Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Made quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

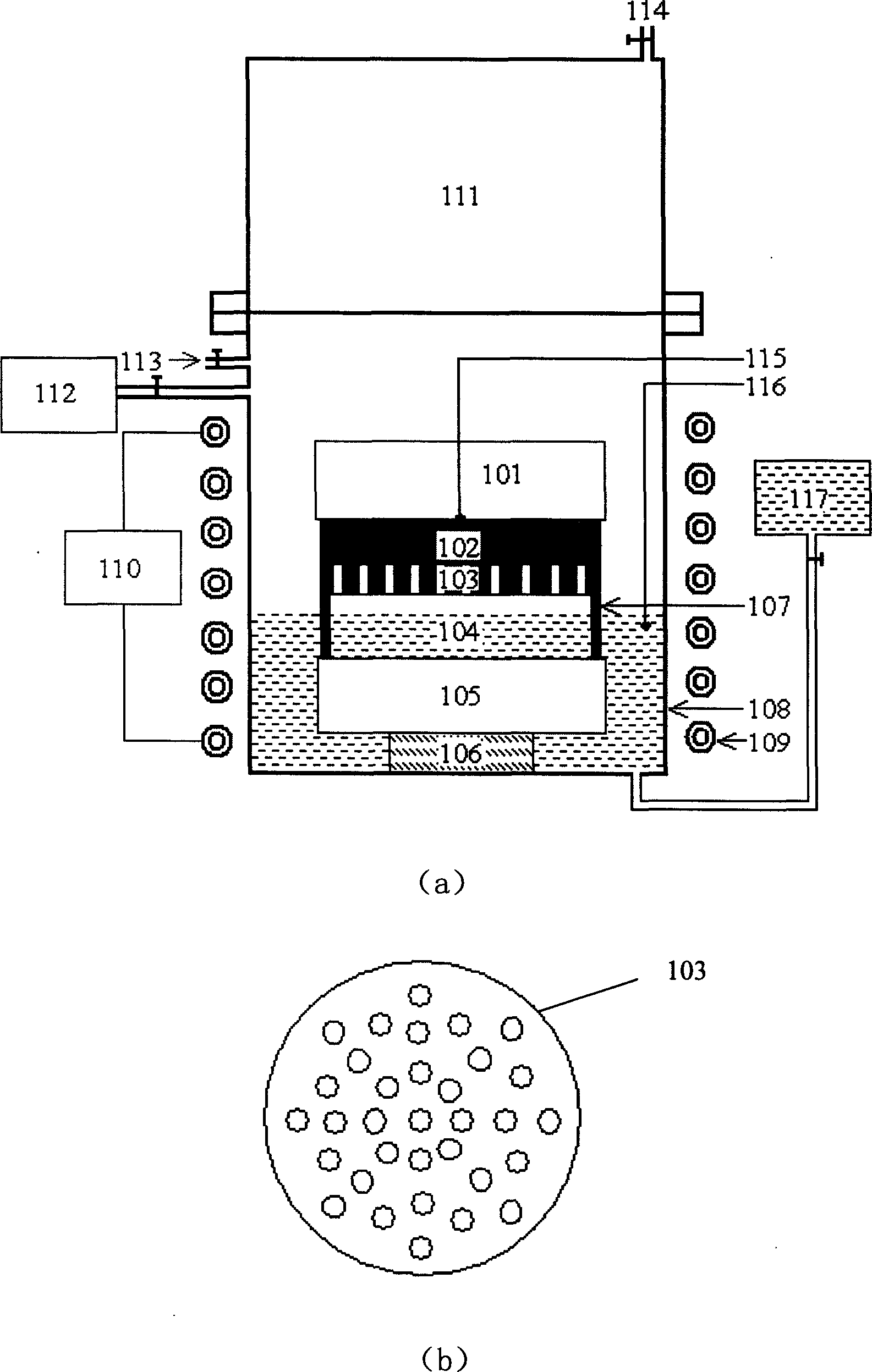

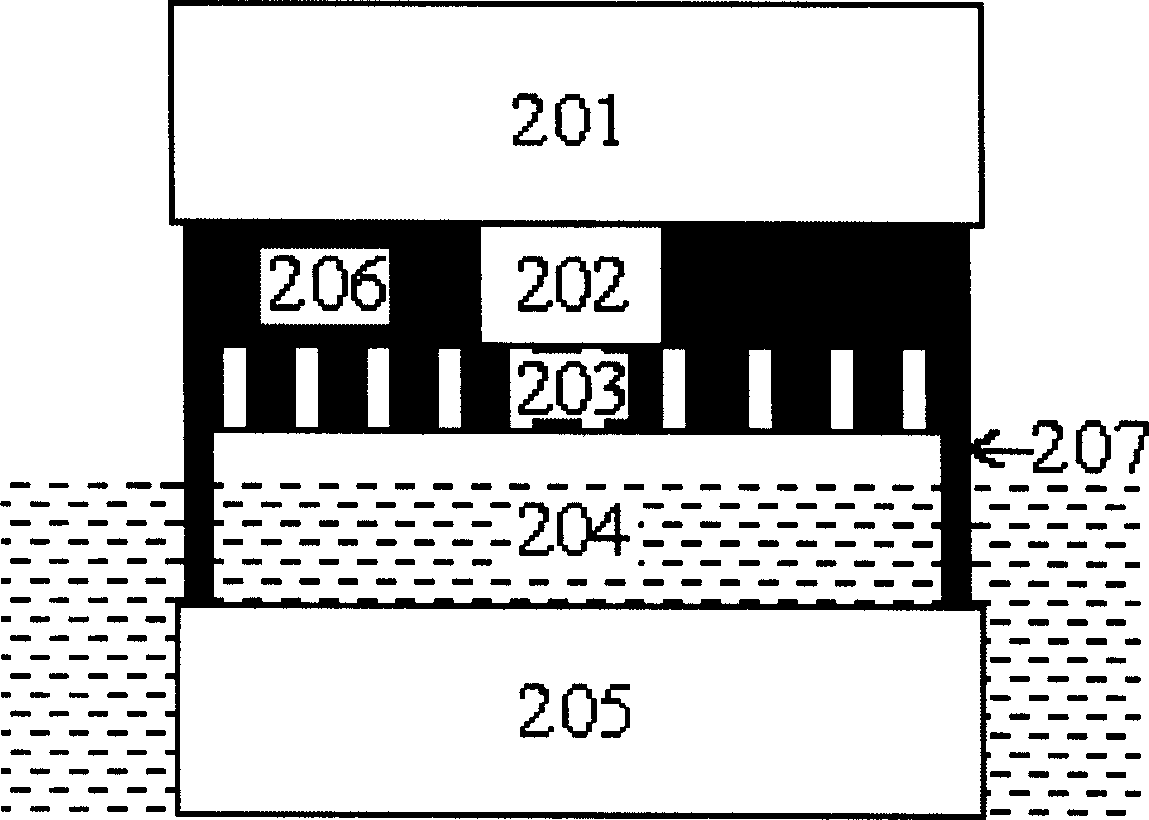

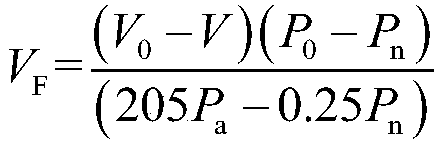

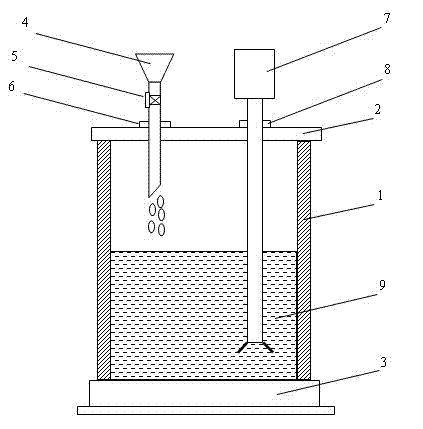

Method for quick-speed preparing carbon/carbon composite material using heat gradient chemical gas phase infiltration

InactiveCN1766153AEasy to achieve process temperatureImprove controllabilitySolid state diffusion coatingChemical vapor deposition coatingCarbon compositesGas phase

The invention discloses a method to quick prepare C / C composite material by heat-gradient chemical gas phase permeation, which comprises: using two upper-lower independent graphite heaters on heat-gradient chemical gas phase permeation device to realize boil and gasify the liquid predecessor and provide high-active carbon source for cracking reaction by lower heater; locating the prefabricated body and upper heater on top of predecessor liquid surface by supporting bar and hole-contain supporting board to realize heat the prefabricated body and form heat gradient along its thickness orientation by upper heater; passing long-path convection and diffusion, the gasified carbon source enters the prefabricated body to crack and generate deposition for 4~10h, and obtaining the product with density as 1.6~1.8g / cm3. This invention needs simple devices, has technical parameters easy to regulate, reduces energy greatly, and has wide application.

