Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Improve ablation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

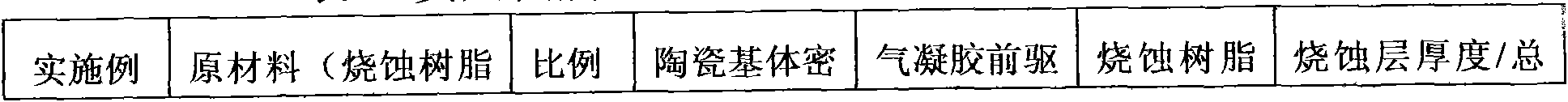

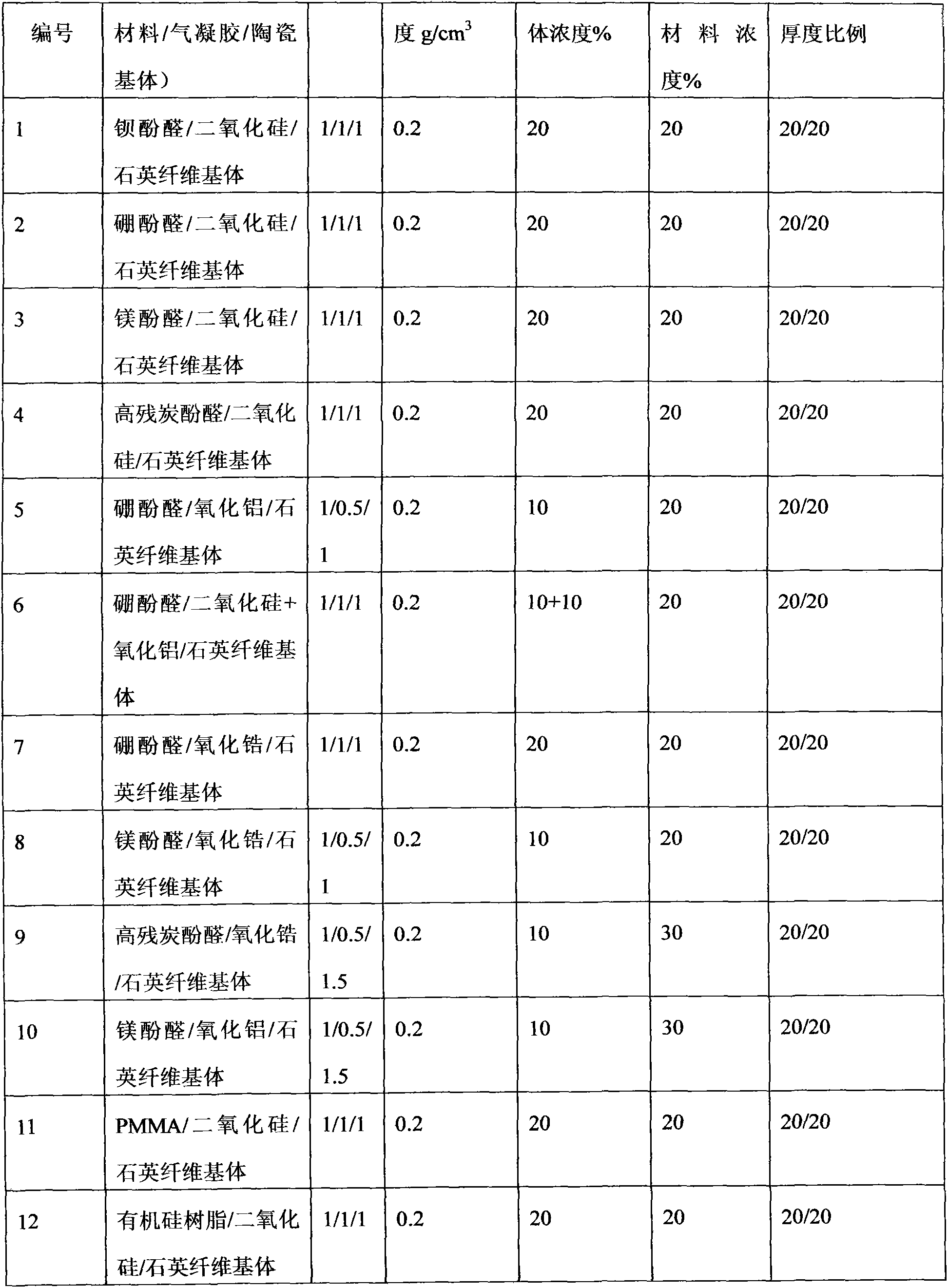

Micro-ablation insulating material and preparation method thereof

InactiveCN103449825AGood ablative thermal insulation capabilityDimensional abilityThermal insulationPolyresin

The invention discloses a micro-ablation insulating material. The micro-ablation insulating material comprises an ablation resin material and a rigid thermal-insulation material, wherein the rigid thermal-insulation material comprises a ceramic base body and an aerogel material. The invention also provides a preparation method of the micro-ablation insulating material. The method comprises the steps of compounding the aerogel material and the ceramic base body to manufacture the rigid thermal-insulation material, compounding the rigid thermal-insulation material and the ablation resin material, and gelling, drying and curing the ablation resin material. The proportions of the rigid thermal-insulation material and the ablation resin material, and the composition and the structure of the composition of the rigid thermal-insulation material and the ablation resin material in the thickness direction can be adjusted according to different using requirements. The micro-ablation insulating material has high designability, excellent superhigh-temperature heat-insulating property, strong variable-dimension ability and good processing performance, can be manufactured into various profiles and sizes, and has good application prospect in the fields of external protection of reentry type aircrafts and thermal protection of superhigh-temperature engines.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

