Thermoplastic phenolic resin with low bisphenol compound content as well as preparation method and application thereof

A technology of phenolic compounds and phenolic resins, applied in the field of new materials, can solve the problems of reducing the softening point and viscosity of phenolic resins, affecting the manufacturability of phenolic resins, and increasing the crosslinking density of resins, so as to achieve improved performance, excellent thermal stability, High value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the novolak resin with low bisphenol compound content in the embodiment of the present invention specifically includes the following steps:

[0035] The first step is the synthesis of phenolic resin:

[0036] Add phenolic compounds, aldehydes, water and acidic catalysts to the reaction kettle to obtain a mixture; specifically, it can be, in terms of mole parts, 5 to 160 parts of phenolic compounds and 0.01 to 20 parts of acidic catalysts, and phenol The molar ratio of the aldehyde compound to the aldehyde compound is 1: (0.85 to 1.3), and then it is dissolved in 200 to 1000 mL of water.

[0037] Stir and heat the mixture and reflux for 0.5-4h. After the mixture is cooled, let it stand for 0.5~2h, siphon out the upper layer of water, change the condensation to vacuum distillation, heat, and raise the temperature of the reactor to 110~130℃ under the pressure of 6~14kPa until it reaches the preset requirement Or maintain the preset reaction time to obt...

Embodiment 1

[0054] The comparative example is a phenolic resin containing a larger amount of bisphenol compounds.

[0055] According to the mass ratio of phenolic resin: extractant=1:2, add 50g of purchased phenolic resin and 100g of xylene into a four-necked flask equipped with a stirring blade and a condenser, and stir at 160℃ for 1h under a nitrogen atmosphere. , Pour out the supernatant while it is hot, complete the process of extracting bisphenol compounds once, repeat the above extraction process 5 times, and dry the solvent to obtain the novolak resin with low content of bisphenol compounds, the yield is 90%, grinding Later characterize.

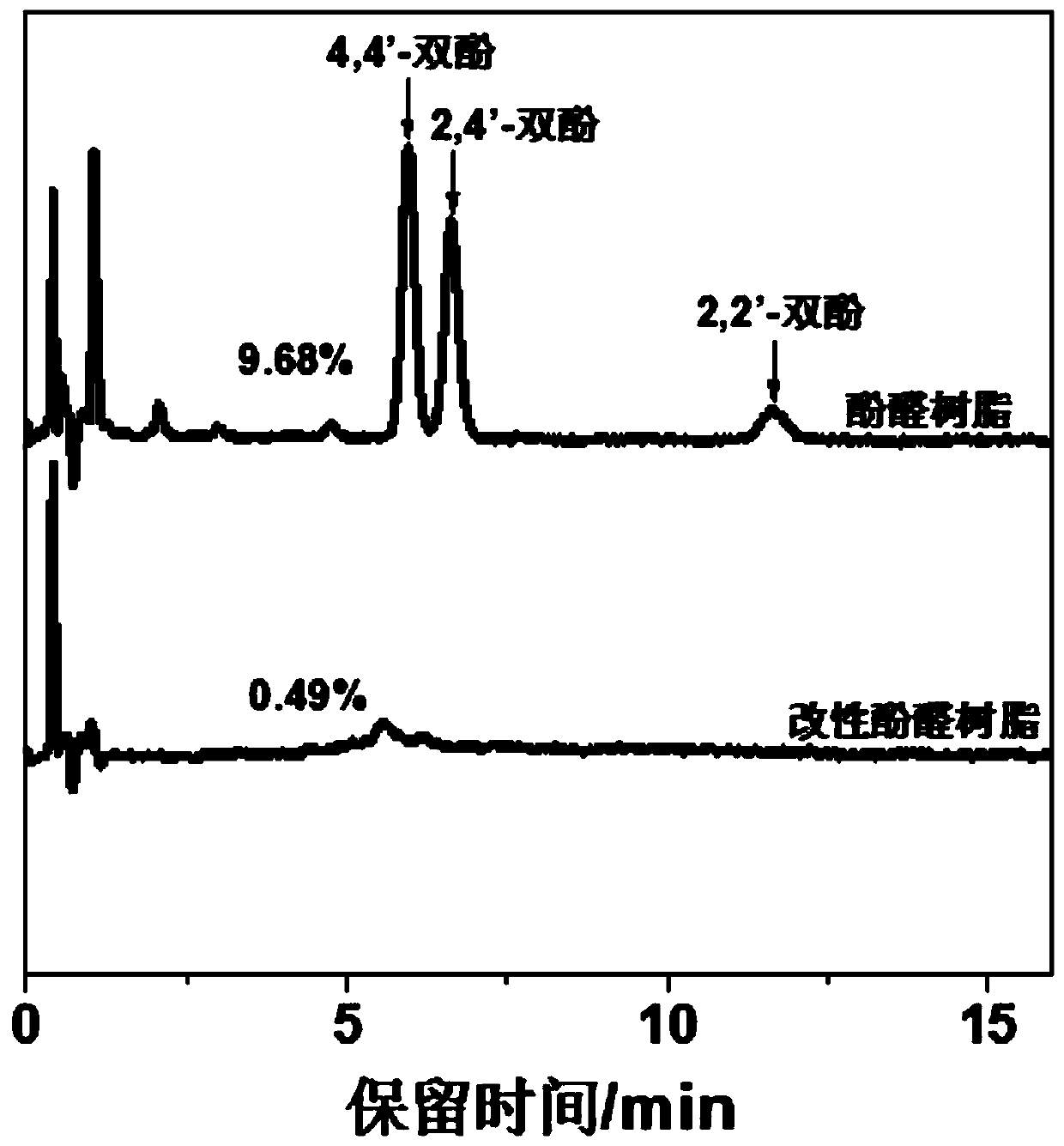

[0056] See figure 1 , Using liquid chromatography to quantify the content of bisphenol in phenolic resin, liquid chromatography test conditions are: chromatographic column: C18 (2.1×50mm, 3mm); column temperature: 30℃; mobile phase: methanol: water = 38:62 Volume ratio; Flow rate: 0.4mL / min; UV detection wavelength: 270nm. The liquid chromatographic...

Embodiment 2

[0061] Add 130 g of phenol (1.38 mol), 13 mL of water, 92.4 g of 37% formaldehyde solution (1.14 mol) and 1 g of oxalic acid dihydrate into a 1000 mL reaction kettle, stir and heat the mixture, and reflux for 30 min. Add 1g of oxalic acid hydrate, continue to reflux for 1h, add 400mL of water, wait for the mixture to cool, let it stand for 30min, siphon out the upper layer of water, and change the condensation to vacuum distillation, heating, and under the pressure of 10kPa, make the kettle temperature rise At 120°C, until the requirement is reached, a novolak resin containing a larger amount of bisphenol compounds can be obtained with a yield of 103%.

[0062] According to the mass ratio of novolak resin: extractant=1:2, add 50g of synthetic phenolic resin and 100g of xylene into a four-necked flask equipped with a stirring blade and condenser, and stir at reflux temperature under an inert atmosphere For 1 h, the supernatant was poured out while it was hot to complete an extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com