Owner:XI AN JIAOTONG UNIV

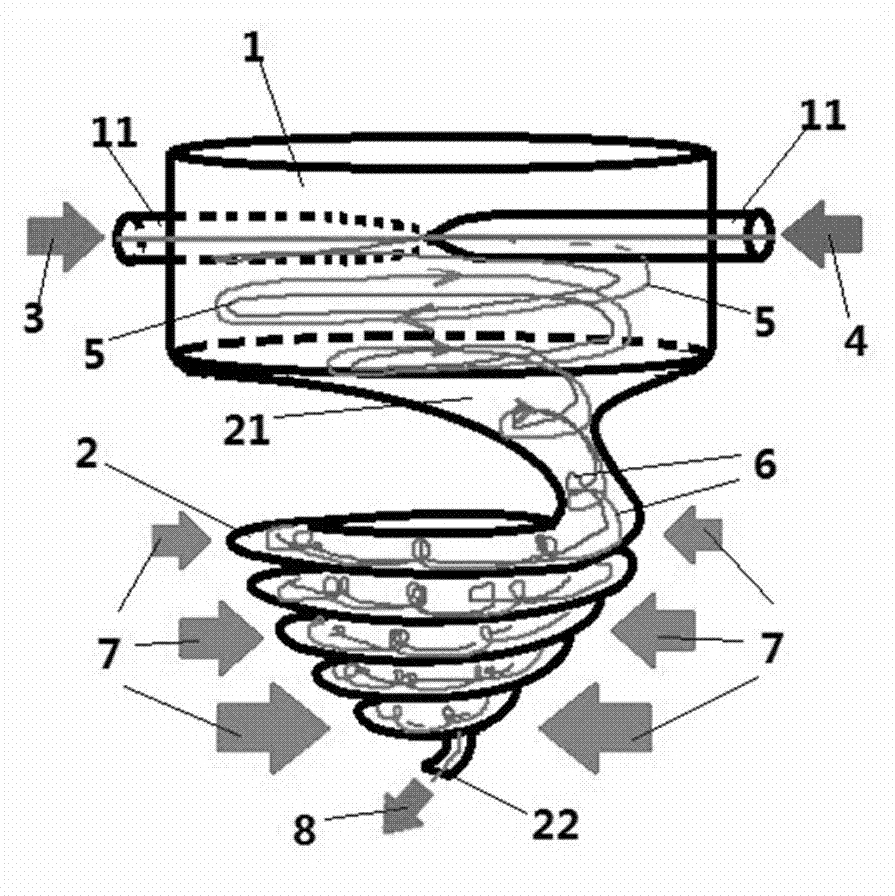

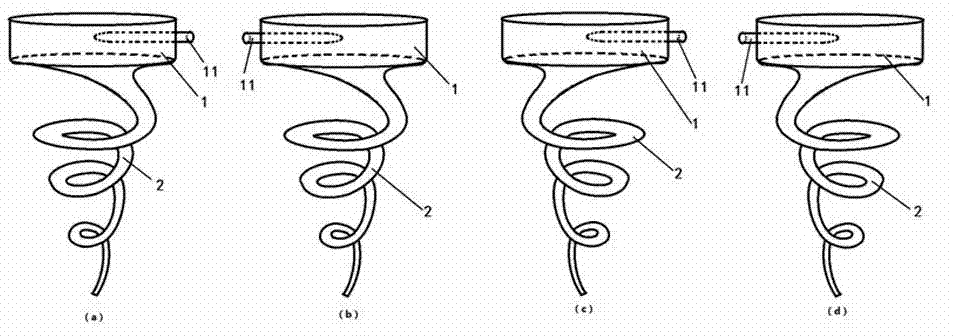

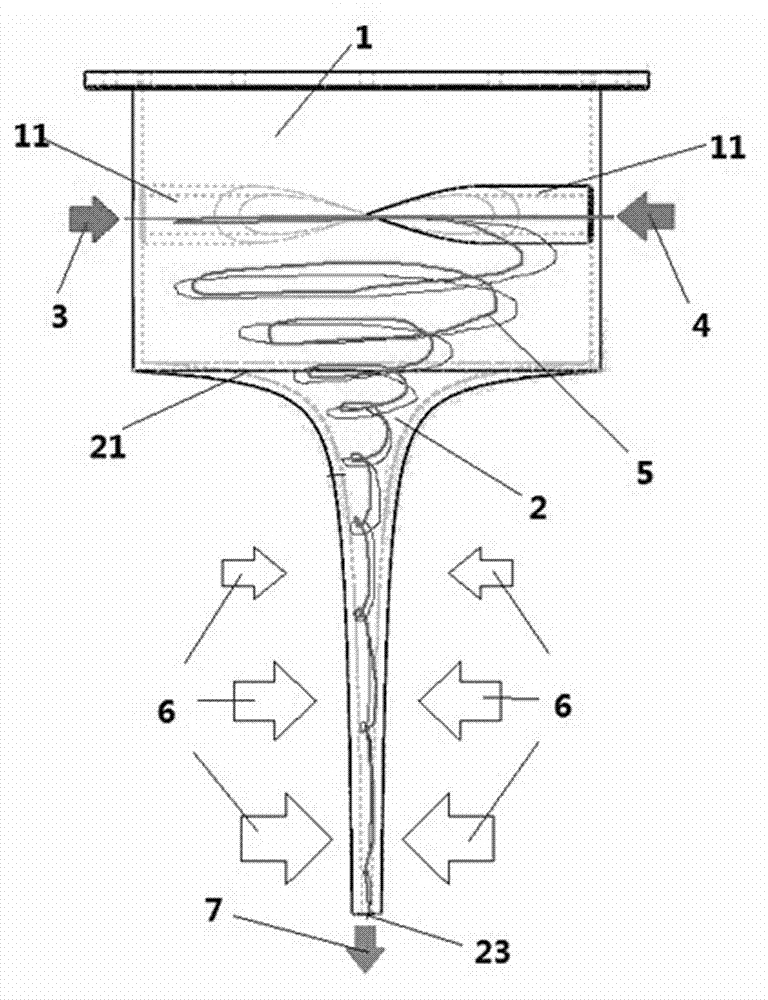

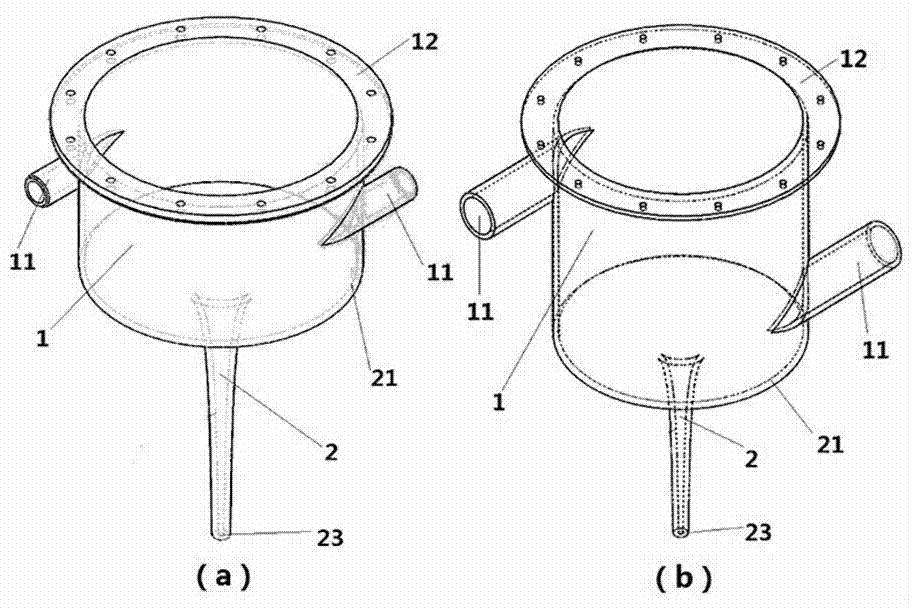

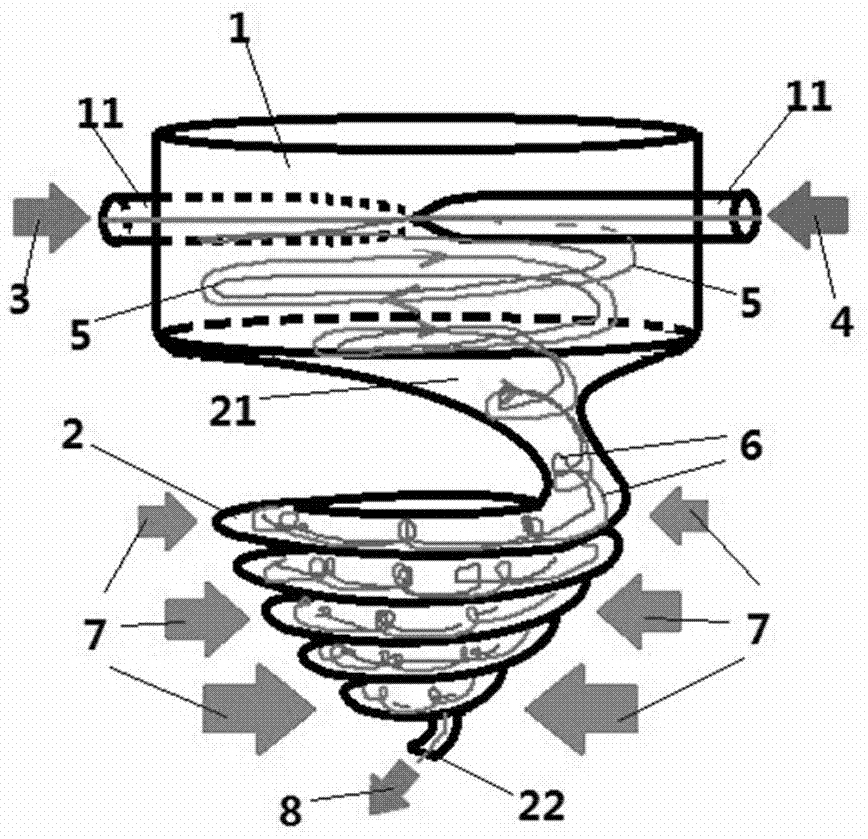

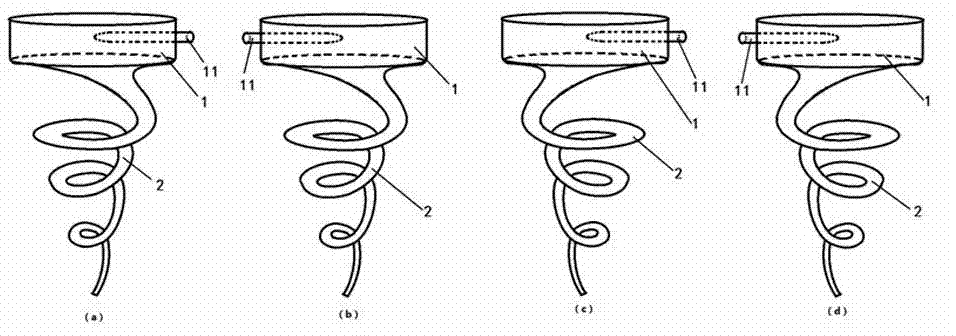

Emulsifying method and device by double-vortex-body vortex

The invention relates to an emulsifying method and device by double-vortex-body vortex. Two or more fluids (liquids or gases) which can not be mixed together, such as oil and water, simultaneously flow through a double-vortex-body vortex generator, make a double-vortex-body centripetal vortex motion and are discharged from the lower end to form an emulsion. The double-vortex-body vortex generator is formed by connecting a main body container and a spiral double-vortex-body vortex tube, wherein more than one feed port distributed around the circumference in the same tangential direction is arranged around the circumference of the main body container; and the bottom end of the double-vortex-body vortex tube is a small-diameter end used as a discharge port. A fluid flows in through a tangential feed port of the main body container to form a centripetal vortex motion; and the fluid flows through the double-vortex-body vortex tube on the lower part to form a double-vortex-body centripetal vortex motion and is coherent with vacuum zero point energy to form a double-vortex-body centripetal vortex internal pressure field, and the field acts on the fluid flowing through the double-vortex-body vortex tube to form a better double-vortex-body vortex emulsion.

