Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Guaranteed to melt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of welding dissimilar steel 10Cr9Mo1VNb and 1Cr18Ni9

InactiveCN101011774AGuaranteed performanceGuaranteed to meltArc welding apparatusWelding/cutting media/materialsTemperature controlEngineering

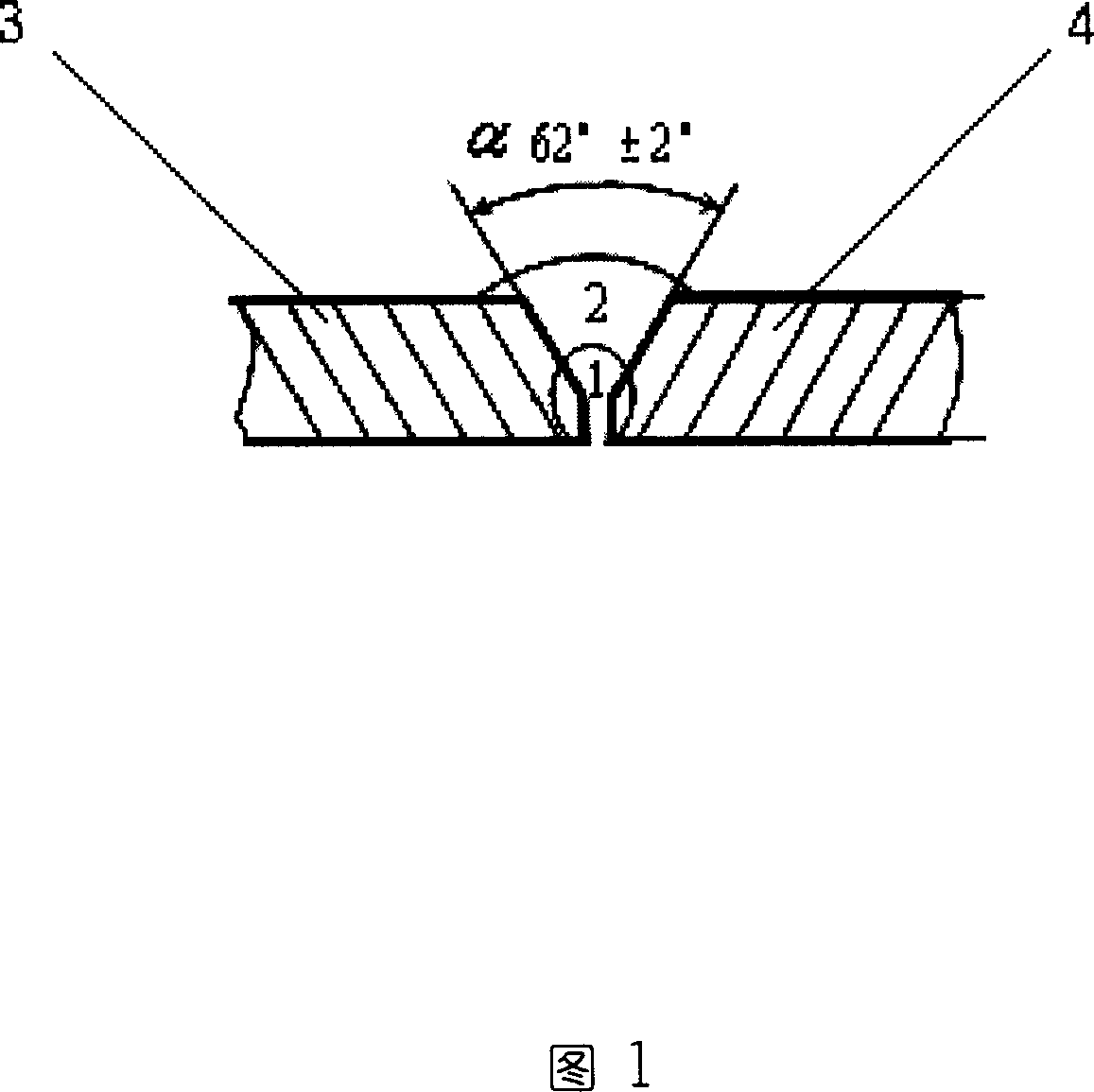

The invention provides a method for the welding of steels like 10Cr9Mo1VNb and 1Cr18Ni9, which controls the temperature between 150-200deg.C before welding at the layer. With the back welding current being 115A / 85A(peak / base), welding speed 2-3cm / min, thickness no less than 3mm, filling welding current 150A / 20A (peak / base), welding speed 2-3cm / min, width of the welding channel being 2-3 times of the solder wire. It has smaller welding depth, reasonable control of the fuse ratio and chemical effusion.

Owner:WORKER WELDING & CUTTING TECHN ASSOC OF HEBEI

Oxide dispersion strengthening low activity ferrite/martensite steel and smelting method thereof

ActiveCN106756434ASufficient oxygen contentLow viscosityIncreasing energy efficiencyRare earthManganese

The invention discloses oxide dispersion strengthening low activity ferrite / martensite steel and a smelting technology and a smelting method of the oxide dispersion strengthening low activity ferrite / martensite steel, and belongs to the technical field of special steel metallurgy. The oxide dispersion strengthening low activity ferrite / martensite steel comprises raw materials including, by mass percent, 8.9%-9.1% of electrolytic chromium, 0.4%-0.5% of electrolytic manganese, 0.05%-0.08% of high-purity silicon, 0.08%-0.12% of high-purity graphite, 1.4%-1.6% of metal tungsten, 0.1% of metal tantalum, 0.18%-0.22% of metal vanadium, 0.1%-0.25% of sponge titanium, 0.2%-0.5% of high-purity rare earth yttrium, 1% of oxide scales and the balance high-purity low-sulfur low-phosphorus pig iron. A preparing method of the oxide dispersion strengthening low activity ferrite / martensite steel comprises material preparing, vacuum induction smelting, casting, forging and electroslag remelting processes, ODS-RAFM is prepared, and the large-specification ODS steel high in density, uniform in component, little in energy consumption, high in purity, stable in smelting method and capable of meeting the need of large nuclear power equipment is achieved.

Owner:NORTHEASTERN UNIV

Method for continuously predicting carbon content of converter molten pool

ActiveCN101832967AGuaranteed to meltUniform compositionMaterial analysis by electric/magnetic meansMelting tankCommunications system

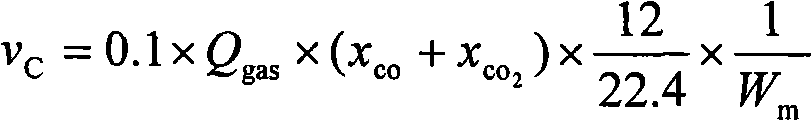

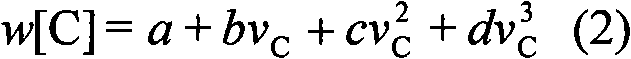

The invention discloses a method for continuously predicting carbon content of a converter molten pool, which comprises data acquisition, raw material control, operation control and technical process and specifically comprises the following steps of: in the data acquisition, detecting converter gas flow by using a converter gas flow meter, transmitting all detection information to a computer through a data communication system, and analyzing and calculating the detection information through the following two mathematical models w[C]=0.1*(sigma Cori-sigma Cde) / Wm (1); in the raw material control, controlling a waste steel ratio to be 8 to 13 percent, and controlling the weight percentage of light waste steel and heavy waste steel to be 14 to 70 percent; in the operation control, holding a fixed gun position and a fixed smoke hood in 2 to 3 minutes before finishing blowing; and in the technical process, ensuring that the carbon content of the molten pool meets the formula (1) when the oxygen blowing amount accounts for less than or equal to 75 percent of the total oxygen blowing amount and the carbon content of the molten pool meets the formula (2) when the oxygen blowing amount accounts for over 75 percent of the total oxygen blowing amount. The method fulfills the purpose of continuously predicting the carbon content of the converter molten pool by combining the mathematical models and the technical process.

Owner:ANGANG STEEL CO LTD

Bamboo charcoal profiled fiber and preparation method thereof

InactiveCN102154715AGuaranteed to meltGuaranteed compressionHollow filament manufactureFilament/thread formingYarnPolyester

The invention discloses bamboo charcoal profiled fiber with good product quality and low production cost, and a preparation method thereof. The fiber comprises the following components in percentage by weight: 94-99 percent of melt-spun slices, 1-6 percent of bamboo charcoal fine particles, 0.05-0.5 percent of surfactant and 0.1-1 percent of antioxidant, wherein the melt-spun slices are polyester, polyamide, polypropylene, polyethylene and modified polymers of polyester, polyamide, polypropylene and polyethylene; and the bamboo charcoal fine particles are black bamboo charcoal or white bamboo charcoal with the particle sizes of less than 2 mum. The preparation method comprises the following steps of: (1) preparing the bamboo charcoal fine particles according to a certain proportion, adding the surfactant and the antioxidant into a double-screw machine in a mixed conveying way, and directly putting the dried melt-spun slices into the hybrid double-screw machine; (2) melting and extruding the melt-spun slices in the double-screw machine, uniformly mixing the melt-spun slices with the bamboo charcoal fine particles and an aid, and conveying the mixture into a spinning box for direct spinning, by means of connection of a flange bent pipe; (3) spinning a blend melt with a spinning component from a spinneret plate, cooling, blowing and winding to obtain bamboo charcoal profiled nascent fibers; and (4) performing stretching twice and heat setting according to a continuous yarn or short yarn post-processing procedure. The invention is suitable for the bamboo charcoal profiled fiber and preparation thereof.

Owner:浙江三马锦纶科技股份有限公司

Converter smelting process with low lime consumption

InactiveCN110373511AAvoid meltingGuaranteed to meltManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

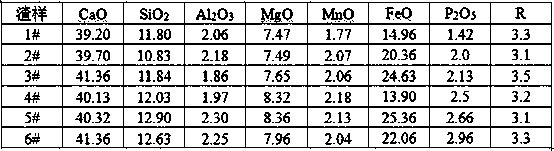

The invention discloses a converter smelting process with low lime consumption. The process comprises the steps that part of final slag is reserved according to the content of P2O5 in converter slag before converter tapping; after tapping, a deoxidizer is added according to the FeO content in the slag to reduce the oxidizability of the slag; all light-burned dolomite required in the dephosphorization period is added, slag splashing furnace protection operation is carried out, scrap steel is added firstly, and all lime required in the dephosphorization period is added; molten iron is added after the lime is added, a deoxidizing gun is ignited, and return ore or ore is added to adjust slag components after ignition; after the dephosphorization time, the carbon content and the temperature reach the requirements, inverse dephosphorization slag operation is carried out; after slag pouring is finished, the deoxidizing gun is ignited for the second time, and the feeding amount is controlled according to the alkalinity requirement; and oxygen supply is stopped when the carbon and the temperature meet the requirements, and part of the final slag is reserved according to the mass percentagecontent of P2O5 in the final slag for next smelting in the furnace. Lime consumption is reduced, the converter slag amount and the steel material consumption are reduced, and the problems of phosphorus enrichment, phosphorus return and dry dedusting explosion release in the slag are avoided.

Owner:HANDAN IRON & STEEL GROUP +1

Preparation method of Ti2AlNb alloy material

ActiveCN106319236AImproves ingredient uniformityGood chemical uniformitySelf consumptionHeating time

The invention discloses a preparation method of a Ti2AlNb alloy material. The method comprises the steps of 1, preparing a Ti2AlNb alloy ingot through vacuum self-consumption electric arc melting, kish furnace smelting and vacuum self-consumption electric arc melting; 2, conducting primary homogenization treatment on the Ti2AlNb alloy ingot; and 3, wrapping the Ti2AlNb alloy ingot with asbestos cloth, then conducting heat-preservation heat treatment, and then sequentially conducting cogging forging, improved forging and finished product forging, so that the Ti2AlNb alloy material is finally obtained. The preparation method of the Ti2AlNb alloy material is simple in preparation process and reasonable in process design; an alloy is uniform in structure and stable in performance; the alloy ingot can be effectively refined, purified and homogenized through a smelting method; through the high-quality ingot, smooth implementation of subsequent hot working is guaranteed; by means of homogenization treatment, uniformity of alloy elements can be further improved through element diffusion; and wrapping treatment is conducted with the asbestos cloth, the temperature of the material can be effectively prevented from being lowered in the whole forging process, and large-deformation-amount forging for one heating time is achieved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparing method of titanium fire resistance coating

ActiveCN107138878AHigh hardnessHigh temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaAlloyFire resistance

The invention discloses a preparing method of a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal can be completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