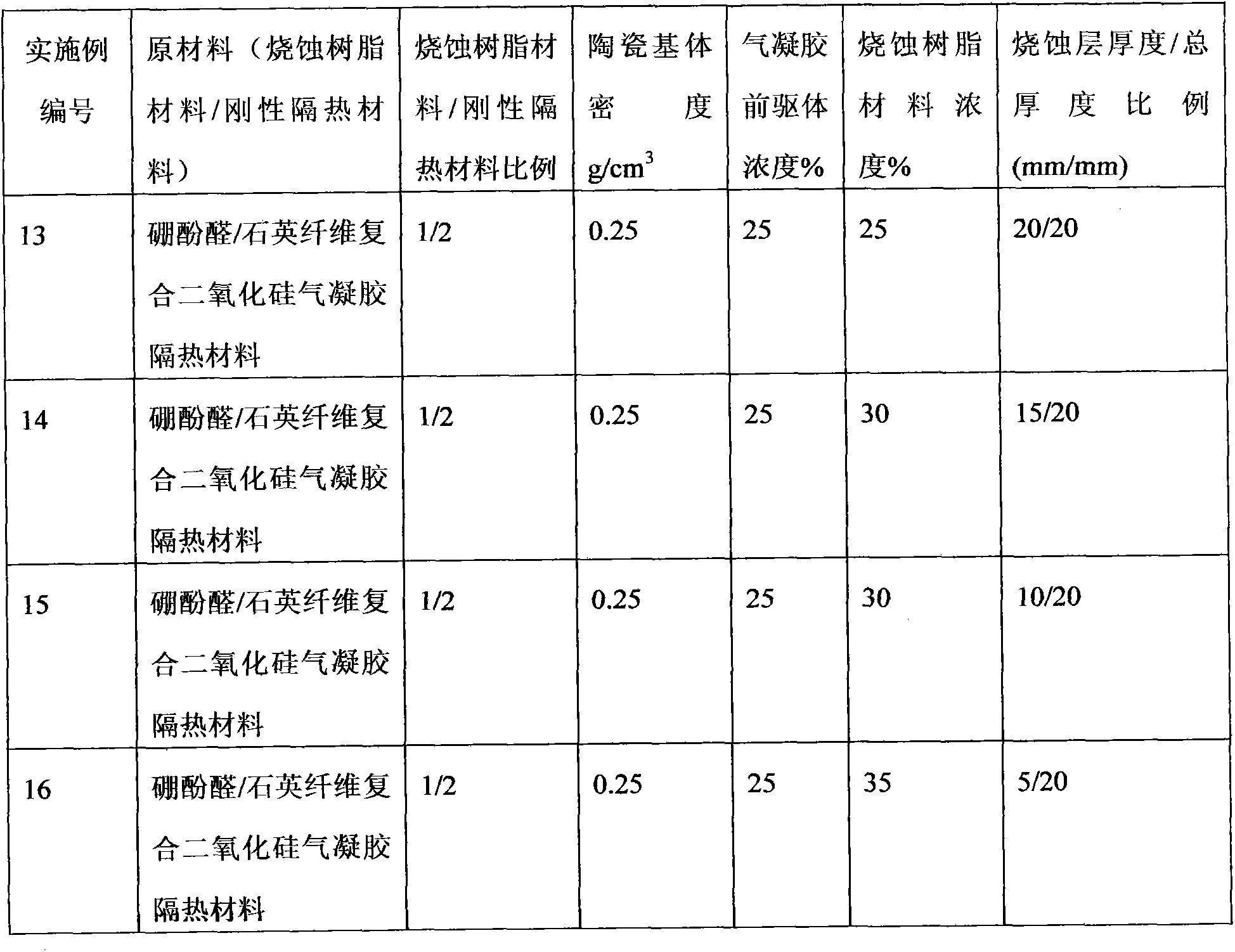

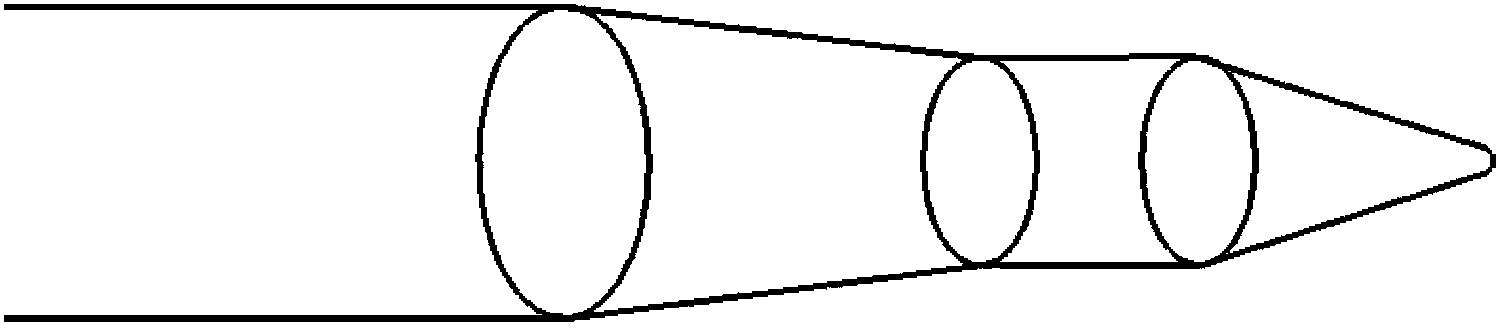

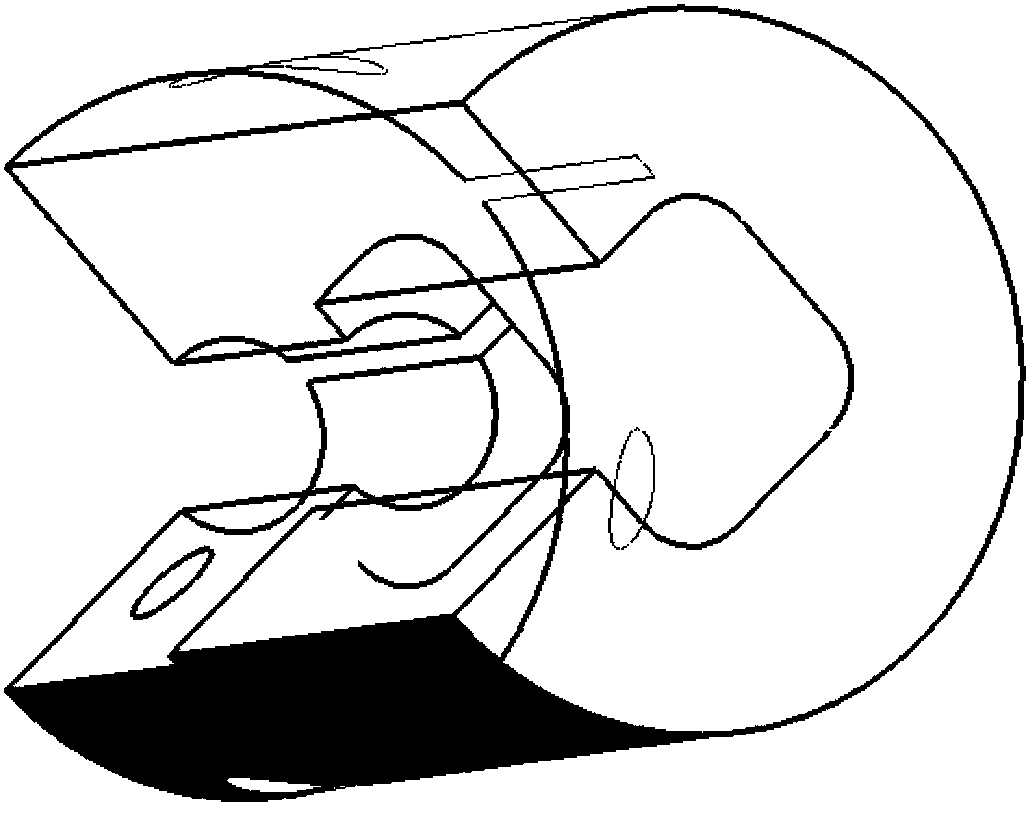

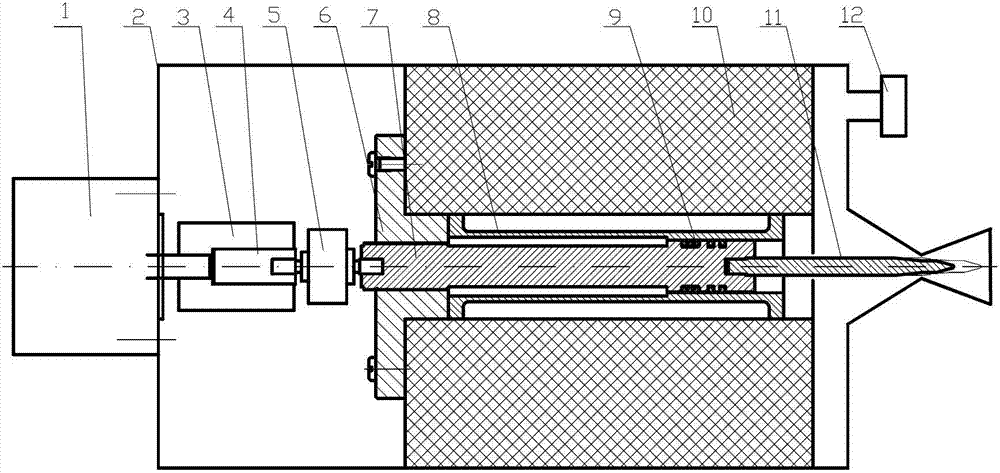

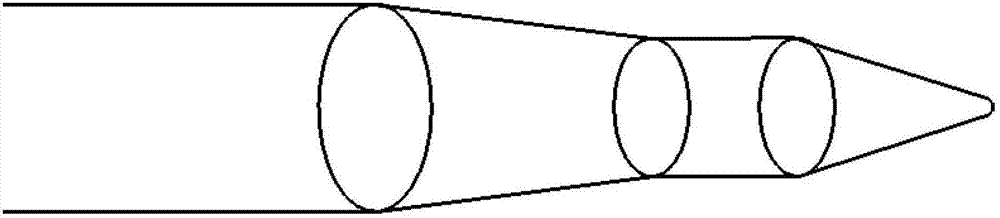

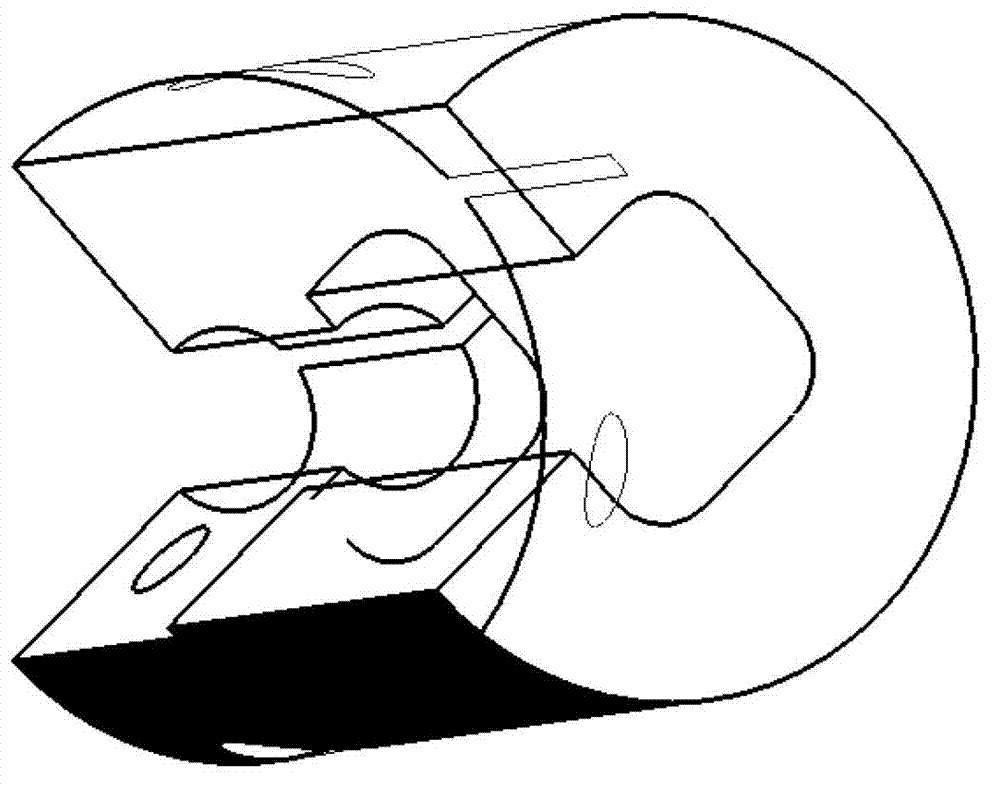

Electric conical valve type gas flow regulator for solid rocket ramjets

The invention discloses an electric conical valve type gas flow regulator for solid rocket ramjets. A drive motor is fixed to a connecting box. One end of a coupling is fixedly connected with a shaft of a motor, and a slider is disposed in a slide hole in the other end of the coupling. The slider is fixedly connected with a valve stem through a tension and pressure sensor. A drive nut is fixedly connected to a solid gas generator. The valve stem passes the drive nut and in threaded fit with the drive nut. A conical valve head is fixedly connected with the valve stem in a threaded manner and extends into a spray pipe of the gas generator. The gas generator is in an inner shell structure which is hollow. The valve stem is fitted in the inner shell, and a bushing is fitted between the valve stem and the gas generator. One end of the valve stem, close to the conical valve head, is provided with a peripheral circular groove, and a moving seal is disposed in the circular groove. A pressure sensor is mounted on the rear head of the gas generator. The electric conical valve type gas flow regulator for solid rocket ramjets is simple in structure, small in size, reliable in operation, low in ablation effect, low in cost, and accurately controllable.