Owner:彭伟明

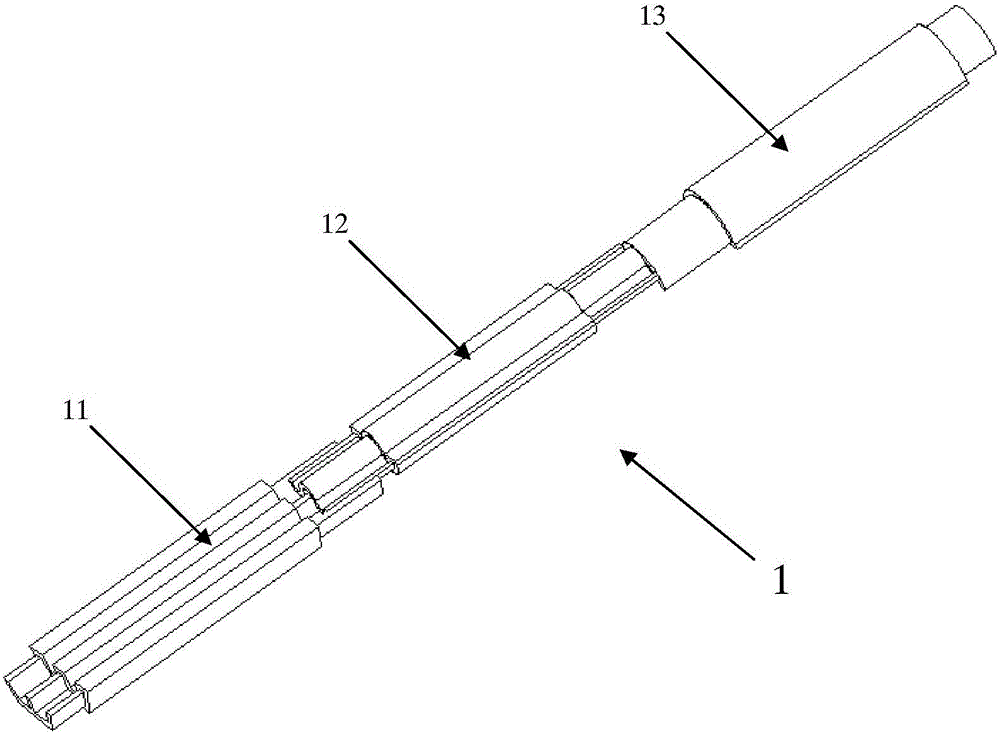

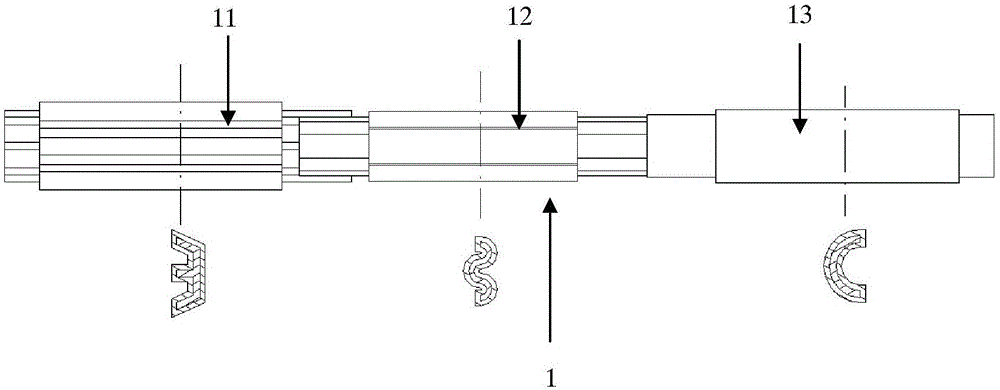

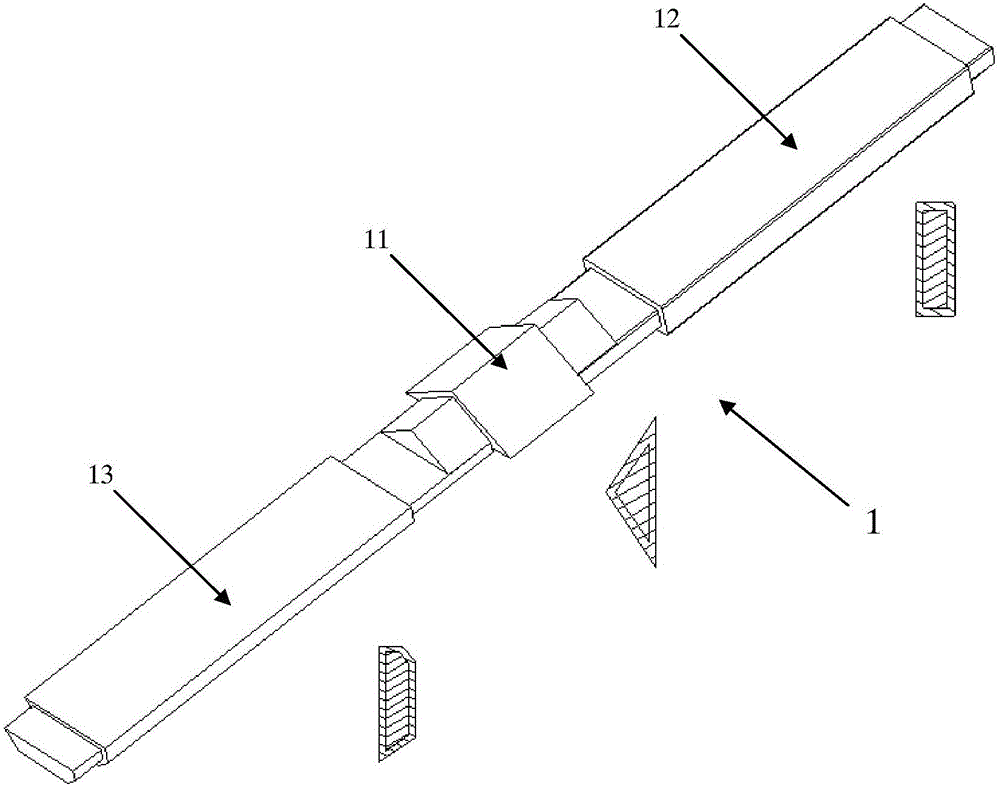

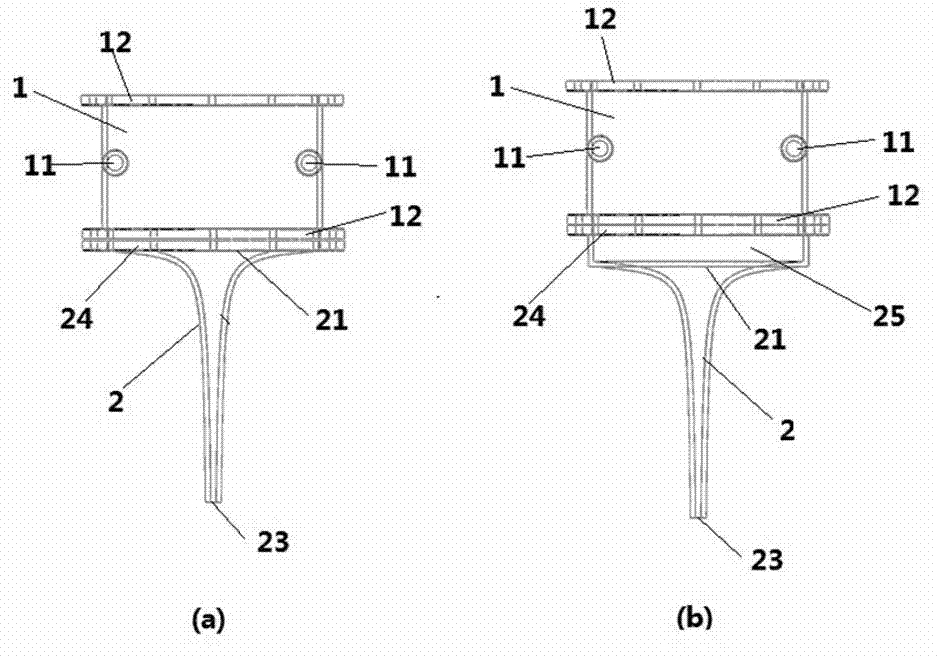

Special-shaped cable and preparation method thereof

ActiveCN106653163ADoes not affect operationReduced eddy current effectDetails of conductive coresManufacturing wire harnessesAbnormal shapedConsumables

The invention discloses a special-shaped cable and a preparation method thereof. The conductive core of the special-shaped cable is composed of at least two conductive core segments in an end-to-end way, wherein the cross sections of the conductive core segments are different in shape. The conductive core segments are externally wrapped by an insulating layer. The contour of the insulating layer is fit with the conductive core segments. The cable has great bending performance and can also be greatly fit with a vehicle body so that consumables can be saved and the safety performance can be greatly enhanced. The cable is made of the aluminum or aluminum alloy conductive cores so that the vehicle body is enabled to be light-weighted, and the production cost of the motor vehicle can be reduced. The preparation method of the special-shaped cable comprises the steps of manufacturing the conductive core segments, connection of the conductive core segments and manufacturing of the insulating layer so that the production efficiency and the productivity can be effectively enhanced according to different production requirements and the production cost can be reduced.

Owner:长春捷翼汽车科技股份有限公司

Hot pot seasoning as well as preparation method and use method thereof

The invention provides hot pot seasoning which comprises a soup material and a special condiment package, wherein the soup material comprises beef bulalo, edible oil, hot pepper, ginger, bean halves and compound spice; the special condiment package comprises the following materials: 0.02 to 0.06 part of star anise, 0.01 to 0.04 part of kaempferia galanga, 0.03 to 0.10 part of fennel, 0.05 to 0.11 part of fructus amomi, 0.01 to 0.06 part of amomum kravanh pierre ex Gagnep., 0.04 to 0.07 part of cassia bark, 0.03 to 0.07 part of amomum tsaoko, 0.01 to 0.03 part of flos caryophylli, 0.005 to 0.02 part of dried orange peel, 0.02 to 0.08 part of Szechuan lovage rhizome, 0.03 to 0.08 part of bay leaf, 0.01 to 0.05 part of pepper, 0.01 to 0.05 part of sesame, 0.005 to 0.02 part of fructus momordicae, 0.07 to 0.15 part of fructus gardeniae, 0.005 to 0.02 part of purple perilla, and 0.01 to 0.04 part of semen alpiniae katsumadai.

Owner:周兴星

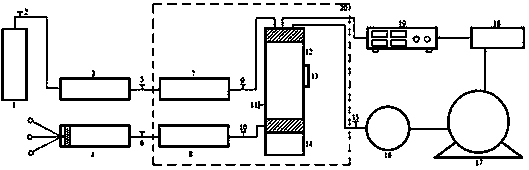

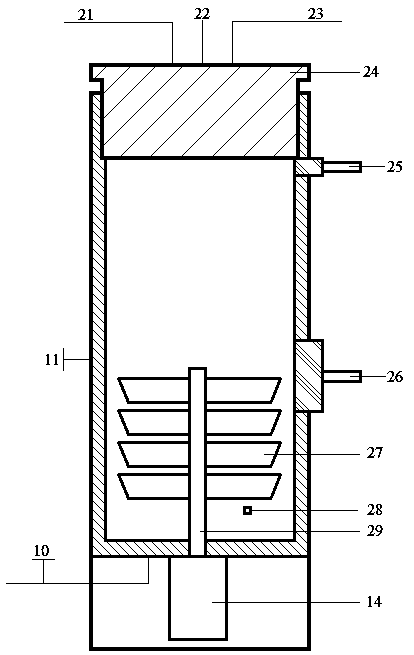

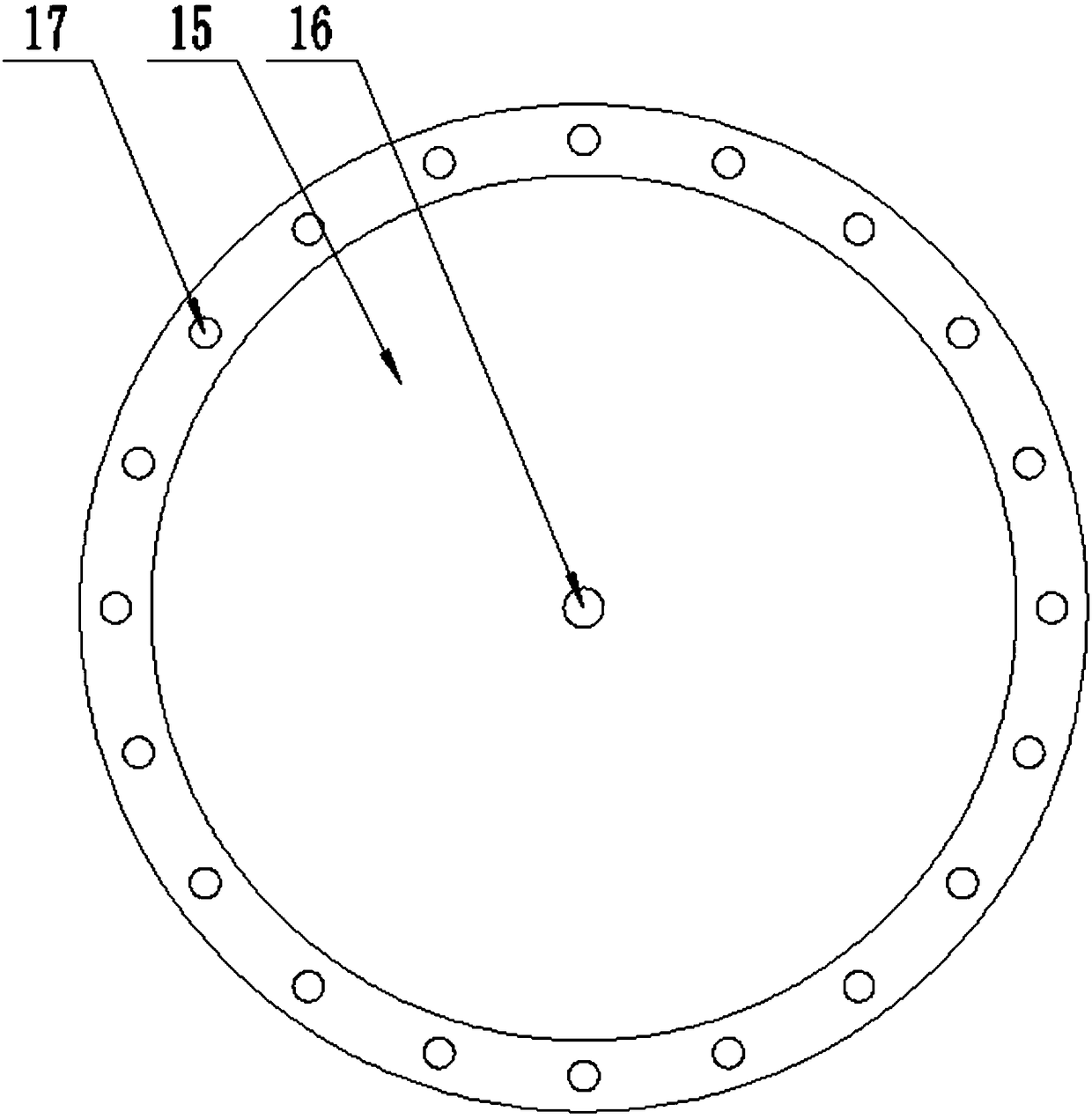

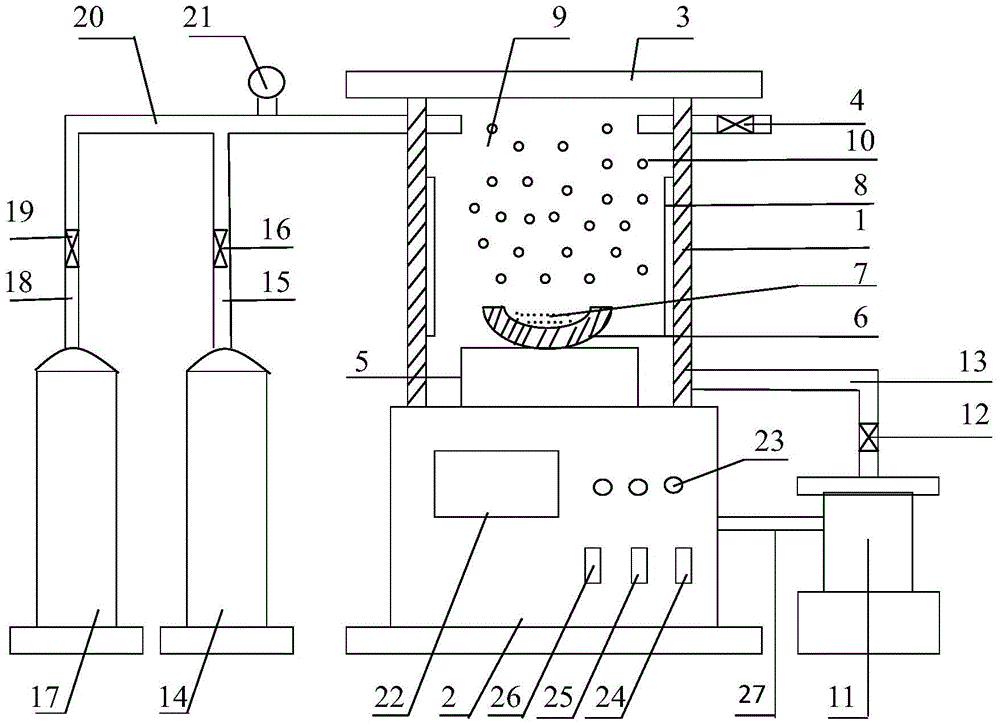

Decomposition characteristic test system for solid fluidization exploitation of marine non-diagenetic hydrate and method

The invention discloses a decomposition characteristic test system for the solid fluidization exploitation of marine non-diagenetic hydrate and a method. The system comprises a methane source (1), anair compressor (3), a constant-flux pump (4), an intermediate gas container (7), an intermediate solution container (8), a high-pressure reaction kettle (12), a return pressure controller (16), a gasflowmeter (17), a computer (18), a temperature and pressure monitor (19), and a constant-temperature gas bath tank (20). The method comprises the following steps: (1) quartz sand is added into the high-pressure reaction kettle; (2) the methane source is pumped into the intermediate gas container, and experimental solution is injected into the intermediate solution container; (3) temperature is regulated to experimental temperature, the fluids of the intermediate solution container and the intermediate gas container are pumped into the high-pressure reaction kettle, an agitating motor is switched on, and a synthesis experiment is started; (4) solution is replenished into the reaction kettle; (5) an outlet valve is opened, a decomposition experiment is started, and decomposition characteristic parameters, such as gas production rate and accumulated gas production rate, are recorded. According to the invention, the principle is reliable, operation is easy and convenient, and the decomposition characteristics of hydrate particles under different operation conditions can be accurately evaluated.