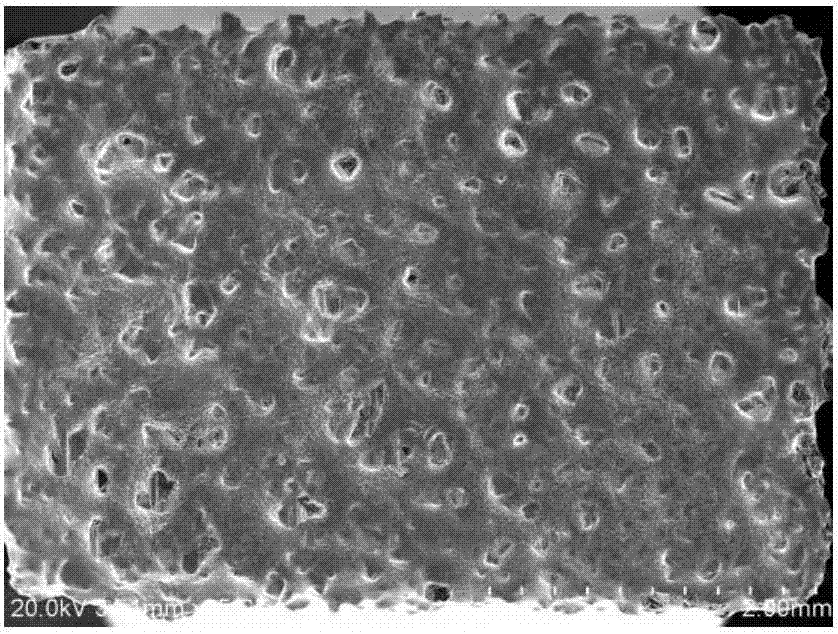

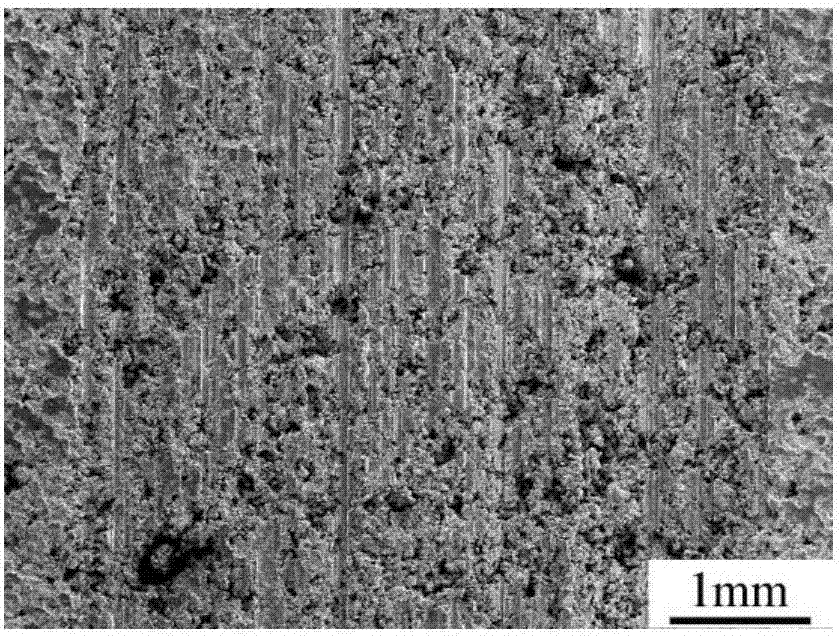

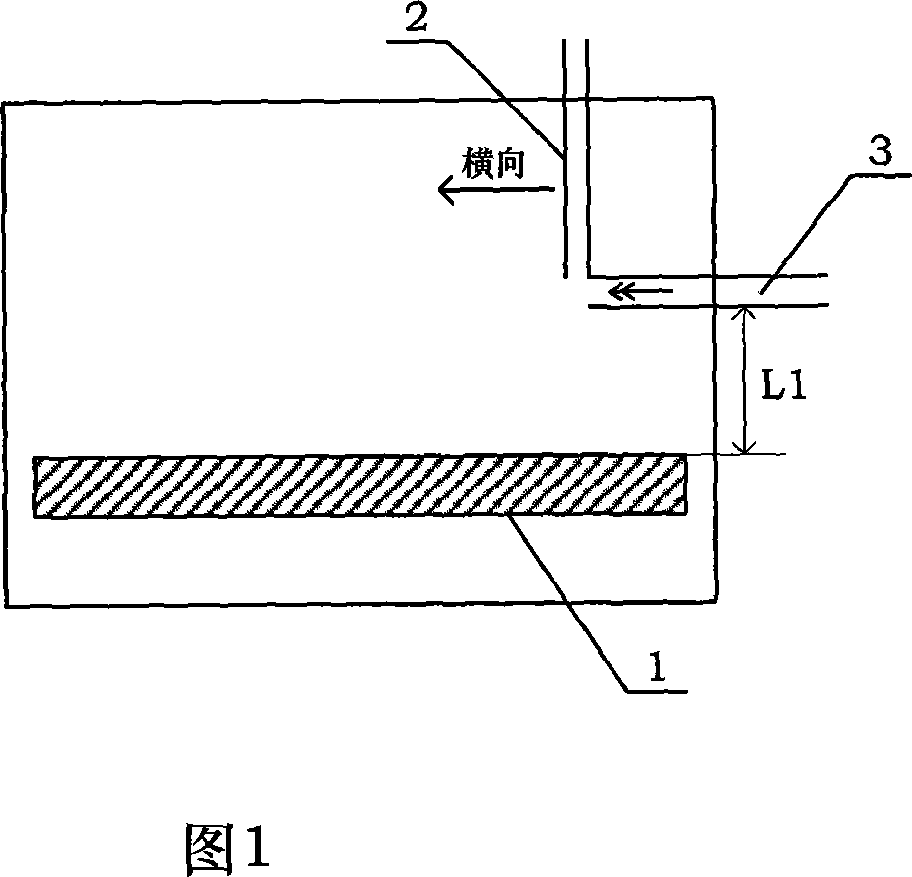

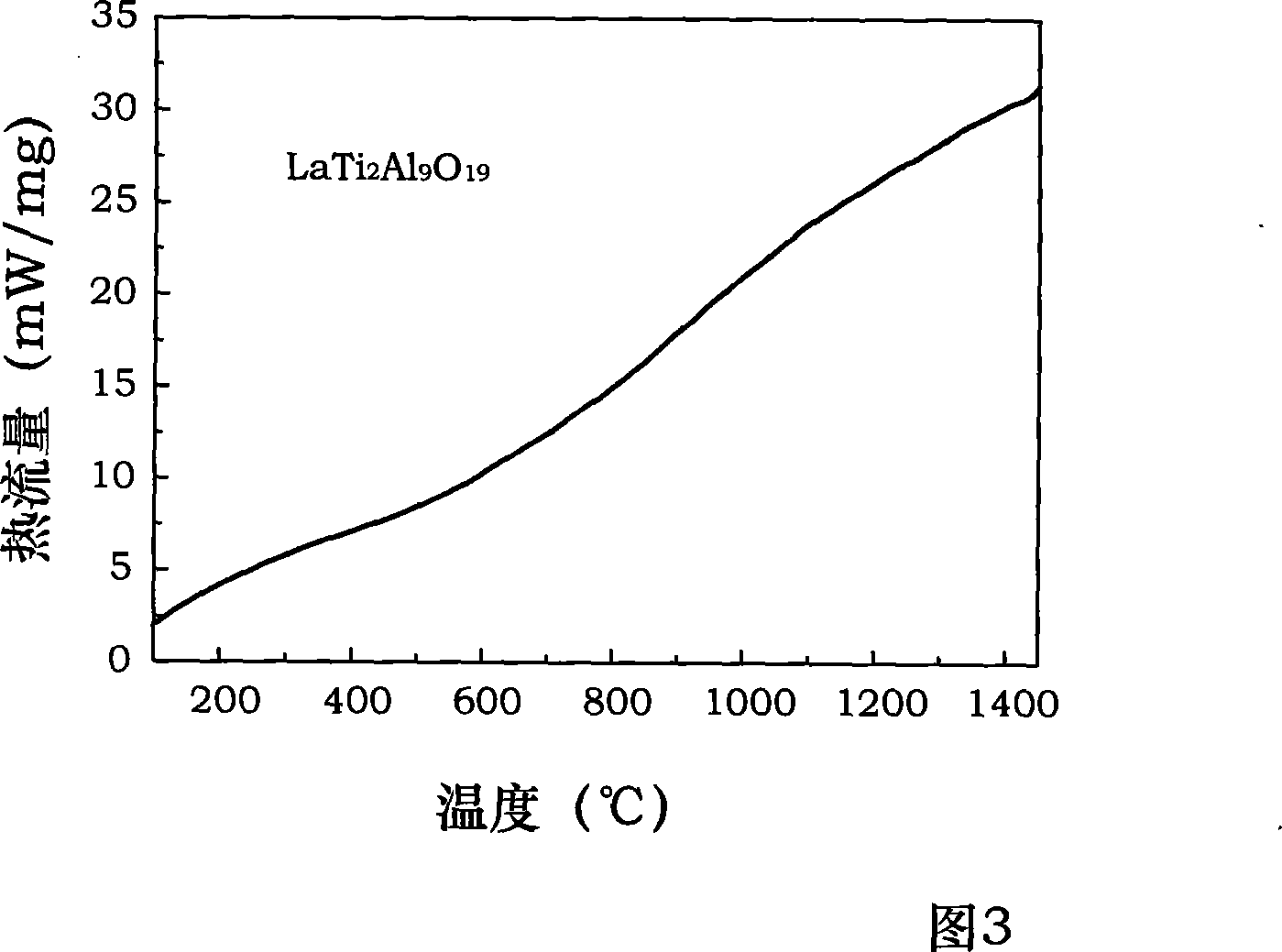

Method for preparing heat barrier coating with column form crystal structure ceramic layer

InactiveCN101078117AAvoid decompositionMaintain high temperature structural stabilityEfficient propulsion technologiesMetallic material coating processesThermal isolationMetallurgy

The invention discloses a thermal barrier coating preparation method with the columnar crystals coating to solve the problem of non-crystal coating and low anti-thermal in normal plasma spraying for the LaTi2Al9O19 ceramic material. It changes the distance and the technique data of the tack coat and ceramic powder channel in the normal plasma spraying process, so the thermal barrier coating of the LaTi2Al9O19 with the stable energetic and the columnar crystal structure. The thermal isolation temperature is 130deg.C-300deg.C and improves the strain limit and anti-thermal character, the hot circle life can reach above 1500 times and improves by 4 times.

Owner:BEIHANG UNIV

Preparation method of molybdenum metal grille

ActiveCN109014230AHigh sphericityIncrease heatAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strength3d printer

The invention discloses a preparation method of a molybdenum metal grille. The preparation method comprises the steps of 1, conducting cold isostatic pressing, high-temperature sintering, hot fine forging and straightening treatment on molybdenum powder to obtain a molybdenum rod; 2, machining the molybdenum rod into spherical molybdenum powder through plasma rotating electrode powder manufacturing equipment; and 3, preparing a molybdenum metal grille molded part with the spherical molybdenum powder as a raw material through a powder bed electron beam 3D printer and then conducting annealing,hot isostatic pressing and alkaline washing in sequence to obtain the molybdenum metal grille. According to the preparation method, the molybdenum powder is prepared into the spherical molybdenum powder; the molybdenum metal grille is prepared through the powder bed electron beam 3D printer; according to the characteristics that the spherical molybdenum powder is good in fluidity, compact and uniform in particle and tight in combination after quick melting and the heat of electron beams is high, the defects that molybdenum metal is high in strength, low in plasticity, very easy to oxidize andpoor in formability and is not likely to be machined into complex structural parts and functional parts are overcome, the specification and using properties of the molybdenum metal grille are improved, and the preparation cost is saved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