Owner:NANJING UNIV OF SCI & TECH

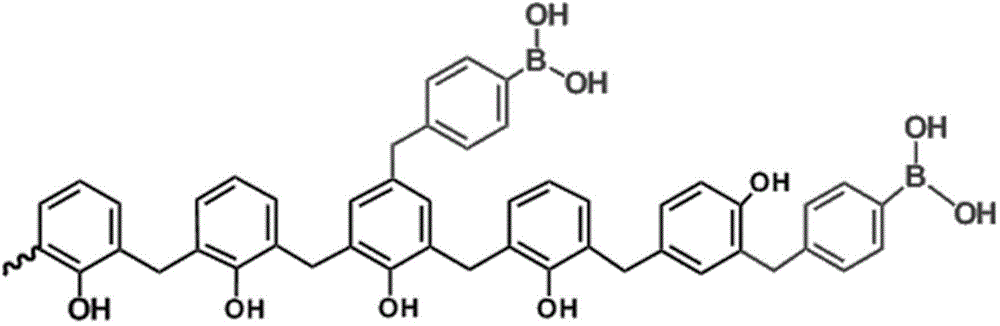

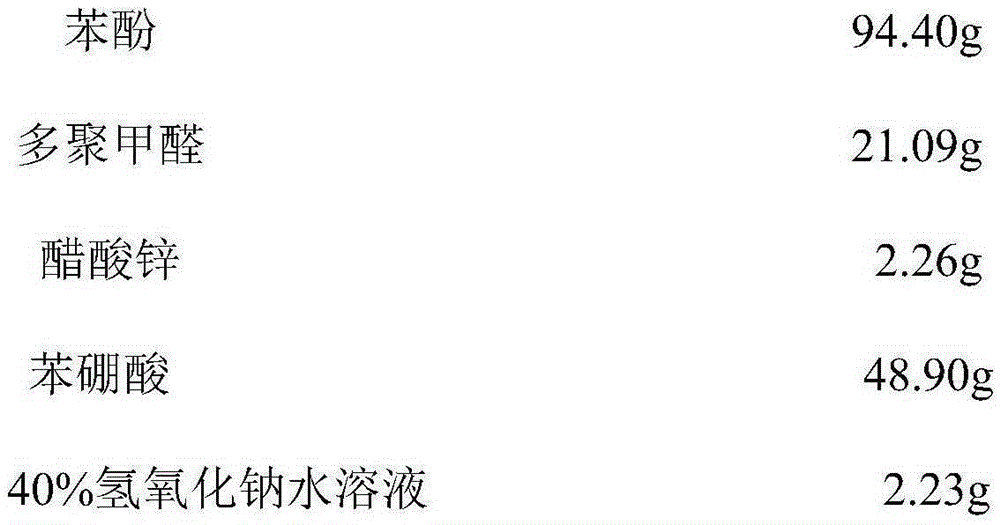

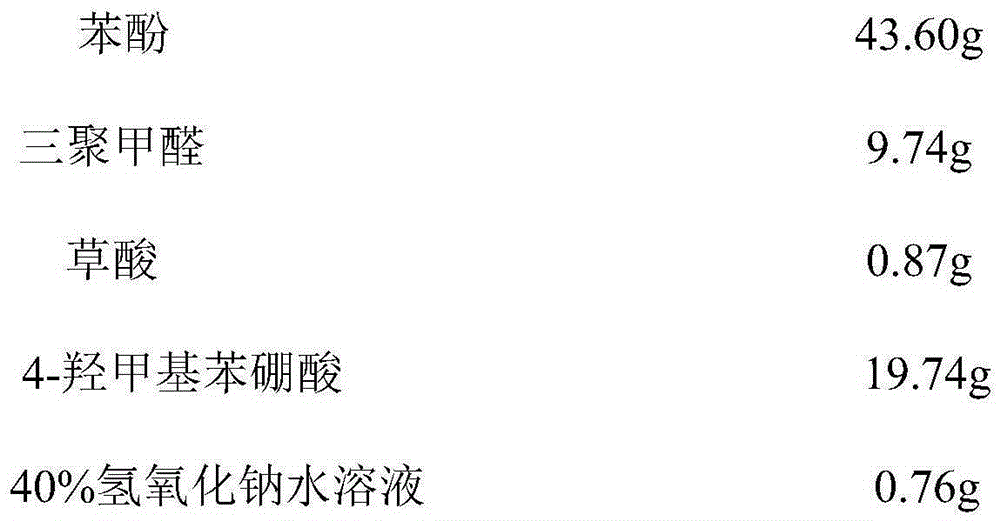

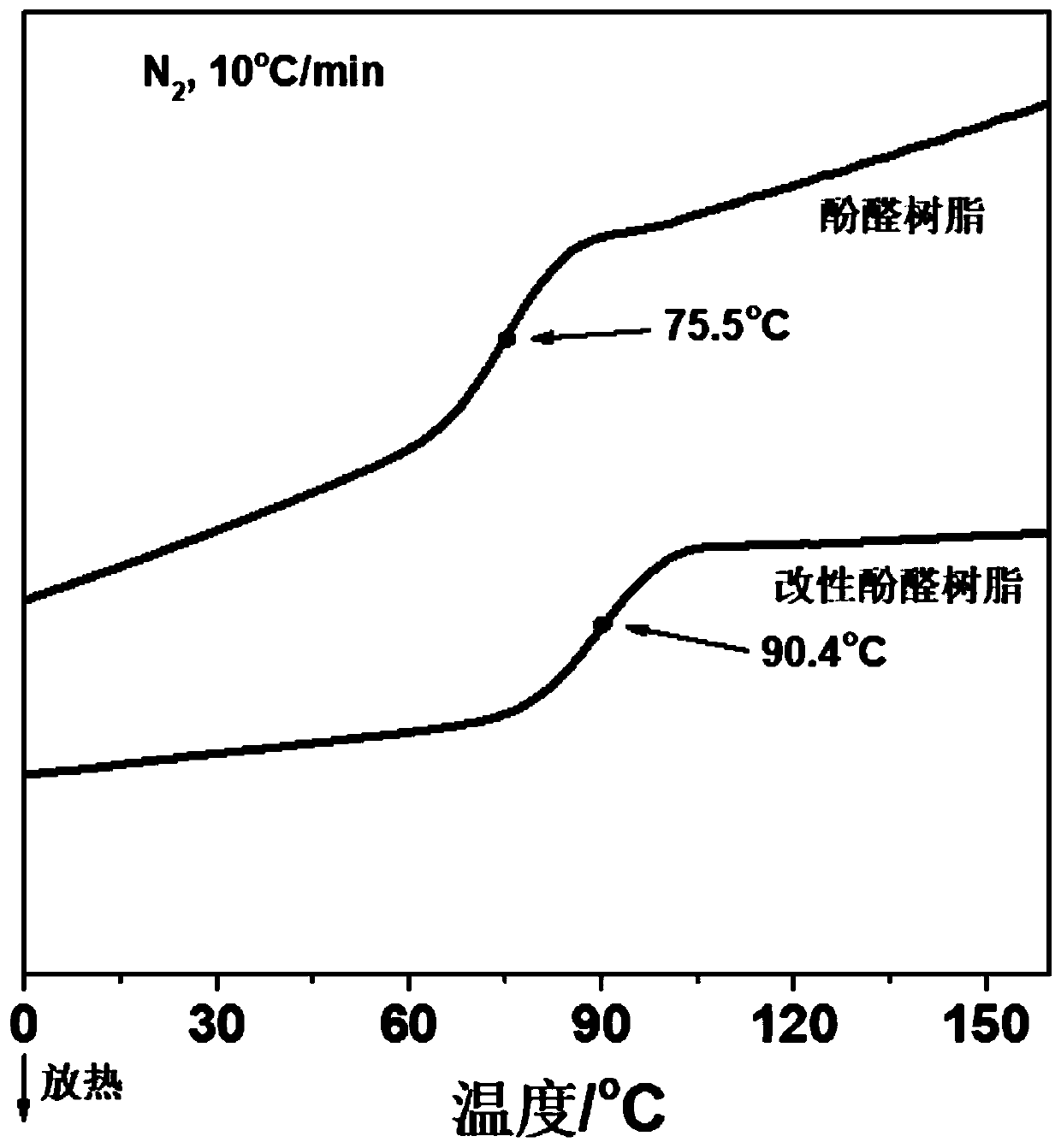

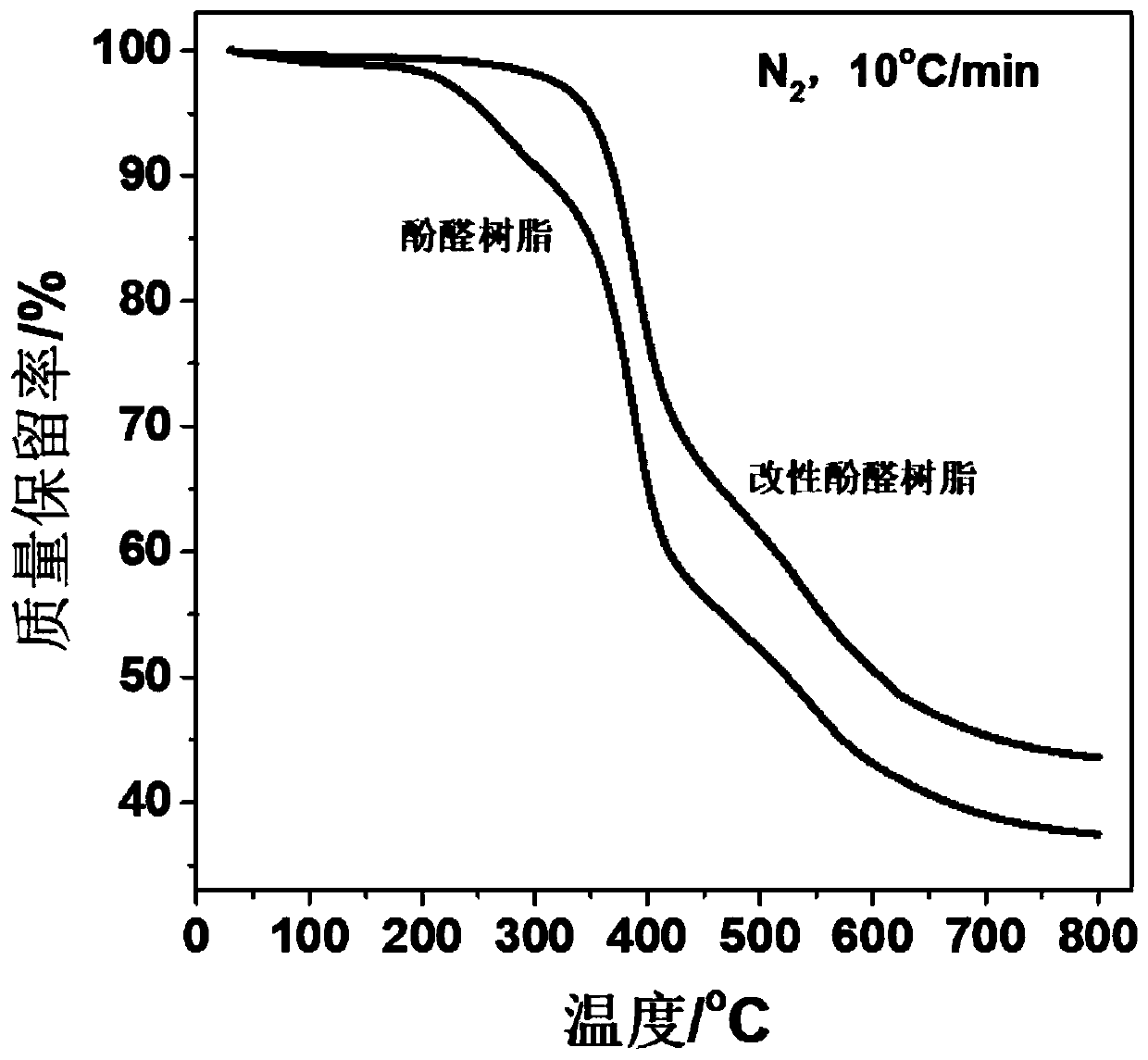

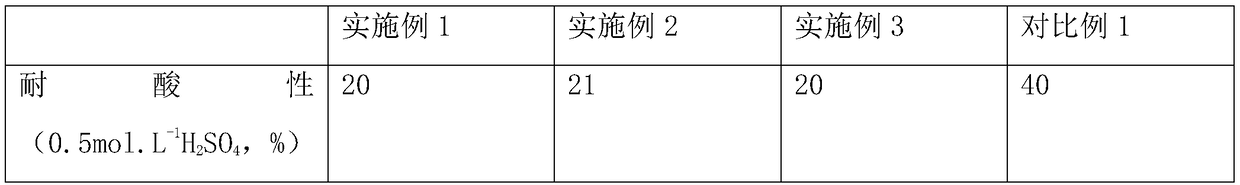

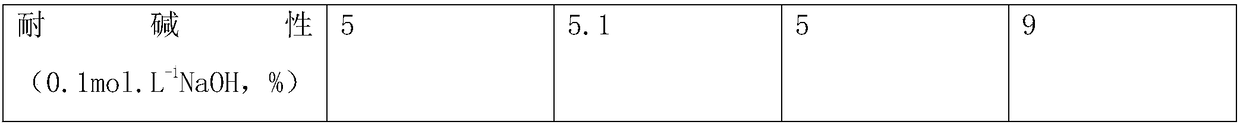

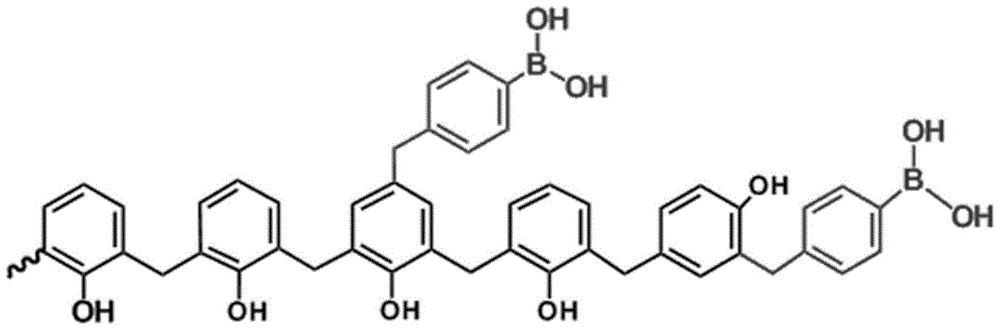

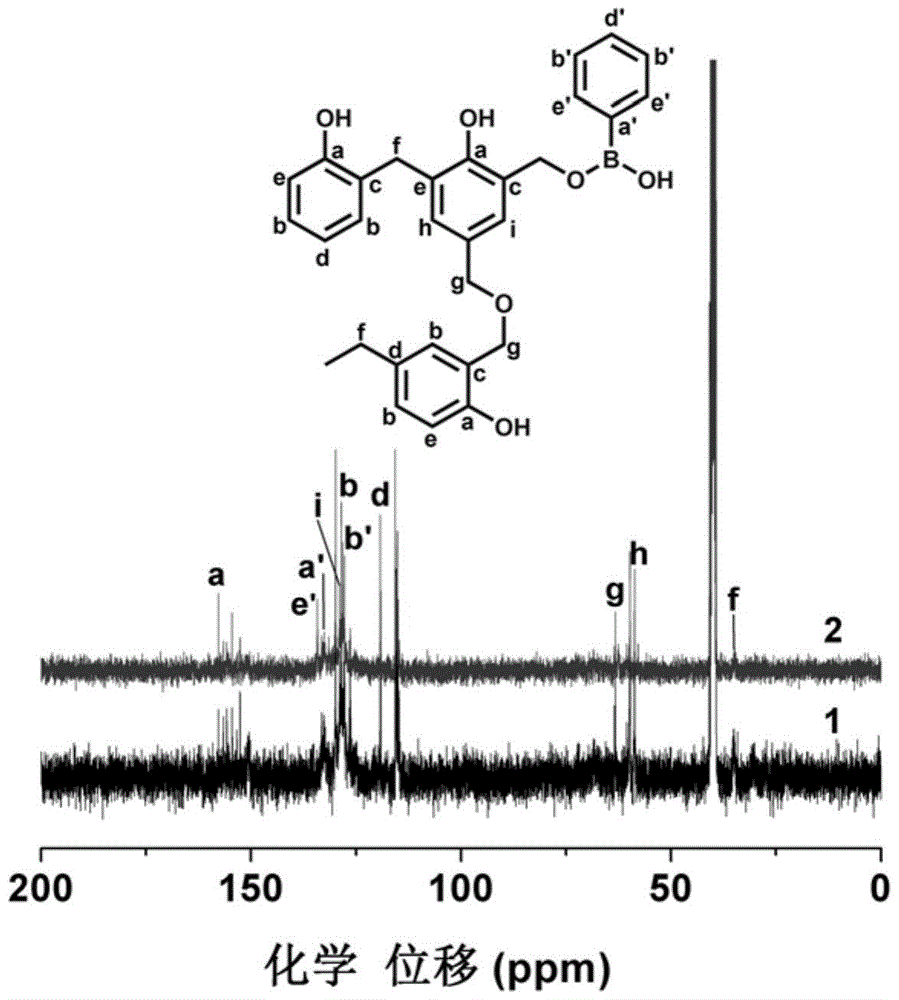

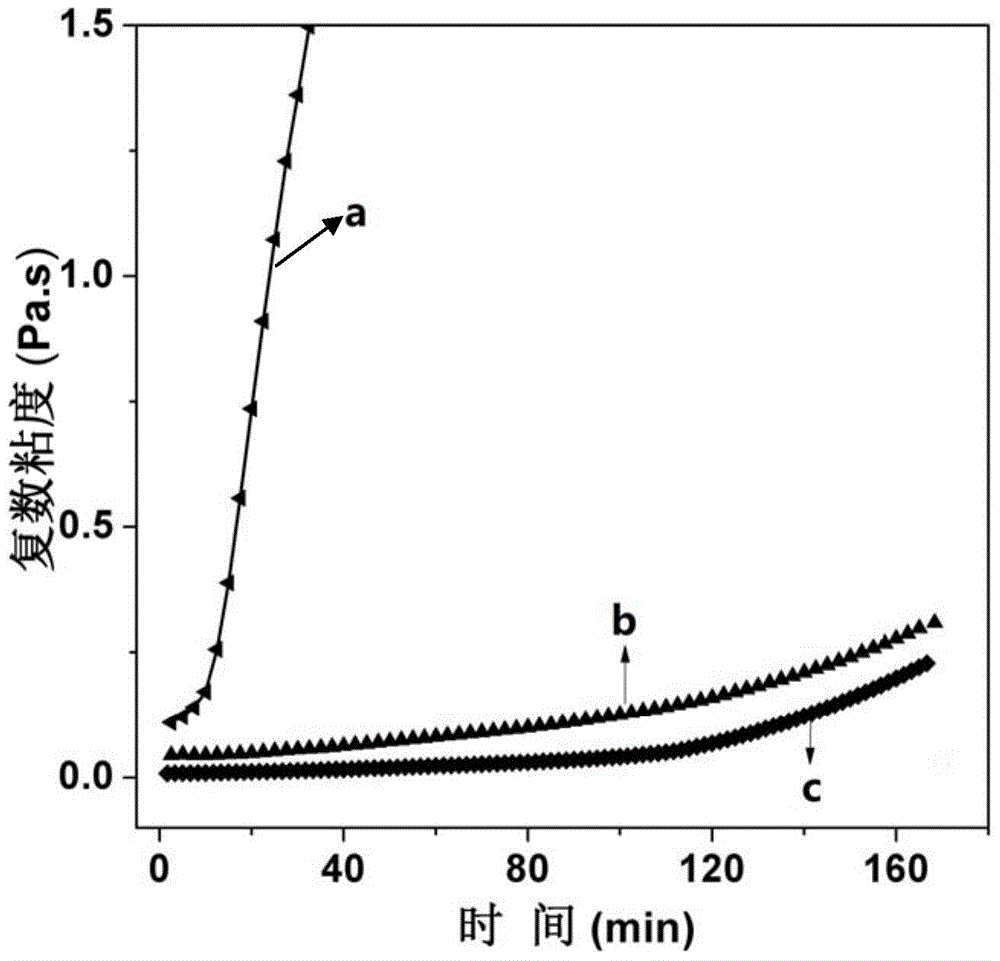

Preparation method of aryl-containing boron thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Carbon / phenolic heat insulating composite material and manufacturing process thereof

ActiveCN101440193AImprove ablation performanceGood heat insulationWoven fabricsYarnAlkaline earth metal

The invention relates to a carbon / phenol-formaldehyde heat-insulating composite material and production technology thereof. The carbon / phenolic aldehyde heat-insulating composite material takes viscose glue based carbon fibers as reinforcements and phenol-formaldehyde resin as a substrate, wherein the weight percent of the phenol-formaldehyde resin is between 30 and 45 percent; the carbon content of the viscose glue based carbon fibers adopted is between 95 and 97 percent; the tensile strength is more than or equal to 0.80 GPa; and the content of alkali metals or alkaline-earth metals is less than or equal to 100 mu g / g. The composite material has the advantages of superior ablation property, good heat-insulating property and light weight, and meets the use requirements under the environmental condition of high status. The production technology for the carbon / phenolic aldehyde heat-insulating composite material adopts the mode of taking chopped fiber yarns or woven fabrics of the viscose glue based carbon fibers as the reinforcements, and forming by a die stamping technology or a winding technology. The composite material prepared by the technology has good comprehensive performance, is light and thin under the condition of the same heat-insulating effect, and has significance in the aspect of high-end application limited by weight and size.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparing method for ablation-resisting boron-modified thermoplastic phenolic resin

The invention relates to a preparing method for ablation-resisting boron-modified thermoplastic phenolic resin. For solving the problems that at present, boron-modified phenolic resin is complex in production process and pollutes environment, and an obtained composite material product is high in porosity, solvent is not used in the synthetic process, an effective catalyst is adopted to make a boron-containing compound react fully, a resin structure is connected in a copolymerization mode, the suitable reaction temperature and the suitable time are controlled, and the boron-containing thermoplastic phenolic resin which is high in molecular weight, low in volatile content and low in curing volume shrinkage rate is synthesized, wherein the composite material of the resin is high in ablation performance and mechanical property. While the good heat resistance and ablation resistance of the boron-containing compound are brought into full play, the manufacturability and the mechanical property of the boron-containing phenolic resin are improved, and it is the research core to meet the requirement of aerospace development with the thermoplastic phenolic resin having a high carbon yield, a suitable softening point and good manufacturability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

