Lithium battery cell soft packaging membrane and battery

A packaging film, lithium battery technology, applied in the direction of lithium batteries, secondary batteries, battery pack components, etc., can solve the problems of restricting the application and development of lithium ion batteries, and achieve the effect of ensuring performance, improving service life, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

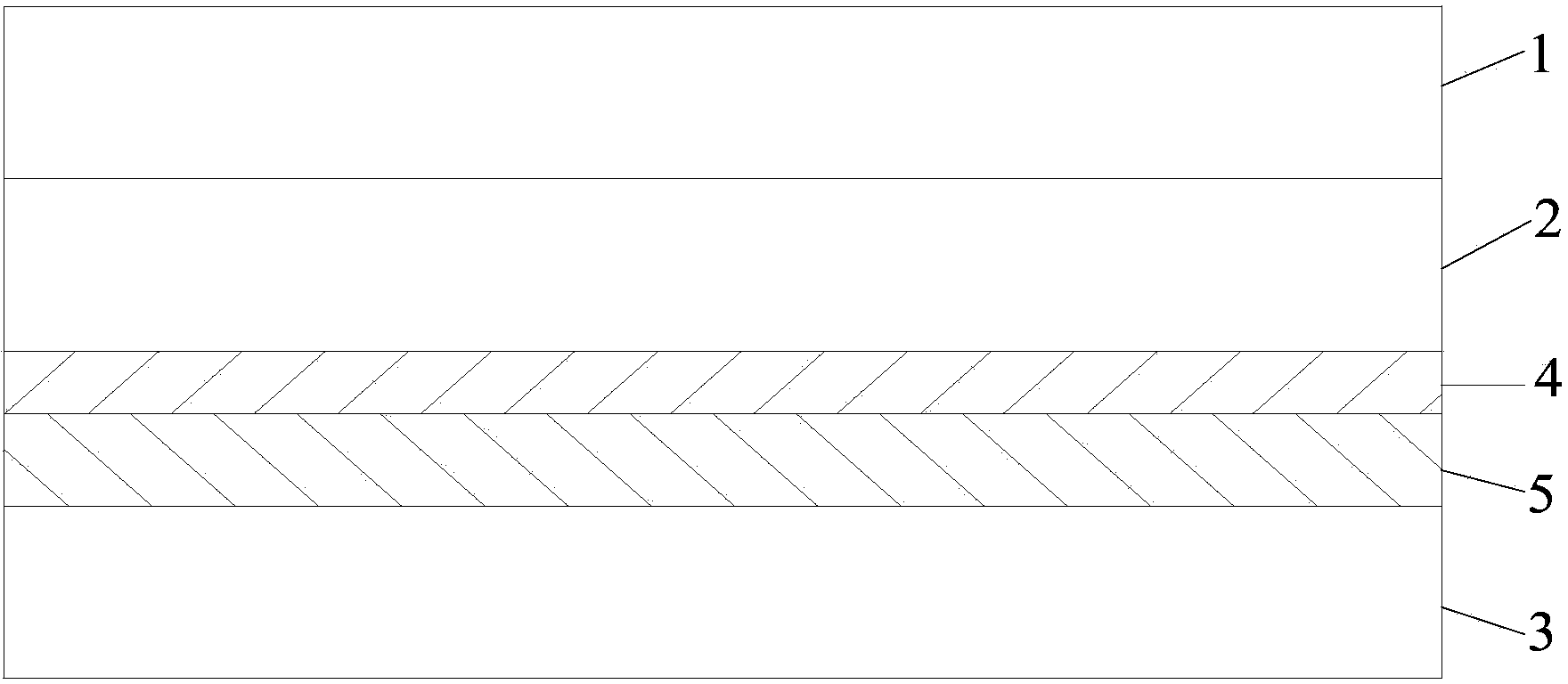

[0024] see figure 2 , figure 2 It is a schematic structural diagram of a flexible packaging film for lithium battery cores provided in an embodiment of the present invention. The flexible packaging film for lithium battery cores provided in an embodiment of the present invention includes an isolation layer 1, an aluminum foil layer 2, and a sealing layer 3 arranged in sequence, wherein the aluminum foil layer A protective layer 4 is arranged between 2 and the sealant layer 3 .

[0025] Wherein, the isolation layer 1 may be a nylon layer or a polyester layer, and the isolation layer 1 and the aluminum foil layer 2 are bonded together through an adhesive layer (not shown in the figure).

[0026] Considering the performance of the packaging film, the embodiment of the present invention controls the thickness of the isolation layer 1 to be between 20 and 30 microns, the thickness of the aluminum foil layer 2 to be between 30 and 90 microns, and the thickness of the protective l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com