Preparation method of brake block material for rubber and plastic mixing motor vehicle

A technology of motor vehicles and brake pads, which is applied in the field of preparation of rubber-plastic hybrid motor vehicle brake pad materials, can solve the problems of brake pad fracture, brake pad cracking, affecting the braking effect and service life of brake pads, and achieve resistance Increased capacity, improved mechanical properties, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

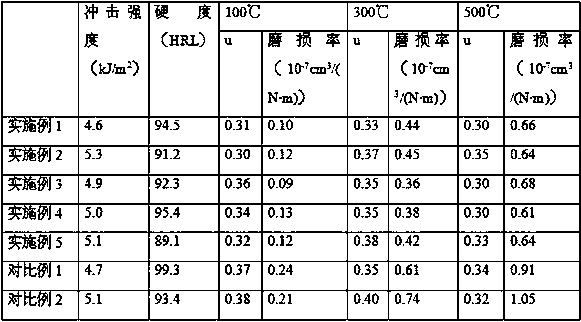

Examples

Embodiment 1

[0018] A method for preparing a rubber-plastic hybrid vehicle brake pad material, comprising the following steps:

[0019] S1. Modification of carbon fiber: heat the carbon fiber to 800°C in nitrogen containing less than 2% oxygen, then cool to room temperature in nitrogen, then oxidize the carbon fiber in concentrated nitric acid with a concentration of 65% for 2 hours, and then use deionized water After washing to pH = 7, dry, and finally coat and dry with an ethanol solution of 2% silane coupling agent Si 69;

[0020] S2. Preparation of modified calcium carbonate: place calcium oxide in hot distilled water at 70°C in a water bath at 70°C, adjust the speed at 300r / min, and react for 30min to obtain calcium oxide slurry, add distilled water to the calcium oxide slurry, place In a water bath at 15°C, bubble CO at a rate of 200 mL / min. 2 Gas, adjust the rotating speed at 800r / min to obtain carbonized calcium carbonate slurry, heat up the carbonized calcium carbonate slurry to ...

Embodiment 2

[0024] A method for preparing a rubber-plastic hybrid vehicle brake pad material, comprising the following steps:

[0025] S1. Modification of carbon fiber: heat the carbon fiber to 1000°C in nitrogen containing less than 2% oxygen, then cool to room temperature in nitrogen, then oxidize the carbon fiber in concentrated nitric acid with a concentration of 75% for 2 hours, and then use deionized water After washing to pH = 7, dry, and finally coat and dry with an ethanol solution of 2% silane coupling agent KH 550;

[0026] S2. Preparation of modified calcium carbonate: place calcium oxide in hot distilled water at 70°C in a water bath at 70°C, adjust the rotation speed at 500r / min, and react for 30min to obtain calcium oxide slurry, add distilled water to the calcium oxide slurry, place In a water bath at 15°C, bubble CO at a rate of 500 mL / min. 2 Gas, adjust the rotating speed at 800r / min to obtain carbonized calcium carbonate slurry, heat up the carbonized calcium carbonate...

Embodiment 3

[0030] A method for preparing a rubber-plastic hybrid vehicle brake pad material, comprising the following steps:

[0031] S1. Modification of carbon fiber: heat the carbon fiber to 850°C in nitrogen containing less than 2% oxygen, then cool to room temperature in nitrogen, then place the carbon fiber in concentrated nitric acid with a concentration of 72% for 2 hours, and then use deionized water After washing to pH = 7, dry, and finally coat and dry with an ethanol solution of a silane coupling agent with a concentration of 2%, wherein the silane coupling agent is a silane coupling agent Si with a mass ratio of 1:1 69 and silane coupling agent KH 550 mixture;

[0032] S2. Prepare modified calcium carbonate: place calcium oxide in hot distilled water at 70°C in a water bath at 70°C, adjust the speed at 360r / min, and react for 30min to obtain calcium oxide slurry, add distilled water to the calcium oxide slurry, place In a water bath at 15°C, bubble CO at a rate of 300 mL / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com