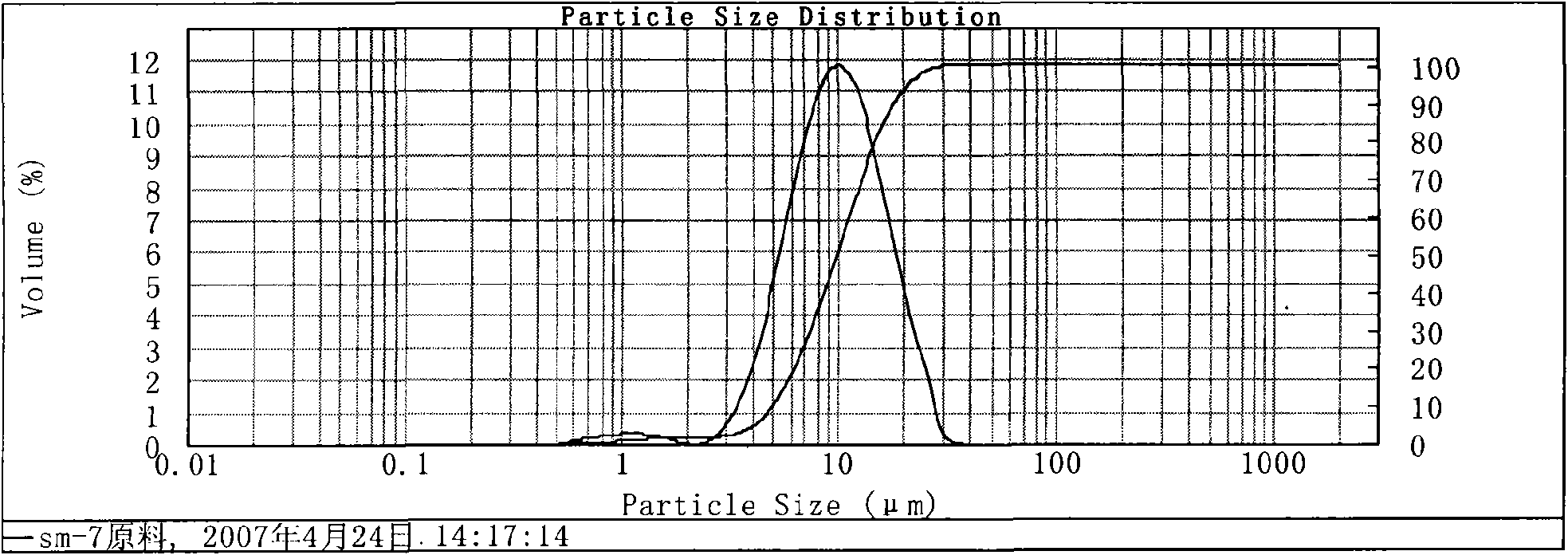

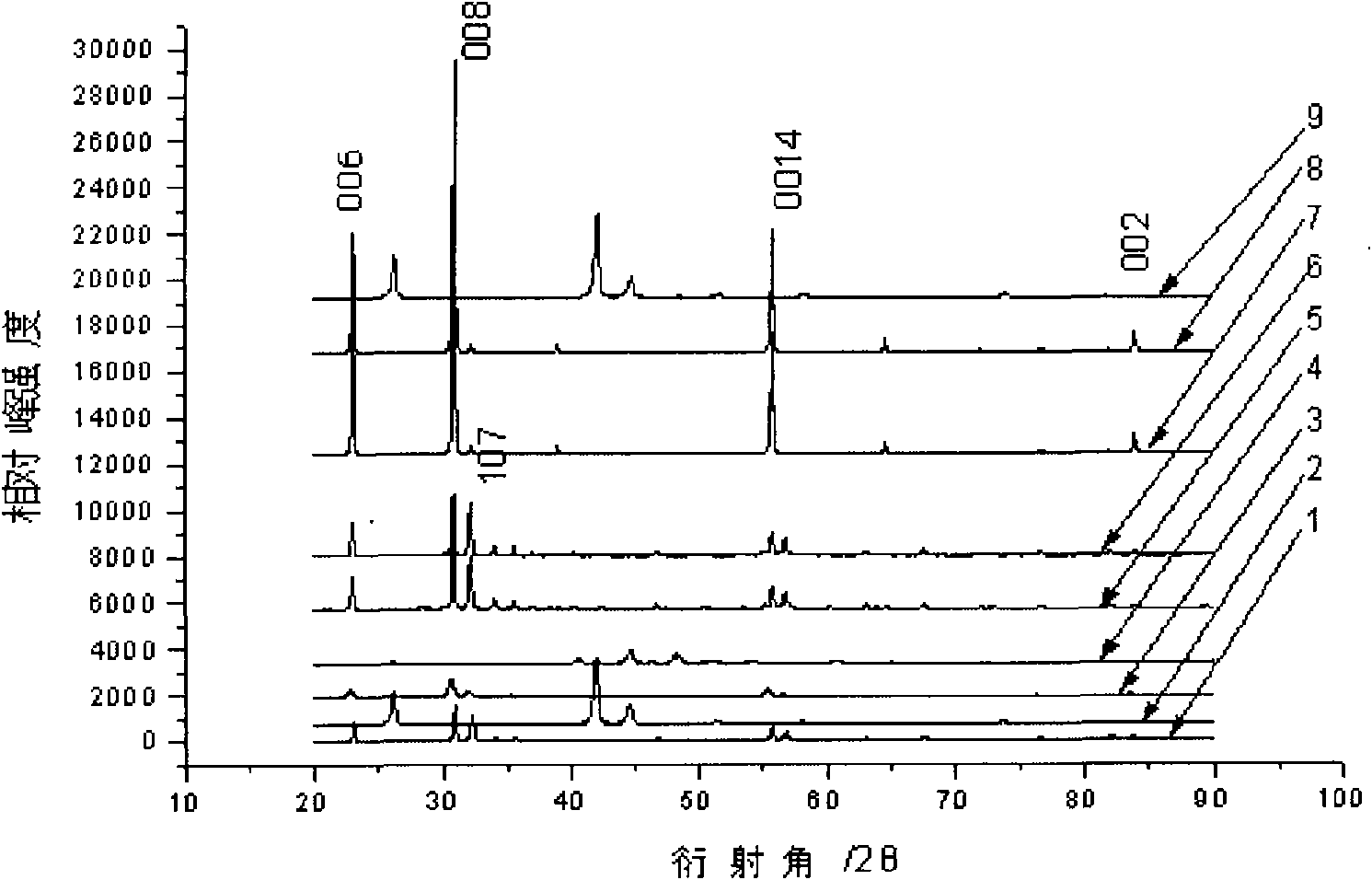

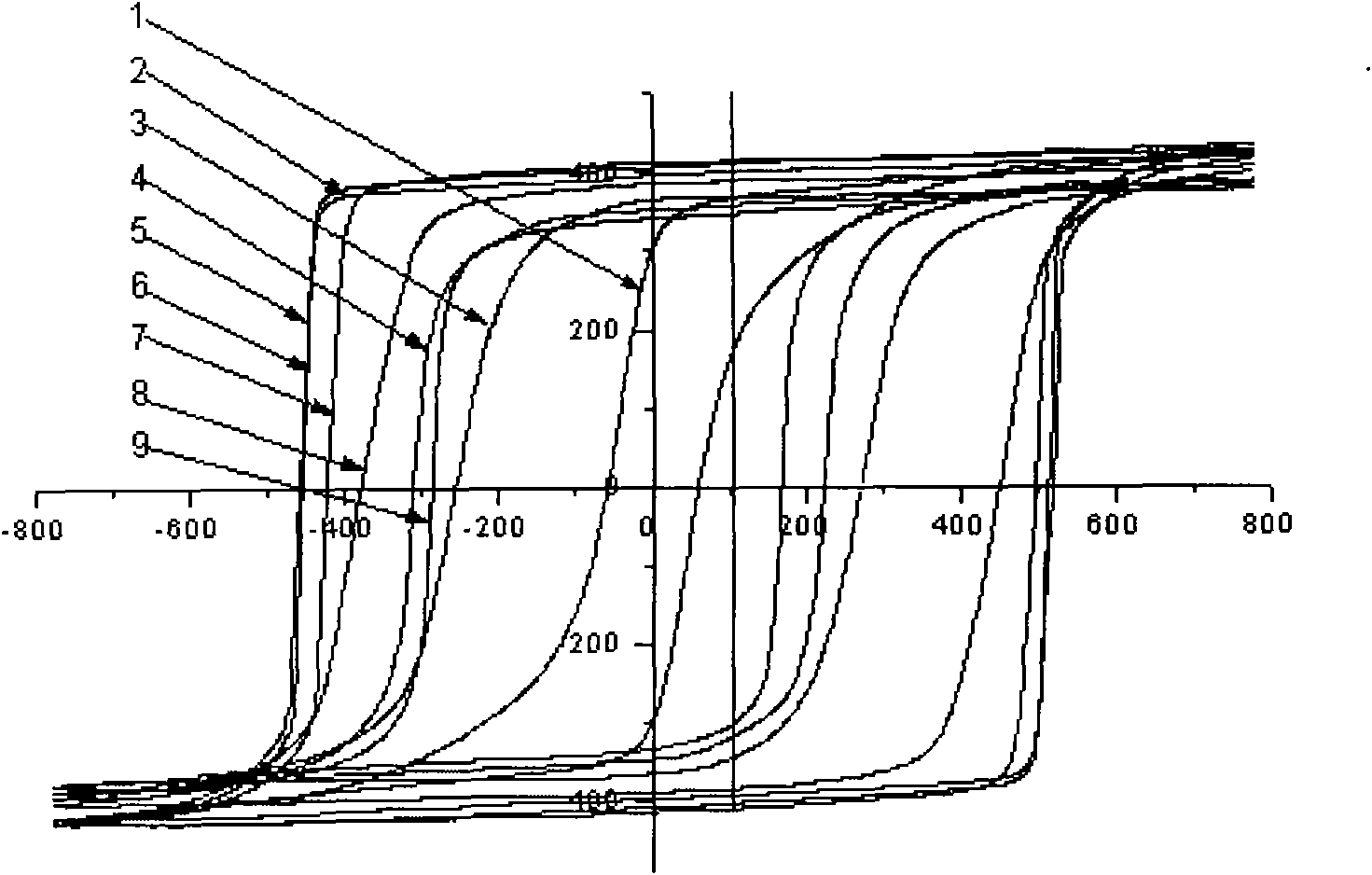

Method for preparing magnetic material of rare-earth permanent magnet ferrite

InactiveCN101599332AReduce the amount addedGuaranteed to meltInorganic material magnetismCeriumLanthanum

The invention discloses a method for preparing magnetic material of rare-earth permanent magnet ferrite; a ferrite pre-burning material including strontium or barium is used as the main material to prepare the magnetic material of rare-earth permanent magnet ferrite with high performance after the adding of auxiliary agent, the wet milling process, the magnetic forming process and the high-temperature sintering; the invention uses the extracted carbonate mixture having rare-earth concentrate powder with rich lanthanum or having lanthanum rare-earth concentrate powder to replace the conventional pure rare-earth oxide or pure rare-earth hydroxide, and improves the properties of the ferrite magnet by the lanthanum element in the rare-earth; cerium replaces the cobaltous oxide to improve the coercive intensity; the substances such as iron, silicon, calcium and aluminium partially replace the non-rare-earth oxide auxiliary agent, which must be added; the permanent magnet ferrite prepared by the following method of the invention comprises the following magnetic properties: Br is greater than or equal to 390 mT; Hcj is greater than or equal to 250 kA / m, and BH(MAX) is greater than or equal to 25 kj / m3. The invention can make full use of rich lanthanum rare-earth in China, thereby reducing the production cost of ferrite.

Owner:SHANGHAI INST OF TECH

Method for sealing edge of plastic cellular sandwich board and apparatus thereof

ActiveCN107379726AWon't crushImprove side wall strengthLamination ancillary operationsSynthetic resin layered productsSandwich boardMechanical engineering

The invention relates to a method for sealing an edge of a plastic cellular sandwich board and an apparatus thereof. According to the invention, an edge sealing zone is arranged outside the contour of a product, in the edge sealing zone, a high-temperature part is inserted between an upper skin and a lower skin of the edge, honeycomb is removed through fusing, the upper skin and the lower skin are softened, and then the upper skin and the lower skin are turned to a center, so that edge sealing of the product is realized. According to the edge sealing method, the product edge is full and firm, the product edge intensity is enhanced, the problem of edge enclosing of a PPHC material is solved, and an application of the PPHC material on a spare wheel cover plate is promoted.

Owner:宁波正海汽车内饰件有限公司

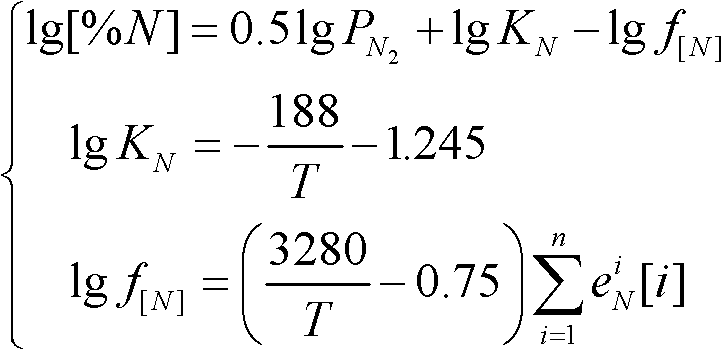

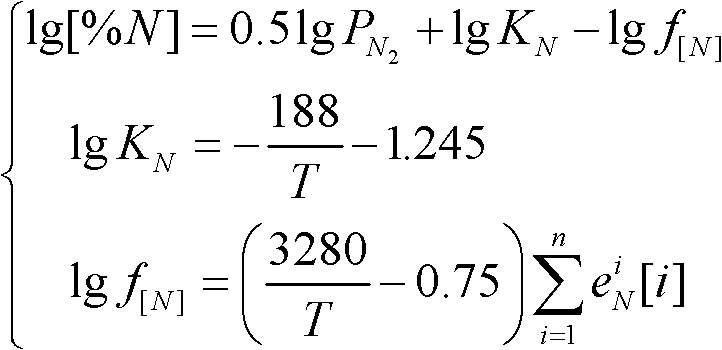

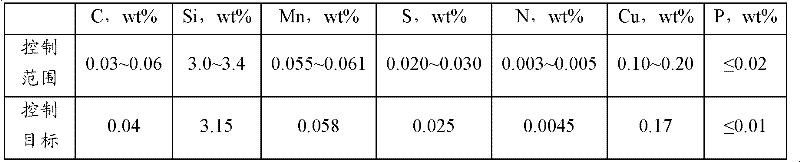

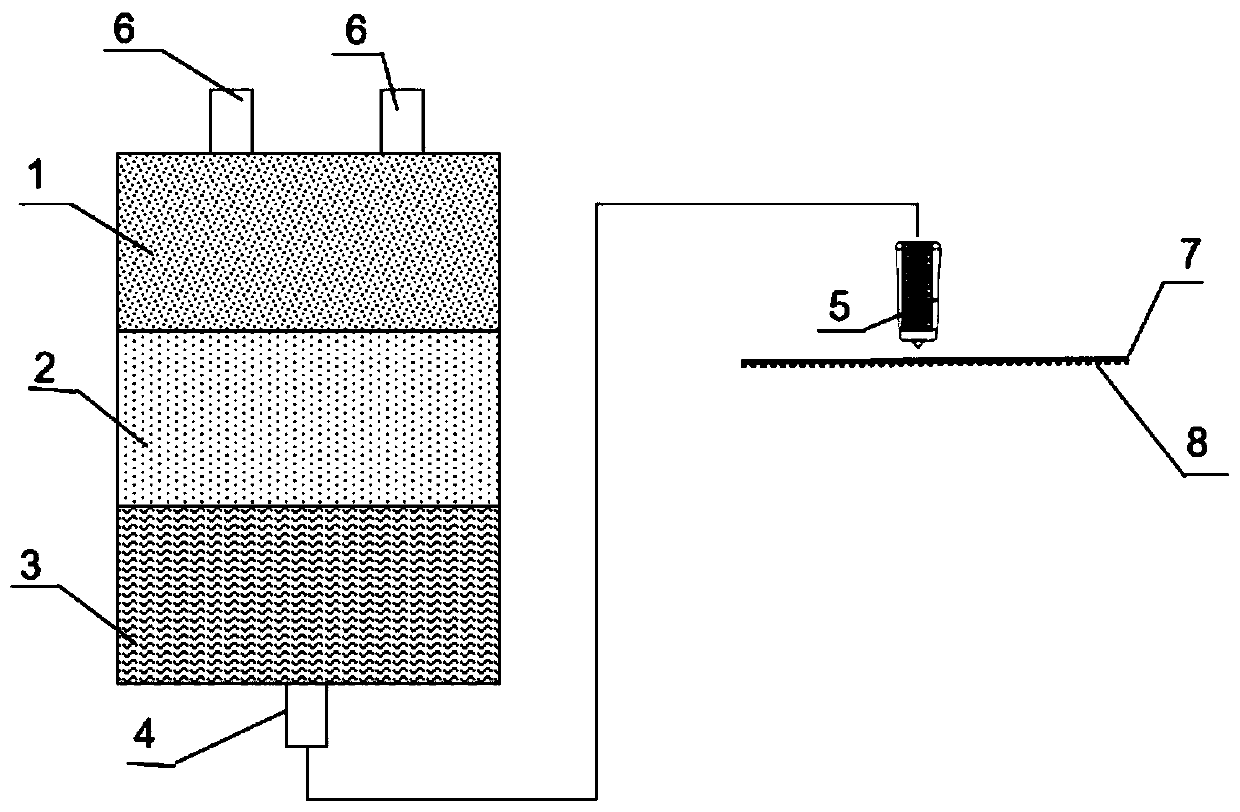

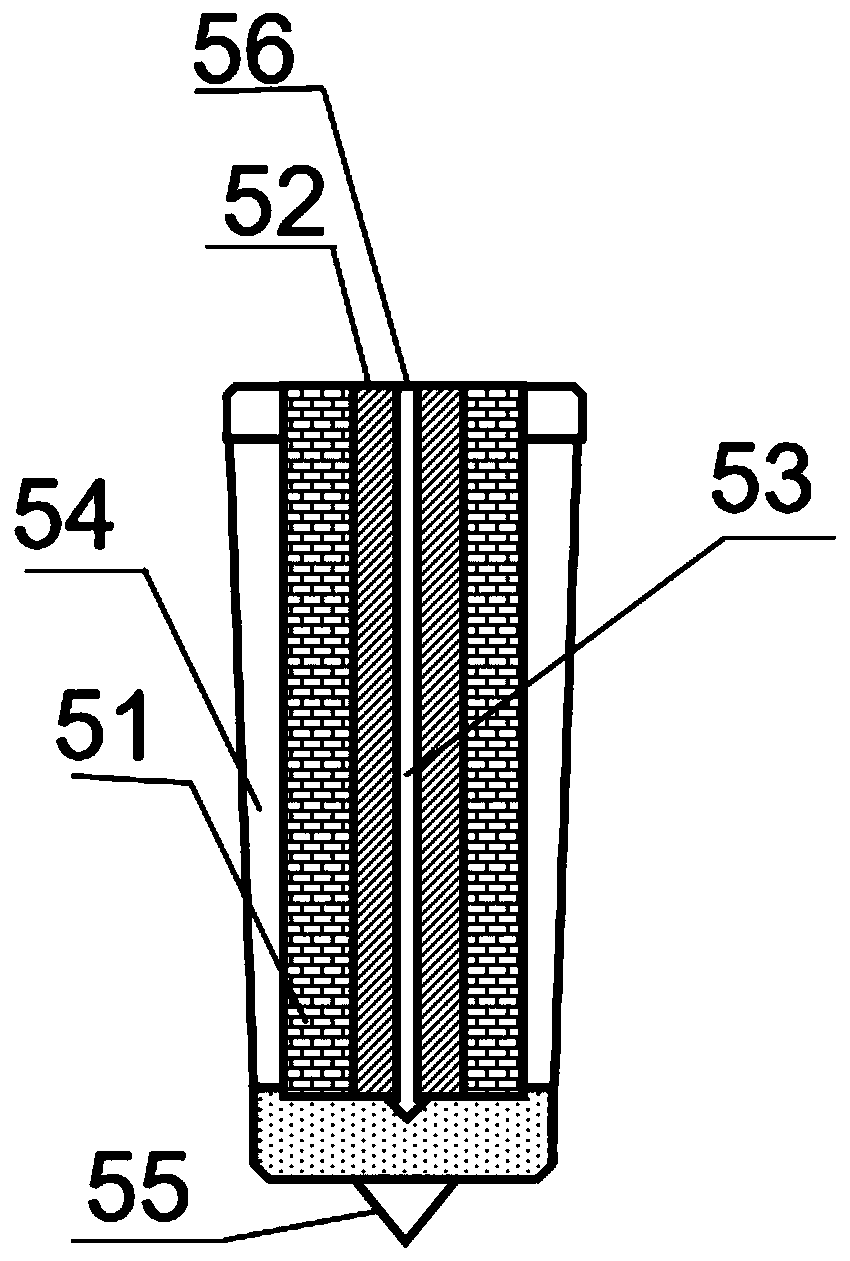

Method for controlling content of nitrogen in oriented silicon steel

The invention discloses a method for controlling the content of nitrogen in oriented silicon steel. The method comprises the following steps: placing pure iron used as the raw material and carbon in a crucible, placing accessories in a vacuum hopper according to the alloy raw material proportion and the charging sequence, wherein the alloy raw material proportion is calculated according to the content of each element in the oriented silicon steel; heating the furnace charge to melt, and refining the molten steel; adding aluminum to deoxidize after refinement, then adding metallic silicon or an alloy containing the nonvolatile elements of the oriented silicon steel to perform alloying; deciding whether to inject argon or nitrogen according to the content of nitrogen in the oriented siliconsteel; adding nitrogen-containing ferromanganese to adjust nitrogen under the protective atmosphere, adding other alloy raw materials to meet the target contents; and performing the vacuum charged pouring of molten steel at a proper molten steel temperature. Therefore, the narrow component range control of nitrogen element in the oriented silicon steel can be realized by adopting the method for controlling the content of nitrogen in the oriented silicon steel.

