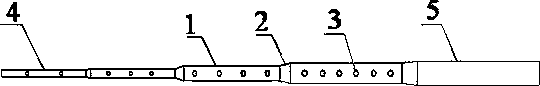

Pipe body structure of step type hole protecting pipe for gas extraction hole in soft coal bed

A technology for gas drainage and soft coal seam, which is applied in the field of hole protection pipes, can solve the problems of easy blocking of hole protection pipes, easy collapse of gas drainage holes, and difficulty in gas extraction, and achieves high gas drainage efficiency and large overall deflection. , The effect of not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

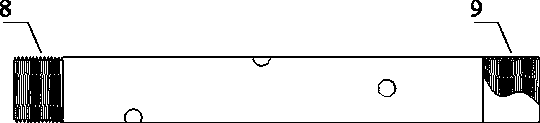

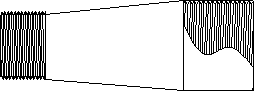

[0017] Embodiment 1: The hole-protecting pipe is sequentially connected by multiple groups of pipes from the front end to the end; the diameters of different groups of pipes are different, and the diameter of each group of pipes decreases sequentially from the front end to the end of the hole-protecting pipe, and the adjacent two pipes of different groups It is connected by reducing pipe joints; the overall profile of the hole protection pipe is a stepped structure with a gradual change in diameter; the diameters of the pipes in the same group are equal, and they are connected by 3 to 10 pipes, and the length of each pipe is equal, ranging from 1.5m to 3m; There are no sieve holes on the tube wall of the frontmost group of tubes, and sieve holes are set on the tube walls of the other groups of tubes. The sieve holes on the same group of tubes have the same aperture; the number of sieve holes in each group decreases from the front end to the end; The diameter of each group of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com