Owner:SOUTHWEST PETROLEUM UNIV

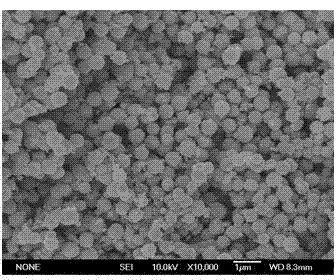

Quick preparation method for multi-shell cuprous oxide nano-spheres

InactiveCN103395821ASimple processEasy to operateMaterial nanotechnologyCopper oxides/halidesEthylic acidHydrate

The invention relates to a quick preparation method for multi-shell cuprous oxide nano-spheres. Cuprous oxide is prepared from copper acetate serving as a raw material, deionized water serving as a solvent and hydrazine hydrate serving as a reducer at normal temperature, and the multi-shell cuprous oxide nano-spheres are quickly prepared through centrifugal separation and vacuum drying. The preparation method is simple and easy to operate, and can realize quick large-scale production, the product has good morphology and is of a multi-shell structure, the granularity is nano-scale, the diameters of the multi-shell nano-spheres are 300-500nm, the product purity is high and reaches 98 percent, and the preparation method is a quite ideal method for quickly preparing the multi-shell cuprous oxide nano-spheres.

Owner:TAIYUAN UNIV OF TECH

Preparation method of spherical lithium-sulfur battery cathode material, and product

InactiveCN109378466AMade quicklyReduce manufacturing costPositive electrodesLi-accumulatorsAdhesiveLithium–sulfur battery

The invention discloses a preparation method of a spherical lithium-sulfur battery cathode material, and further discloses the spherical lithium-sulfur battery cathode material prepared through the method. The preparation method comprises the steps: a sulfur precursor, a carbon source, an adhesive and a polar adsorption additive are dispersed into water, after even stirring, spray drying is conducted, and the monodisperse spherical cathode material is prepared. The spherical lithium-sulfur battery cathode material is constituted by sulfur, a carbon carrier, a polymeric additive and the polar adsorption additive; and the spherical lithium-sulfur battery cathode material is presented to be a spherical particle or a monodisperse spherical particle under a scanning electron microscope, whereinthe spherical particle is evenly distributed with the sulfur and formed by carbon nano tubes which are mutually staggered and entangled, and the monodisperse spherical particle is evenly distributedwith the sulfur and formed by graphene sheets which are mutually staggered and entangled. The preparation method is simple, the lithium-sulfur battery cathode material can be quickly prepared, the prepared spherical lithium-sulfur battery cathode material has the high adsorption capacity and electrical conductivity, and monodispersity, and can be effectively loaded with the sulfur, and a formed conductive network is practically available.