Owner:CENT IRON & STEEL RES INST

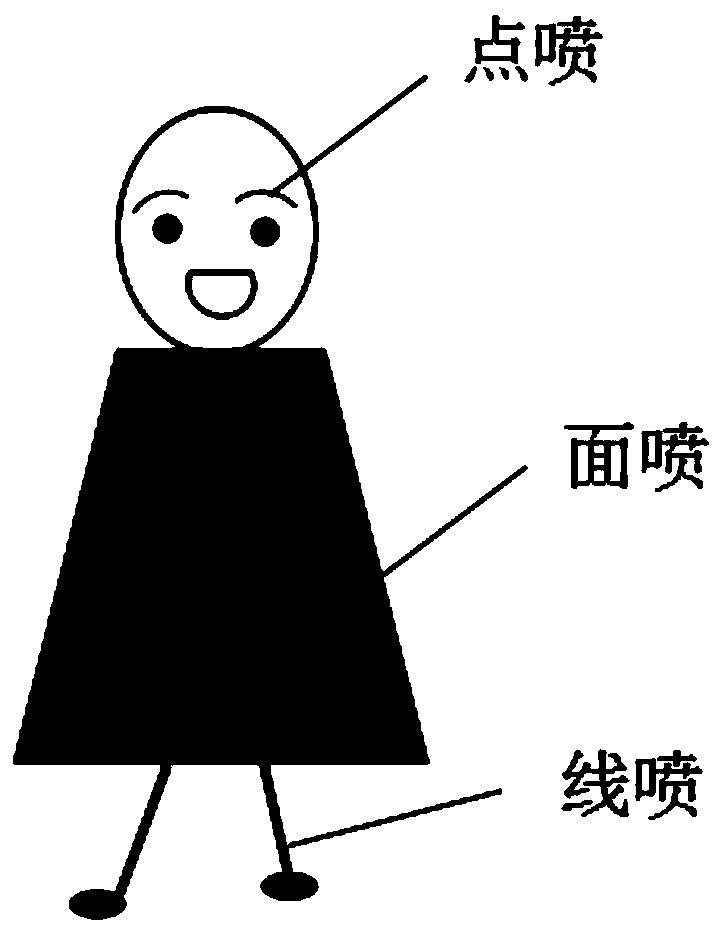

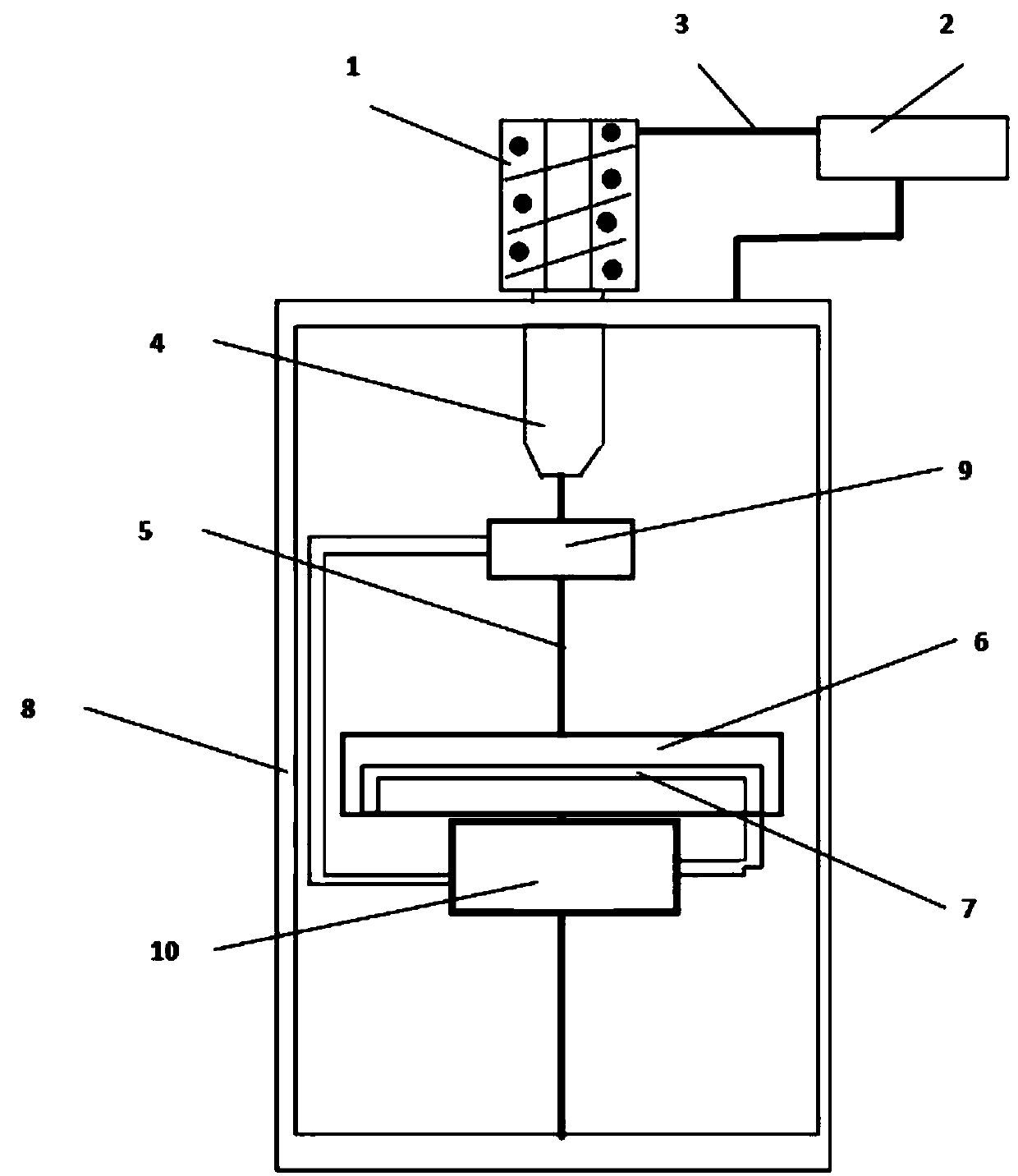

Spray type 3D printing device and method based on composite material

ActiveCN110355993AOvercome the problem of many internal defectsSimple structureAdditive manufacturing apparatus3D object support structuresSpray nozzleEngineering

The invention discloses a spray type 3D printing device and method based on a composite material, and belongs to the technical field of 3D printing. The problem that many internal defects of a 3D printing product in the prior art exist is solved. Powder of an object to be printed is thoroughly mixed through a mixing system, then raw materials are fully melted through a dispersion system, a meltingsystem and a cooling system, and printing is completed by an atomizing spray head after dispersion even distribution is carried out; a heating chamber in the spray head heats and melts a wire in a molten throat pipe, complete melting of the wire is further ensured, and liquid can stably flow after melting; and in addition, air pressure in an air supply passage is accurately controlled, the size and shape of jet nozzles of the spray head are intelligently selected according to the object to be printed, one from point spray, line spray and surface spray can be selected according to the conditions, uneven temperature release in the printing process is reduced, the influence of material stress is eliminated, the warpage of time is eliminated, the defects are reduced, and the processing efficiency is improved.

Owner:XI AN JIAOTONG UNIV

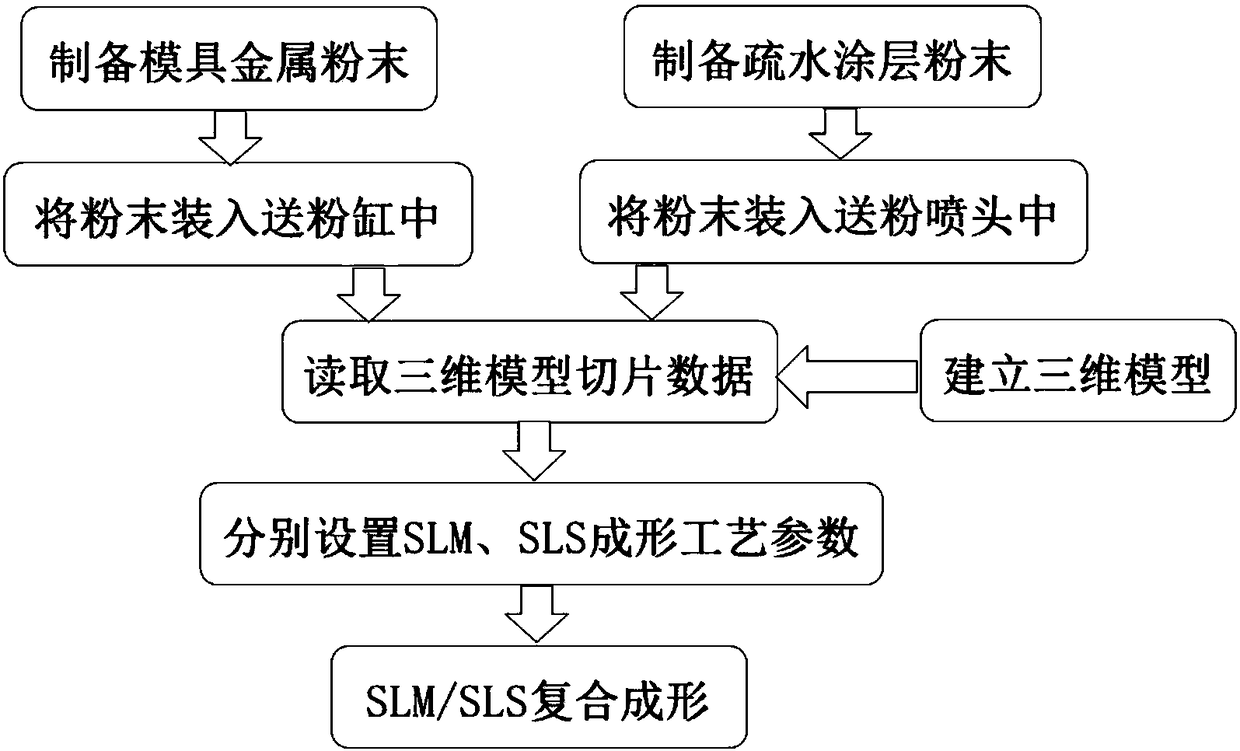

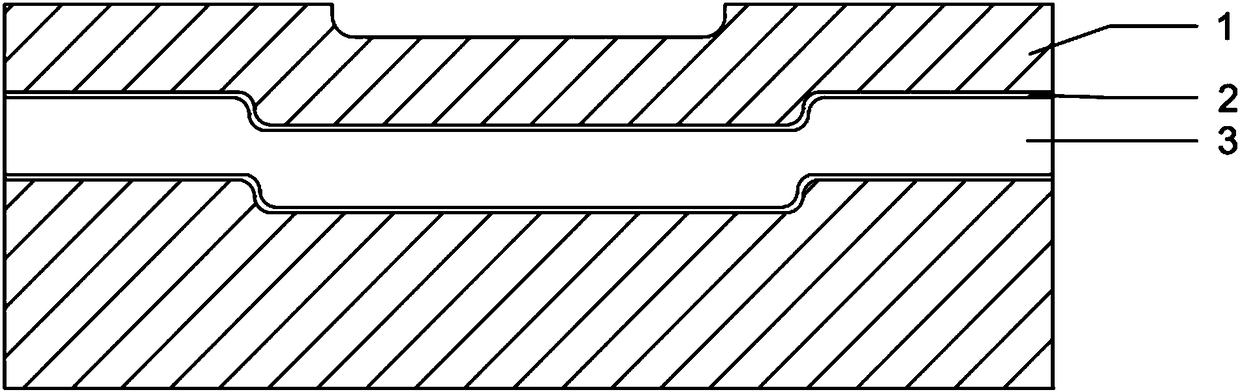

Conformal cooling channel with hydrophobic effect and production method thereof

ActiveCN108372305AAvoid cloggingAvoid normal workAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMaterial type

The invention discloses a conformal cooling channel with hydrophobic effect and a production method thereof. The method comprises the following steps: (1) preparing hydrophobic coating powder materials; (2) designing a three-dimensional model with a conformal cooling channel die, and performing slicing treatment; (3) placing die metal powder and hydrophobic coating powder; (4) carrying out shapingtreatment, specifically comprising first performing shaping on the die metal powder by using an SLM (selective laser melting) technology, then performing shaping on the hydrophobic coating powder byusing an SLS technology to form a powder leveling layer; (5) repeating step (4) until the whole conformal cooling channel is completed; (6) taking off the shaped die. Through improving and optimizingthe key material types of inner wall hydrophobic coating and corresponding specific shaping technology, the conformal cooling channel with hydrophobic coating can be obtained, and the technical problems that the cooling efficiency of a die cooling system is low, the conformal cooling channel is easy to block, the surface metal is easy to corrode and the like are solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Manufacturing method for niobium-containing Ti3Al alloy cast ingot

The invention discloses a manufacturing method for a niobium-containing Ti3Al alloy cast ingot. A pure titanium cast ingot is manufactured firstly, then the pure titanium cast ingot is machined into a shining titanium bar, the obtained shining titanium bar, a shining niobium bar and a shining aluminum bar are welded into a consumable electrode in a spliced mode, the consumable electrode is subjected to three times of vacuum self-consuming electric arc melting, and the niobium-containing Ti3Al alloy cast ingot is obtained. The consumable electrode is manufactured in the bar splice welding mode, and manufacturing of intermediate alloy and the step of electrode block pressing are omitted, so that the process is simplified. Meanwhile, due to the fact that the consumable electrode is manufactured by welding the titanium bar, the aluminum bar and the niobium bar in a splicing mode, the effect that the contents of all elements on the same melting cross section in the melting process are consistent can be ensured; and due to the fact that the titanium bar, the aluminum bar and the niobium bar are all compact materials, the defects of nonuniform chemical components caused by different local melting speeds or impurity inclusion caused by block falling and the like are avoided. The alloy cast ingot manufactured through the method is uniform in component, and the defects that in the prior art, the niobium element is segregated severely, alloy components are inaccurate and the uniformity is poor are overcome.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

