High-resilience insole and manufacturing method thereof

A high-rebound, insole technology, applied in the field of insole manufacturing, can solve the problems of uneven distribution of TPU particles, weak resilience, and difficult processing, and achieve complete protection and reinforcement of physical properties, good strength and resilience, Strong integrity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

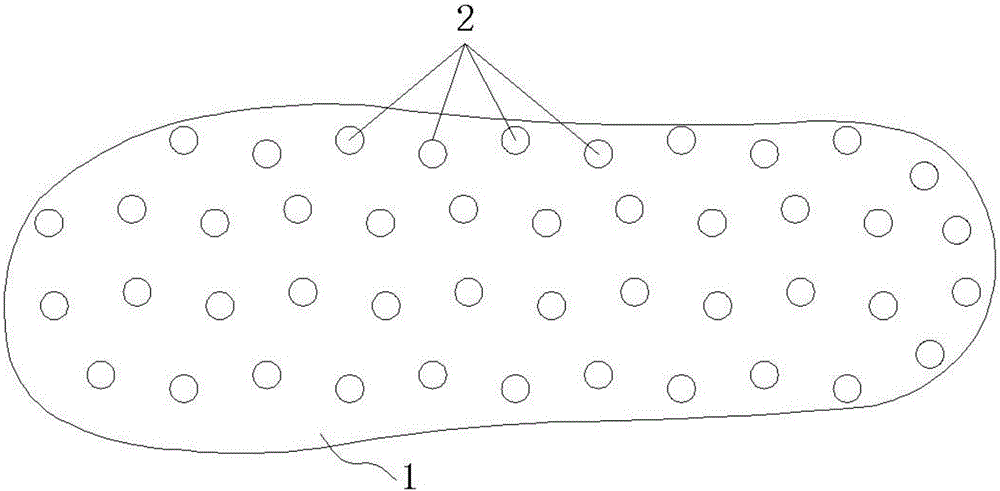

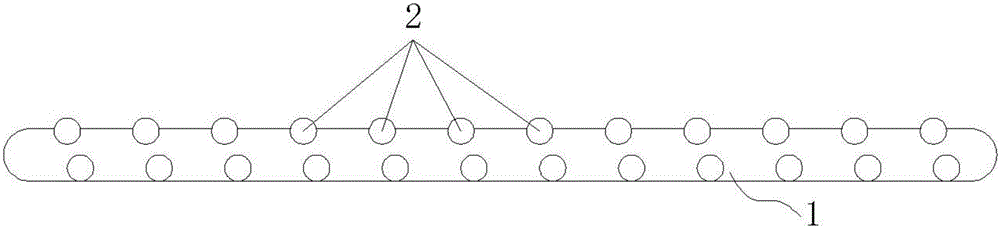

[0023] refer to figure 1 and figure 2 , the manufacture method of high resilience insole of the present invention, comprises the following steps:

[0024] Step a, PU chooses PU supplied by Foshan Hongbaoli Chemical Co., Ltd., and the density of PU is 0.2g / cm 3 , and in the PU, a mixture of triethylenediamine and ethylene glycol in a ratio of 1:800 is mixed as a catalyst, and the quality of the mixed catalyst is 0.3% of the PU mass, and 3kg of the above-mentioned materials are put into the barrel, Then heat to 40°C and keep the temperature constant to make the PU fully foam;

[0025] In step b, the elastic particles are selected from TPU particles supplied by Taizhou Global Xingye Chemical Technology Co., Ltd., and the density of TPU particles is 0.1g / cm 3 , and its particle diameter is 3mm, and its melting point is around 170°C. Put 1kg of the above TPU particles into the barrel and stir evenly to obtain a mixture;

[0026] In step c, the pouring machine is the DL330PU po...

Embodiment 2

[0029] refer to figure 1 and figure 2 , the manufacture method of high resilience insole of the present invention, comprises the following steps:

[0030] Step a, PU chooses PU supplied by Dongguan Mirenzhan Chemical Co., Ltd., and the density of PU is 0.25g / cm 3 , and the mixture of 1,6-hexanediol is mixed in the PU with a ratio of 1:900 as a catalyst, and the quality of the mixed catalyst is 0.5% of the PU quality, and the above-mentioned materials of 4kg are put into the barrel, and then heated To 45 ℃ and constant temperature, so that PU fully foam;

[0031] In step b, select the EVA particles of type 28-25 supplied by Suzhou Ziyunxuan Plastic Co., Ltd. for the elastic particles, and the density of the EVA particles is 0.15g / cm 3 , and its particle diameter is 4mm, and its melting point is about 190°C. Put 1kg of the above-mentioned EVA particles into the barrel, and stir evenly to obtain a mixture;

[0032] In step c, the pouring machine is the DL330PU pouring machin...

Embodiment 3

[0035] refer to figure 1 and figure 2 , the manufacture method of high resilience insole of the present invention, comprises the following steps:

[0036] Step a, PU chooses PU supplied by Suzhou Newt Packaging Materials Co., Ltd., and the density of PU is 0.3g / cm 3 , and in this PU, the mixture of 1,4-butanediol is mixed in a ratio of 1:1000 as a catalyst, and the quality of the mixed catalyst is 0.6% of the PU quality, the above-mentioned materials of 5kg are put into the cylinder, and then Mix the color paste into the barrel, then heat it to 55°C and keep the temperature constant to make the PU fully foam;

[0037]Step b, the elastic particles are selected from the rubber particles supplied by Hongfa Plastic Raw Materials Management Department in Zhangmutou, Dongguan City, and the density of the rubber particles is 0.2g / cm 3 , and its particle diameter is 5mm, and its melting point is about 200°C. Put 1kg of the above-mentioned rubber particles into the barrel, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com