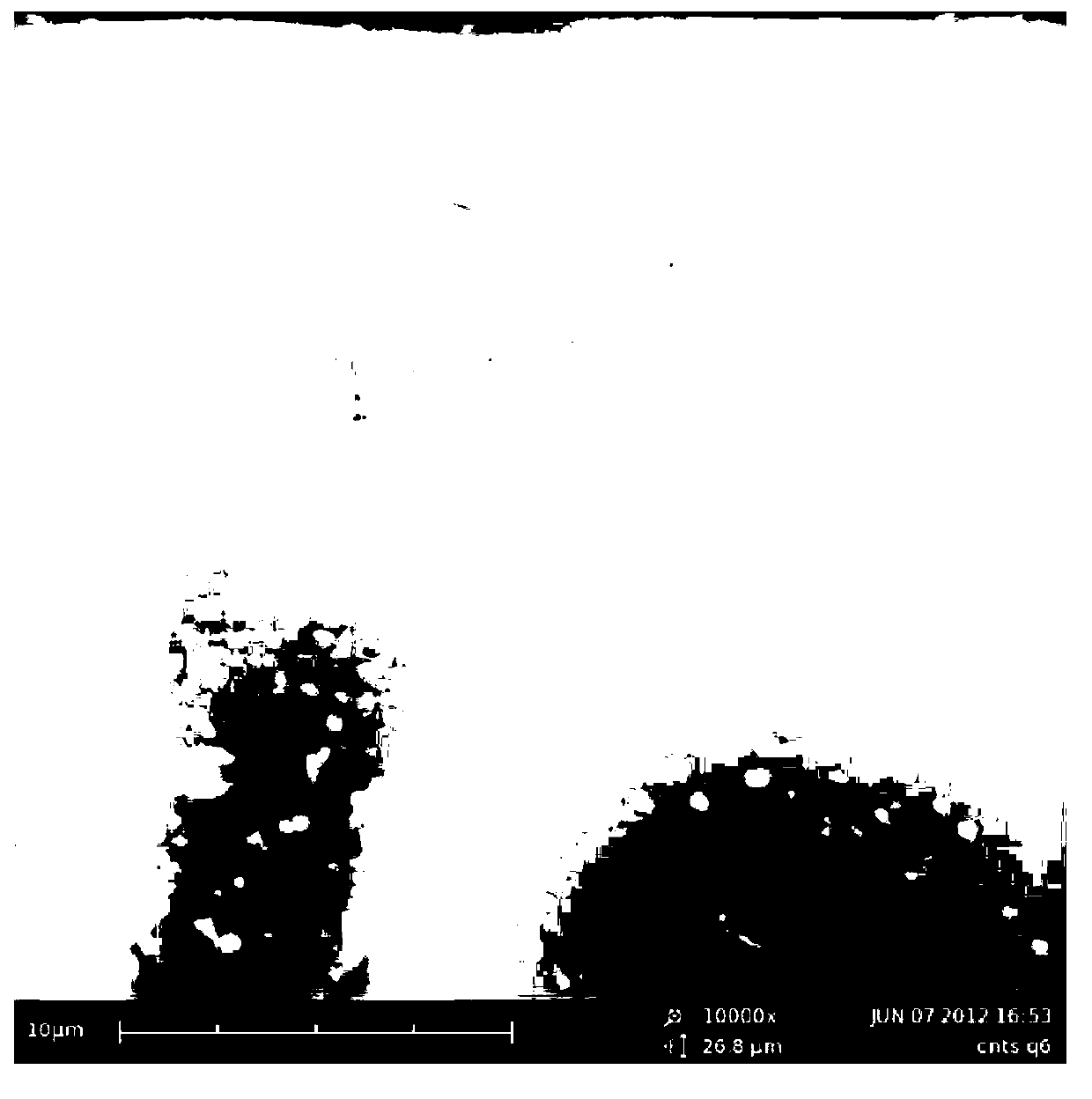

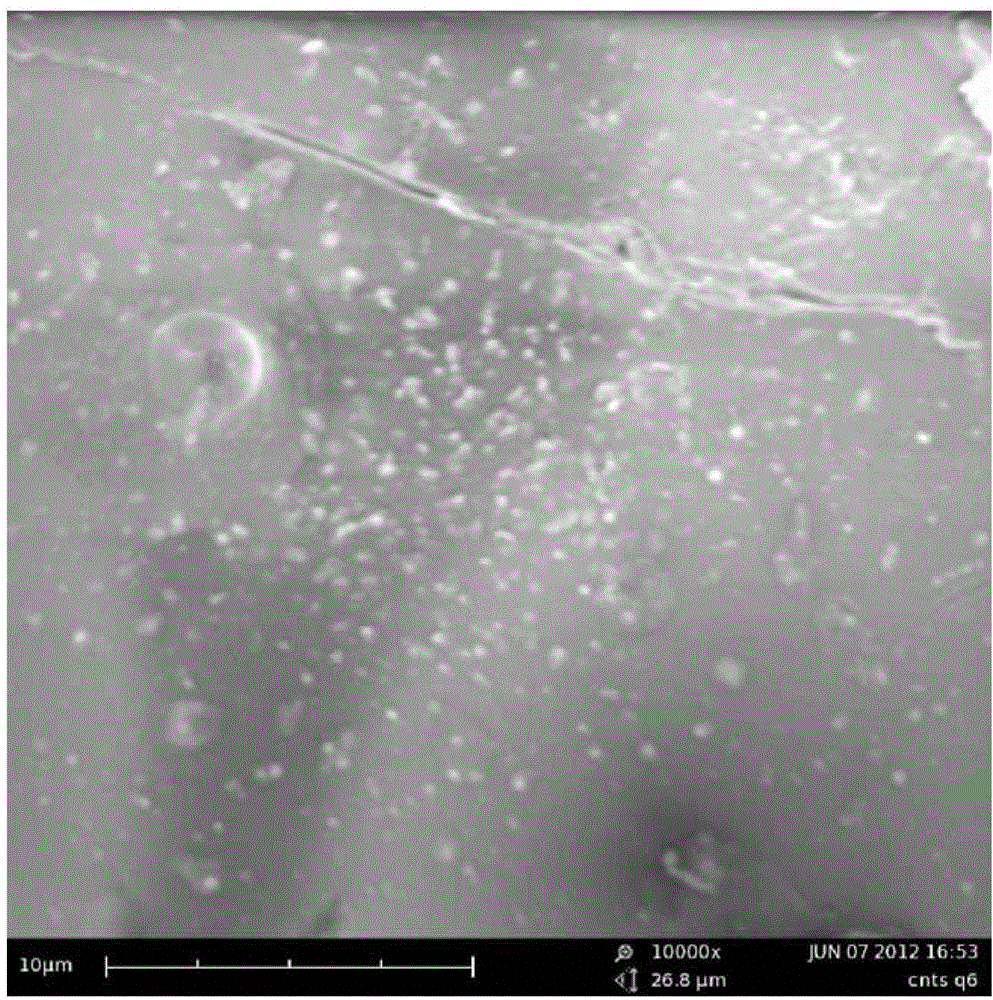

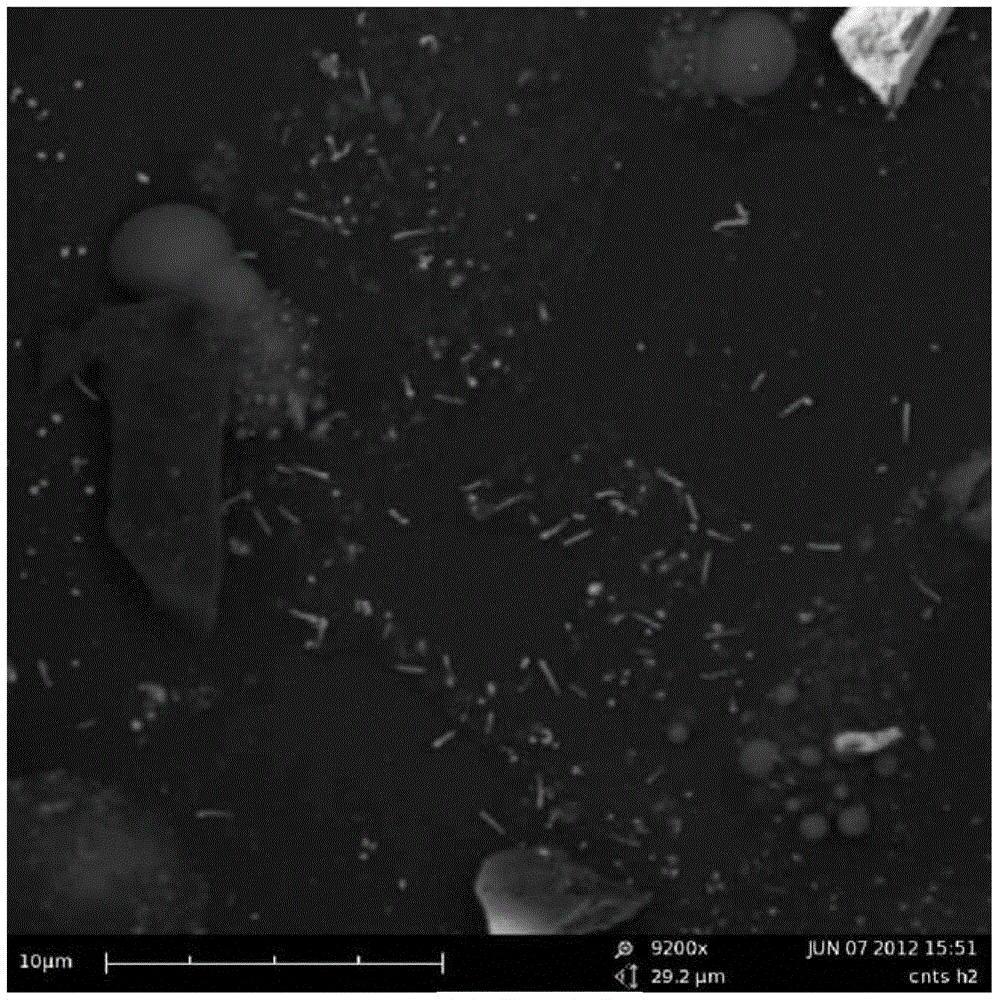

Preparation method of light ablative material

The invention discloses a preparation method of a light ablative material, relates to a preparation method of a thermal protection material, and is aimed at solving the technical problem of high density of the existing carbonization type light ablative material taking phenol-formaldehyde resin as a substrate. The method comprises the following steps of: dissolving boron phenol-formaldehyde resin in acetone to prepare a boron phenol-formaldehyde resin solution; adding the uniformly mixed microsphere filler and carbon nanotube into the boron phenol-formaldehyde resin solution, and mixing uniformly; standing to volatize acetone to obtain mixed paste; putting the phenol-formaldehyde honeycomb cut into a die inner cavity shape into a die, and filling the mixed paste into the phenol-formaldehyde honeycomb to obtain a composite green body; and curing and forming the composite green body to obtain the light ablative material. Through the invention, the density of the prepared light ablative material is as low as 0.2-0.4g / cm<3>, the linear ablativity is 0.035-0.115mm / s, and the mass ablativity is 0.0177-0.0216g / s; and the light ablative material can be used as a thermal protection material of a spacecraft.

Owner:HARBIN INST OF TECH

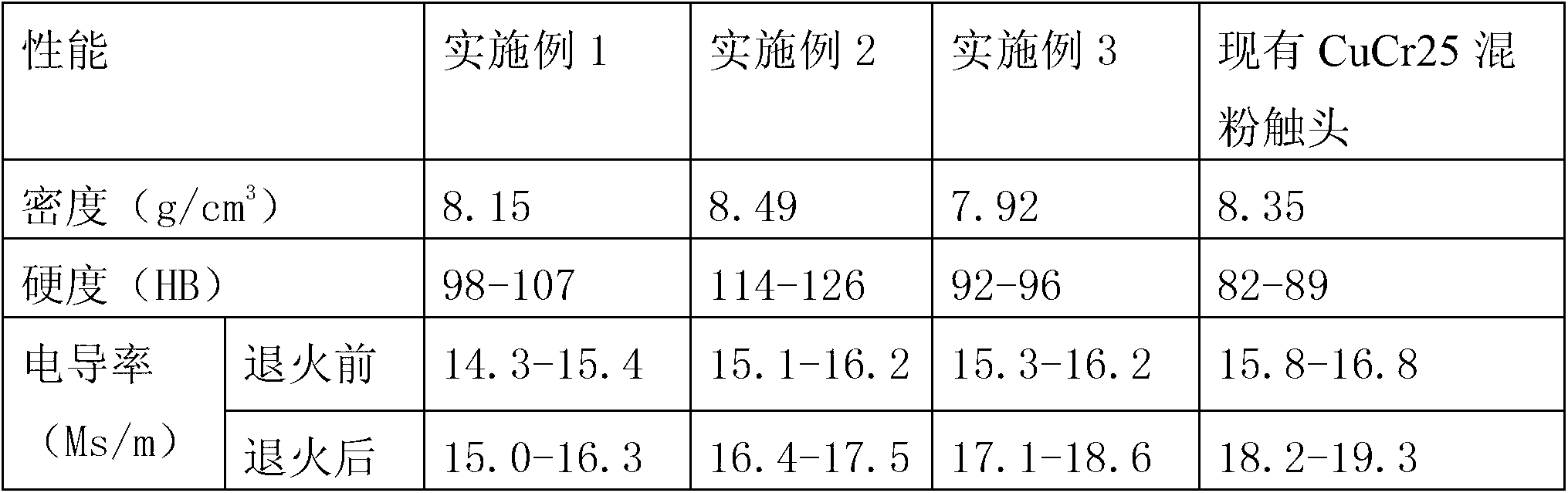

Contact material applied to middle-high-voltage vacuum switch-on/off and preparation method for same

The invention discloses a contact material applied to middle-high-voltage vacuum switch-on / off and a preparation method for the same. The contact material is prepared from the following raw materials in percent by weight: 5-50% of Cr powder, 1-15% of carbide and the balance of Cu powder. Compared with the prior art, the contact material disclosed by the invention has the beneficial effects that a design thought of further distributing a ceramic phase with a higher melting point in the existing copper-based material except a Cr phase with a high melting point is adopted; the ceramic phase has the functions of reinforcing the mechanical performance of the copper-based material and improving the welding resistance of the contact material; and via a hot-pressing sintering process, the compactness of a mixed powder contact is improved, and the material defects of closed pores, enrichment and the like of the mixed powder contact are reduced, thus improving the ablation performance of the contact material. Therefore, the contact material applied to middle-high-voltage vacuum switch-on / off disclosed by the invention is low in resistivity, improved in hardness, mechanical strength and compactness compared with common mixed powder contacts, improved in the voltage-resistant capacity of the mixed powder contact, strong in switch-on / off capacity, and good in welding resistance.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

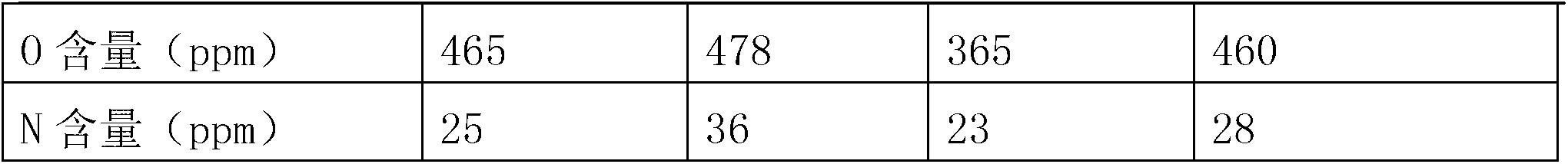

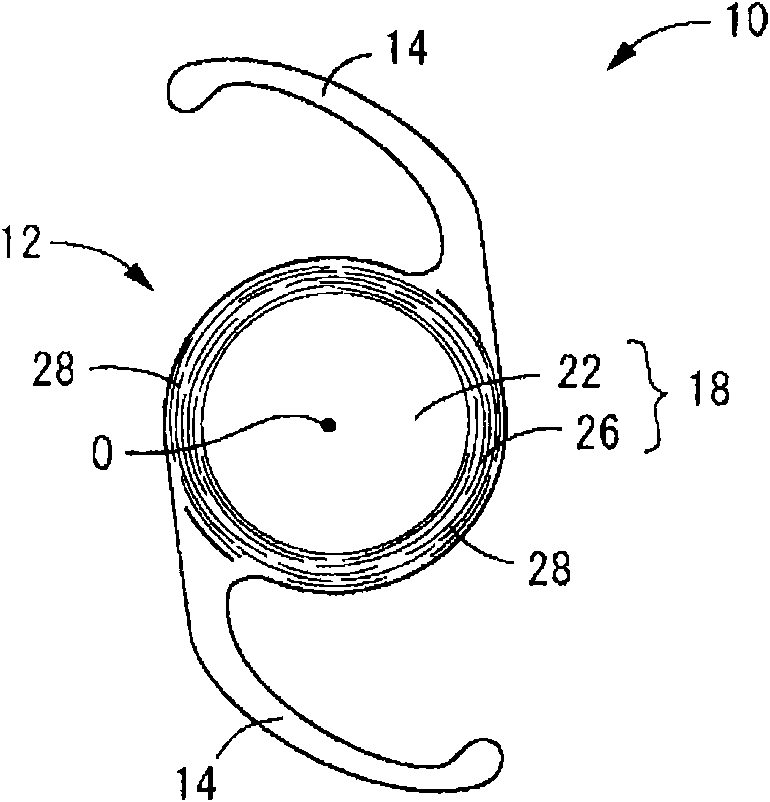

Intraocular lens and its manufacturing method

InactiveCN102088929AImprove surface roughnessHigh strengthOptical articlesCorrugation articlesEntire cellTransmittance