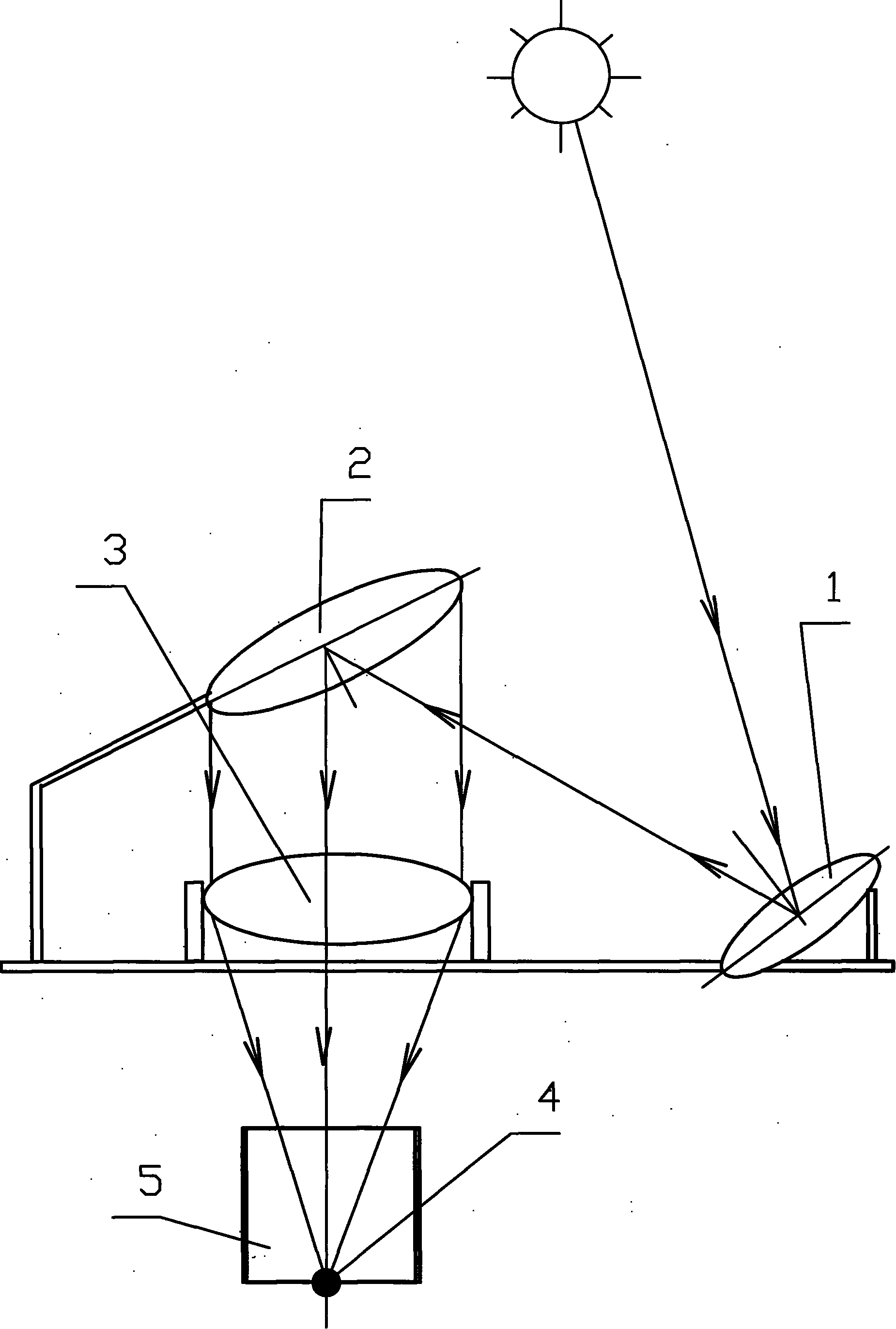

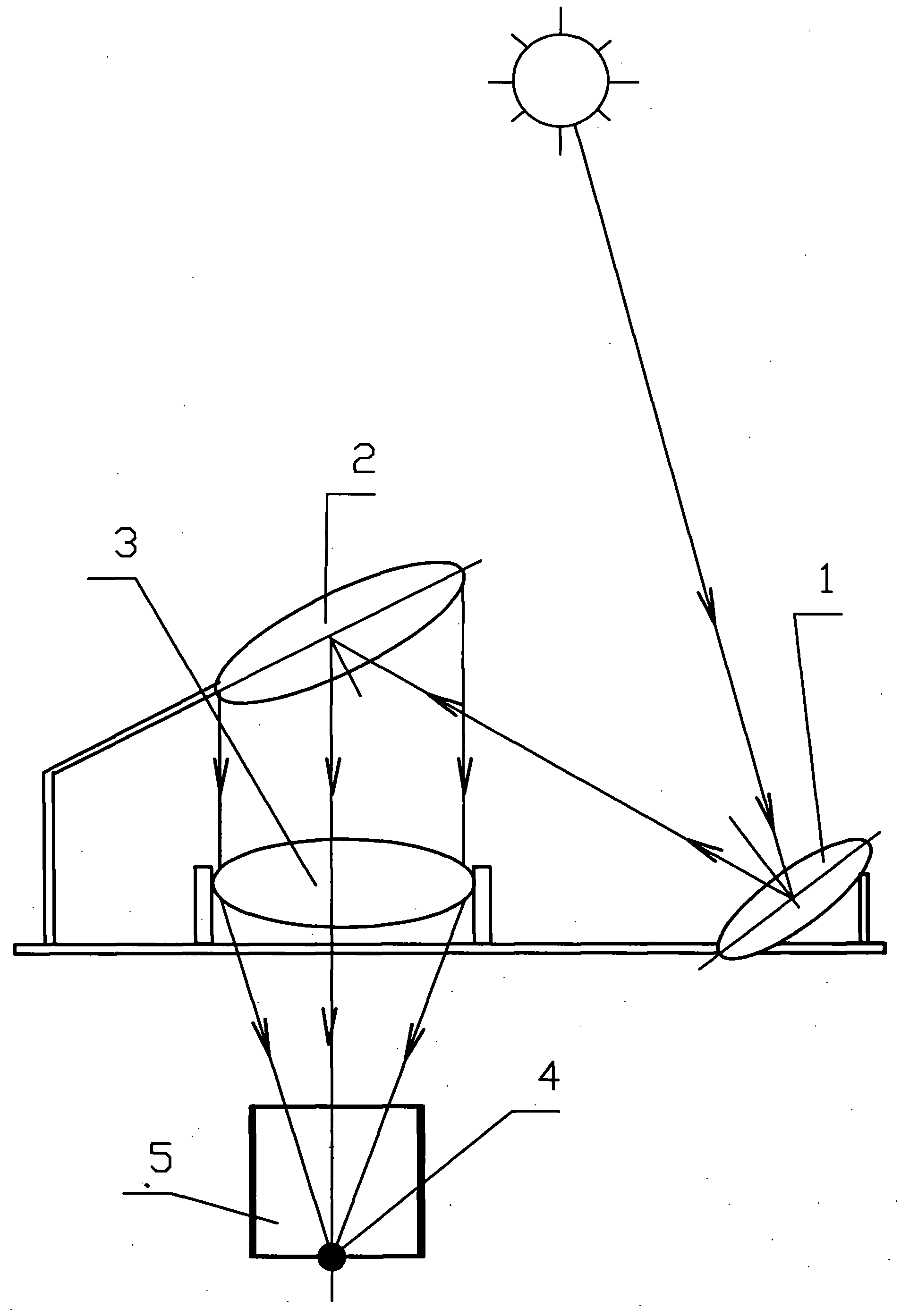

Solar sand stabilization method and system

Owner:然国廉 +1

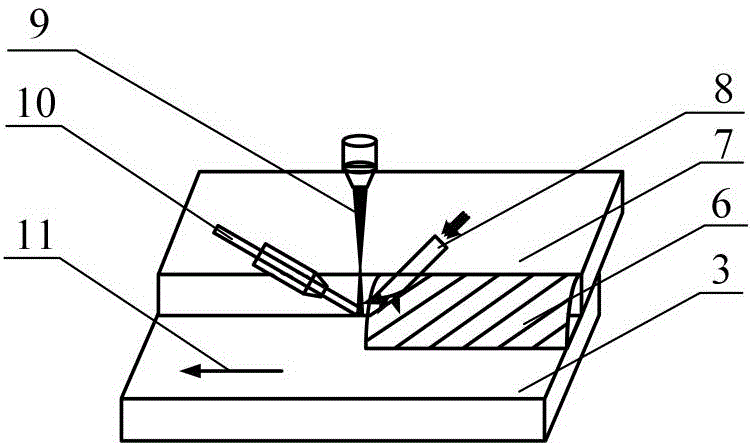

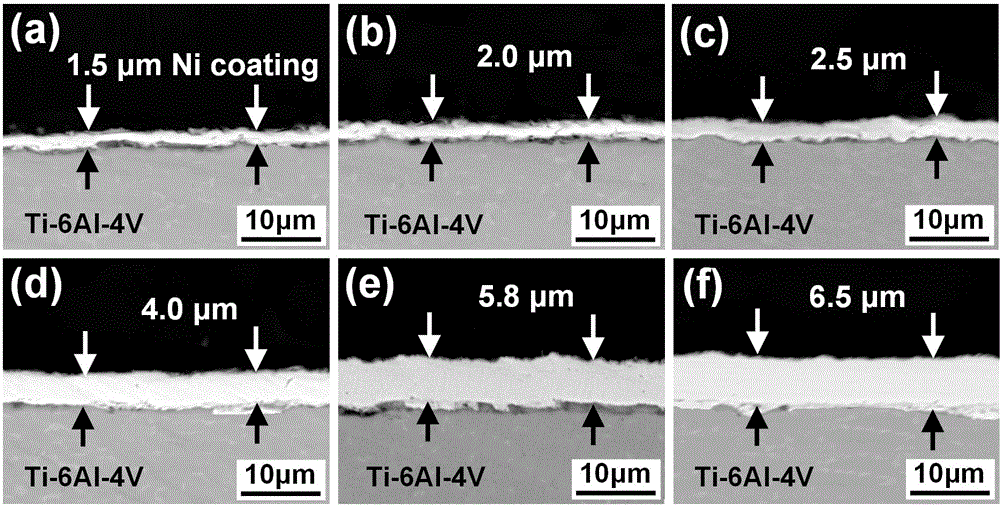

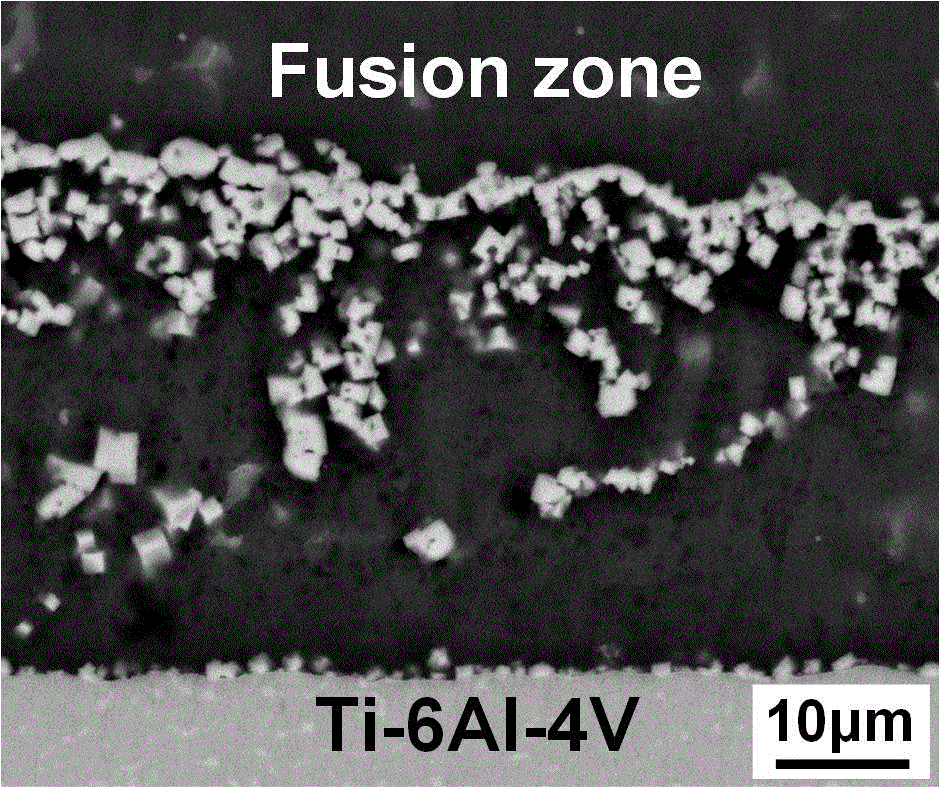

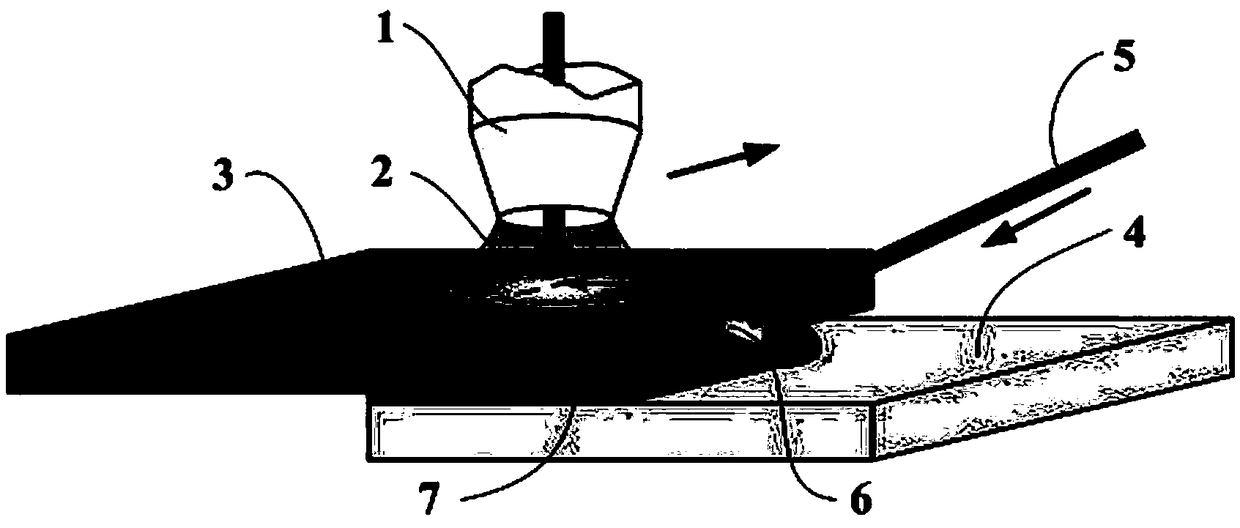

Magnesium/titanium laser melting braze welding method assisted by nickel-plated layer

InactiveCN106270878AAchieve metallurgical connectionGuaranteed to meltSoldering apparatusLap jointTitanium

The invention discloses a magnesium / titanium laser melting braze welding method assisted by a nickel-plated layer. The method is applicable to the field of dissimilar metal welding and is used for solving the problems of no occurrence of metallurgic reaction and great melting point difference between the existing magnesium / titanium. The method is characterized in that firstly, nickel is electroplated on a titanium plate subjected to acid cleaning is used as a middle layer; then, a lap joint mode that a magnesium plate is positioned at the upper part and the titanium plate is positioned at the lower part is used; meanwhile, high-pure argon gas is used for positive and opposite side protection; the magnesium / titanium connection is realized through magnesium alloy wire filling. The method has the advantages that the moistening spreading capability of the magnesium alloy on the titanium plate is effectively improved; joints without obvious defects can be obtained; the tensile strength can reach 243 N / mm; the joint efficiency is 90 percent of a magnesium plate; higher practical values are realized.

Owner:HARBIN INST OF TECH AT WEIHAI

High-speed 3D printer with cooling system

ActiveCN107696478ARapid coolingQuickly complete the printing processManufacturing driving means3D object support structuresEngineeringCore system

The invention discloses a high-speed 3D printer with a cooling system. The high-speed 3D printer comprises two core systems including the cooling system and a rapid wire discharging system, wherein the cooling system is connected with the rapid line discharging system; and the rapid three-dimensional printing can be realized. The high-speed 3D printer has the contents that by utilizing the coolingsystem, a printed material can be rapidly cooled and condensed and can be combined with preceding printed materials; an extrusion mechanism adopts a spiral wire feeding mechanism, so that the wire feeding speed and uniformity are guaranteed; and meanwhile, the heating temperature of a spray head is relatively high, the fluidity of the material is improved, and the extrusion speed of the materialis further increased. Finally, the printing efficiency is improved, and the operation efficiency of the printer is liberated.

Owner:BEIJING UNIV OF TECH

Hollowed-out Jun procelian and preparation technology thereof

InactiveCN107188540AClear and pure glaze colorMoist and delicateCeramic materials productionCeramicwareMicrowaveHardness

The invention relates to hollowed-out Jun procelian, comprising two parts, i.e., base procelian and glazed porcelain, wherein a plurality of through holes are formed in the outer surface of the base procelian; the pre-separation between pore-making granules and a green body is realized by means of microwave treatment on the pore-making granules evenly doped in the base procelian green body through the through holes; then, the green body is subjected to high-temperature sintering, so that the pore-making granules are melted, and the hollowed-out Jun procelian is obtained. After the hollowed-out Jun procelian and a preparation technology thereof, provided by the invention, are adopted, the preparation of the hollowed-out Jun procelian which is good in finished product hardness, high in molding rate and low in loss on ignition can be realized by means of a base procelian raw material formula, a base procelian firing method and improvement for a glaze formula and a glaze firing technology.

