High-impact-resistance pillow-shaped composite sleeve and sleeve assembly

A composite casing, high-impact technology, used in electrical components, cable installation in ground conduits, cable installation in underground pipes, etc., can solve problems such as uneven force, rupture, and insufficient impact resistance of casing , to achieve the effect of improving compression resistance, improving impact resistance and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

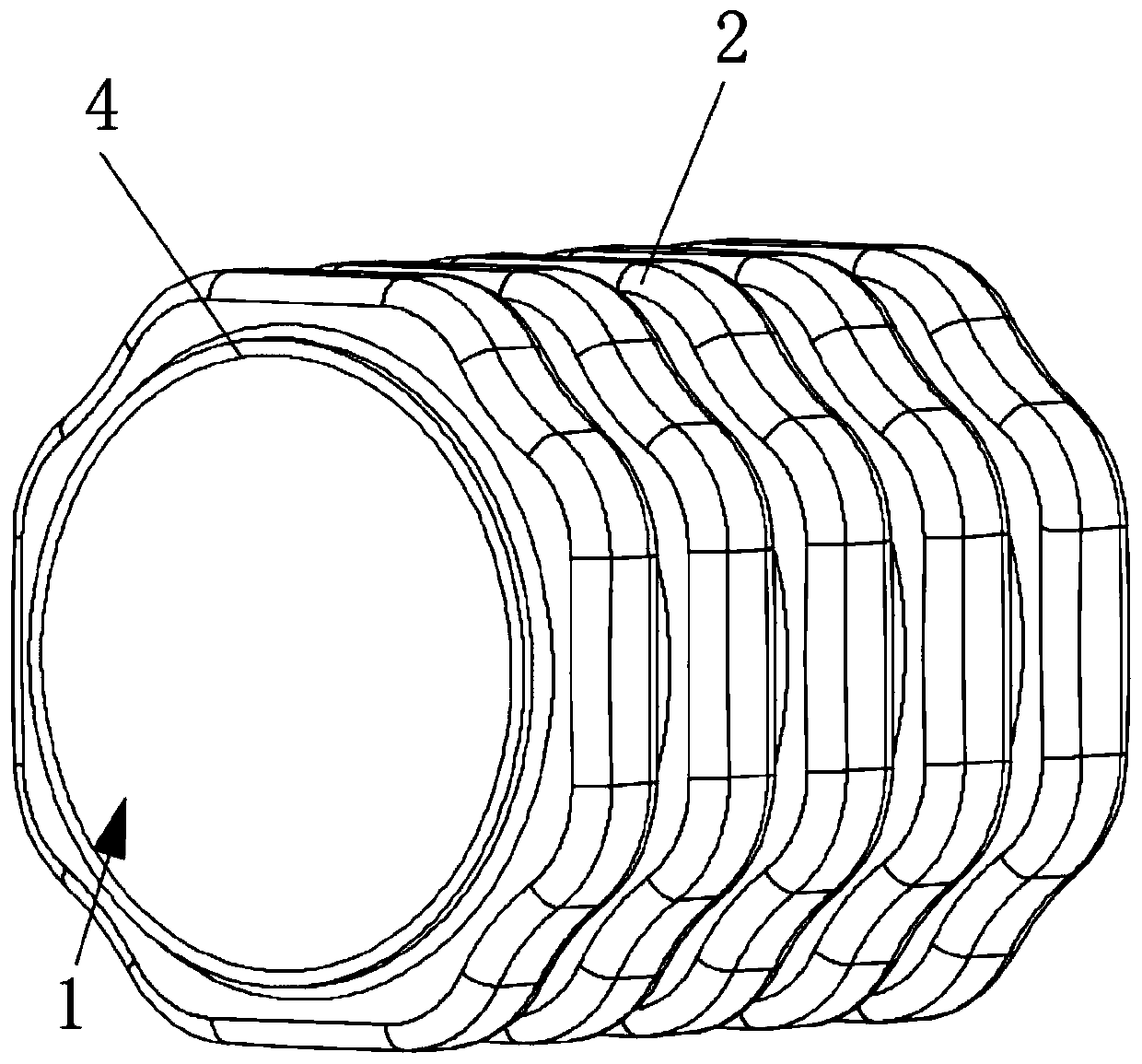

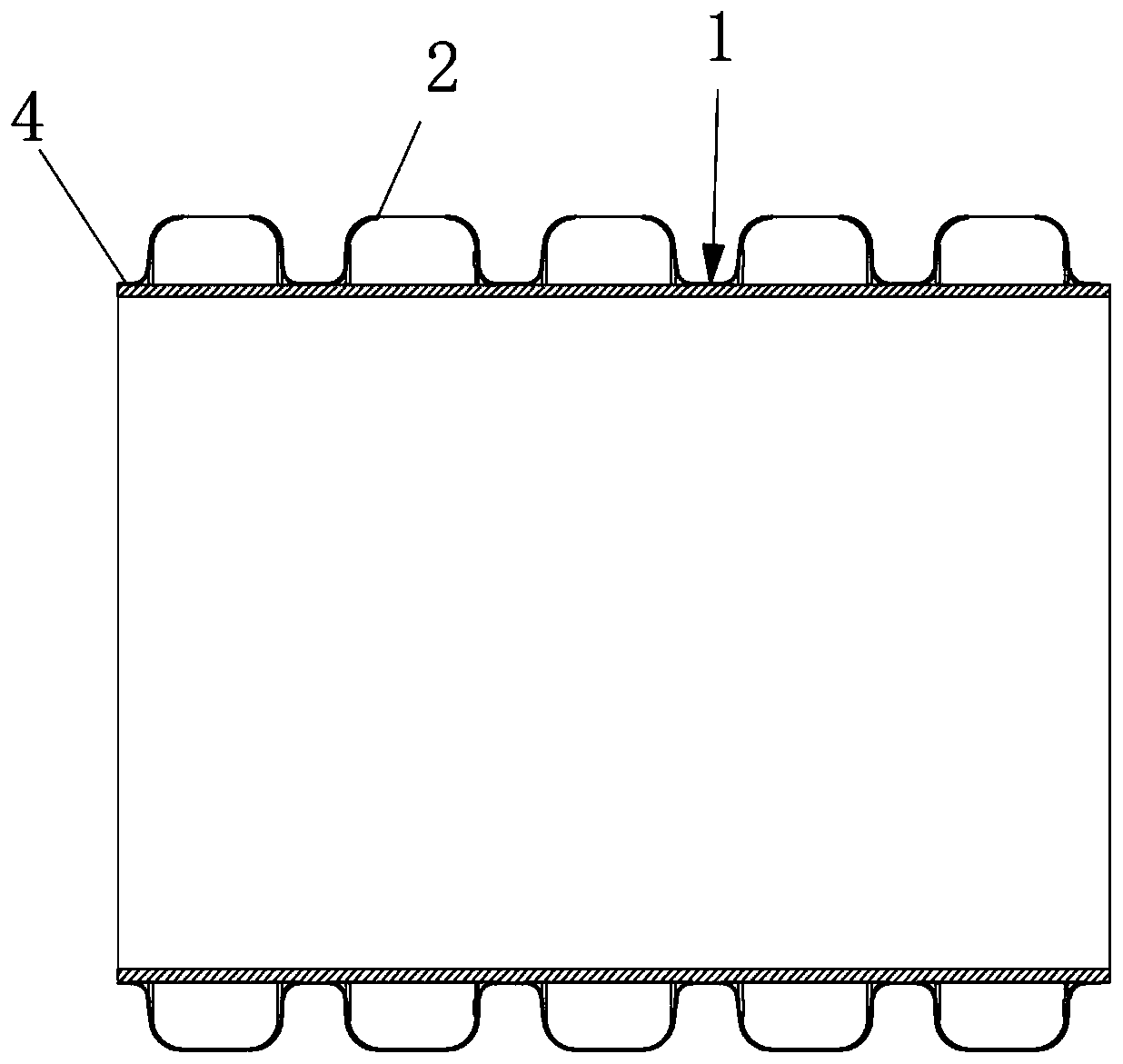

[0038] Such as Figure 1-4 As shown, a high-impact pillow-shaped composite casing includes a pipe body 1 and a plurality of anti-impact ribs 2 arranged on the outer wall of the pipe body 1, two adjacent anti-impact ribs 2 are arranged at intervals, and the anti-impact reinforcement The outer circumference of the ribs 2 is square and the four corners of the impact-resistant ribs 2 are recessed to form fillets 3 . Both ends of the pipe body 1 have connecting parts 4 extending outward.

[0039] The outer wall of the pipe body 1 is provided with a plurality of anti-impact ribs 2, and the structure of the anti-impact ribs 2 is used and the corners are recessed to form an inner fillet 3, which improves the compressive capacity of the anti-impact ribs 2 and improves the impact resistance of the high-impact pillow. The compressive strength of the composite casing in the vertical direction. At the same time, if the pressures received by multiple anti-impact ribs 2 are different, the fo...

Embodiment 2

[0045] Such as Figure 5 As shown, a sleeve assembly includes a plurality of high-impact pillow-shaped composite sleeves described in Embodiment 1, and two adjacent high-impact pillow-shaped composite sleeves communicate and abut against each other.