Owner:HENAN NORMAL UNIV

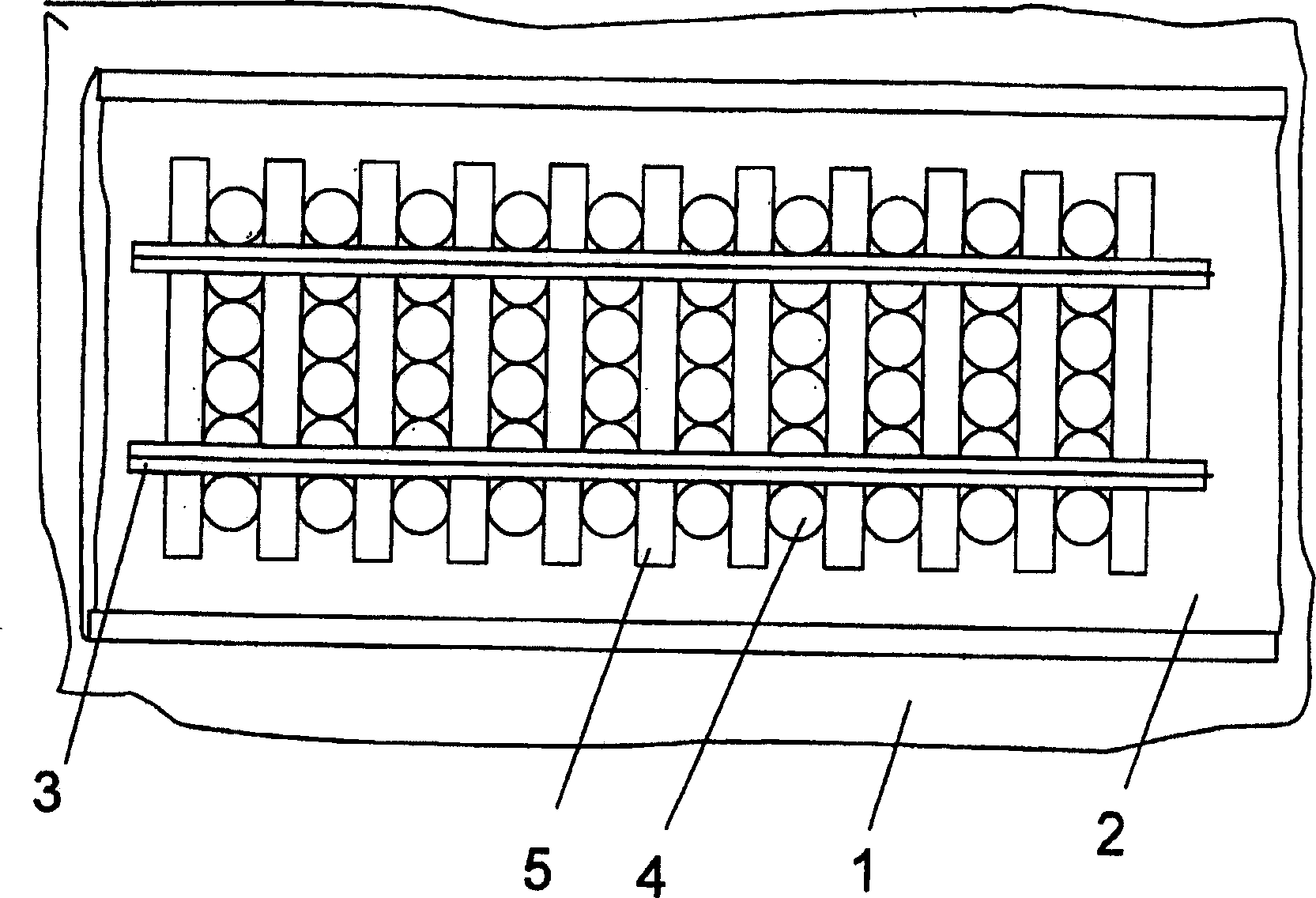

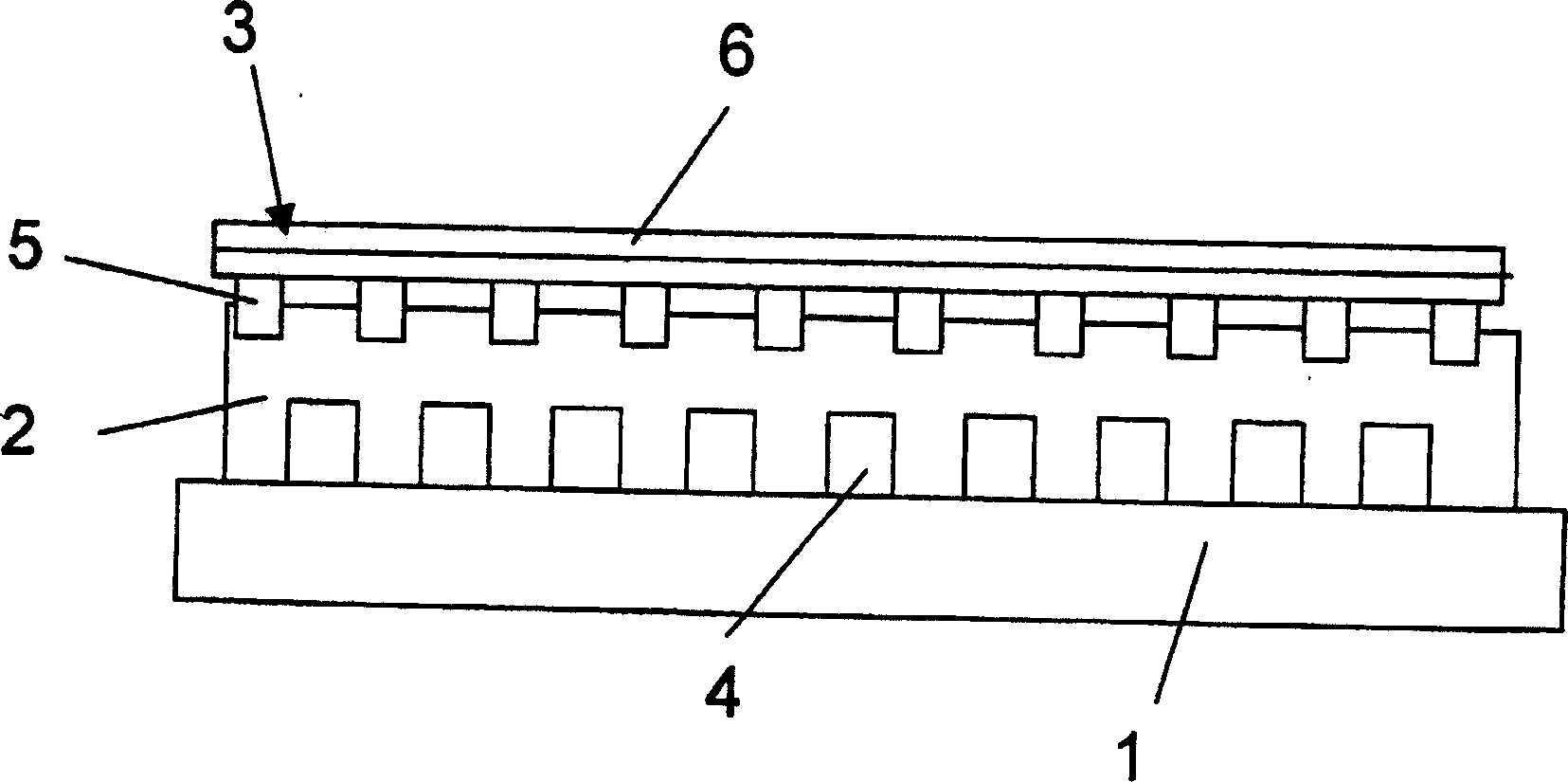

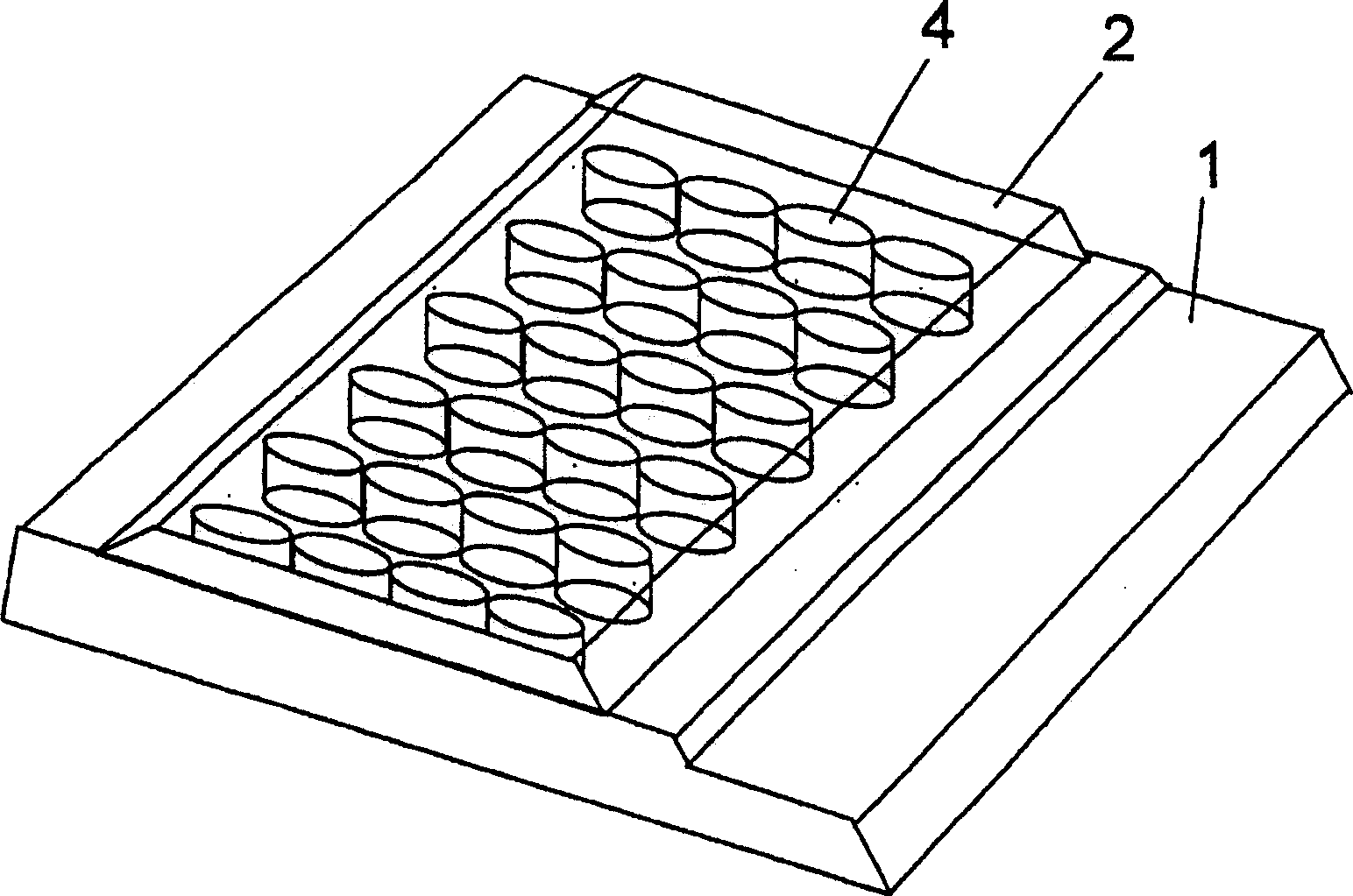

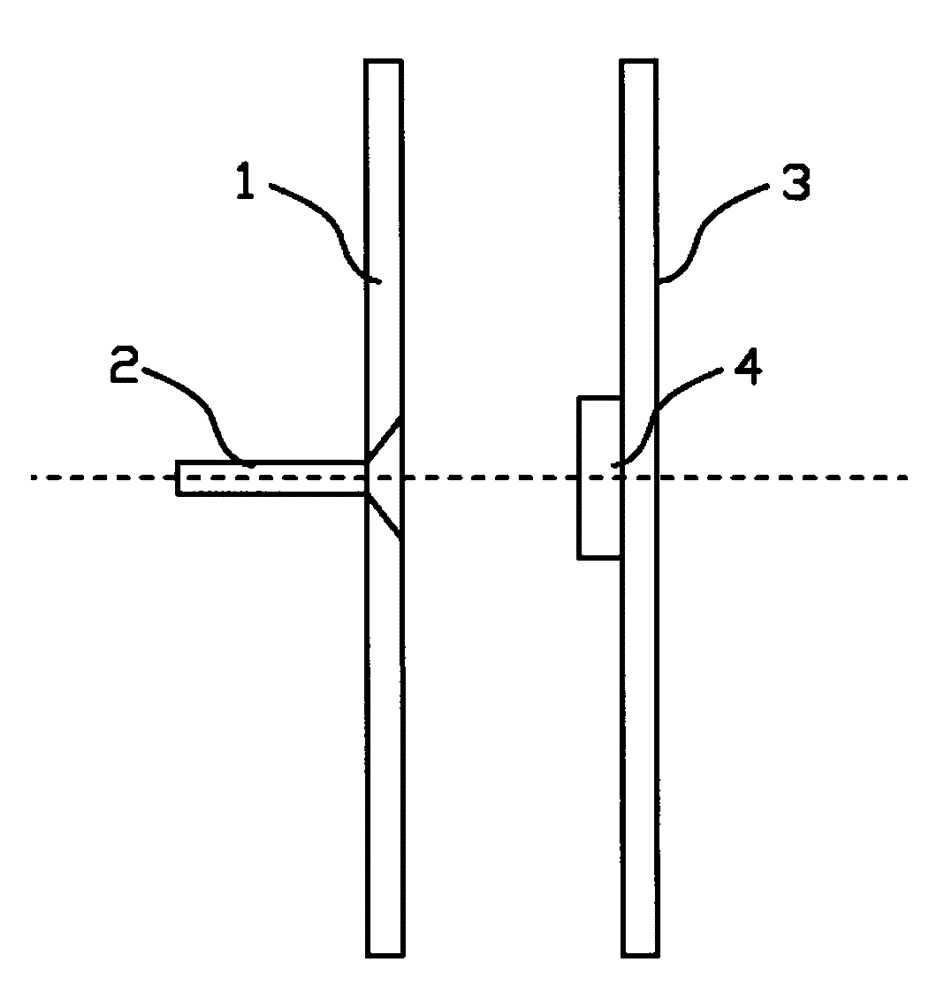

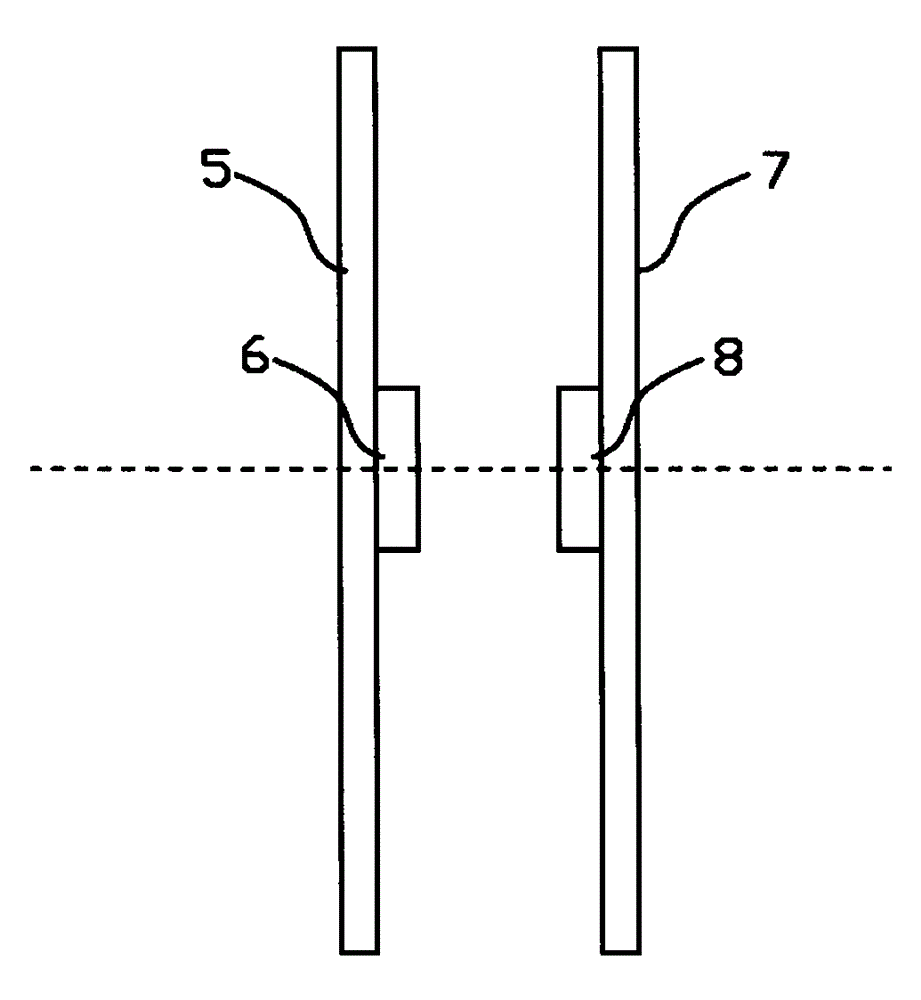

Method for constructing a rigid track and a communication track

InactiveCN1732315ALow costSave materialBallastwayRailway track constructionRoad surfacePrecast concrete

The invention relates to a method for constructing a rigid track for high-speed rail traffic. According to said method, the inventive rigid track is either constructed from precast concrete components (7) arranged on a track bed structure (2,4;16), an intermediate region between the concrete components (7) and the track bed structure (2,4;16) being filled in with a solidifying filling material (8) in order to fix the position of the concrete components (7), or from cast-in-situ concrete or a combination of concrete components (7) and cast-in-situ concrete on the track bed structure (2,4;16). The inventive method is characterised in that the track bed structure (2,4;16) is created from an existing ballast bed (2), the ballast being at least partially compacted. The invention also relates to a corresponding communication track of a rigid track.

