in performance, the stability is good, and the service life of the product is prolonged.

Owner:SUZHOU MESOR SYST TECH

Nuclear radiation resistant mobile cable for crown block

ActiveCN111710461AAvoid wear and tearPrevent mutual rolloverPlastic/resin/waxes insulatorsFlat/ribbon cablesNuclear radiationTetrafluoroethylene

The invention discloses a nuclear radiation resistant mobile cable for a crown block, and belongs to the technical field of cables. The cable comprises a cable core, an insulating layer, an armor layer and a sheath layer. The cross section of the sheath layer is elliptical, the outer side surface of the sheath layer is provided with a wear-resistant groove, the sheath layer is an irradiation crosslinked polyethylene outer sheath, and a crosslinked polytetrafluoroethylene material, a flame-retardant material and an elastic material are filled between the armor layer and the insulating layer. The cable core in a flat shape, and a first protective sleeve and a second protective layer are arranged in the protective sleeve. The cross section of each first protective sleeve is square, the innerside of each first protective sleeve is provided with a main wire core, each first protective sleeve is provided with a first arc-shaped groove and a second arc-shaped groove, the opposite sides of every two adjacent first protective sleeves are spliced to form a cavity, the cross section of the second protective layer is oval, and a ground wire core is arranged in the second protective layer. Thecable is good in nuclear radiation resistance, flame retardance and stamping resistance, good in flexibility, capable of preventing the cables from rolling and winding each other during dragging andcapable of relieving abrasion caused by long-time use.

Owner:ANHUI DUJIANG CABLE GROUP

Preparation process of rubber and plastic heat insulation material

PendingCN114058063AMild preparation conditionsGood sound absorption and noise reductionMethacrylateBenzoic acid

The invention belongs to the technical field of heat insulation materials, particularly relates to a preparation process of a rubber and plastic heat insulation material, and aims to solve the problems that a heat insulation material in the prior art cannot meet the performance requirements of heat insulation, water resistance, fire prevention and the like at the same time, and is low in strength, not resistant to pressure, small in stamping resistance, easy to age, not durable, poor in comprehensive performance and the like. The preparation process of the rubber and plastic heat insulation material comprises the following steps: adding silicone rubber, cyclohexyl methacrylate and diethylene glycol dibenzoate into recycled waste foamed plastic, mixing, adding a heat insulation filler, epoxidized soybean oil, oleamide, stearic acid, sulfur, an antioxidant, a flame retardant and a foaming agent, and mixing to obtain the rubber and plastic heat insulation material. The obtained rubber and plastic heat insulation material has excellent heat insulation and heat preservation, sound absorption and noise reduction, fire prevention, flame retardance, moisture prevention, water prevention and the like, is high in strength, has good stamping resistance and aging resistance, is excellent in comprehensive performance and long in service life, and can be widely applied to the fields of buildings, metallurgy, chemical engineering, electric power and the like.

Owner:合肥汇东橡塑有限公司

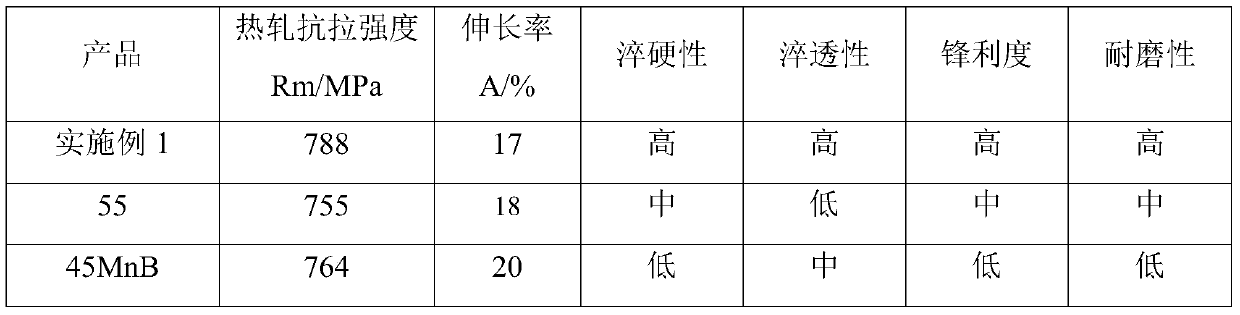

Tool steel hot-rolled steel strip and preparing method thereof

InactiveCN111500932AImprove hardenabilityImprove wear resistanceManufacturing convertersProcess efficiency improvementPunchingMaterials science

The invention relates to a tool steel hot-rolled steel strip and a preparing method thereof. The tool steel hot-rolled steel strip comprises following components including, by mass percent, 0.52%-0.59% of C, 0.60-0.90% of Mn, 0.15%-0.35% of Si, 0-0.015% of S, 0-0.030% of P, 0.020%-0.040% of Ti, 0.0012%-0.0035% of B, 0.010%-0.050% of Als, 0-0.20% of Cu, 0-0.5% of impurities and the balance Fe. Thetool steel hot-rolled steel strip has high hardenability, high abrasion resistance and good punching resistance, the production technology is high in operability and good in controllability, industrial production is easy, and the production cost is low.

