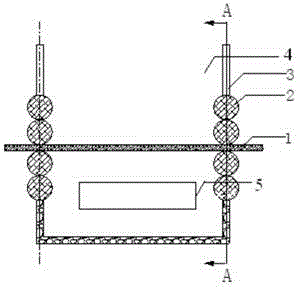

A method and electroplating tank for single-sided copper plating of wide-width stainless steel strip

A technology of stainless steel strips and electroplating tanks, applied in the direction of plating tanks, etc., can solve the problems of non-continuous production, long time consumption, serious environmental pollution, etc., and achieve the effect of improving the bonding force of the coating, reducing surface roughness, and enhancing the complexing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

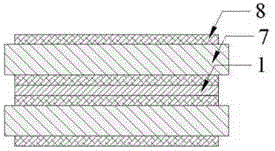

[0066] Adopt the method of horizontal transmission, electroplate the lower side, use 430 stainless steel strip as the base material, the thickness is 0.25mm, the width is 600mm, adopt the following process to process it.

[0067] (1) Chemical degreasing

[0068] The process conditions are: each liter of washing water contains 60g of degreasing powder and 5mL of detergent; the temperature is 55°C and the time is 3min; wash with hot water;

[0069] (2) Electrodegreasing

[0070] The process conditions are: Electrolyte: Each liter of electrolyte includes 60g of sodium hydroxide, 40g of sodium carbonate, and 30g of trisodium phosphate; the temperature is 55°C, and the current density is 3A / dm 2 ;

[0071] First, use the stainless steel strip as the cathode, and the inert electrode as the anode, and electrolytically degrease for 5 minutes; then use the stainless steel strip as the anode, and the inert electrode as the cathode, and degrease for 5 minutes; first wash it with hot wa...

Embodiment 2

[0098] Adopt the way of horizontal transmission, electroplate the lower side, use 201 stainless steel strip as the base material, the thickness is 0.15mm, the width is 120mm, adopt the following process to process it.

[0099] (1) Chemical degreasing

[0100] The process conditions are: each liter of washing water contains 60g of degreasing powder, 5mL of detergent; the temperature is 55°C, and the time is 3min;

[0101] wash with hot water;

[0102] (2) Electrodegreasing

[0103] The process conditions are: Electrolyte: Each liter of electrolyte includes 60g of sodium hydroxide, 40g of sodium carbonate, and 30g of trisodium phosphate; the temperature is 50°C, and the current density is 3A / dm 2 ;

[0104]First, use the stainless steel strip as the cathode, and the inert electrode as the anode, and electrolytically degrease for 5 minutes; then use the stainless steel strip as the anode, and the inert electrode as the cathode, and degrease for 5 minutes;

[0105] Wash with h...

Embodiment 3

[0131] Adopt the method of horizontal transmission, electroplate the lower side, use 304 stainless steel strip as the base material, the thickness is 0.2mm, the width is 200mm, adopt the following process to process it.

[0132] (1) Chemical degreasing

[0133] The process conditions are: each liter of washing water contains 80g of degreasing powder and 5mL of detergent; the temperature is 55°C and the time is 3min; and it is washed with hot water.

[0134] (2) Electrodegreasing

[0135] The process conditions are: Electrolyte: Each liter of electrolyte includes 60g of sodium hydroxide, 40g of sodium carbonate, and 30g of trisodium phosphate; the temperature is 65°C, and the current density is 3A / dm 2 ;

[0136] First, use the stainless steel strip as the cathode, and the inert electrode as the anode, and electrolytically degrease for 5 minutes; then use the stainless steel strip as the anode, and the inert electrode as the cathode, and degrease for 5 minutes; first wash it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com