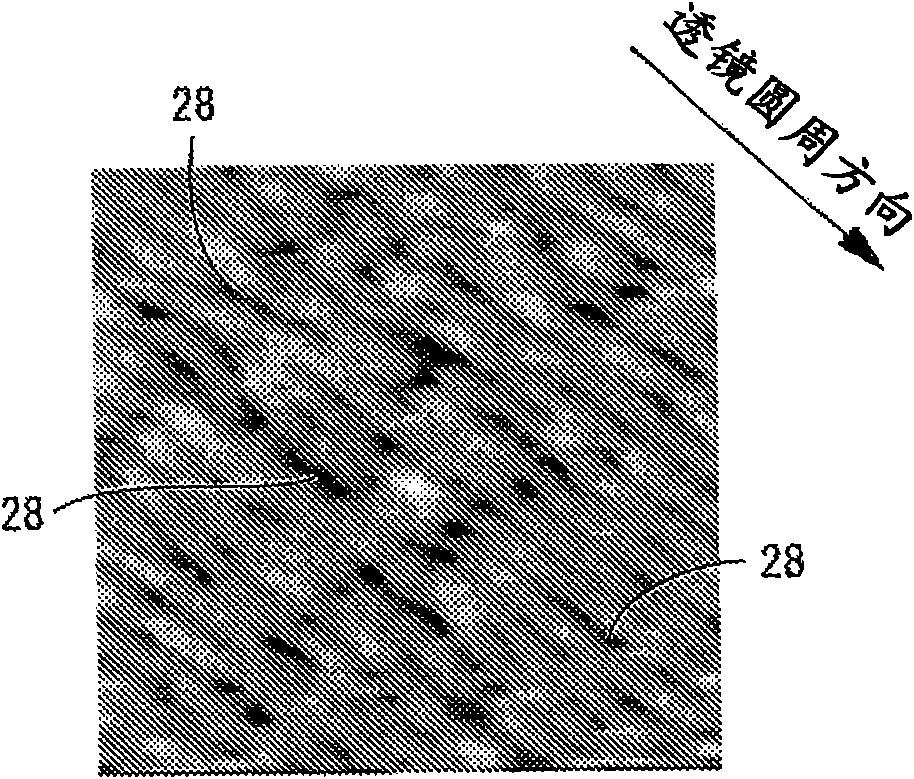

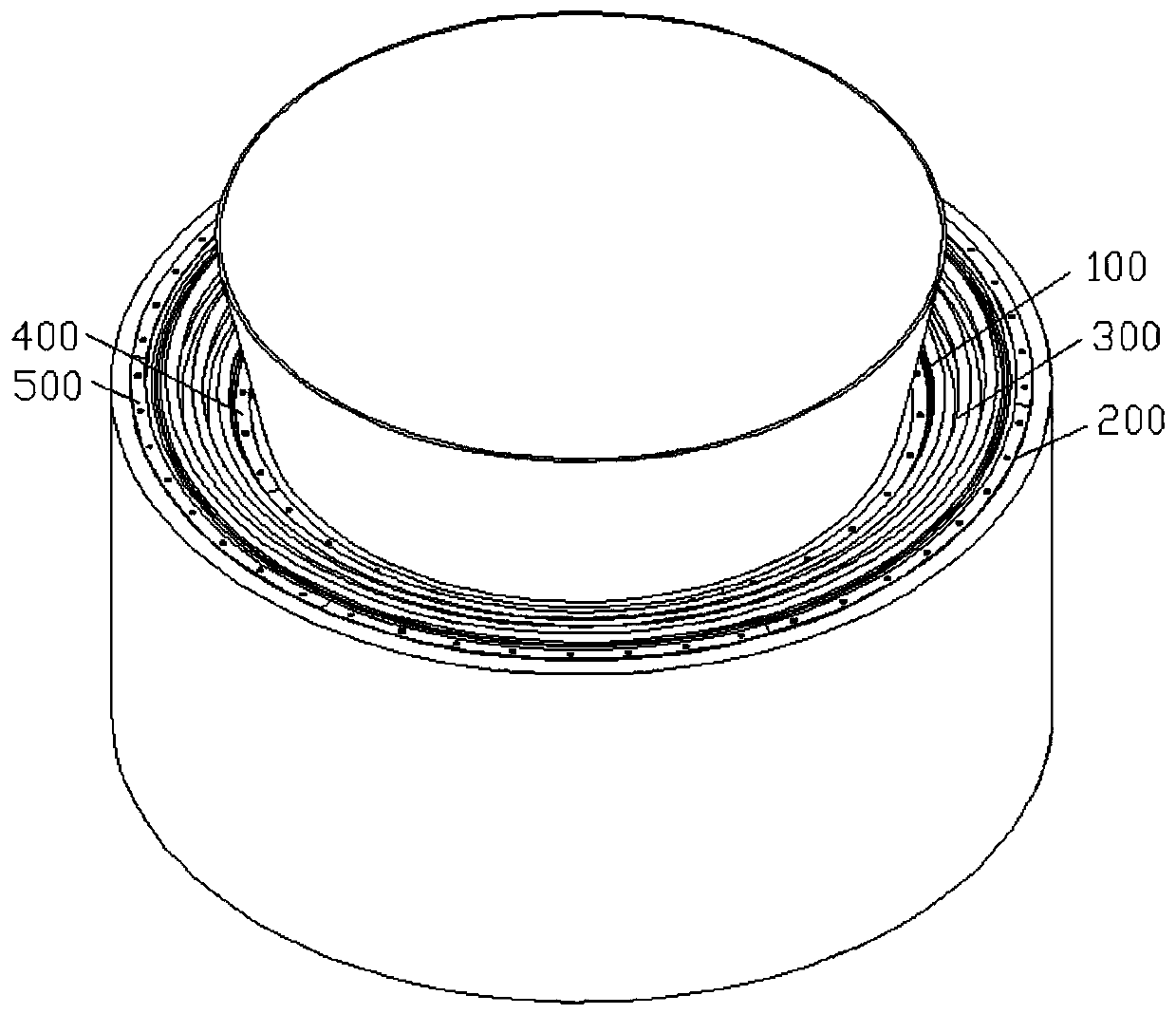

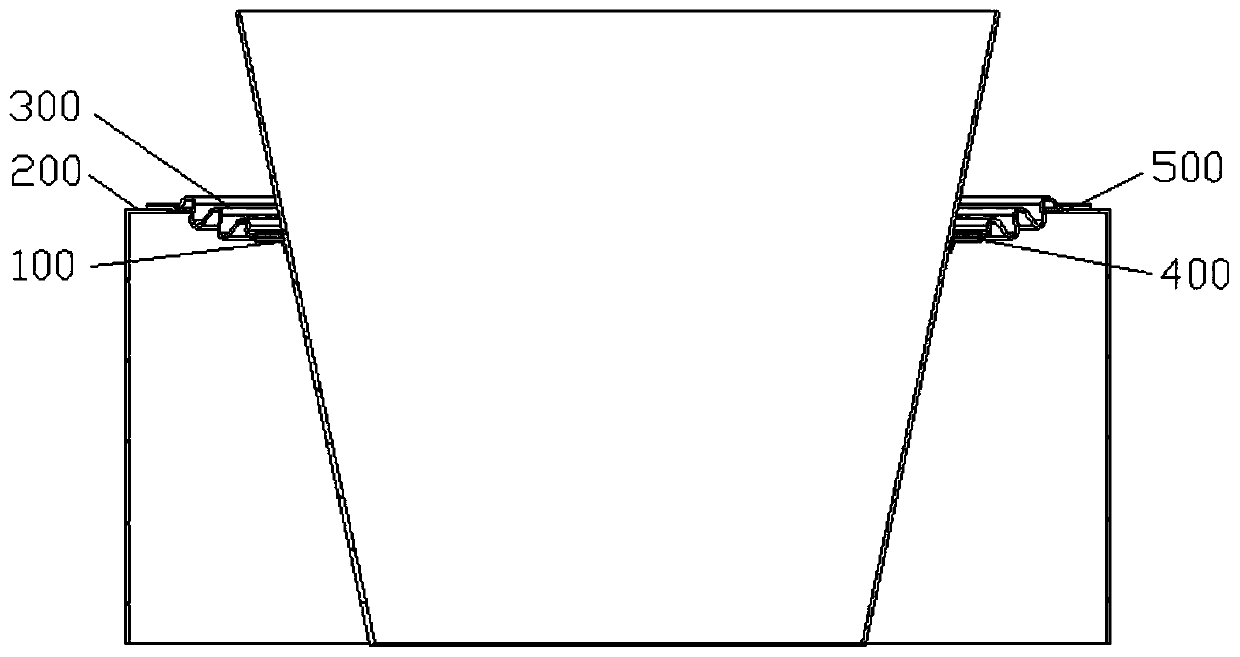

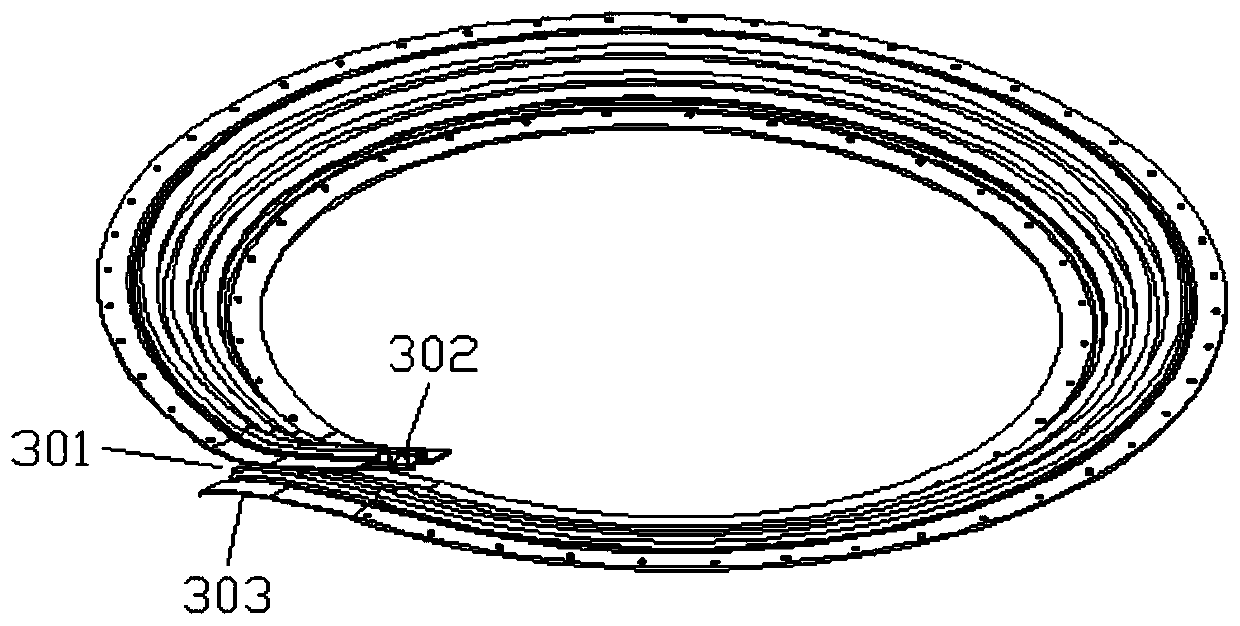

An intraocular lens having a novel structure including an adequately large effective optical part and producing an excellent suppressing effect on a secondary cataract. At least a part of the lens surfaces (16, 18, 30) of an intraocular lens is cell inducing regions (26, 32) where a large number of linear micro-grooves (28) having depths of 0.01 to 1.0 [mu]m, widths of 0.1 to 2.0 [mu]m, and predetermined lengths, circumferentially extending are directly formed. The micro-grooves (28) are connected in the circumferential direction of the lens surfaces (18, 30) to construct a chaining structure and are periodically arrayed in the radial direction of the lens surfaces (18, 30) to construct a periodic structure. The transmittance to visible light in the cell inducing regions (26, 32) is 60% or more thanks to the formation of the linear micro-grooves (28) over the whole cell inducing regions (26, 32) with no space between the linear micro-grooves.

Owner:KOWA CO LTD

Preparation technology of glass fiber cloth

InactiveCN103434255AHigh temperature resistantImprove performanceSucessive textile treatmentsLaminationGlass fiberTemperature resistance

The invention relates to the field of glass fiber cloth manufacturing, and discloses a preparation technology of glass fiber cloth. The preparation technology comprises the steps of manufacturing grey cloth, rebeaming, and performing first thermal cleaning, second thermal cleaning, air airing and surface treatment. The glass fiber cloth has outstanding high temperature resistance, and good ablation performance, and an insulation grade of an electrotechnical product is raised.

Heat-proof device for swing type rocket engine nozzle

The invention discloses a heat-proof device for a swing type rocket engine nozzle, and belongs to the technical field of heat-proof and insulation devices for space launch. The heat-proof device for the swing type rocket engine nozzle comprises a nozzle flange, a cabin shell rear end cover and a heat-proof telescopic apron board; the nozzle flange is connected with an inner ring end surface of theheat-proof telescopic apron board, and the cabin shell rear end cover is connected with an outer ring end surface of the heat-proof telescopic apron board; the section of the heat-proof telescopic apron board is of a corrugated structure; and the heat-proof telescopic apron board is made of flexible ablation-resistant heat-proof materials. The problems that the structure is cracked due to poor ductility, and internal equipment is burnt by flame backflow since the apron board is of a flat plate type or conical surface heat insulation structure made of metal or composite materials are solved. The heat-proof telescopic apron board is made of flexible ablation-resistant heat-proof materials, and the section is of the corrugated structure, the flame of an engine can be prevented from flowing back to the interior of a cabin body, the returned flame is blocked from entering the cabin body, and the heat-proof device has high barrier property on ablation property and gas flow.

Owner:TIANJIN ISTAR ADVANCED MATERIAL TECH CO LTD

High-strength and high-temperature-resistant glass fiber

The invention relates to the technical field of glass fibers, in particular to a high-strength and high-temperature-resistant glass fiber. The high-strength and high-temperature-resistant glass fibercomprises 60.5-64.5% of SiO2, 8.0-11.0% of Al2O3, 12.0-16.0% of CaO, 3.0-6.0% of MgO, 2-5% of Li2O, 0.5-0.9% of ZrO2, 0.8-1.4% of TiO2, 0.3-0.7% of Na2O, 0.2-0.6% of K2O, 0.3-0.5% of Fe2O3, 0.4-0.8% of SiC, 0.5-1.5% of B2O3, 0.5-1.1% of CeO2 and 0.3-0.8% of GeO2. The produced high-strength and high-temperature-resistant glass fiber is high in mechanical strength and mechanical performance, good inchemical stability and thermal stability, excellent in high temperature resistance and widely applicable.

Owner:ANHUI TONGLI NEW MATERIALS

Processing technology of glass fiber

The invention discloses a processing technology of glass fiber. Specifically, the steps are as follows: adding raw material glass, a clarifying agent, a halide, mirabilite, quartz sand and firefly powder into a melting furnace; heating the melting furnace to make a temperature of the glass rise, first performing preheating, then performing melting, performing wire-drawing on a molten glass liquidby using a wire drawing machine, performing cooling forming on the drawn glass fiber by water, putting the cooled glass fiber into an acid solution, and stirring the acid solution by using an acid resistant pump under assistance of bubbling stirring to enhance ion exchange. The technology is simple and practicable, the produced glass fiber has good insulation, good corrosion resistance, high mechanical strength, and excellent high-temperature resistance, can be used at 1100 DEG C or less for a long time, has good ablation performance, and better high-temperature resistance, chemical corrosionresistance and elastic modulus, and is widely used in manufacturing of precision instrument thermal protection parts, ablation materials, thermal insulation materials and other fields.