Owner:任合超

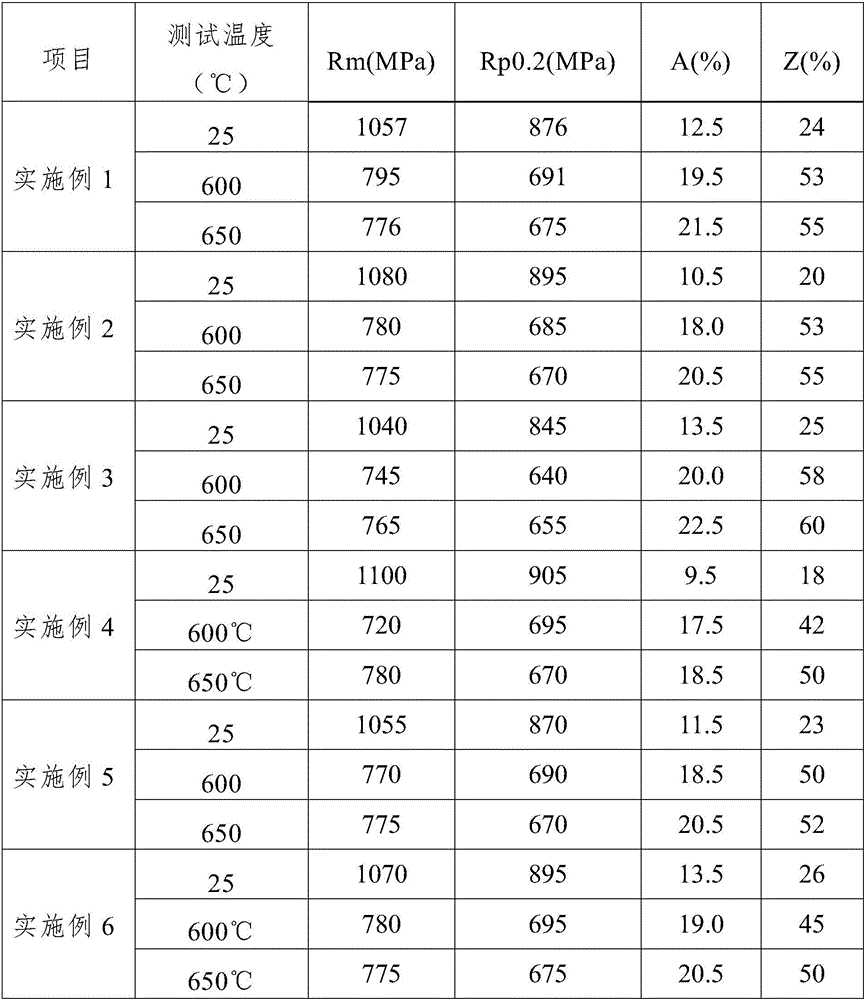

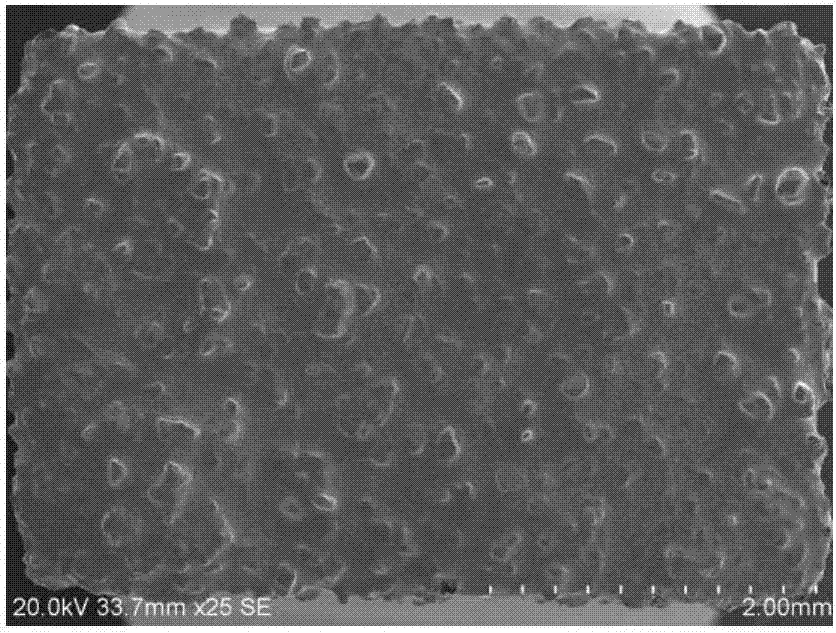

Method for producing nickel-based steel from high-phosphorus molten iron

ActiveCN111411300AOptimizing the Converter ProcessMeet the needs of industrial productionManufacturing convertersProcess efficiency improvementTemperingSlag

The invention discloses a method for producing nickel-based steel from high-phosphorus molten iron, and relates to the technical field of steel smelting. By adopting converter smelting, the P contentof used molten iron is 0.130% to 0.150%, by adopting a method of slag retention at the early stage and double slag at the later stage, the final smelting temperature is 1580-1620 DEG C, in the middleand later periods of smelting, the bottom stirring flow is 350-400 NL / min, the final slag alkalinity is 4.0, the final slag control amount is 10-12 tons, the converter decarburization rate is larger than or equal to 99%, and the dephosphorization rate is larger than or equal to 96%; and through LF refining, RH vacuum treatment, arc continuous casting machine pouring, by adopting TMCP rolling and ACC water cooling to 300 + / -20 DEG C, air cooling is performed to room temperature, a steel plate is heated to 550 + / -10 DEG C, tempering is performed for 3*h min, and air cooling is performed to roomtemperature. The converter process is optimized, a product is conveyed to a heating furnace to be heated after vacuum treatment and casting of an arc-shaped continuous casting machine, TMCP rolling and ACC water cooling are adopted, and after tempering treatment, performance detection is qualified.

Owner:NANJING IRON & STEEL CO LTD

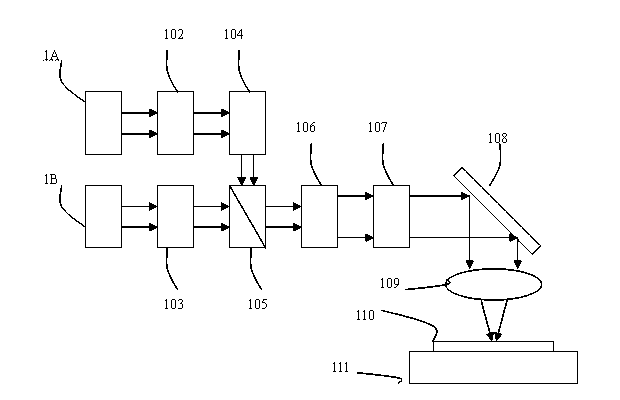

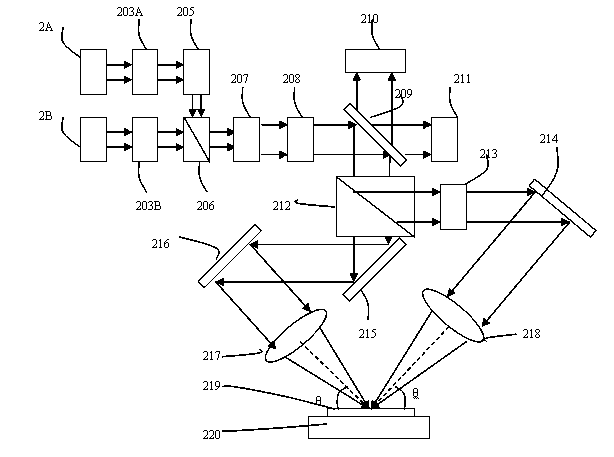

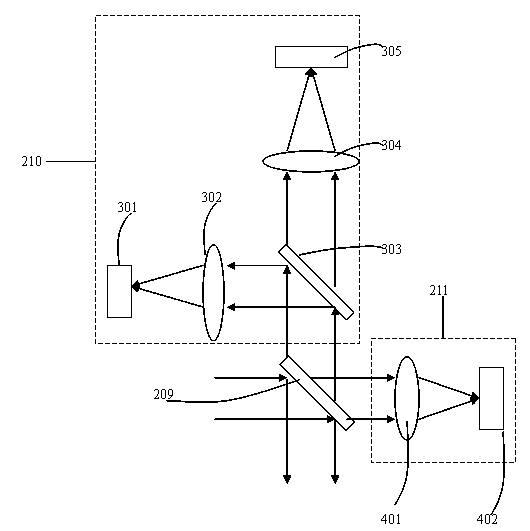

Laser annealing device and method

ActiveCN104078339AImprove utilization efficiencyImprove absorption efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusOptical pathLaser annealing

The invention discloses a laser annealing device and a method. The device comprises a laser source, a light path part, a light path monitoring part and a motion part, wherein the laser source comprises two P-pole linear polarization laser devices; and laser beams emitted by the two P-pole linear polarization laser devices pass through the light path part, are treated by a beam splitting part, and then are emitted to the surface of a silicon wafer of the motion part at near brewster angles. Compared with the prior art, the laser annealing device adopts the two P-pole linear polarization laser devices, light emitted from a laser device is converted into S-pole polarized light, the S-pole polarized light is synthesized and then passes through a light path treatment part, then two light beams are separated, the S-pole light beam is reduced to P-pole light, and finally the two light beams are emitted at brewster angles. Therefore, the two laser beams can be emitted at the brewster angles, the light path treatment part is not too complicated, and the utilization efficiency of laser energy is improved greatly.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Titanium fire resistance coating

ActiveCN107142474AHigh hardnessHigh temperature oxidation resistanceMetallic material coating processesBand shapeAlloy

The invention discloses a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal is completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

