Preparation method of zirconium and/or tungsten-based multiphase ceramic coating

A composite ceramic and tungsten-based technology, applied in the field of composite materials, can solve the problems of poor density, low bonding strength between coating and substrate, uneven distribution of coating surface, etc., and achieve good ablation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The invention provides a method for preparing a zirconium and / or tungsten-based multiphase ceramic coating, which uses a molten salt method to prepare a tungsten or zirconium ceramic coating, comprising:

[0052] mixing the chloride salt and the metal powder to obtain a mixed powder; the metal powder includes tungsten powder and / or zirconium powder;

[0053] Degreasing and activating the carbon-carbon matrix to obtain an activated carbon-carbon matrix;

[0054] The activated carbon-carbon matrix is subjected to a salt bath in the mixed powder to obtain a zirconium and / or tungsten-based multiphase ceramic coating.

[0055] In the present invention, the chloride salt is preferably selected from two or more of sodium chloride, potassium chloride and barium chloride; the purity of the chloride salt is preferably 99.4 to 99.6%, more preferably 99.5% .

[0056] In the present invention, the metal powder is preferably tungsten powder or zirconium powder. In the present in...

Embodiment 1

[0093] Mix sodium chloride, barium chloride, and tungsten powder according to the mass ratio of 1:1:1, add them to the ball mill tank, use absolute ethanol ball mill to wet mix for 24 h, and the mixed powder mixed by ball milling is placed in a vacuum at 50°C. Dry in a drying oven, and the mixed powder passes through a 150-mesh sieve several times to fully mix the metal powder and the chloride salt.

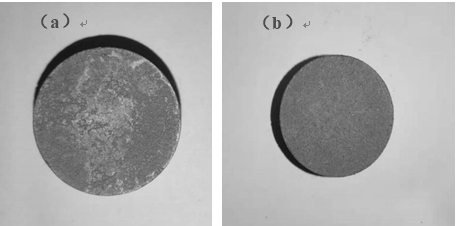

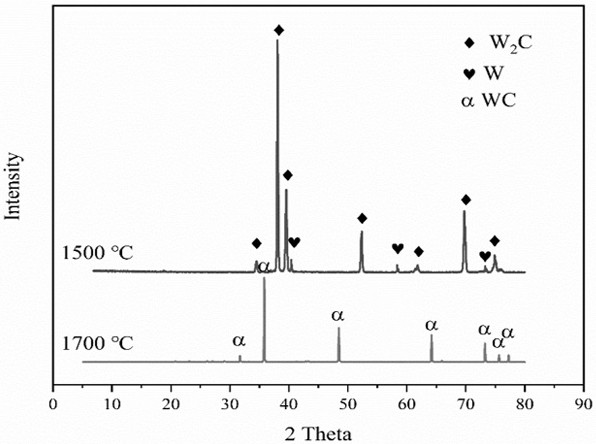

[0094] The carbon / carbon matrix (M30 model product provided by Changsha Jieshun New Material Co., Ltd.) has a density of 1.75g / cm 3 , some oil stains remain on the surface of the substrate during processing, and 10g / L Na 2 CO 3 The solution was soaked in a water bath at 80°C for 20 min to remove oil stains, and then ultrasonically cleaned with deionized water to remove residual Na on the surface. 2 CO 3 , and finally place the substrate in a nitric acid solution with a mass concentration of 60% in a water bath at 80°C for surface activation treatment. After the activation trea...

Embodiment 2

[0101] Mix sodium chloride, barium chloride, and zirconium powder according to the mass ratio of 1:1:1, add them to the ball mill tank, use absolute ethanol ball mill to wet mix for 24 h, and the mixed powder mixed by ball milling is placed in a vacuum at 50 ° C. Dry in a drying oven, and the mixed powder passes through a 150-mesh sieve several times to fully mix the metal powder and the chloride salt.

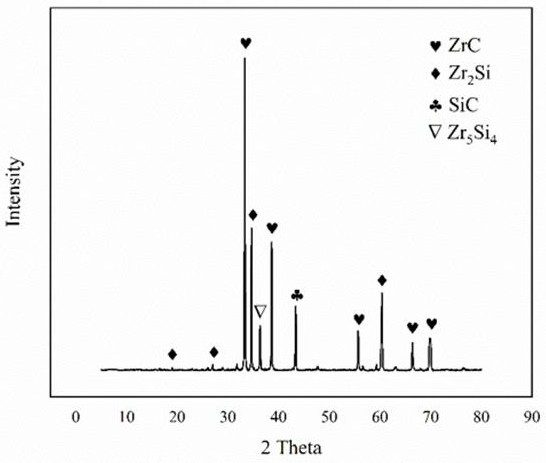

[0102] Modified C / C matrix (provided by Hunan Boyun New Material Co., Ltd.) has a density of 2.55 g / cm 3 , some oil stains remain on the surface of the substrate during processing, and 15 g / L Na 2 CO 3 The solution was soaked in a water bath at 80°C for 20 min to remove oil stains, and then ultrasonically cleaned with deionized water to remove residual Na on the surface. 2 CO 3 , and finally place the substrate in a nitric acid solution with a mass concentration of 60% in a water bath at 80°C for surface activation treatment, and the carbon-carbon substrate after the activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal stress | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com