Owner:佛山市嘉懿行农业科技有限公司

Preparation method for glass fiber

InactiveCN107032596ASmooth appearanceUniform colorGlass making apparatusMuffle furnaceWork in process

The invention relates to a preparation method for glass fiber. The method comprises the following steps: 1) mixing and fusing raw materials, and wiredrawing to form a crude fiber product; 2) putting the crude fiber product into a muffle furnace, removing water attached to the glass fiber surface, and then performing acid-base immersion cleaning, thereby acquiring a refined glass fiber product; 3) soaking the refined glass fiber product into a NaOH solution and then taking out, washing with distilled water, taking out and dispersing in absolute ethyl alcohol of a coupling agent KH570, regulating pH and dispersing with an ultrasonic meter, thereby acquiring a semi-finished product of glass fiber; 4) removing surface alkali liquor by spraying the surface of the semi-finished product of glass fiber with warm water, then soaking in clean water, and washing with the assistance of a hot water pump till the pH value is less than 6, thereby acquiring a to-be-finished product of glass fiber; 5) performing thermal shaping treatment on the to-be-finished product of glass fiber, and performing gumming, grouting and drying on the surface, thereby acquiring the end product. The preparation method has the advantages of simple structure, low cost and suitability for large-scale industrial manufacturing.

Owner:合肥钢骨玻璃制品有限公司

Closed discharge gap triggered by plasma jet and application thereof

PendingCN110430655AReliable actionImprove controlSpark gap detailsPlasma techniquePlasma jetHigh pressure

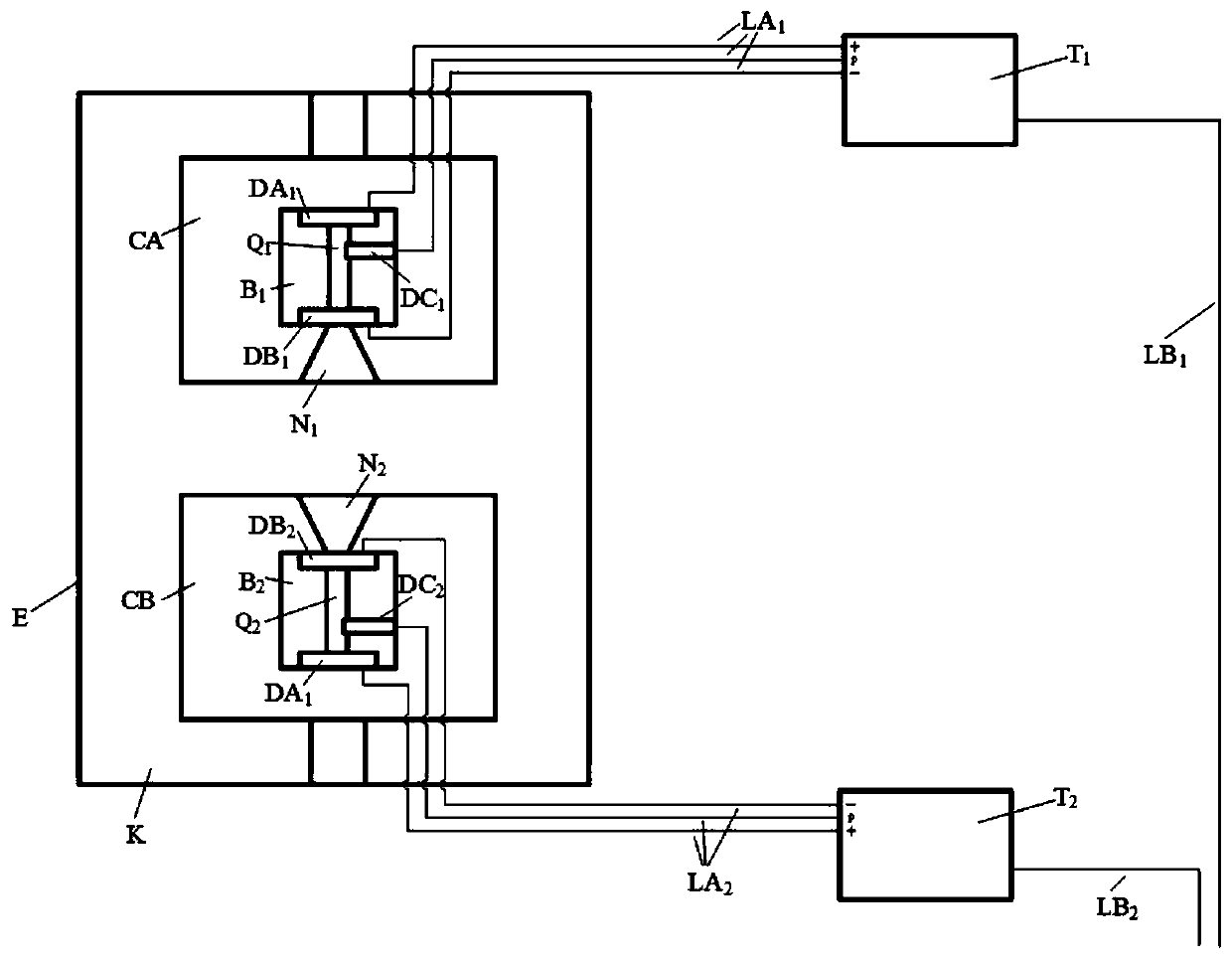

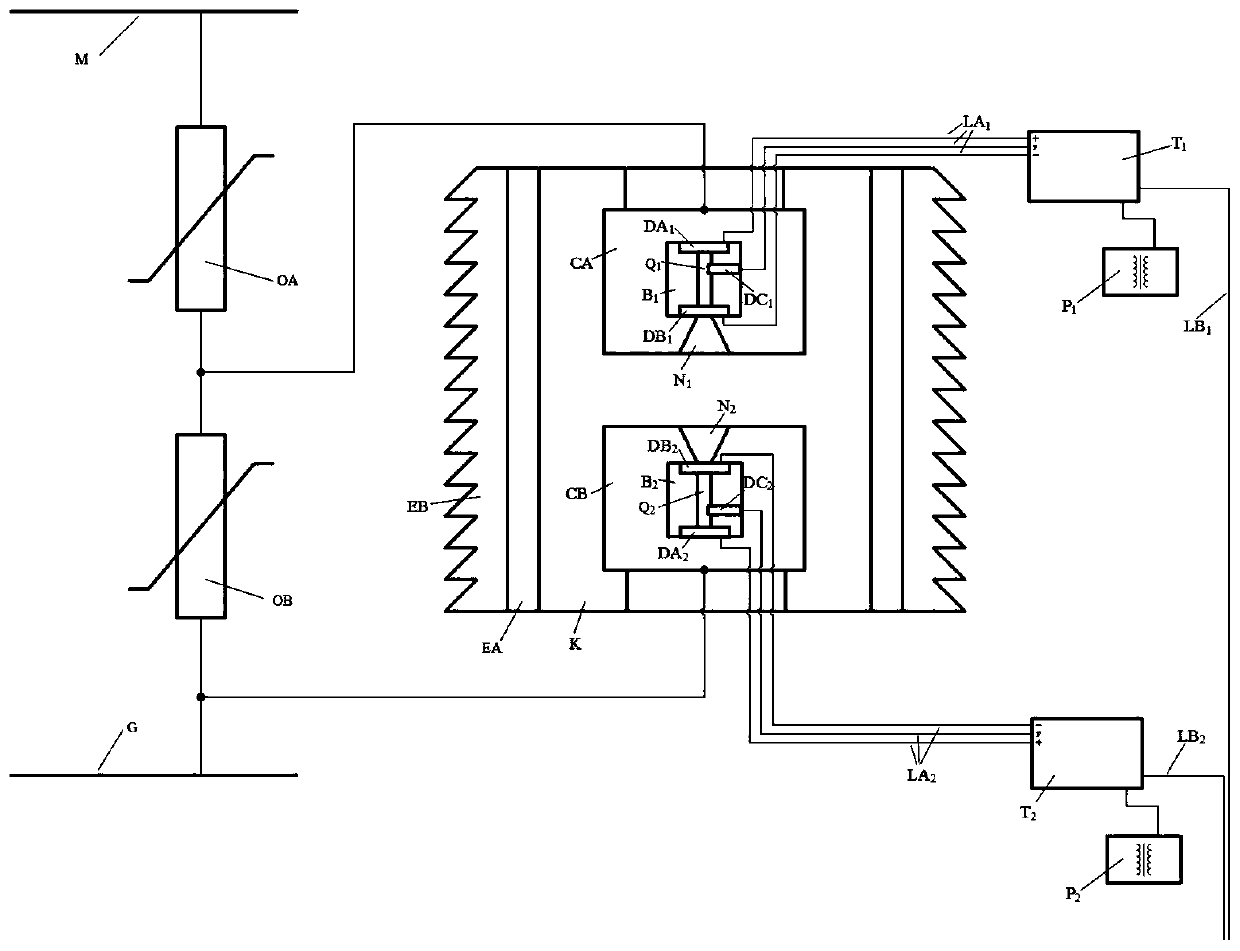

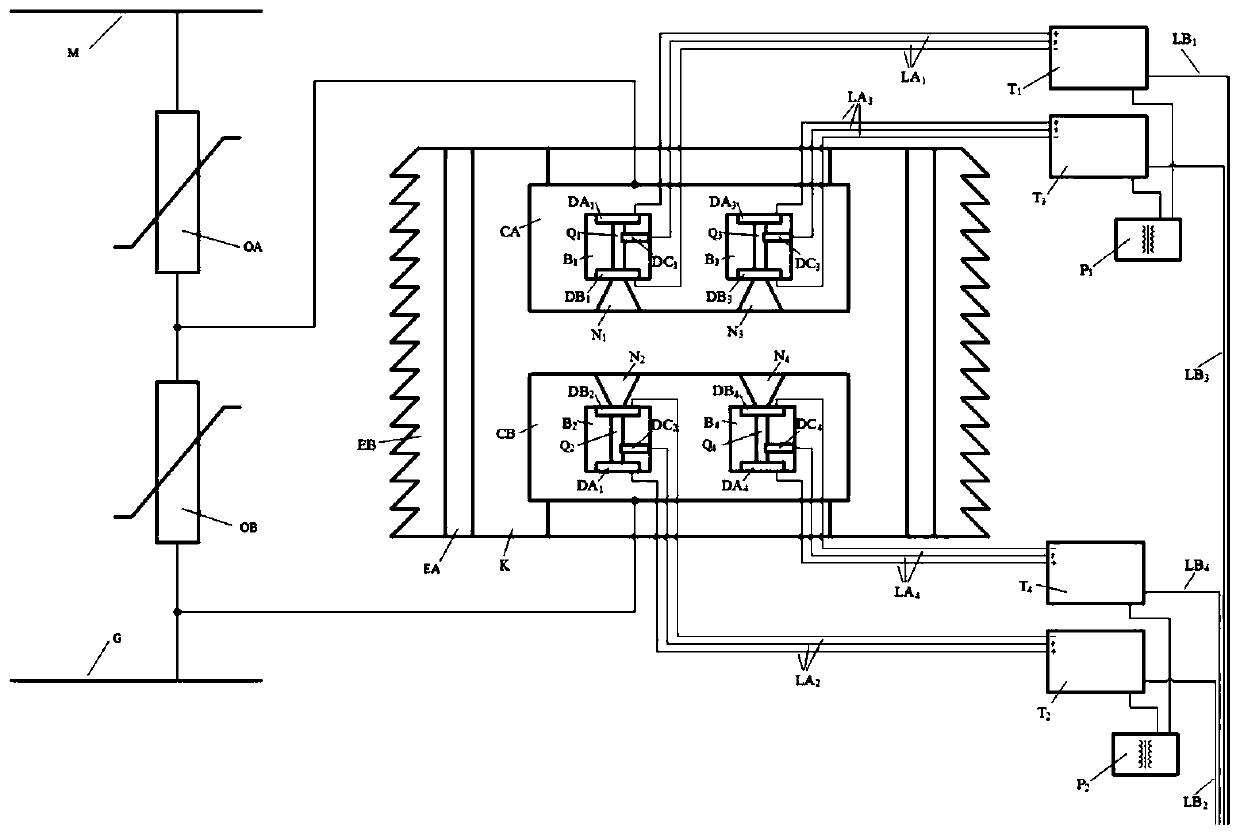

The invention discloses a closed discharge gap triggered by a plasma jet and an application thereof. The closed discharge gap comprises a plasma spraying unit comprising an injection device and a plasma trigger T, wherein the injection device is arranged in a contact unit, generates plasmas and ablate the ablation materials through pulse voltages and currents and generates a plasma jet by adoptinga capillary action of an elongated cavity, the injection device is connected with a plasma trigger T through the high voltage wire LA, the contact unit is arranged in the cavity unit for tolerance ofarc ablation, the cavity unit is used for providing a closed high-pressure gaseous medium environment. The closed discharge gap can ensure the reliable operation in the low work parameters, improvesthe control performances of the discharge gap, increases the work range and service life of the discharge gap, solves the problems that the arc is extinguished due to the small gap current, avoids thegap breaking, and replaces the complex and high-cost energy storage and freewheeling device.