Owner:马克斯博革建筑两合有限公司

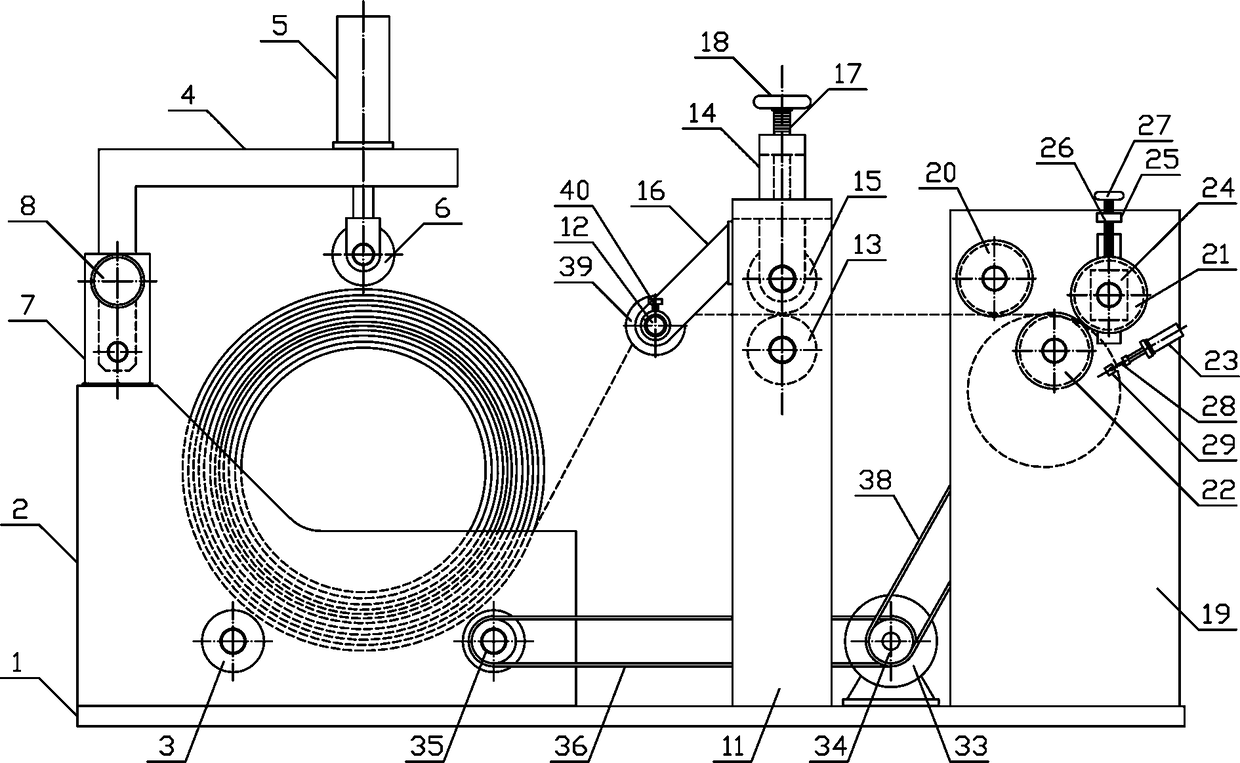

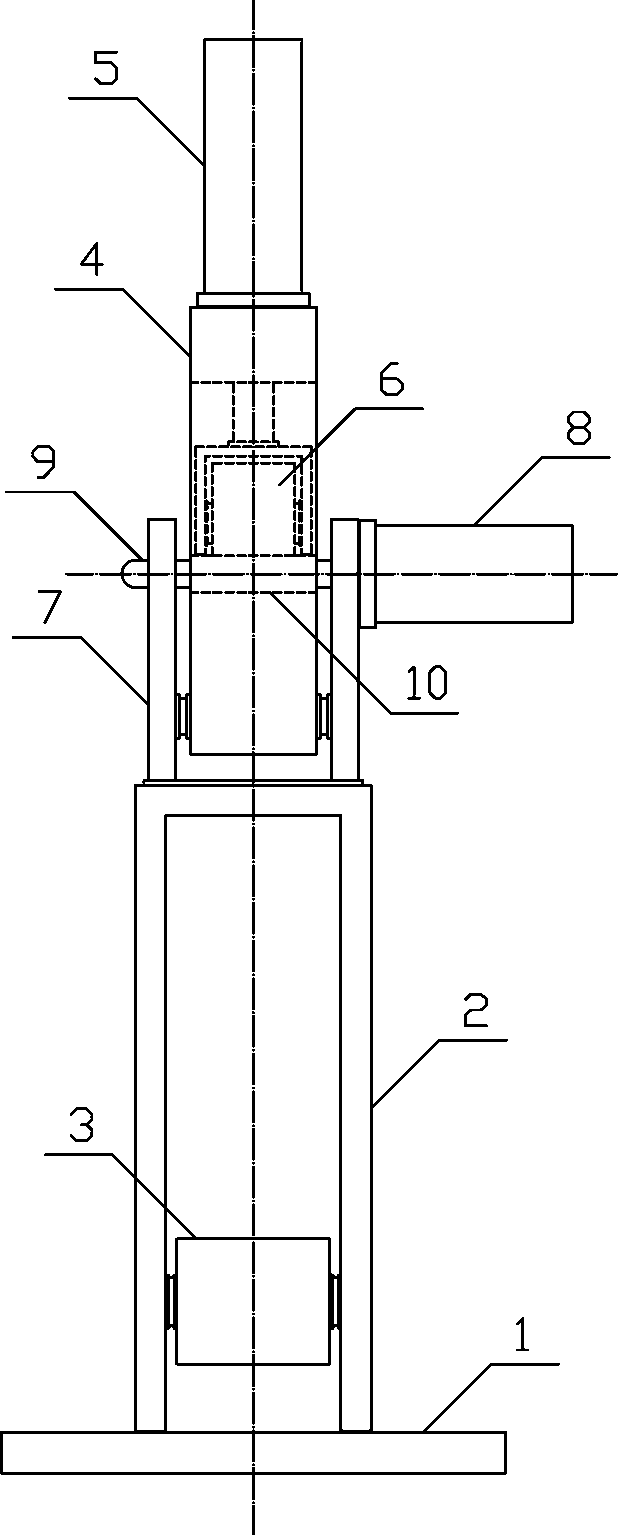

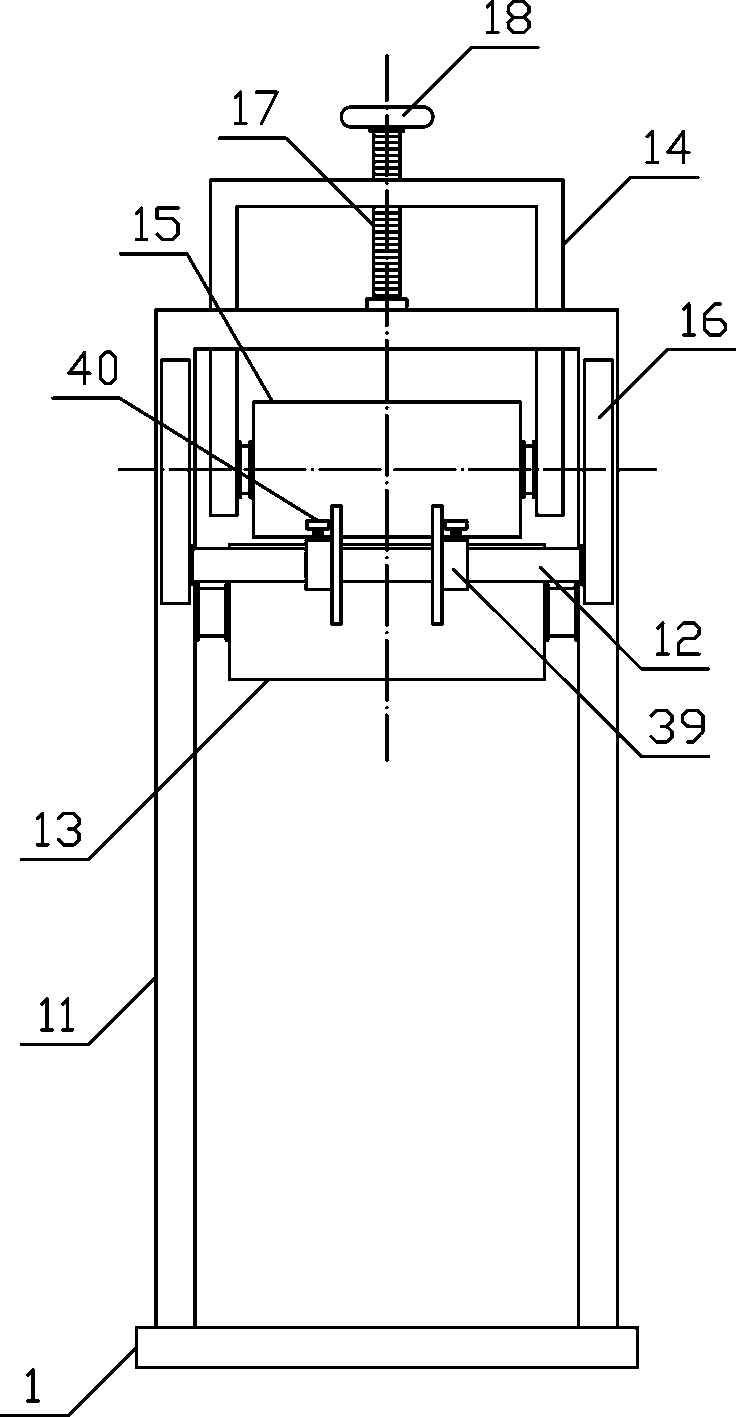

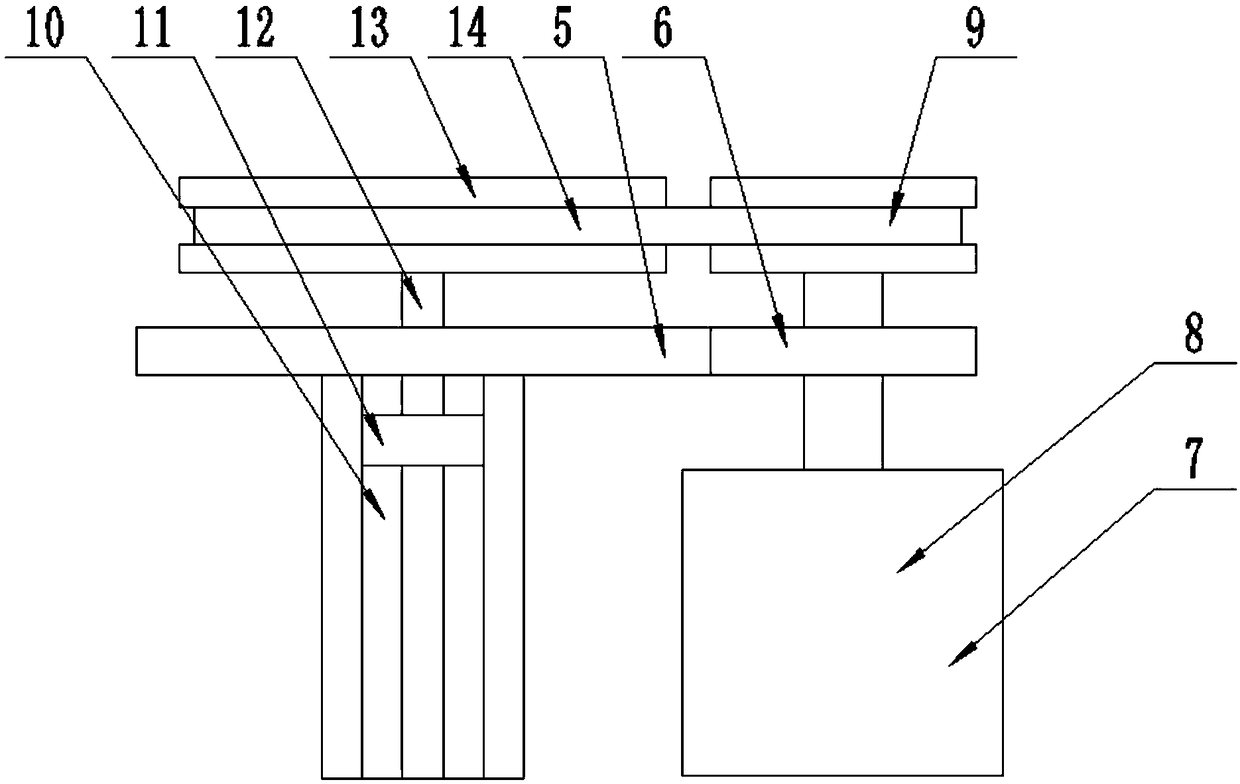

Airbag pressing ring forming device

PendingCN108188748AReasonable structural designAccurate transmissionMetal-working feeding devicesShearing machinesEngineeringMechanical equipment

The invention discloses an airbag pressing ring forming device, and belongs to the field of water heating equipment machining mechanical equipment. The airbag pressing ring forming device comprises afixed base, an unwinding mechanism, a guide mechanism and a forming and collecting mechanism. Roll bearing wheels are vertically and symmetrically arranged on the inner sides of the two ends of the lower portion of a roll clamping support correspondingly. A roll pressing support is vertically arranged on the upper side of the roll clamping support, and a guide support is vertically arranged in themiddle of the upper side of the fixed base. A guide roll is horizontally and rotationally connected to a guide supporting plate, and a pressing roll is horizontally arranged over a bearing roll. Theforming and collecting mechanism comprises a forming support, a guide wheel, a bending wheel, a pull wheel and a cut-off air cylinder. A cutting blade is horizontally arranged at the output end of thecut-off air cylinder, and a collecting ring guide rod is obliquely arranged at the upper end of a fixed round rod upwards. The airbag pressing ring forming device is reasonable in structural design,metal strap rolls can be fast and efficiently conveyed, machined and bent into rings stably, the formed rings can be continuously cut off and collected one by one, and the needs of production and machining are met.

