Preparation process of metal wear-resistant alloy flange

A wear-resistant alloy and preparation technology, applied in the field of flange manufacturing, can solve the problems of inconvenient handling and transportation, heavy flange weight, poor wear resistance, etc., to achieve easy handling and transportation, reduce residual stress and brittleness, high resistance The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

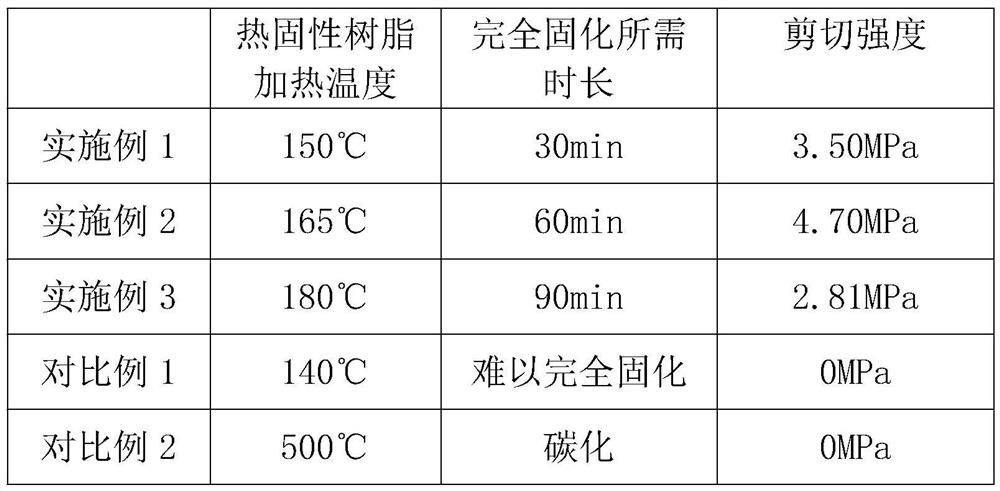

Embodiment 1

[0026] Embodiment 1, produce metal wear-resistant alloy flange according to the following specific steps:

[0027] S1. Raw material preparation:

[0028] Casting raw material preparation;

[0029] Carbon 0.8-1.2%, silicon 0.6-0.8%, chromium 18-22%, manganese 2.2-3.2%, vanadium 0.2-0.6%, phosphorus 0.01-0.03%, nickel 0.4-0.8%, molybdenum 0.2-0.5%, nitrogen 0.2% -0.4% and zinc 0.06-0.08%, the balance is copper, iron and unavoidable impurities.

[0030] Core material preparation;

[0031] Carbon fiber 5%, thermosetting resin 70%.

[0032] S2. Bottom shell prefabrication of blank parts:

[0033] Mix the weighed casting raw materials and put them into a furnace with a temperature of 1450-1500°C for alloy melting. At the same time, select a flange bottom shell mold of a suitable size and preheat it after cleaning, and put it in the flange mold A layer of mesh traveler, when the temperature in the furnace reaches 1500-1520 ℃, the solution is sampled for spectral analysis, after ...

Embodiment 2

[0044] Embodiment 2, produce metal wear-resistant alloy flange according to the following specific steps:

[0045] S1. Raw material preparation:

[0046] Casting raw material preparation;

[0047] Carbon 0.8-1.2%, silicon 0.6-0.8%, chromium 18-22%, manganese 2.2-3.2%, vanadium 0.2-0.6%, phosphorus 0.01-0.03%, nickel 0.4-0.8%, molybdenum 0.2-0.5%, nitrogen 0.2% -0.4% and zinc 0.06-0.08%, the balance is copper, iron and unavoidable impurities.

[0048] Core material preparation;

[0049] Carbon fiber 25%, thermosetting resin 55%.

[0050] S2. Bottom shell prefabrication of blank parts:

[0051] Mix the weighed casting raw materials and put them into a furnace with a temperature of 1450-1500°C for alloy melting. At the same time, select a flange bottom shell mold of a suitable size and preheat it after cleaning, and put it in the flange mold A layer of mesh traveler, when the temperature in the furnace reaches 1500-1520 ℃, the solution is sampled for spectral analysis, after p...

Embodiment 3

[0062] Embodiment 3, produce metal wear-resistant alloy flange according to the following specific steps:

[0063] A preparation process of a metal wear-resistant alloy flange, comprising the following steps:

[0064] S1. Raw material preparation:

[0065] Casting raw material preparation;

[0066] Carbon 0.8-1.2%, silicon 0.6-0.8%, chromium 18-22%, manganese 2.2-3.2%, vanadium 0.2-0.6%, phosphorus 0.01-0.03%, nickel 0.4-0.8%, molybdenum 0.2-0.5%, nitrogen 0.2% -0.4% and zinc 0.06-0.08%, the balance is copper, iron and unavoidable impurities.

[0067] Core material preparation;

[0068] 45% carbon fiber, 45% thermosetting resin.

[0069] S2. Bottom shell prefabrication of blank parts:

[0070] Mix the weighed casting raw materials and put them into a furnace with a temperature of 1450-1500°C for alloy melting. At the same time, select a flange bottom shell mold of a suitable size and preheat it after cleaning, and put it in the flange mold A layer of mesh traveler, when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com