Owner:西安西交瑞力电气研究院有限公司

EPDM heat-insulation layer material, and preparation method and application thereof

InactiveCN109851924AGood process performanceImprove construction accuracyThermal insulationEPDM rubber

The invention relates to an EPDM heat-insulation layer material, and a preparation method and an application thereof, specifically to a windable EPDM heat-insulation layer material and a preparation method and an application for the windable EPDM heat-insulation layer material, belongs to the technical field of heat insulation of solid rocket motors, and specifically relates to an EPDM heat-insulation material which can be prepared into a raw adhesive tape, is applicable to a winding molding process and has excellent comprehensive performance. According to the invention, through addition of polar rubber into EPDM rubber for reinforcement, an unvulcanized heat-insulation layer material has certain tensile strength, and is easily prepared into a strip-shaped heat-insulation layer and wound into a disk, so continuous molding and mechanized operation can be realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

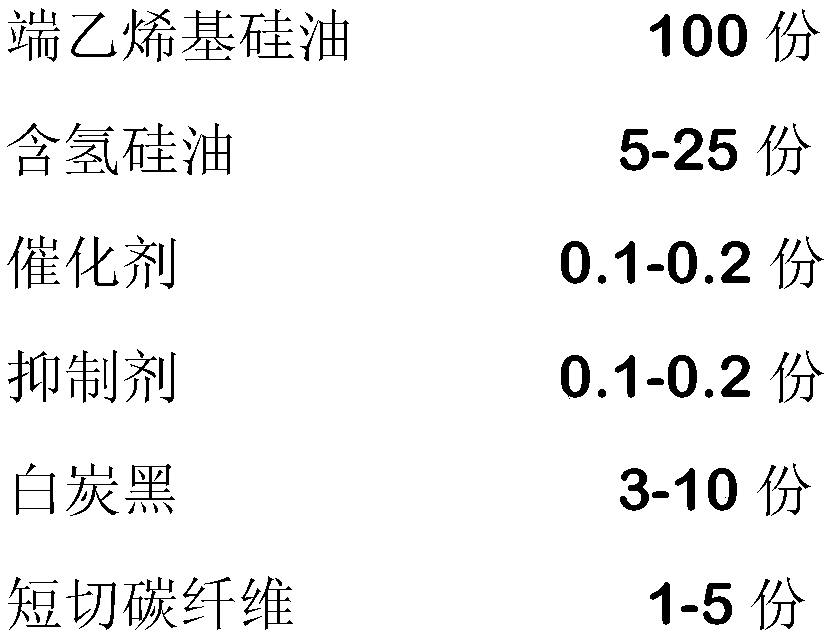

Aramid honeycomb-reinforced silicon-based heat insulating material and preparation method thereof

ActiveCN108164741AImprove structural stabilityImprove ablation performanceCoatingsThermal insulationRoom temperature

The invention relates to an aramid honeycomb-reinforced silicon-based heat insulating material and a preparation method thereof and belongs to the field of thermal insulation in a missile engine. Through use of an aramid honeycomb with skeleton reinforcing effects, the structural stability of the silicon-based heat insulating material is improved, excellent ablation resistance is obtained and thearamid honeycomb-reinforced silicon-based heat insulating material can be used in the field of thermal insulation in a missile engine. The glue in pores of the aramid honeycomb is a room temperature vulcanized silicone rubber composite material. The aramid honeycomb-reinforced silicon-based heat insulating material in the field of thermal insulation in a missile engine satisfies the requirements on heat insulating in the missile engine. Through use of the aramid honeycomb in the silicon-based heat insulating material, the aramid honeycomb-reinforced silicon-based heat insulating material is obtained.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

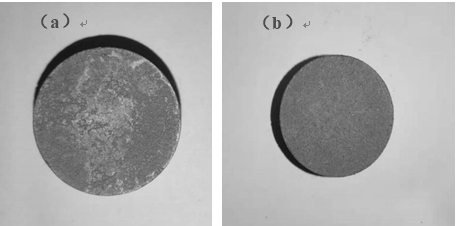

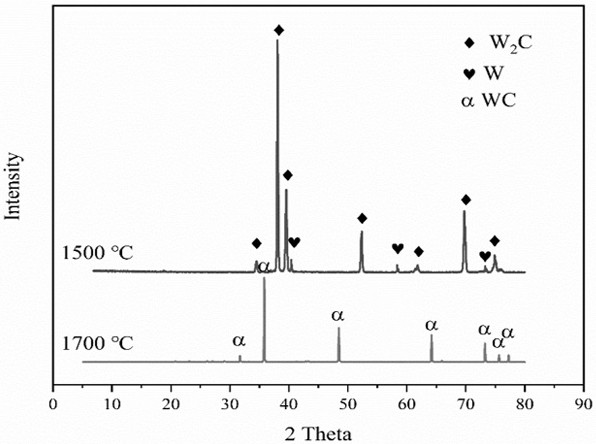

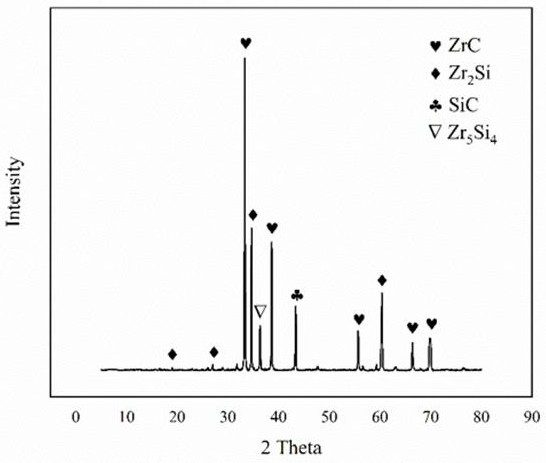

Preparation method of zirconium and/or tungsten-based multiphase ceramic coating

The invention provides a preparation method of a tungsten and / or zirconium-based multiphase ceramic coating, which comprises the following steps: adding a mixture of a carbon-carbon matrix and chlorine salt metal powder into a graphite crucible, dissolving and flowing molten salt in a high-temperature argon atmosphere, and carrying out salt bath on the surface of the carbon-carbon matrix to prepare the ceramic coating. According to the preparation method provided by the invention, the carrier effect of a molten salt liquid phase at the temperature of 1300-1700 DEG C is ingeniously utilized, and the ceramic multiphase coating with high density is deposited on the surface of the carbon-based material. The method provided by the invention is short in production period, simple in process and cost-saving.

Owner:CENT SOUTH UNIV

Novel glass fiber

InactiveCN107651854ASmooth appearanceUniform colorGlass making apparatusTemperature resistanceSilicon dioxide

The invention discloses a new type of glass fiber, which relates to the technical field of new materials. The glass fiber is mainly composed of SiO2, Al2O3 and CaO raw materials, and on this basis, MgO, ZrO2, TiO2, Fe2O3, Na2O, K2O and Li2O and other components are introduced. The manufacturing process includes raw material mixing and melting, acid leaching, water cleaning, heat treatment, post-surface treatment, etc. The glass fiber prepared by the above process has high silica content, smooth appearance and uniform color, which can be well applied to Various post-processing manufacturing processes, excellent high temperature resistance, can be used for a long time below 1100°C, has good ablation performance, better high temperature resistance, chemical corrosion resistance and elastic modulus, and can be widely used in the manufacture of precision instruments Heat protection parts, ablation materials, thermal insulation materials and other fields.

Owner:内江市旭日环境科技有限公司

Preparation method of graphite crucible

The invention discloses a preparation method of a graphite crucible. The preparation method comprises the following steps: S1, raw material preparation: raw materials comprise graphite scraps, an Acheson furnace petroleum coke resistance material, an Acheson furnace petroleum coke thermal insulation material and medium-temperature coal pitch; s2, burdening: graphite is crushed and ground into graphite powder, then the graphite powder is mixed with the Acheson furnace petroleum coke resistance material, the Acheson furnace petroleum coke resistance material and the Acheson furnace petroleum coke heat preservation material according to the mass ratio of 3: 2: 5, the mixture is ground into mixed powder, the mixed powder is mixed with medium-temperature coal pitch, the mass percent of the mixed powder in the mixing process is 65%-85%, and the medium-temperature coal pitch is obtained; the mass percent of the medium-temperature coal pitch is 15%-35%; s3, mixing and kneading; s4, profiling is conducted; s5, roasting; and S6, processing. A hot-pressing cold-out one-time forming method is adopted, the obtained product is excellent in performance and shows good thermal shock resistance, ablation performance, leakage-proof performance and mechanical strength, and the preparation process has the advantages in the aspects of saving energy, protecting the environment, shortening the period and improving the aging efficiency.

Owner:吉林科工碳业有限公司

Electric conical valve type gas flow regulator for solid rocket ramjets

The invention discloses an electric conical valve type gas flow regulator for solid rocket ramjets. A drive motor is fixed to a connecting box. One end of a coupling is fixedly connected with a shaft of a motor, and a slider is disposed in a slide hole in the other end of the coupling. The slider is fixedly connected with a valve stem through a tension and pressure sensor. A drive nut is fixedly connected to a solid gas generator. The valve stem passes the drive nut and in threaded fit with the drive nut. A conical valve head is fixedly connected with the valve stem in a threaded manner and extends into a spray pipe of the gas generator. The gas generator is in an inner shell structure which is hollow. The valve stem is fitted in the inner shell, and a bushing is fitted between the valve stem and the gas generator. One end of the valve stem, close to the conical valve head, is provided with a peripheral circular groove, and a moving seal is disposed in the circular groove. A pressure sensor is mounted on the rear head of the gas generator. The electric conical valve type gas flow regulator for solid rocket ramjets is simple in structure, small in size, reliable in operation, low in ablation effect, low in cost, and accurately controllable.

Owner:NANJING UNIV OF SCI & TECH

Glass fiber enhanced composite material

InactiveCN108948667AImprove ablation performanceImprove high temperature resistanceCarbon fibersAntioxidant

The invention discloses a glass fiber enhanced composite material. The glass fiber enhanced composite material is prepared from the following raw materials in parts by weight: 7 to 9 parts of epoxy resin, 5 to 10 parts of cyanate resin, 11 to 16 parts of glass fibers, 2 to 6 parts of carbon fibers, 2 to 6 parts of graphite fibers, 3 to 7 parts of ceramic whiskers, 2 to 4 parts of zinc oxide whiskers, 1 to 2 pats of rare-earth complex nanoparticles, 1 to 5 parts of a curing agent, 2 to 5 parts of a toughening agent, 2 to 4 parts of nano titanium dioxide, 2 to 4 parts of nano diatomite, 1 to 3 parts of a lubricant, 3 to 5 parts of turpentine oil, 1 to 3 parts of a silane coupling agent, 0.5 to 1 part of an antioxidant, 1 to 5 parts of polyethylene glycol and 1 to 3 parts of zinc stearate. The glass fiber enhanced composite material prepared by the invention has good ablation performance, better high temperature resistance, chemical corrosion resistance, impact resistance, ageing resistance, oxidization resistance, weather resistance and elastic modulus.

Owner:旌德县源远新材料有限公司

Preparation method of glass fiber composite material

InactiveCN108249769AImprove ablation performanceImprove high temperature resistanceGlass making apparatusMolten stateGlycidyl methacrylate

The invention provides a preparation method of a glass fiber composite material. The preparation method comprises the following steps that a, glass powder, selected high filter residue, calcium oxide,magnesium oxide, titanium dioxide, aluminum oxide and silicon dioxide are mixed and smashed, and mixed powder is obtained; b, a substrate material, glycidyl methacrylate, sodium pyrophosphate and pentaerythritol ester are mixed to be uniform and melted to be at a molten state, and a first material is obtained after heat preservation is conducted; c, the mixed powder is added into the first material and melted and stirred, then subjected to fusion wiredrawing, and a crude product is obtained; and d, the crude product is subjected to acidification treatment, treatment is conducted on the crudeproduct by using a silane coupling agent, heat treatment is conducted consecutively, and finally drying is conducted. The prepared glass fiber composite material has good ablation performance, betterhigh temperature resistance, the chemical corrosion resistant property and the elasticity modulus.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Preparation method of light ablative material

The invention discloses a preparation method of a light ablative material, relates to a preparation method of a thermal protection material, and is aimed at solving the technical problem of high density of the existing carbonization type light ablative material taking phenol-formaldehyde resin as a substrate. The method comprises the following steps of: dissolving boron phenol-formaldehyde resin in acetone to prepare a boron phenol-formaldehyde resin solution; adding the uniformly mixed microsphere filler and carbon nanotube into the boron phenol-formaldehyde resin solution, and mixing uniformly; standing to volatize acetone to obtain mixed paste; putting the phenol-formaldehyde honeycomb cut into a die inner cavity shape into a die, and filling the mixed paste into the phenol-formaldehyde honeycomb to obtain a composite green body; and curing and forming the composite green body to obtain the light ablative material. Through the invention, the density of the prepared light ablative material is as low as 0.2-0.4g / cm<3>, the linear ablativity is 0.035-0.115mm / s, and the mass ablativity is 0.0177-0.0216g / s; and the light ablative material can be used as a thermal protection material of a spacecraft.