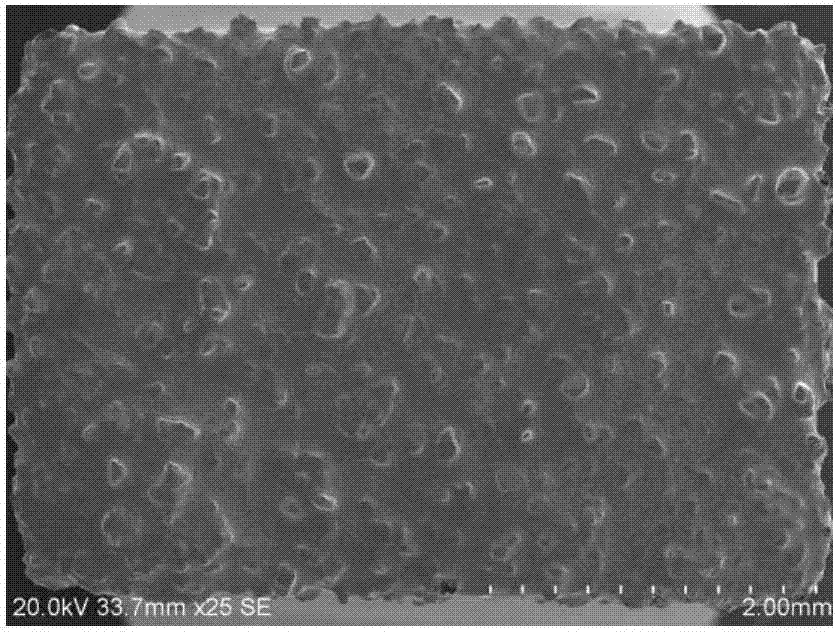

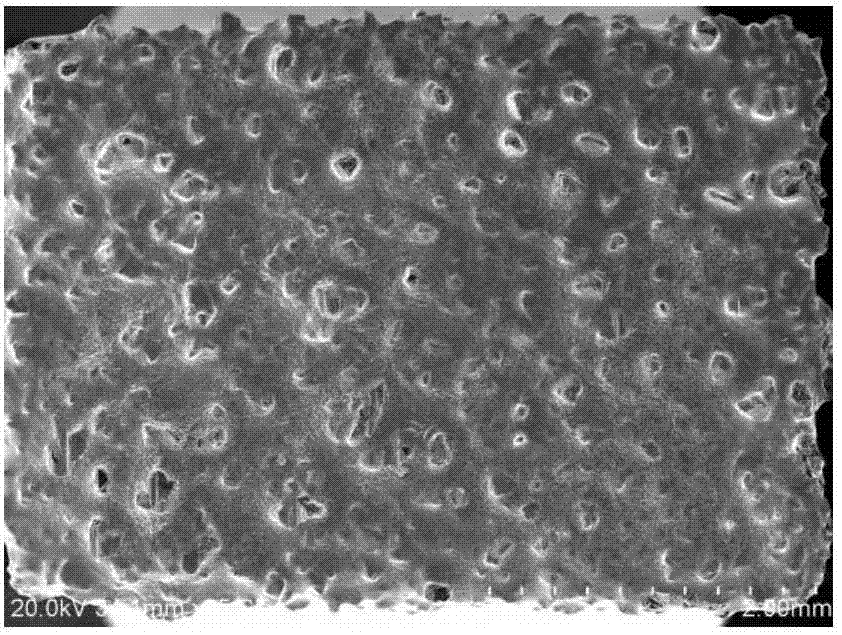

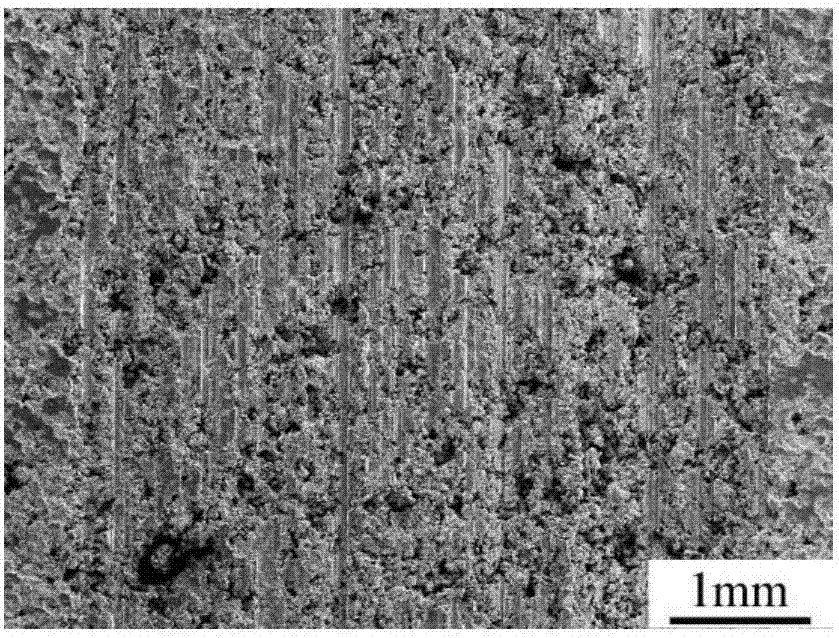

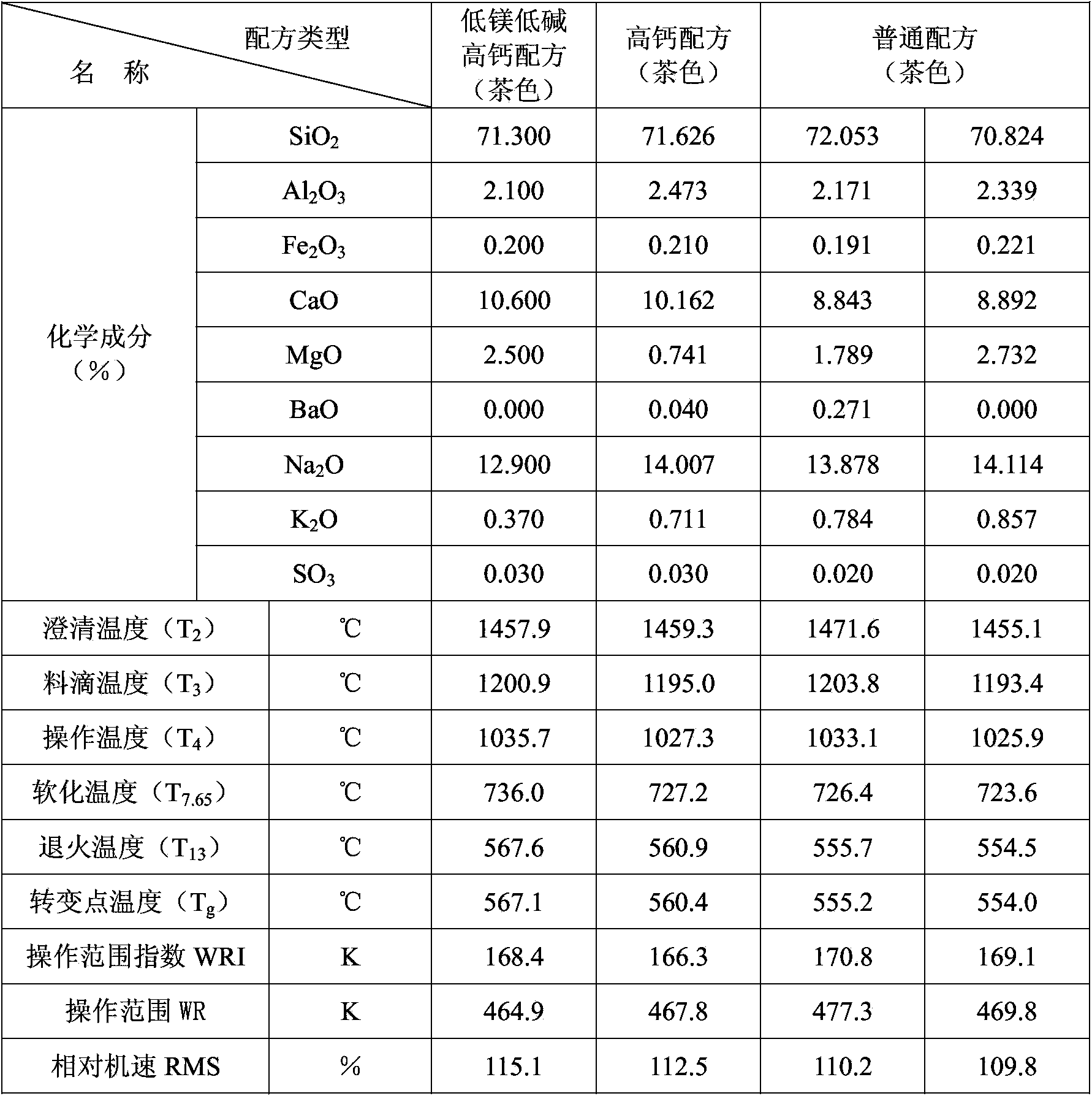

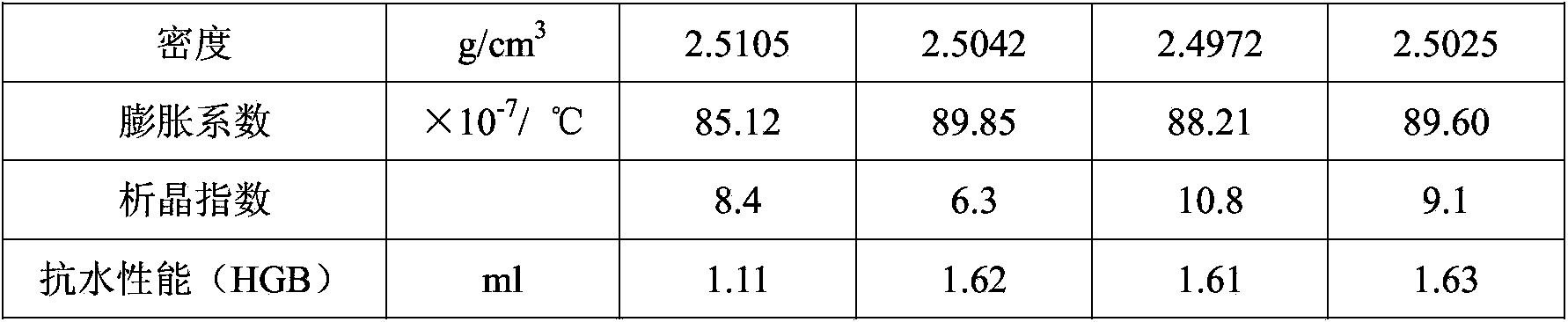

Bottle glass formula

The invention relates to a bottle glass formula, wherein the bottle glass comprises, by weight, 69.5-72.5% of SiO2, 1.9-3.1% of AlO3, 10.2-10.6% of CaO, 2.0-2.5% of MgO, 12.8-13.0% of Na2O, 0.3-0.7% of K2O, less than or equal to 0.3% of Fe2O3, and less than or equal to 0.3+ / -0.1%. According to the bottle glass formula of the present invention, in the high calcium formula, the total content of CaO+MgO is increased, the Na2O amount is reduced, and the appropriate MgO content is maintained, such that the material performance of the glass is adjusted, the molding performance of the glass is improved, and the relative machine speed is increased and the water resistance (HGB) of the glass product is substantially increased in the case of the same mold cooling air flow. In addition, the soda ash consumption is reduced so as to easily achieve energy saving and reduce cost.

Owner:CHINA LIGHT IND INT ENG CO LTD

Method for diluting and eliminating center line segregation of continuous casting slab by utilizing additive material

The invention relates to a method for diluting and eliminating center line segregation of a continuous casting slab by utilizing an additive material. The method comprises the following steps: acquiring the parameters of production working conditions; determining supply speed va, the thickness d of the additive material and the width w of the additive material, wherein w is larger than d; calculating a segregation index of the tail end of a liquid core based on a standard solute concentration C<standard> to obtain a solute concentration Coi, and adopting an inverse method to obtain a solute concentration Ca of the additive material; obtaining a selection concentration C<selection> according to a formula that C<selection> is larger than or equal to Ca and smaller than C<standard>; selectingand / or manufacturing the additive material according to the thickness d of the additive material, the width w of the additive material and the selection concentration C<selection>, and continuously conveying the additive material to the tail end of the liquid core in a vibrating manner. According to the method for diluting and eliminating center line segregation of the continuous casting slab byutilizing the additive material provided by the invention, the center line segregation is alleviated and eliminated by utilizing proportioning of alloy components, and meanwhile the additive materialcan eliminate center loosening. The additive material is completely molten after reaching the tail end of the liquid core; under a vibration effect, the molten liquid group is totally mixed with casting liquid inside the tail end of the liquid core, so two great internal quality defects about center line segregation and center loosening inside the continuous casting slab are simultaneously prevented.

Owner:NORTHEASTERN UNIV

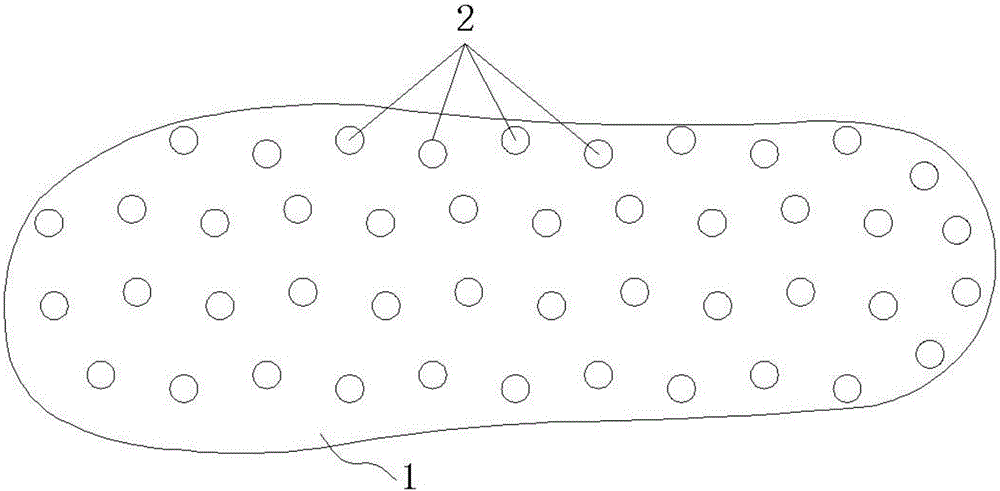

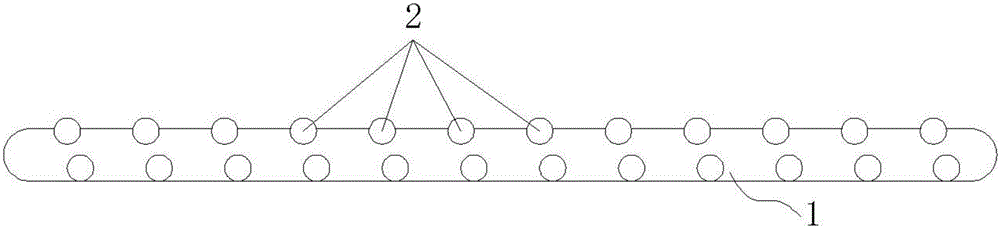

High-resilience insole and manufacturing method thereof

The invention discloses a high-resilience insole which comprises a PU insole body and elastic particles. The elastic particles are embedded in the PU insole body, and the density of the elastic particles ranges from 0.1 g / cm<3> to 0.2 g / cm<3>.The high-resilience insole is simple in structure, and foldable while not likely to deform, and has high resilience. The invention further discloses a manufacturing method of the high-resilience insole. The manufacturing method comprises the following steps that firstly, 3-5 parts of PU by weight and a catalyst are put into a material barrel, then the mixture is heated to 40-55 DEG C, and the temperature is maintained to be constant; secondly, 1 part of elastic particles with the melting point higher than 55 DEG C by weight are added into the material barrel and then stirred evenly, and a mixture is obtained; thirdly, the mixture is injected into a mold, cooling and sizing are carried out, and the high-resilience insole is obtained. The manufacturing method is simple in processing step, low in processing cost and high in reliability, and the obtained finished product is high in yield, large in strength and resilience and high in practicability.

Owner:东莞市天强鞋材有限公司

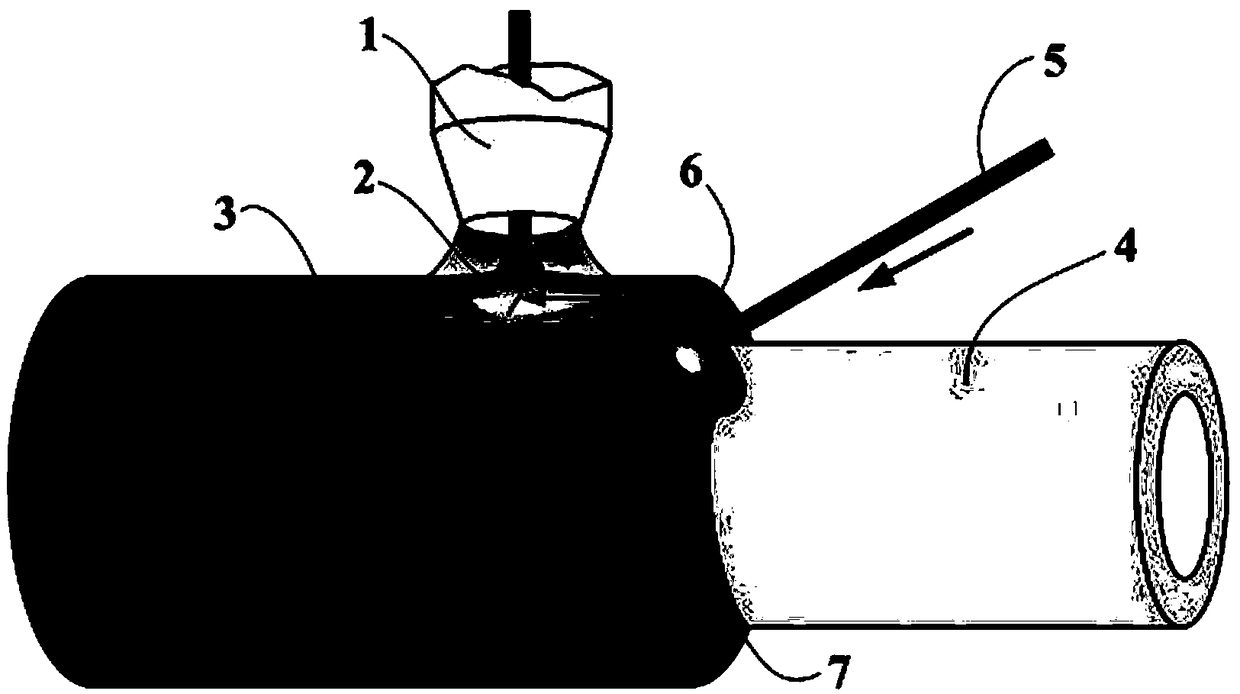

TIG brazing process for copper-aluminum dissimilar metal

ActiveCN109175562AImprove conductivityImprove mechanical propertiesSoldering apparatusArc welding apparatusChemical reactionCopper

The invention discloses a TIG brazing process for copper-aluminum dissimilar metal. The process includes the steps that the overlapping part of copper and aluminum is subjected to grinding through a fine sandpaper, and cleaning; copper is put on aluminum, the joint is fixed, and a cooling device is arranged at the position of the aluminum; the nozzle of a TIG is arranged at a certain distance fromthe surface of the cupper, and the electric arc of the TIG directly heats the copper; welding wires and the aluminum at a certain angle make laterally contact with the joint of the copper and aluminum, after heating for a suitable time, the welding wires are melted to form a molten pool, then welding wires are fed in at a constant speed, and finally a continuous brazing seam is formed. Through the suitable temperature field formed in the brazing joint portion of copper and aluminum dissimilar metals and the suitable temperature gradient formed between the high and low melting point metals, itis ensured that the welding wires are melted and smoothly filled the joint, and the copper and the aluminum are prevented from melting and dissolving seriously, so that the problem that the performance of the brazing joint reduces due to the formation of a hard and brittle compound through the chemical reaction of the dissimilar metals is solved fundamentally.

Owner:驰田汽车股份有限公司

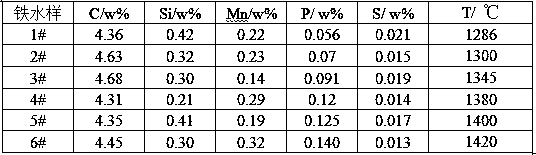

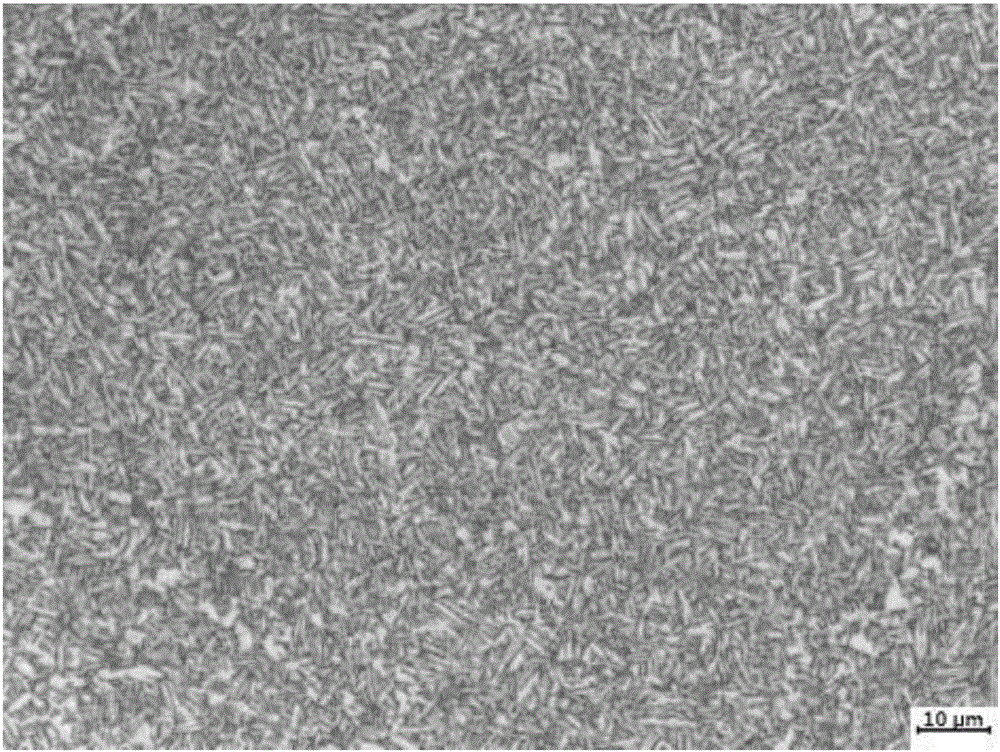

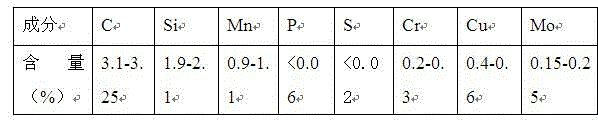

Pouring molten iron and smelting process of natural gas powered cylinder

The invention discloses pouring molten iron and a smelting process of a natural gas powered cylinder. The pouring molten iron is used for solving the problem of bad shrinkage compensation property of the existing pouring molten iron. The pouring molten iron of natural gas powered cylinder disclosed by the invention is composed of the following components in percentage by weight: 3.55-3.65% of carbon, 2.1-2.3% of silicon, 0.5-0.6% of manganese, 0-0.06% of phosphor, 0-0.02% of sulfur, 0.15-0.25% of chromium, 0.5-0.7% of copper, 0.15-0.25% of molybdenum, 0.007-0.009% of magnesium, 0.025-0.030% of rhenium and the balance of iron. The pouring molten iron disclosed by the invention has good shrinkage compensation property, so that the quality of a casting is improved; the poured casting has high strength and good mechanical property to meet the requirements of the natural gas powered cylinder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