[0046] The bushing assembly is easy to assemble and is suitable for protecting cables over long and short distances. Further, the pipe bodies 1 of two adjacent high-impact pillow-shaped composite casings communicate and abut against each other

[0047] The junction of two adjacent high-impact pillow-shaped composite sleeves is welded by heat fusion.

[0048] With the above technical solution, the joints of two adjacent high-impact pillow-shaped composite bushings are tightly bonded, avoiding separation to cause the cables to be exposed and causing damage to the cables, and at the same time avoiding air / water infiltration into the bushing components to accelerate cable aging. Further, the two adjacent high-impact pillow-shaped c...

Embodiment 3

[0050] The difference between this embodiment 3 and embodiment 2 is:

[0051] Such as Image 6 As shown, the sleeve assembly also includes a buckle assembly, which is fastened on the outer walls of two adjacent high-impact pillow-shaped composite sleeves, and the buckle assembly includes a buckle pipe fitting 5 and an abutment The sealing ring (not shown in the figure) on the inner wall of the buckle pipe 5 is used for fastening two adjacent high-impact pillow-shaped composite sleeves.

[0052] Adopt the above-mentioned technical scheme to make the joints of two adjacent high-impact pillow-shaped composite sleeves tightly bonded, avoiding separation and causing the cable to be exposed and causing damage to the cable, and at the same time avoiding air / water infiltration into the sleeve assembly to accelerate cable aging . Further, one end of the buckle pipe fitting 5 is engaged with the impact rib 2 of the first high-impact pillow-shaped composite casing 6 close to the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com