Ceramic-based composite material and preparation method and application thereof

A composite material and ceramic-based technology, which is applied in the field of ceramic-based composite materials and its preparation, can solve the problems of mechanical and anti-oxidation ablation performance decline, rapid oxidation, etc., and achieve the effect of improving oxidation resistance and ablation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

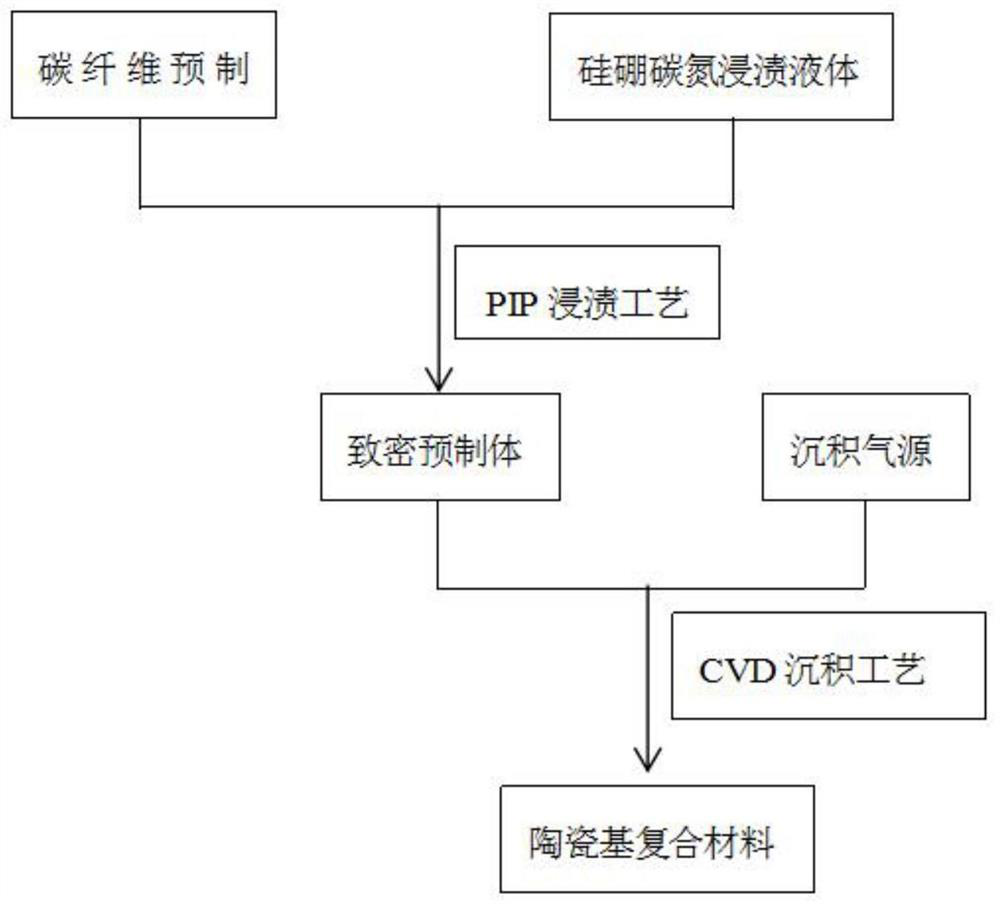

[0028] The present invention also provides a method for preparing the ceramic matrix composite material described in the above technical solution, comprising the following steps:

[0029] impregnating the carbon fiber preform with a silicon boron carbon nitrogen impregnation solution to obtain an impregnated preform;

[0030] The impregnated preform is sequentially subjected to crosslinking, curing and pyrolysis to obtain a dense preform;

[0031] Chemical vapor deposition of silicon carbide on the surface of the dense preform forms a silicon carbide protective layer to obtain the ceramic matrix composite material.

[0032] In the invention, the carbon fiber preform is impregnated with a silicon-boron-carbon-nitrogen impregnating liquid to obtain an impregnated preform. In the present invention, the carbon fiber preform preferably includes a 3D woven carbon fiber preform, a 2.5D woven carbon fiber preform or a 2D woven carbon fiber preform, more preferably a 3D woven carbon f...

