Slasher, with high drying performance, for performing double-dipping and quartic-pressing on wet slashed yarns through roller warp beams

A sizing machine, performance technology, applied in the processing of textile materials, liquid/gas/steam removal with squeeze rollers, liquid/gas/steam yarn/filament treatment, etc., can solve pollution, hairiness and thick film , easy to break and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

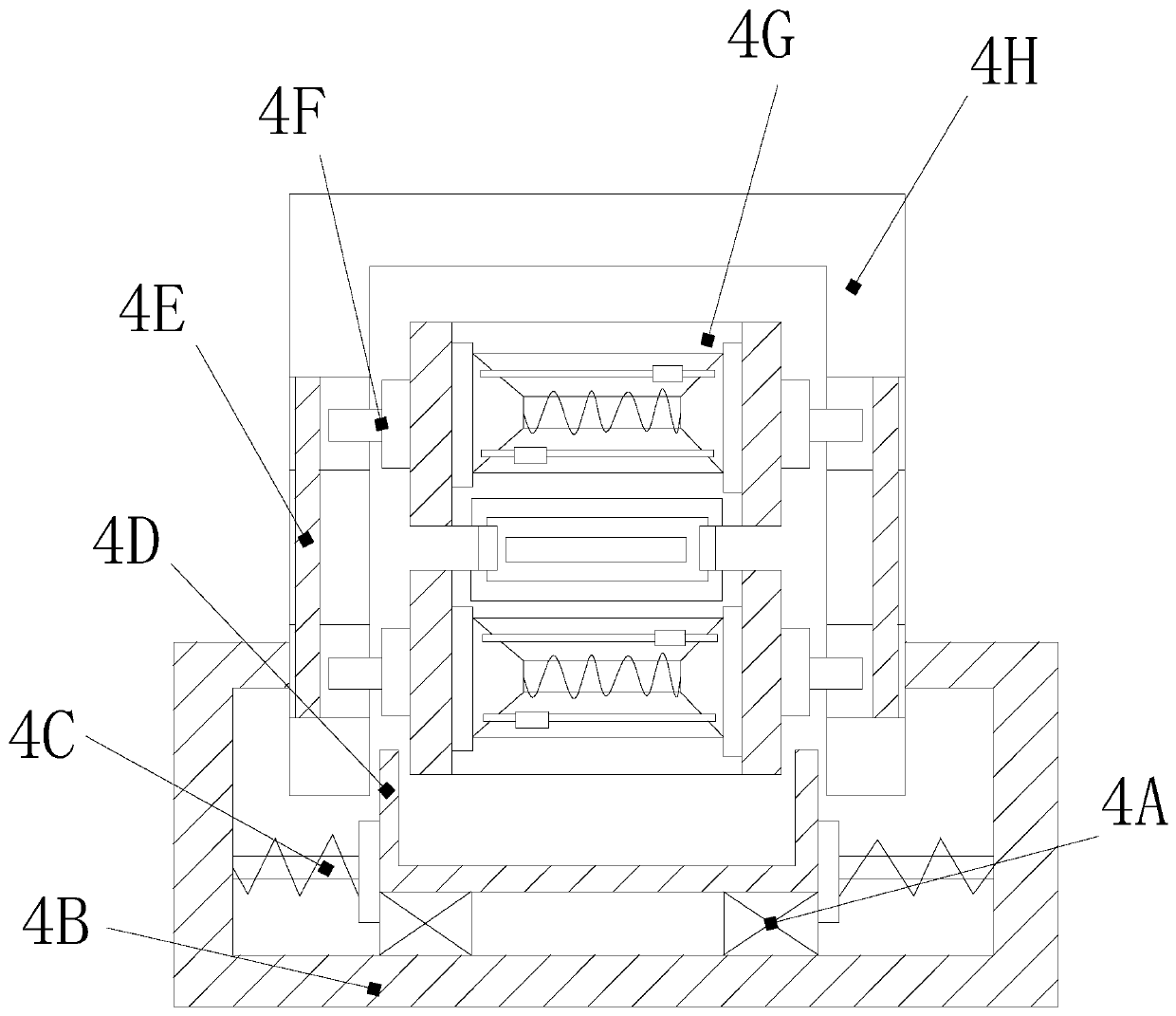

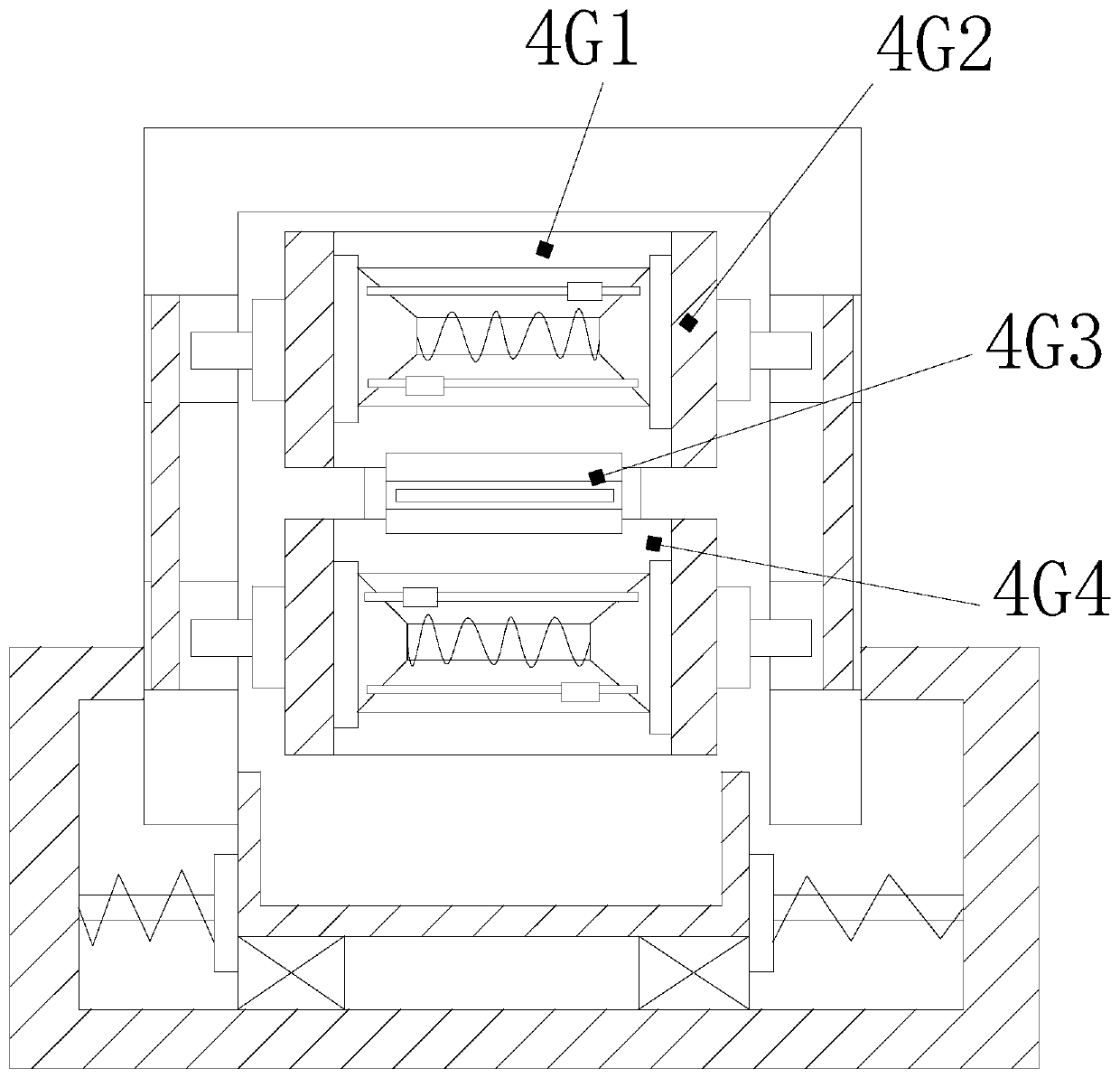

[0030] See Figure 1-Figure 7 , The present invention provides a sizing machine with high drying performance of wet sizing rolls and beams double-immersed and four-pressure sizing machine. The structure includes: an industrial control base 1, a supporting pad conveying table 2, a roller group groove 3, a double The four-pressure immersion oven 4, the I-shaped roll frame 5, the internal pressure rotary column 6, and the gear box 7. The double-immersion four-pressure oven 4 is mechanically connected to the supporting pad conveyor 2 through the groove 3 of the roller rod group. The machine base 1 is mechanically connected to the I-shaped roll winding frame 5 through a gear box 7. The gear boxes 7 are provided with two and are respectively installed on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com