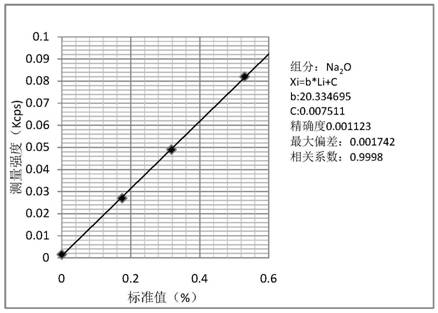

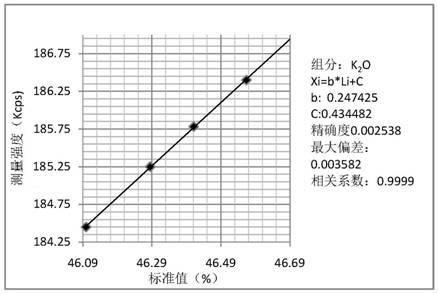

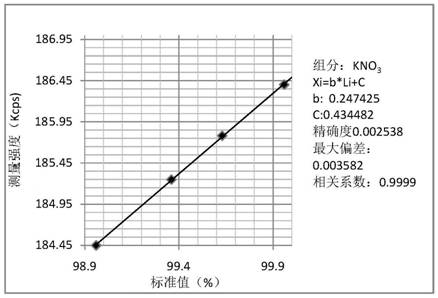

X fluorescence determination method for potassium nitrate ashigh-aluminum glass raw material

PendingCN113092510AFacilitates sample uniformityAchieving Sample UniformityMaterial analysis using wave/particle radiationGlass manufacturingAluminium

The invention discloses an X fluorescence determination method of potassium nitrate as a high-aluminum glass raw material, and belongs to a detection method in the field of glass manufacturing. The method sequentially comprises the following steps: fully mixing a standard sample and a sample to be detected with a mixed fluxing agent (lithium tetraborate and lithium metaborate in a ratio of 2: 1-1: 1) according to a certain dilution ratio (1: 20-1: 15), and transferring the mixture into a platinum yellow crucible; adding a release agent, and respectively melting a standard sample glass sheet and a to-be-detected sample glass sheet by using a high-temperature sample melting furnace according to a set melting time and temperature program; registering the strength and component content of the standard sample glass sheet on an X fluorescence spectrometer, and drawing a standard working curve of the components; and measuring the content of the sample to be measured by using the established standard working curve. The method is an automatic determination method which is high in analysis efficiency and scientific and reliable in analysis result.

Owner:成都中光电科技有限公司 +1

Manufacturing technology for natural aerodynamic cylinder

ActiveCN103600021AHigh dimensional accuracyHigh surface finishFoundry mouldsFoundry coresSurface finishManufacturing technology

The invention discloses a manufacturing technology for a natural aerodynamic cylinder and aims to solve the problems that a conventional cast natural aerodynamic cylinder is low in precision and intensity and has multiple casting defects. The manufacturing technology disclosed by the invention mainly comprises the working procedures of contour and sand core manufacturing, baking, molten iron smelting, vermicularizing treatment and pouring. The natural aerodynamic cylinder manufactured by the manufacturing technology has the characteristics of high contour size precision, high surface smoothness, high intensity and high mechanical property, and the manufacturing technology is particularly suitable for manufacturing of the natural aerodynamic cylinder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

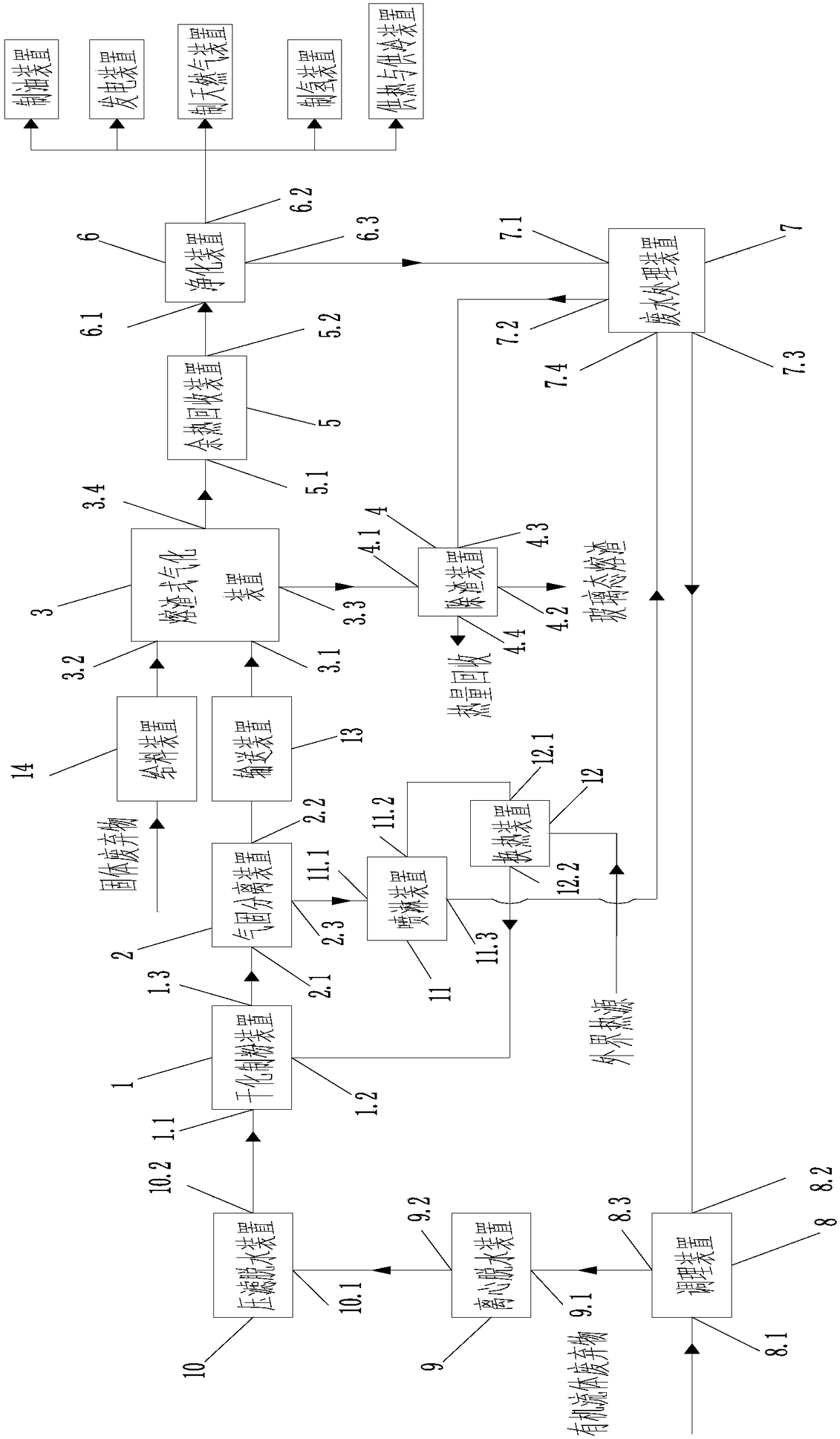

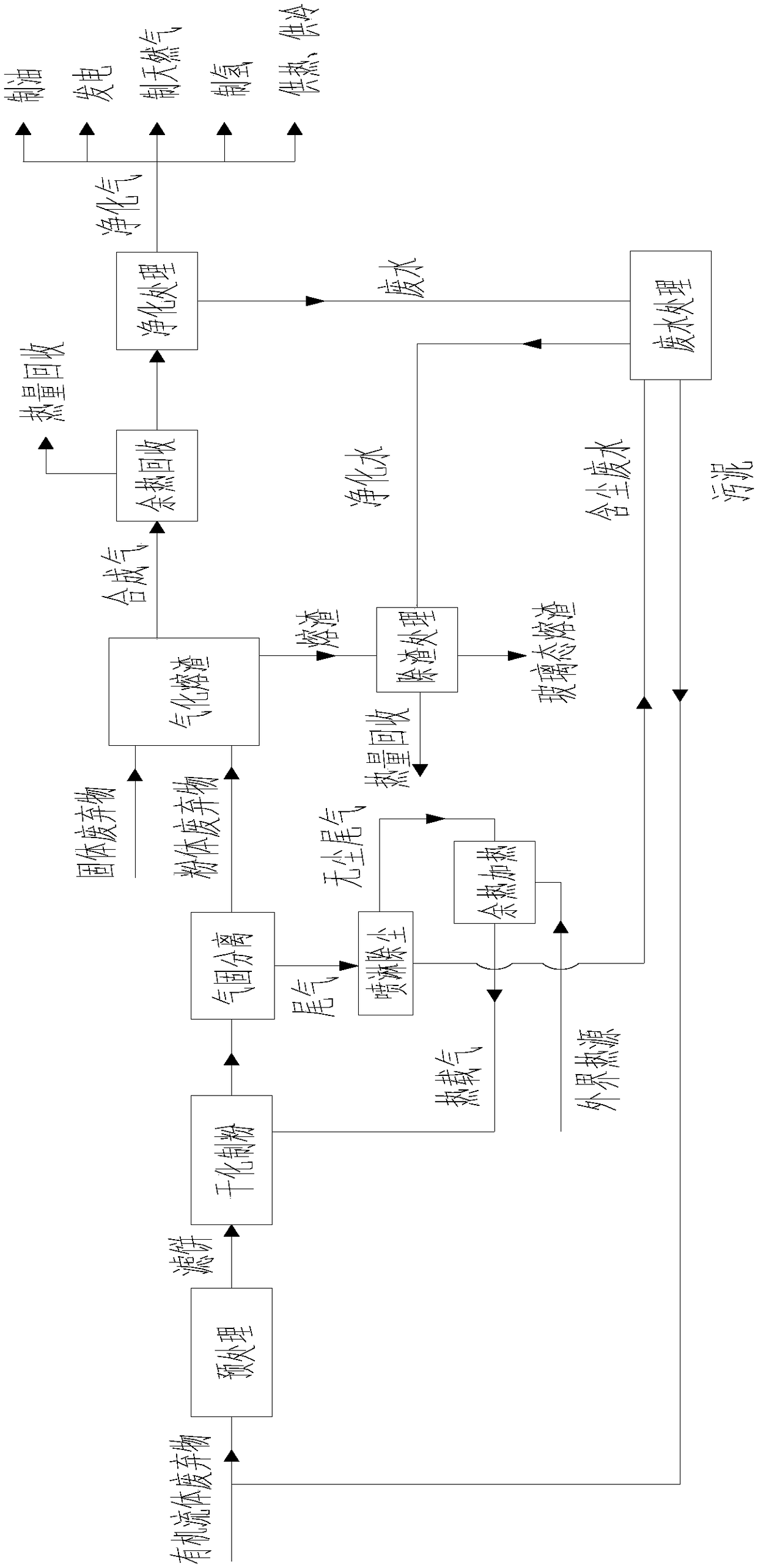

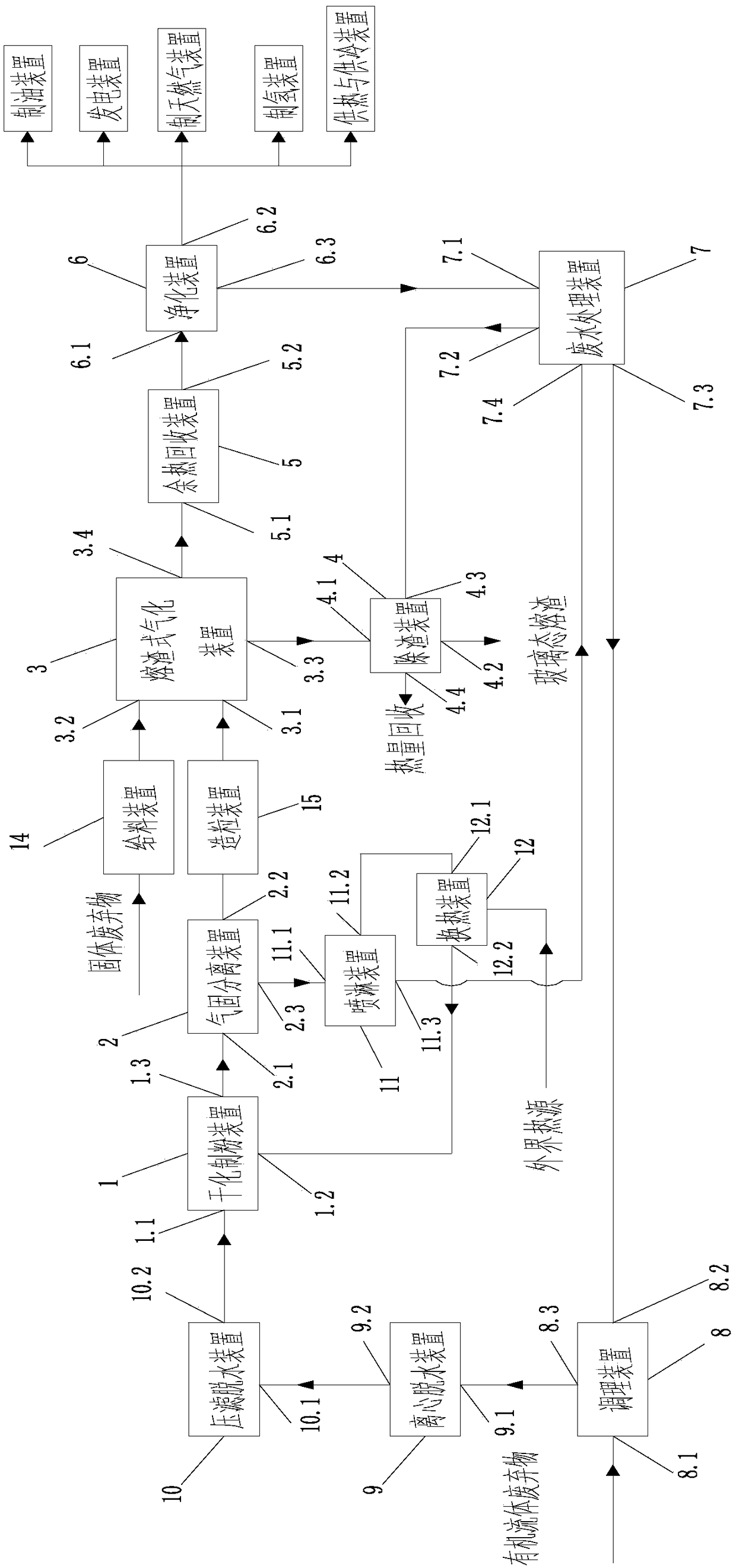

Multielement material collaborative gasification method and system

PendingCN108326012AAchieving co-gasificationMade quicklyWaste processingSolid waste disposalSlagOrganic fluid

The invention discloses a multielement material collaborative gasification method and system. The method comprises the steps of 1, pretreatment, wherein pretreatment is conducted on organic fluid waste, so that filter cakes are obtained; 2, drying for powder production, wherein rotational flow heat exchange is conducted between the filter cakes and heat carrying gas, and meanwhile, crushing impacttreatment is conducted on the filter cakes, so that powder waste is obtained; 3, gas-solid separation, wherein the powder waste and tail gas are separated; 4, gasification of slag, wherein collaborative gasification treatment is conducted on the powder waste and additional solid waste, so that synthesis gas and the slag are obtained; 5, aftertreatment of the synthesis gas, wherein waste heat recovery is conducted on the synthesis gas in the first place, and then purification treatment is conducted, so that purified gas and waste water are obtained; 6, aftertreatment of the slag, wherein chilling treatment is conducted on the slag, so that a glassy-state slag material is obtained; and 7, treatment of the waste water. By means of the multielement material collaborative gasification method,drying treatment can be conducted on the organic fluid waste, and the fluid-form waste is produced into a powder waste material; the powder waste material can serve as a raw material of the gasification slag; and collaborative gasification treatment of the multielement materials, namely the solid waste and the organic fluid waste, is achieved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com