Embodiment 1

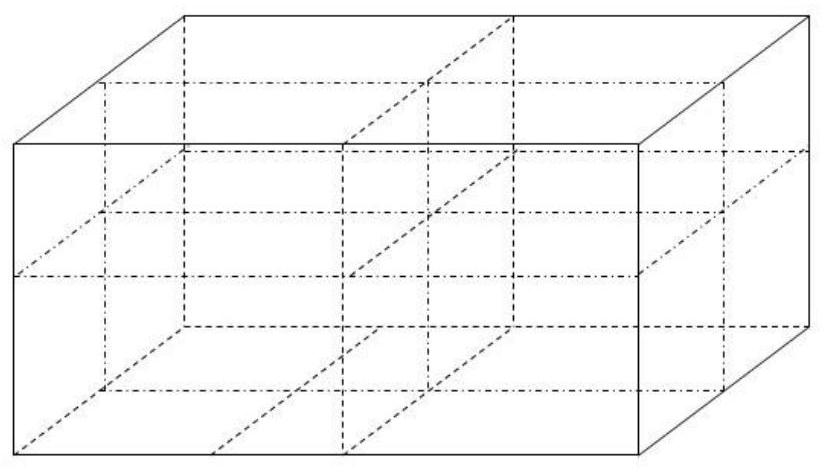

[0051] A cuboid 3D braided carbon fiber prefabricated body with a size of 60*80*12mm (with a porosity of 79%, and a fiber diameter of 6μm) was degummed at 1000°C for 2 hours under a nitrogen atmosphere, and then placed in a pressure reactor, poured Add polysilaborazane (produced by the Institute of Chemistry, Chinese Academy of Sciences) to cover the carbon fiber preform, and impregnate it under the condition of 1MPa for 4h; The cured preform was taken out and placed in a tube furnace, heated to 1000°C for 2.5 hours under a nitrogen atmosphere and pyrolyzed for 2.5 hours. After 7 cycles of impregnation-crosslinking curing-pyrolysis steps, it was treated at 1500°C for 2 hours to obtain a dense preform. ; The porosity of the dense preform is 7%, and the density is 2g / cm 3 ;

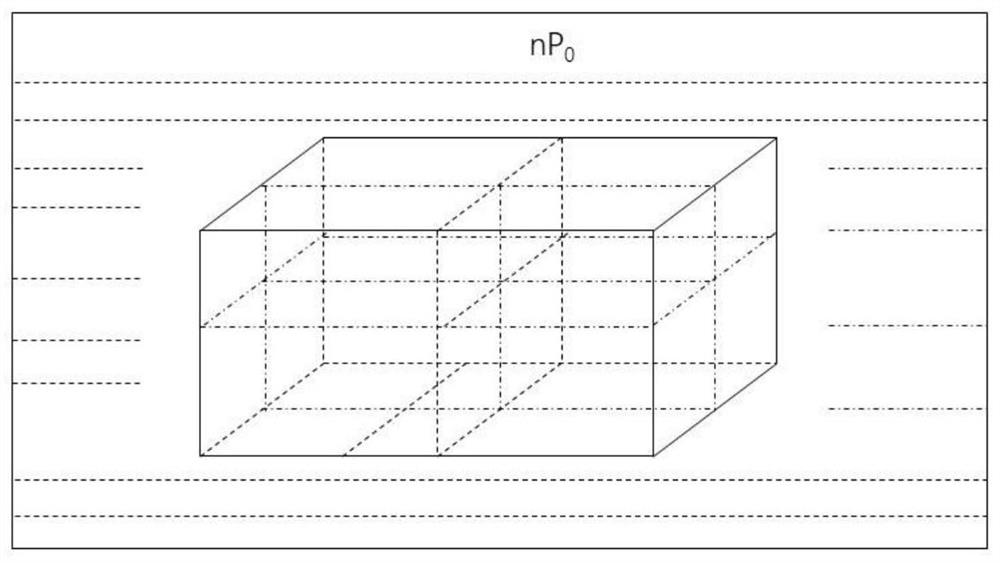

[0052] The dense preform is subjected to chemical vapor deposition to obtain a ceramic matrix composite material with a silicon carbide protective layer thickness of 1500nm; the gas source is a mixed gas w...

Embodiment 2

[0058] A cuboid 2.5-dimensional woven carbon fiber prefabricated body with a size of 60*80*12mm (with a porosity of 79%, and a fiber diameter of 6μm) was degummed at 1000°C for 2 hours in a nitrogen atmosphere, and then placed in a pressure reactor. Add polysilaborazane (produced by the Institute of Chemistry, Chinese Academy of Sciences) to cover the carbon fiber preform, and impregnate it under the condition of 2MPa for 4h; The cured preform was taken out and placed in a tube furnace, heated to 1000°C for 2.5 hours under a nitrogen atmosphere and pyrolyzed for 2.5 hours. After 7 cycles of impregnation-crosslinking curing-pyrolysis steps, it was treated at 1500°C for 2 hours to obtain a dense preform. ; The porosity of the dense preform is 6.2%, and the density is 1.95g / cm 3 ;

[0059] The dense preform is subjected to chemical vapor deposition to obtain a ceramic matrix composite material with a silicon carbide protective layer thickness of 750nm; the gas source is a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com