Owner:NINGBO IRON & STEEL

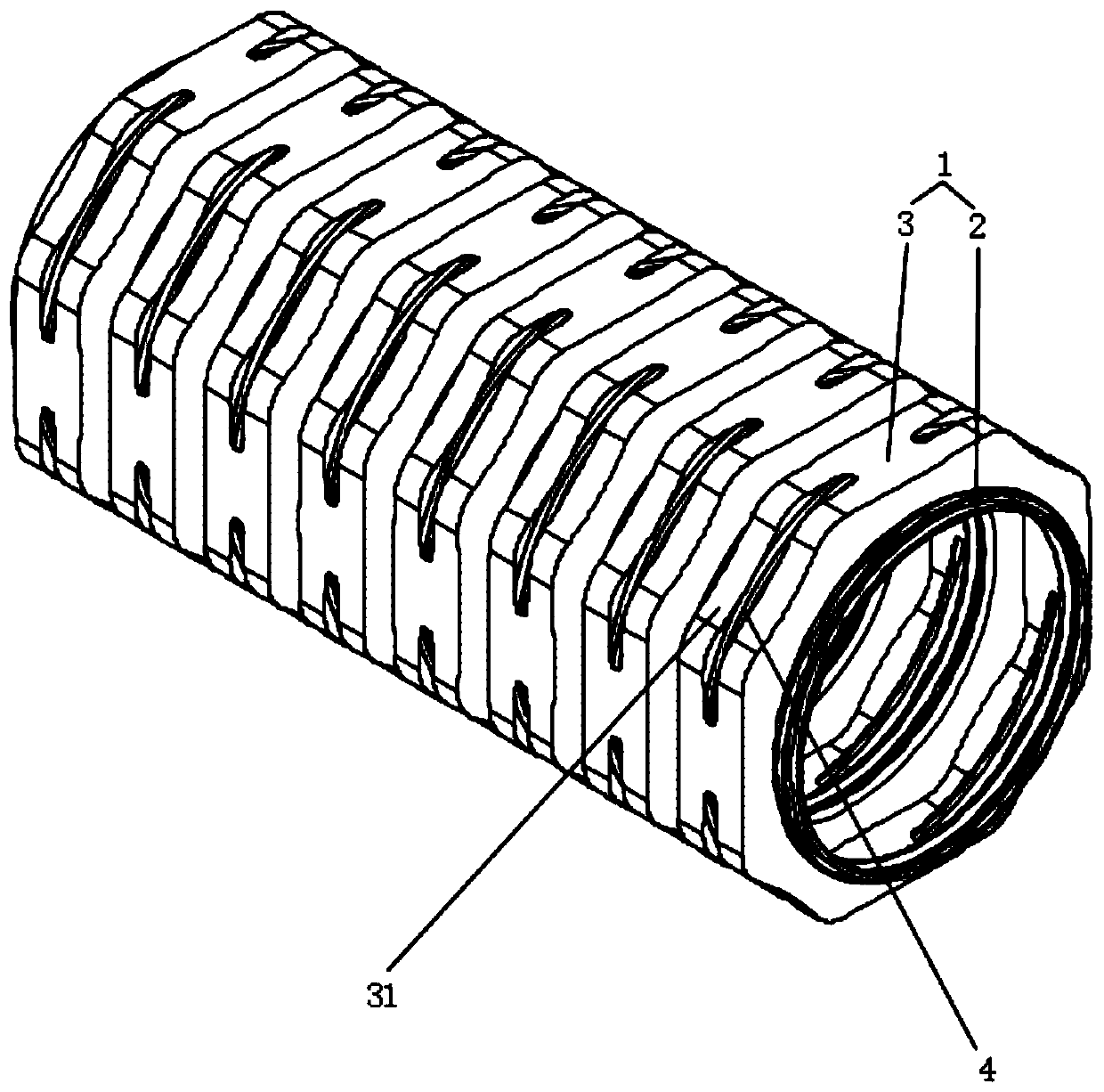

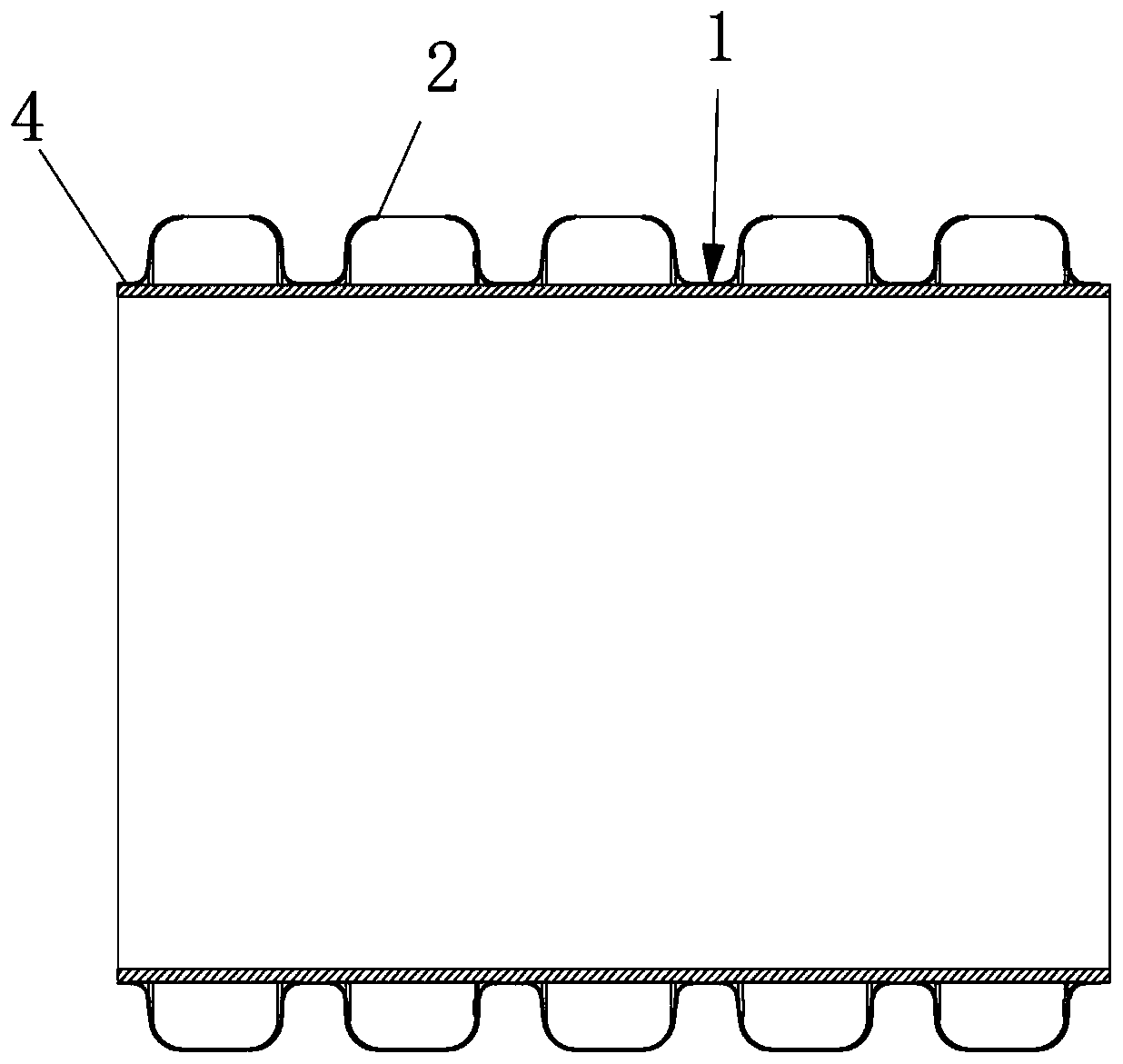

A shock-resistant anti-theft bottle cap

An anti-impact theftproof bottle cap comprises a bottle cap body (1) provided with internal threads, a safety ring belt (2), and an annular theftproof surrounding (4) that are subjected to integral injection molding. A ring kerf (3) is disposed between the bottle cap body (1) and the safety ring belt (2). The ring kerf (3) is provided with a plurality of connecting bridges (31) at equal intervals. The annular theftproof surrounding (4) is reversibly connected to the edge of the safety ring belt (2). The annular theftproof surrounding (4) forms a flange in the inner side of the safety ring belt (2), and the annular theftproof surrounding (4) is connected to the safety ring belt (2) in an obtuse angle manner. An inner ring of the annular theftproof surrounding (4) is close to the center line of the bottle cap, and an outer ring of the annular theftproof surrounding (4) is connected to the safety ring belt (2). Wedge-shaped lugs (41) that are distributed in a spaced manner are formed in the surface of the annular theftproof surrounding (4) away from the inner cavity of the bottle cap. A thin-wall portion (42) is formed between the two adjacent wedge-shaped lugs (41). The wedge-shaped lugs (41) are of a wedge-shaped protrusion structure. The high end of the wedge-shaped lug structure is close to the inner ring, and the low end of the wedge-shaped lug structure is close to the outer ring. The bottle cap can bear the upward stamping force from the interior of a bottle and prevent the bottle cap from being loosened, and has good anti-stamping performance and theftproof performance.

Owner:QUANZHOU HUASHUO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com