Flexible cable with heat dissipation effect

A heat dissipation effect and toughness technology, applied in the direction of bendable cables, insulated cables, cables, etc., can solve the problems of no heat dissipation function and easy fracture of the internal structure, and achieve good toughness, good toughness effect, and increased toughness effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

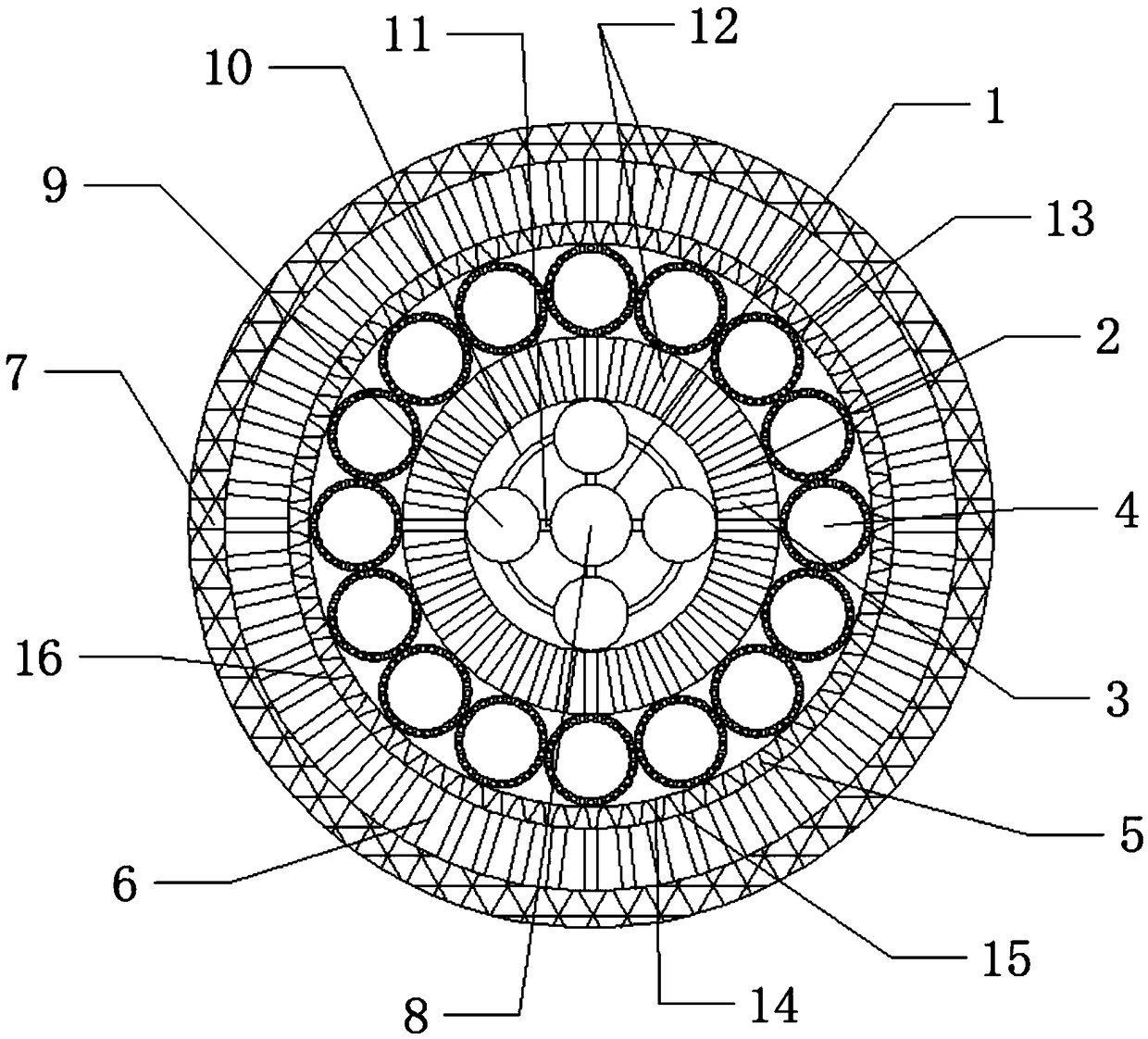

[0028] A flexible cable with heat dissipation effect, comprising a flexible cable core group 1 arranged in the middle, a first heat dissipation grid tube group 2 is arranged on the outside of the flexible cable core group 1, and the grid in the first heat dissipation grid tube group 2 The length of the tube 3 is set along the radial direction of the flexible cable core group 1, and the elastic cable 4 is arranged on the outside of the first cooling grid tube group 2, and the elastic cable 4 is evenly distributed along the circumferential direction outside the first cooling grid tube group 2 There are multiple sets, the elastic cable 4 is provided with a spring coil 5, and the spring coil 5 is provided with a second heat dissipation grid tube group 6, and the outside of the second heat dissipation grid tube group 6 is provided with a heat absorbing layer 7. Through the flexible cable core group 1 arranged in the middle, the toughness effect of the cable in the middle of the cabl...

Embodiment 2

[0030]On the basis of Embodiment 1, the flexible cable core set 1 includes a first cable 8 arranged in the middle, a plurality of second cables 9 arranged outside the first cable 8, and a plurality of the second cables The wires 9 are sequentially connected by arc-shaped connecting strips 10, and the plurality of second cables 9 are fixedly connected to the outer wall of the first cable 8 by connecting strips 11 in turn; the flexible cable core group 1 is connected by a plurality of second The cables 9 and the first cables 8 are sequentially connected, so that after the second cables 9 and the first cables 8 are connected by a connecting strip, because the material of the connecting strips has toughness, the second cables 9, The toughness effect between the first cables 8 is better, and at the same time, the stability between the second cables 9 and the first cables 8 is enhanced, thus having good toughness.

Embodiment 3

[0032] On the basis of Embodiment 2, the first cooling grid tube group 2 and the second cooling grid tube group 6 both include a plurality of hollow hoses 12, and the outer walls of the plurality of hollow hoses 12 are fixedly connected in sequence; The tube has a good heat transfer effect, and at the same time, the first heat dissipation grid tube and the second heat dissipation grid tube composed of a plurality of hollow hoses have the effect of strengthening the stability of the overall structure of the cable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com