Owner:HARBIN INST OF TECH

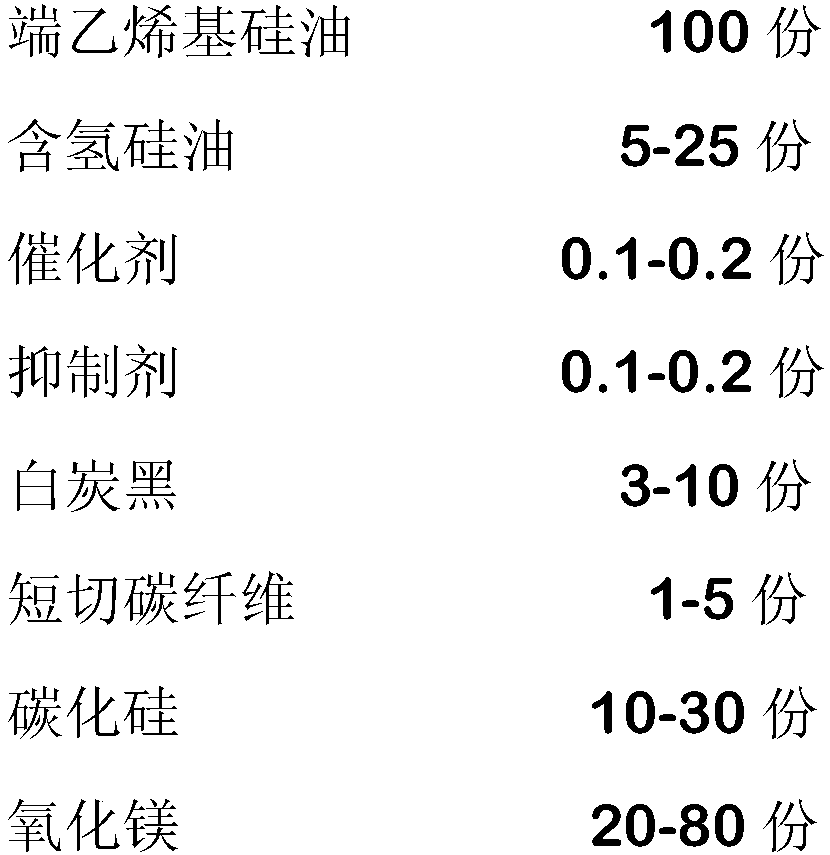

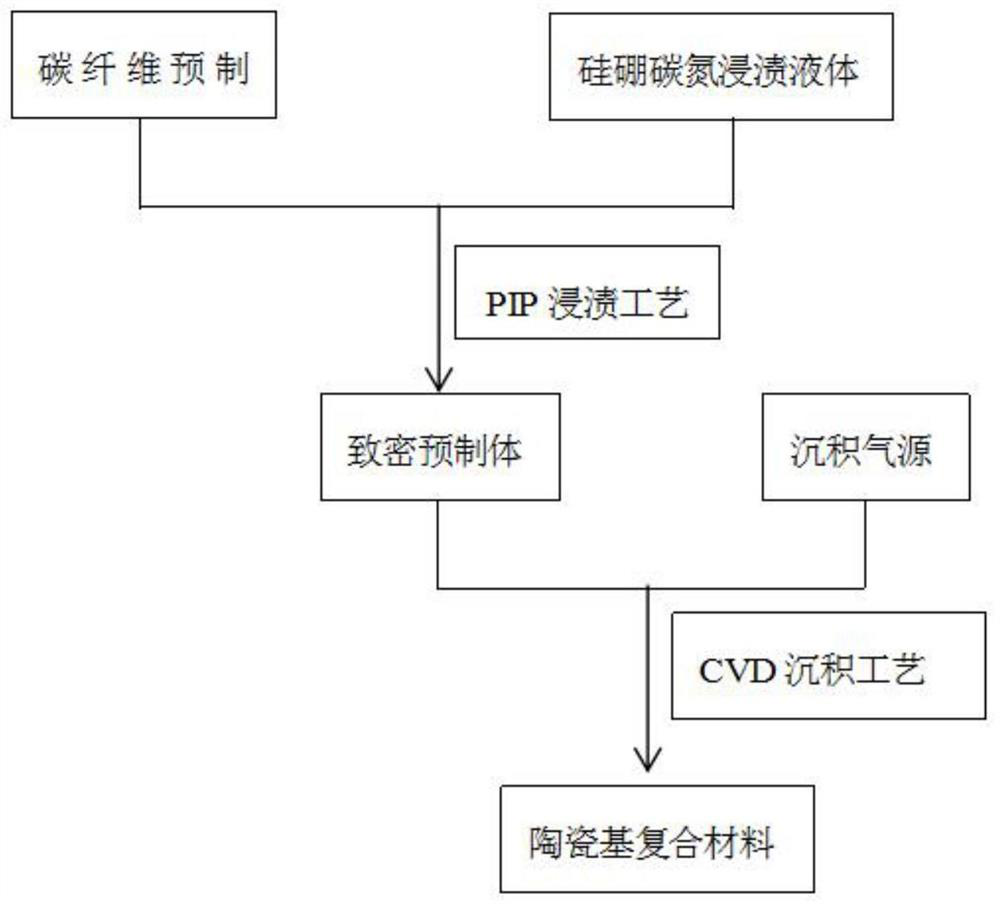

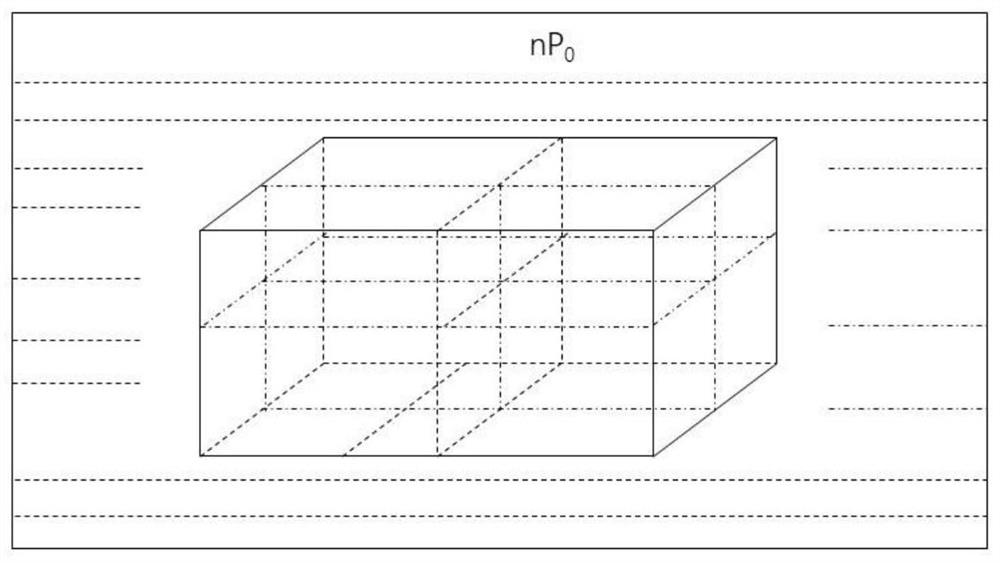

Ceramic-based composite material and preparation method and application thereof

PendingCN113582729AImprove antioxidant capacityImprove ablation performanceCarbide siliconOxidation resistant

The invention belongs to the technical field of ceramic-based composite materials, and particularly relates to a ceramic-based composite material and a preparation method and application thereof. The invention provides the ceramic-based composite material. The ceramic-based composite material comprises a fiber-reinforced silicon-boron-carbon-nitrogen matrix and a silicon carbide protective layer deposited on the surface of the fiber-reinforced silicon-boron-carbon-nitrogen matrix. The ceramic-based composite material provided by the invention comprises the silicon carbide protective layer deposited on the surface of the fiber-reinforced silicon-boron-carbon-nitrogen matrix, and silicon in the silicon carbide protective layer generates thicker silicon dioxide in a high-temperature aerobic environment to isolate external oxygen and protect the internal fiber-reinforced silicon-boron-carbon-nitrogen matrix; therefore, the oxidation resistance and the ablation resistance of the ceramic-based composite material under the high-temperature (3000K) condition are improved.

Owner:SHAOXING RES INST OF SHANGHAI UNIV +1

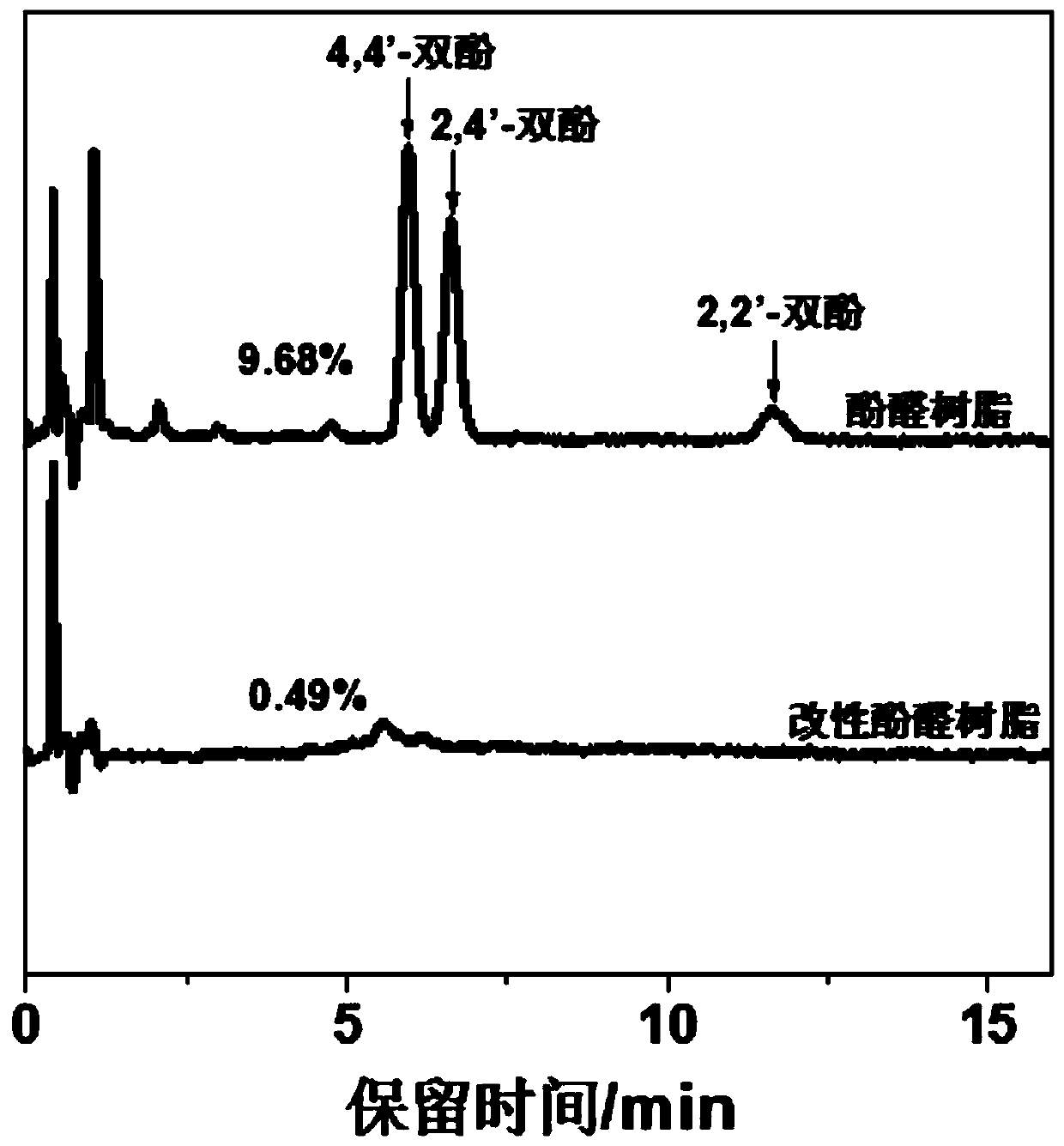

Thermoplastic phenolic resin with low bisphenol compound content as well as preparation method and application thereof

The invention discloses thermoplastic phenolic resin with a low bisphenol compound content as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing thermoplastic phenolic resin with an extractant to obtain a mixture A; in an inert atmosphere, stirring the mixture A for a preset period of time at a reflux temperature of the extractant , and pouring out the supernatant at a temperature higher than the preset temperature to obtain extracted thermoplastic phenolic resin; repeating extraction for a plurality of times; and carrying out reduced pressure distillation to remove the extractant to obtain the thermoplastic phenolic resin with a low bisphenol compound content. The preparation method disclosed by the invention is used for preparing the thermoplastic phenolic resin with an extremely low bisphenol compound content, the thermoplastic phenolic resin obtained by the preparation method has good manufacturability and excellent thermal stability, and good thermal stability and mechanical properties can be achieved by crosslinking the resin with a small amount of the curing agent.

Owner:XI AN JIAOTONG UNIV

Glass fiber and processing technology thereof

The invention discloses a glass fiber which comprises the following raw materials in parts by weight: 30-50 parts of SiO2, 6-10 parts of Al2O3, 1-4 parts of CaF2, 10-14 parts of ZrO2, 11-16 parts of Ln2O3, 4-6 parts of TiO2, 60-70 parts of H2O and 50-70 parts of H3BO3. The glass fiber is mainly prepared by the following steps: mixing the raw materials, melting, drawing, pickling and performing heat setting treatment. The glass fiber disclosed in the invention has the beneficial effects that (1) the glass fiber disclosed in the invention is excellent in acid resistance, low in molding temperature and low in cost, and the production efficiency is improved; (2) the glass fiber disclosed in the invention is excellent in high temperature resistance, can be applicable to a temperature of 1000 DEG C or less for a long time, and has excellent ablation property, excellent high temperature resistance and chemical resistance; (3) the processing technology of the glass fiber is low in cost, simpleto operate and suitable for more small and medium-sized enterprises.

Owner:旌德县源远新材料有限公司

Preparation method of brake block material for rubber and plastic mixing motor vehicle

InactiveCN108395669AHigh mechanical strengthGood compatibilityFriction liningActuatorsCalcium silicateCarbon fibers

The invention provides a preparation method of a brake block material for a rubber and plastic mixing motor vehicle. The method comprises the following steps of S1, modifying carbon fiber; S2, preparing modified calcium carbonate; S3, weighing the following ingredients in parts by weight: 5 to 10 parts of nitrile rubber, 20 to 30 parts of phenolic resin, 5 to 9 parts of aramid pulp meal fiber, 8 to 14 parts of needle-shaped wollastonite, 3 to 5 parts of vermiculite powder, 2 to 4 parts of barite powder, 6 to 8 parts of calcium silicate ceramic powder, 3 to 6 parts of barium sulfate, 5 to 8 parts of basalt fiber, 10 to 20 parts of modified carbon fiber and 1 to 2 parts of modified light calcium carbonate; S4, mixing and stirring the ingredients; performing hot pressing shaping on the mixedmaterials by a hot press; finally performing heat treatment. The brake block material for the rubber and plastic mixing motor vehicle has the characteristics of wear resistance, heat resistance and long service life.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Preparation method of SiC nanowire toughened HfC-SiC complex phase coating by chemical vapor co-deposition

The invention relates to a preparation method of a SiC nanowire toughened HfC-SiC complex phase coating by chemical vapor co-deposition. The preparation method adopts a three-step method and comprises the following steps: firstly, preparing a SiC inner coating by using an embedding method, then, introducing free silicon on the surface of the SiC inner coating by using a vapor siliconizing technology, carrying out chemical vapor deposition on HfC on the surface of a C / C sample with the SiC-SiC inner coating, and enhancing the interface bonding strength between the inner coating and the outer coating through in-situ reaction and diffusion of free silicon in the vapor deposition process. The SiC / HfC-SiC coating which is uniform in thickness, compact in structure, controllable in component and high in binding force can be prepared. On the basis of a mechanical bonding interface of a traditional method, an interface diffusion layer is introduced for diffusion to form diffusion bonding. And the coating process is simple, the reaction period is short, the cost is low, and the development prospect is wide.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for laser-assisted manufacturing of precise circuit

PendingCN114158195AEasy to prepareReduce thicknessConductive material chemical/electrolytical removalMachiningMaterials science

The invention discloses a laser-assisted precise circuit manufacturing method, which comprises the following steps that a production board is provided, and circuits needing to be manufactured on the production board comprise a thick circuit with the circuit distance larger than 50 microns and a precise circuit with the circuit distance smaller than or equal to 50 microns; a film is pasted on the production board, exposure treatment is carried out, exposure of the coarse lines and the precise lines is completed, and all gap parts between the precise lines are exposed; developing and etching the production board, wherein the etching amount during etching is controlled to be greater than half of the copper thickness of the circuit, and the bottom layer base material is not exposed; ablating a gap part between the precision circuits by adopting laser to remove a film and a part of copper layer at the gap of the precision circuits; and carrying out etching treatment and film stripping on the production board again, and forming a thick circuit and a precise circuit on the production board. According to the method, the technological process is optimized, the laser ablation and chemical etching combined copper removal mode is adopted in sequence, manufacturing of the precise circuit with the distance smaller than or equal to 50 micrometers can be achieved, the material and machining cost is low, and the technological process is simple.

Owner:SIHUI FUJI ELECTRONICS TECH

A kind of preparation method of aryl boron-containing thermoplastic phenolic resin

A preparation method of an aryl-containing boron thermoplastic phenolic resin. The method is as below: adding a phenolic compound and a divalent metal salt catalyst into a reaction kettle, adding an aldehyde compound by two times, wherein after the first addition, reacting at 50-70 DEG C for 0.5-2 h, and after the second addition, adding an acidic catalyst, heating to a reflux reaction state for reaction, then removing generated water and unreacted phenolic compounds to obtain the thermoplastic phenolic resin; and adding a boronic acid-containing compound into the thermoplastic phenolic resin, then heating to 100-120 DEG C, removing generated water to obtain the aryl-containing boron thermoplastic phenolic resin; or directly mixing the thermoplastic phenolic resin with the boric acid-containing compound in a solvent evenly and drying to obtain the aryl-containing boron thermoplastic phenolic resin. As the added boronic acid-containing compound contains aryl boric acid, the prepared aryl-containing boron thermoplastic phenolic resin has low water absorption rate and low curing temperature, not only has excellent thermal properties but also shows superior processing and mechanical properties.

Owner:XI AN JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com