Owner:ZHEJIANG TANKPRO IND

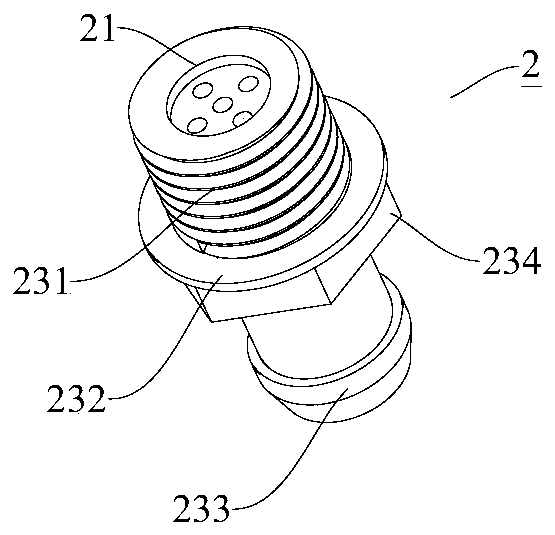

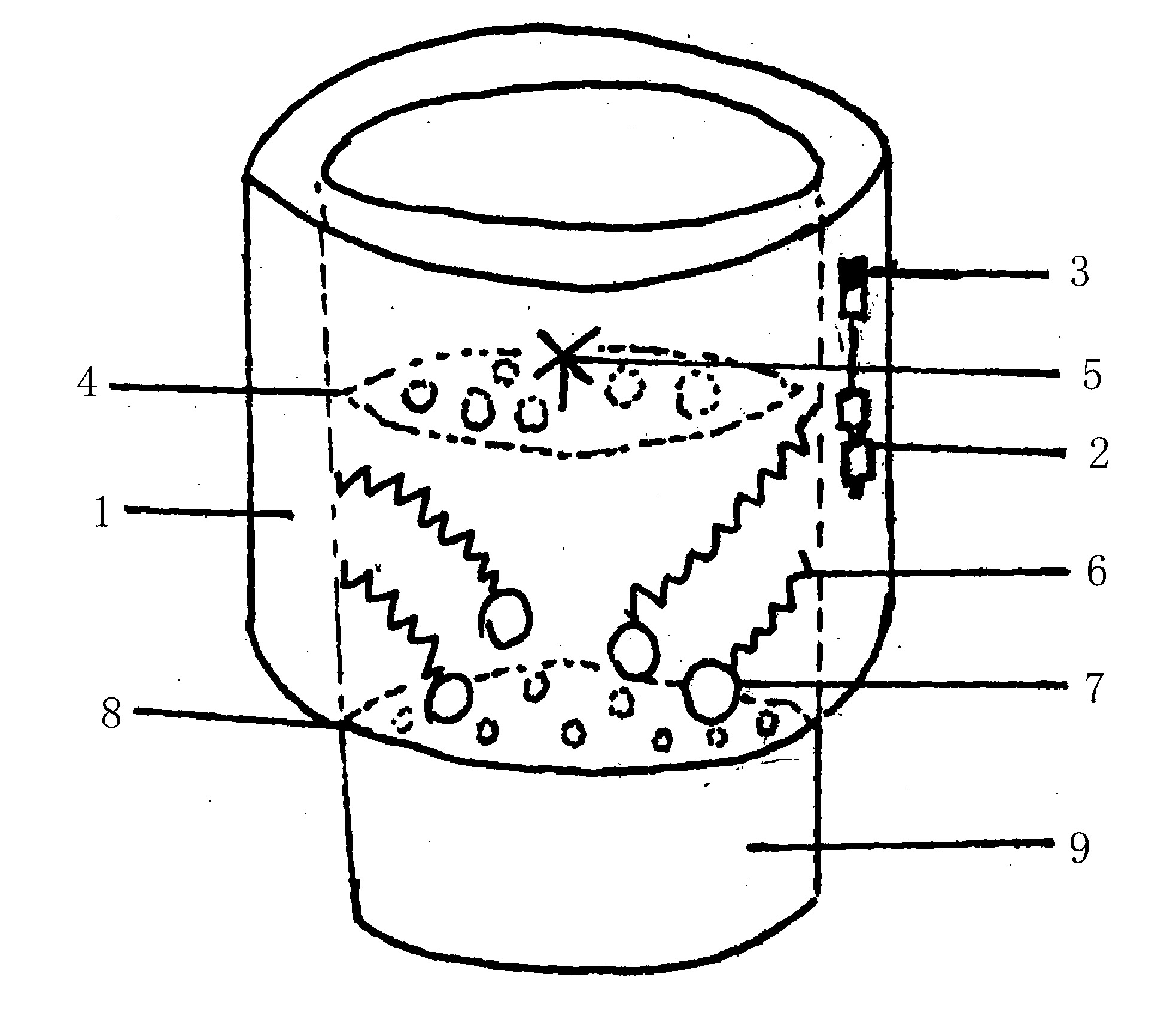

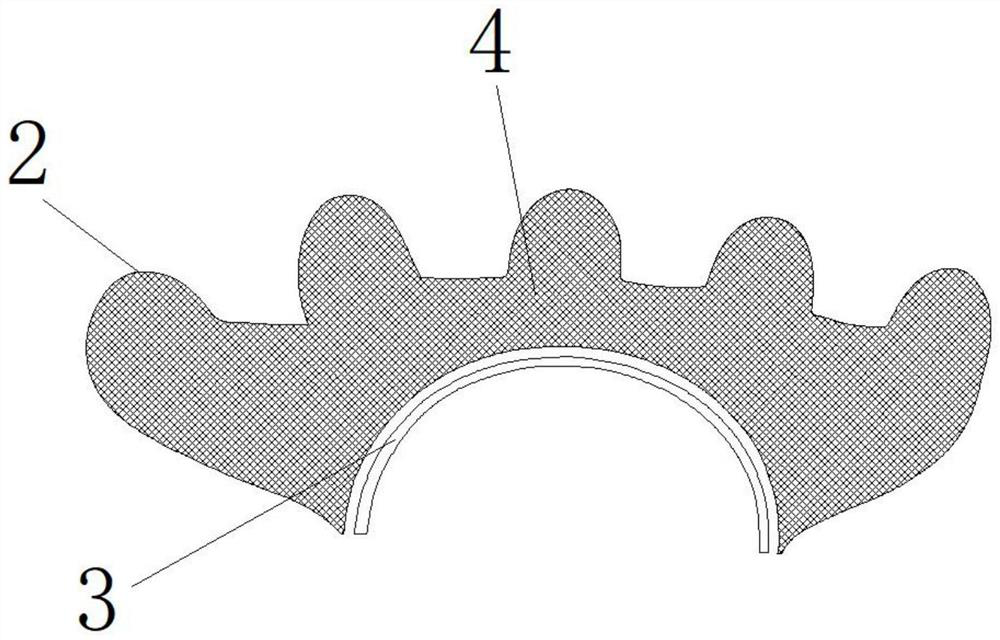

Cavitation piece of micro-bubble generator, micro-bubble generator and washing device

PendingCN111206380AGuaranteed foam making abilitySimple structureFlow mixersTransportation and packagingWater flowEngineering

The invention discloses a cavitation piece of a micro-bubble generator, the micro-bubble generator and a washing device. The cavitation piece has a cavitation inlet and a cavitation outlet for water flow enters and exits; at least one Venturi channel extending from the cavitation inlet toward the cavitation outlet is defined in the cavitation piece; each Venturi channel, in the water flow direction, sequentially comprises a tapered section, a pipeline and an expanding section; the flow area of the tapered section gradually decreases in the direction from the cavitation inlet to the pipeline, the flow area of the expanding section gradually increases in the direction from the pipeline to the cavitation outlet, and the diameter of the pipeline is 0.2-2.0 mm. The cavitation piece provided bythe invention can guarantee the foaming capacity of the cavitation piece and can control the moderate flow rate on the one hand, and has a simple structure, convenient processing and easy cost controlon the other hand.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

