Contact material applied to middle-high-voltage vacuum switch-on/off and preparation method for same

A contact material, medium and high pressure technology, applied in the field of powder metallurgy, can solve the problems of poor welding resistance, low pressure resistance of materials, and inapplicability, and achieve the goal of improving welding resistance, pressure resistance and compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

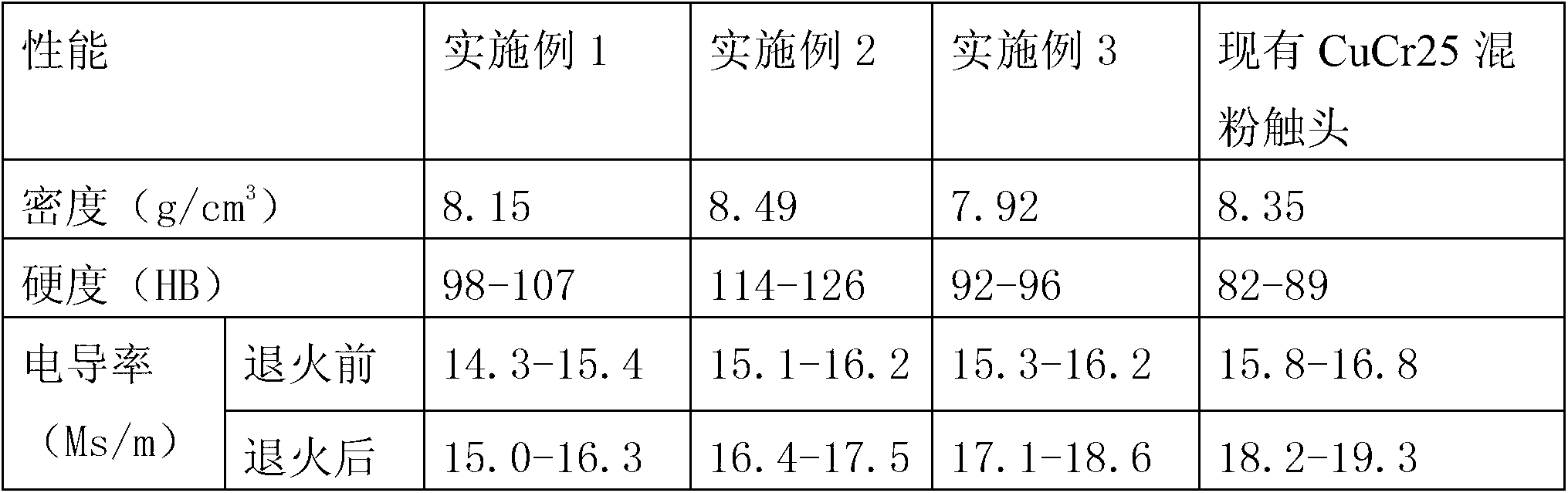

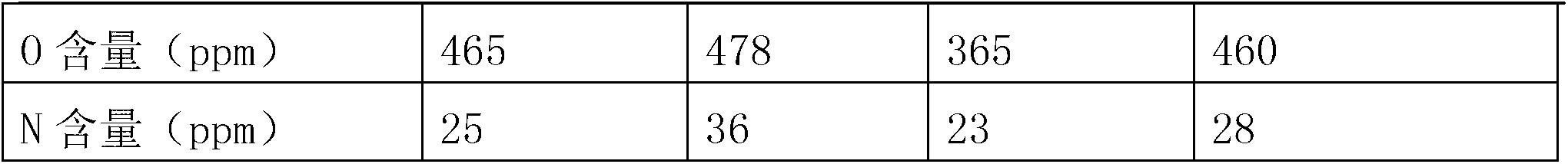

Embodiment 1

[0028] In this embodiment, 10kg of the contact material used in the medium and high pressure vacuum breaking of the present invention is produced, and the composition ratio of each raw material used is:

[0029] Cu6.5kg, accounting for 65% by mass;

[0030] Cr3.0kg, accounting for 30% by mass;

[0031] TiC0.5kg, accounting for 5.0% by mass.

[0032] Preparation steps:

[0033] (1) According to the above chemical ratio, weigh 3.0kg of Cr powder and 0.5kg of TiC powder and mix evenly, then mix in 6.5kg of Cu powder, and mix the powder with a powder mixer for 8 hours;

[0034] (2) Fill the mixed powder into the forming mold, and apply a pressure of 30 MPa through a four-column hydraulic press to form the mixed powder into a compact with a certain shape;

[0035] (3) Put the pressed compact into a graphite crucible, then place the graphite crucible in a vacuum induction hot-pressing sintering furnace, and evacuate to 2×10 -2 After Pa, heat to 800°C, pressurize at 25MPa, keep w...

Embodiment 2

[0039] In this embodiment, 10kg of the contact material used in the medium and high pressure vacuum breaking of the present invention is produced, and the composition ratio of each raw material used is:

[0040] Cu8.1kg, accounting for 81% by mass;

[0041] Cr0.5kg, accounting for 5% by mass;

[0042] ZrC1.4kg, accounting for 14% by mass.

[0043] Preparation steps:

[0044] (1) According to the above chemical ratio, weigh 0.5kg of Cr powder and 1.4kg of ZrC powder and mix evenly, then mix in 8.1kg of Cu powder, and mix the powder with a powder mixer for 8 hours;

[0045] (2) Fill the mixed powder into the forming mold, and apply a pressure of 60 MPa through a four-column hydraulic press to form the mixed powder into a compact with a certain shape;

[0046] (3) Put the pressed compact into a graphite crucible, place the crucible in a vacuum induction hot pressing sintering furnace, and evacuate to 2×10 -2 After Pa, heat to 900°C, pressurize at 50MPa, keep warm for 1 hour, ...

Embodiment 3

[0049] In this embodiment, 10kg of the contact material used in the medium and high pressure vacuum breaking of the present invention is produced, and the composition ratio of each raw material used is:

[0050] Cu: 5.0kg, accounting for 50% by mass;

[0051] Cr: 4.8kg, accounting for 48% by mass;

[0052] B 4 C: 0.2kg, accounting for 2% by mass.

[0053] Preparation steps:

[0054] (1) According to the above chemical ratio, weigh 4.8kg Cr powder and 0.2kg B 4 Mix C powder evenly, then mix in 5.0kg of Cu powder, and mix the powder with a powder mixer for 8 hours;

[0055] (2) Fill the mixed powder into the forming mold, and apply a pressure of 50 MPa through a four-column hydraulic press to form the mixed powder into a compact with a certain shape;

[0056] (3) Put the pressed compact into a graphite crucible, place the crucible in a vacuum induction hot pressing sintering furnace, and evacuate to 2×10 -2 After Pa, heat to 1000°C, pressurize to 40MPa, keep warm for 1 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com