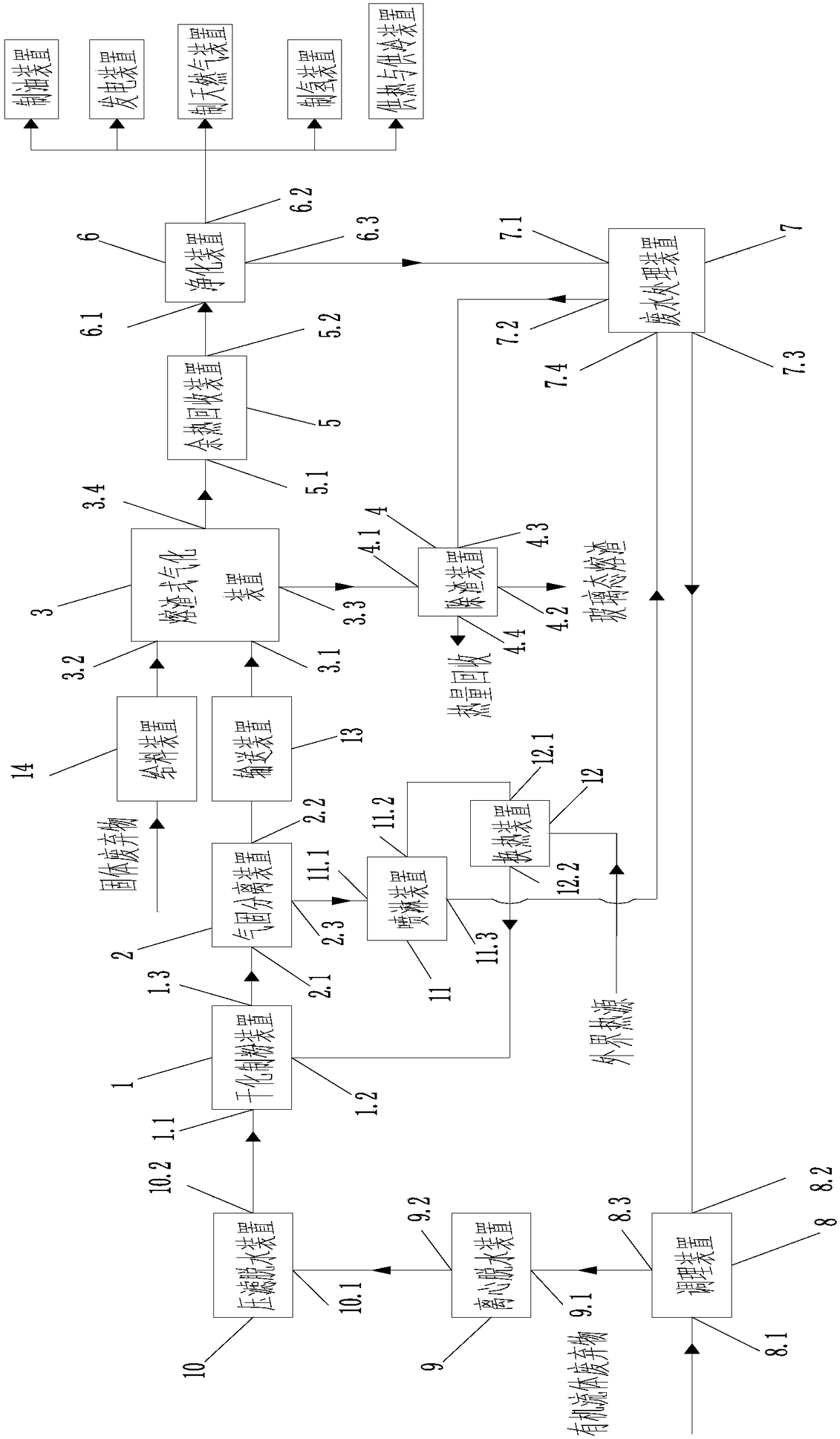

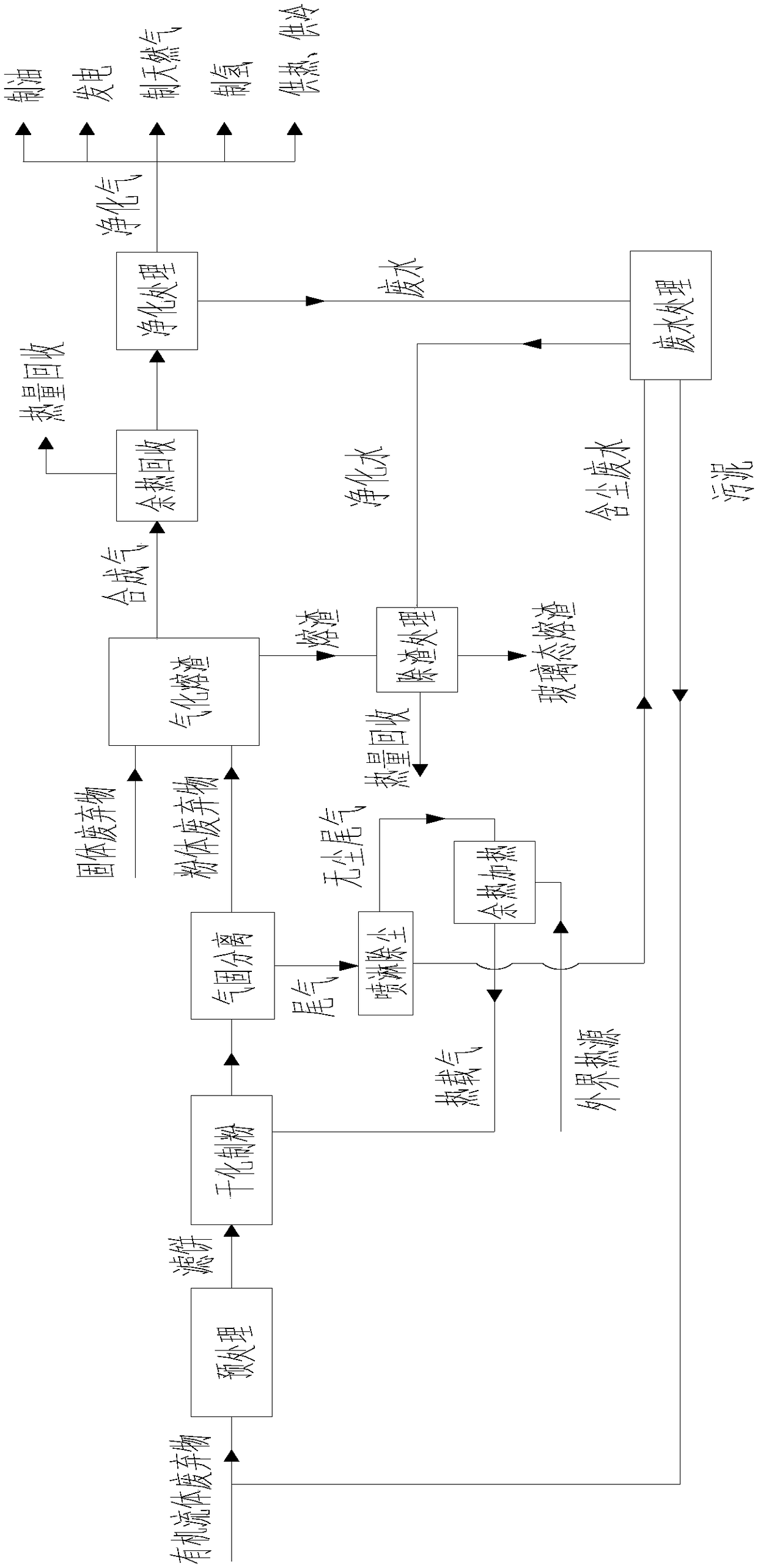

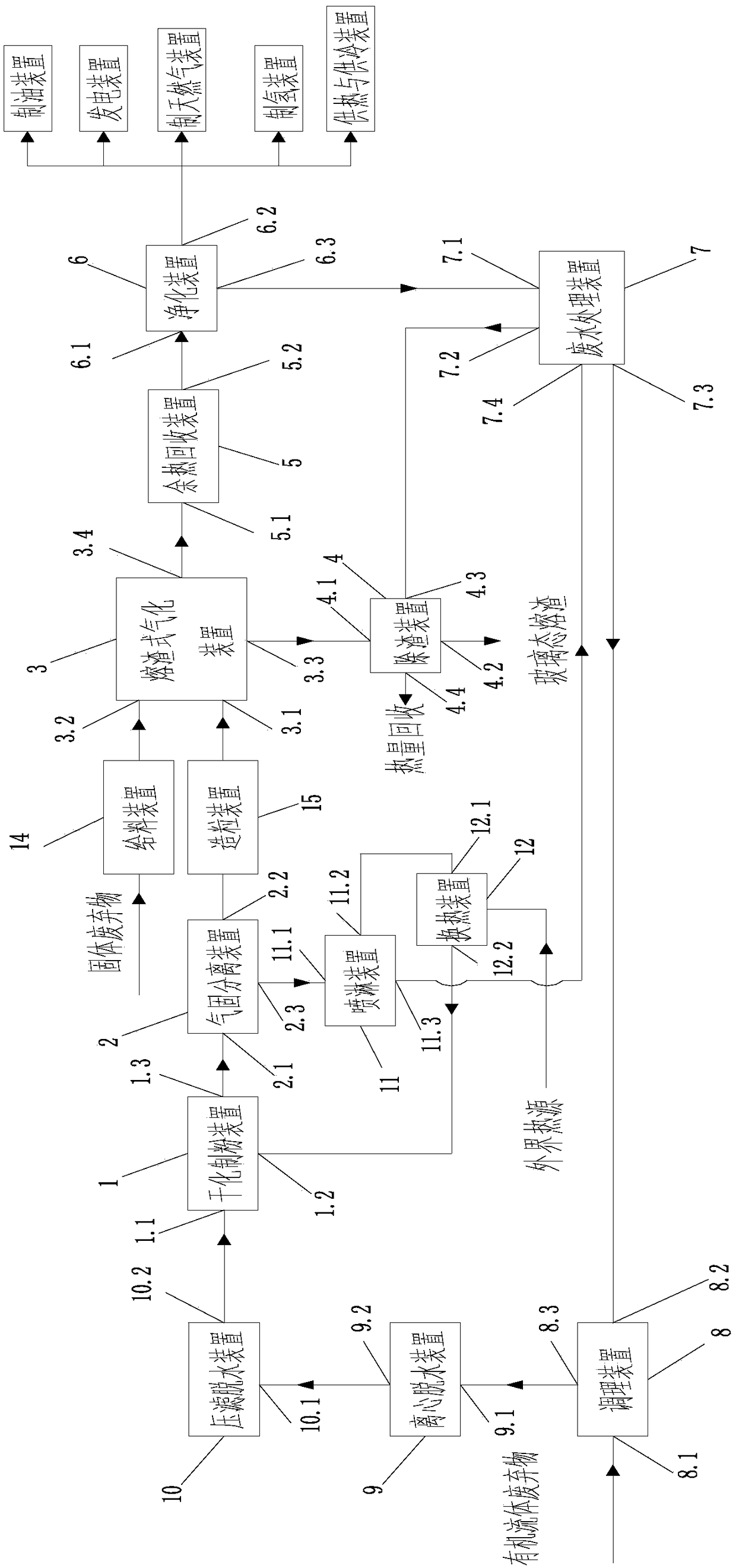

Multielement material collaborative gasification method and system

PendingCN108326012AAchieving co-gasificationMade quicklyWaste processingSolid waste disposalSlagOrganic fluid

The invention discloses a multielement material collaborative gasification method and system. The method comprises the steps of 1, pretreatment, wherein pretreatment is conducted on organic fluid waste, so that filter cakes are obtained; 2, drying for powder production, wherein rotational flow heat exchange is conducted between the filter cakes and heat carrying gas, and meanwhile, crushing impacttreatment is conducted on the filter cakes, so that powder waste is obtained; 3, gas-solid separation, wherein the powder waste and tail gas are separated; 4, gasification of slag, wherein collaborative gasification treatment is conducted on the powder waste and additional solid waste, so that synthesis gas and the slag are obtained; 5, aftertreatment of the synthesis gas, wherein waste heat recovery is conducted on the synthesis gas in the first place, and then purification treatment is conducted, so that purified gas and waste water are obtained; 6, aftertreatment of the slag, wherein chilling treatment is conducted on the slag, so that a glassy-state slag material is obtained; and 7, treatment of the waste water. By means of the multielement material collaborative gasification method,drying treatment can be conducted on the organic fluid waste, and the fluid-form waste is produced into a powder waste material; the powder waste material can serve as a raw material of the gasification slag; and collaborative gasification treatment of the multielement materials, namely the solid waste and the organic fluid waste, is achieved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

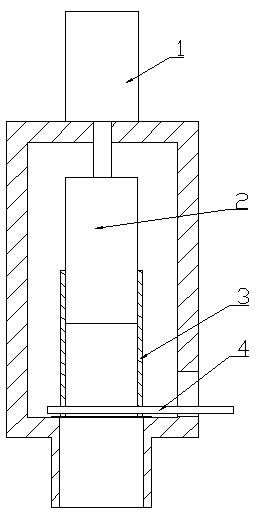

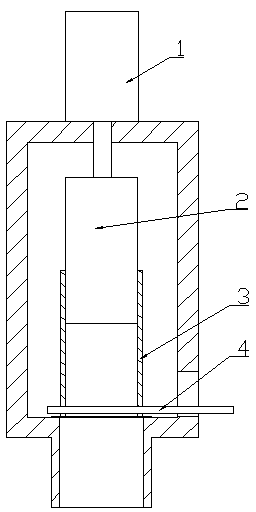

Novel magnetic assembly and preparation method thereof

InactiveCN102982959AReduce product thicknessStable structureMagnetsInductances/transformers/magnets manufactureMagnetBiomedical engineering

The invention discloses a novel magnetic assembly and a preparation method thereof. The novel magnetic assembly comprises a soft magnetic base material and a plastic base material coated on the soft magnetic base material; and at least one end face of the soft magnetic base material is exposed out of one end face of the plastic base material. The preparation method of the novel magnetic assembly comprises the following steps of: taking iron powder and carrying out primary injection on the iron powder by injection molding equipment to form the soft magnetic base material; and then carrying out secondary injection on a plastic material by the injection molding equipment and coating the plastic material on the soft magnetic base material to form the plastic base material, wherein at least one end face of the soft magnetic base material is exposed out of one end face of the plastic base material. According to the invention, a product can be rapidly prepared by carrying out primary injection on materials such as the iron powder and the like in an injection molding manner to form the soft magnetic base material, then carrying out secondary injection on the plastic material and coating the plastic material on the soft magnetic base material to form the plastic base material; the product has a relative small thickness, is more attractive and practical, has a firmer structure and cannot generate the condition of magnet falling, so that the use performance of the novel magnetic assembly is effectively guaranteed and the novel magnetic assembly can meet the application requirements in various places.

Owner:KUNSHAN DINGXINHAO MACHINERY

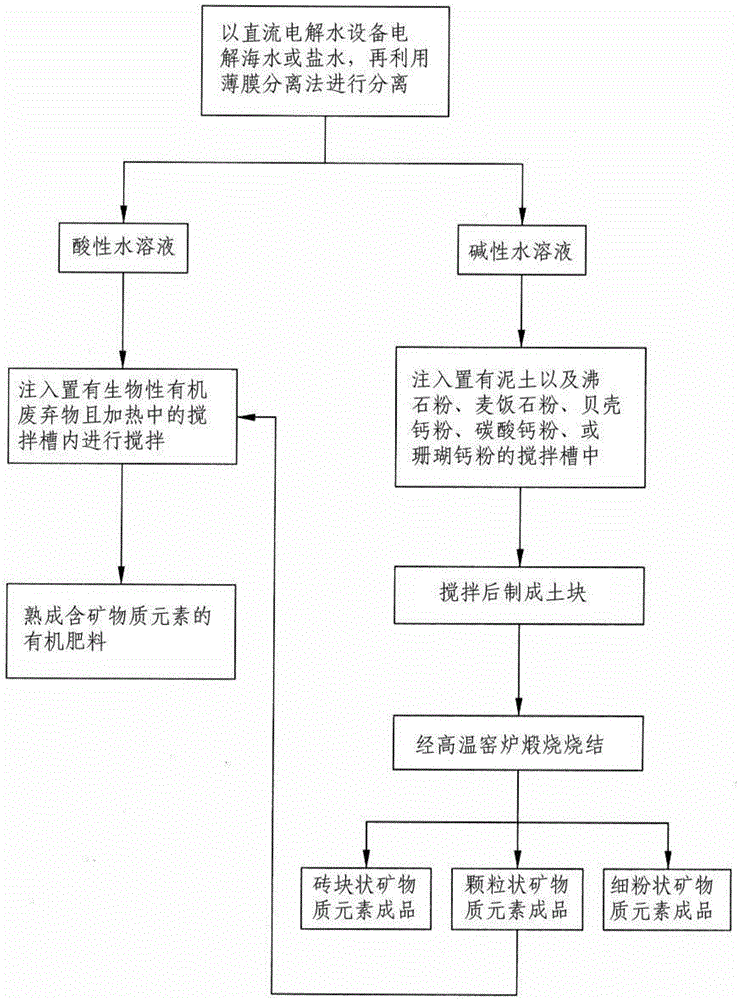

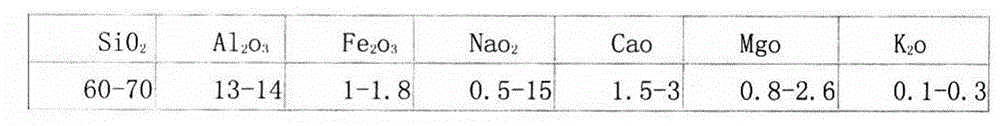

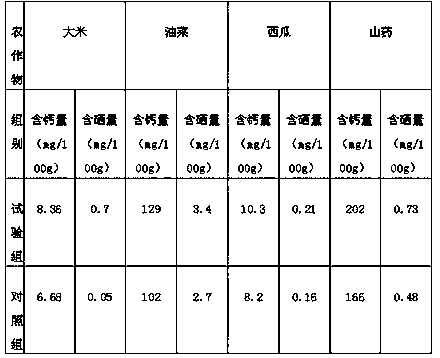

Method for rapidly manufacturing organic fertilizer and feed mineral element additive

The invention provides a method for rapidly manufacturing an organic fertilizer and a feed mineral element additive. The method comprises the following steps: direct current water electrolyzing equipment is used for electrolyzing seawater or brine, a film separation process is used for separating an acidic aqueous solution and an alkaline aqueous solution; the acidic aqueous solution is injected into an agitating tank which contains biological organic waste for carrying out stirring, and an organic fertilizer containing mineral elements is maturated; the alkaline aqueous solution is injected into an agitating tank which contains soil, zeolite powder, Maifan stone powder, shell calcium powder, calcium carbonate powder, or coral calcium powder, stirring is carried out in order to produce soil blocks, the soil blocks are calcined by a high temperature kiln and sintered into mineral element finished products in brick shape, granular shape or fine powder shape; even, the mineral element finished product in granular shape is added into an agitating tank which contains biological organic waste for carrying out stirring, and an organic fertilizer containing mineral elements is maturated.

Owner:陈温乐

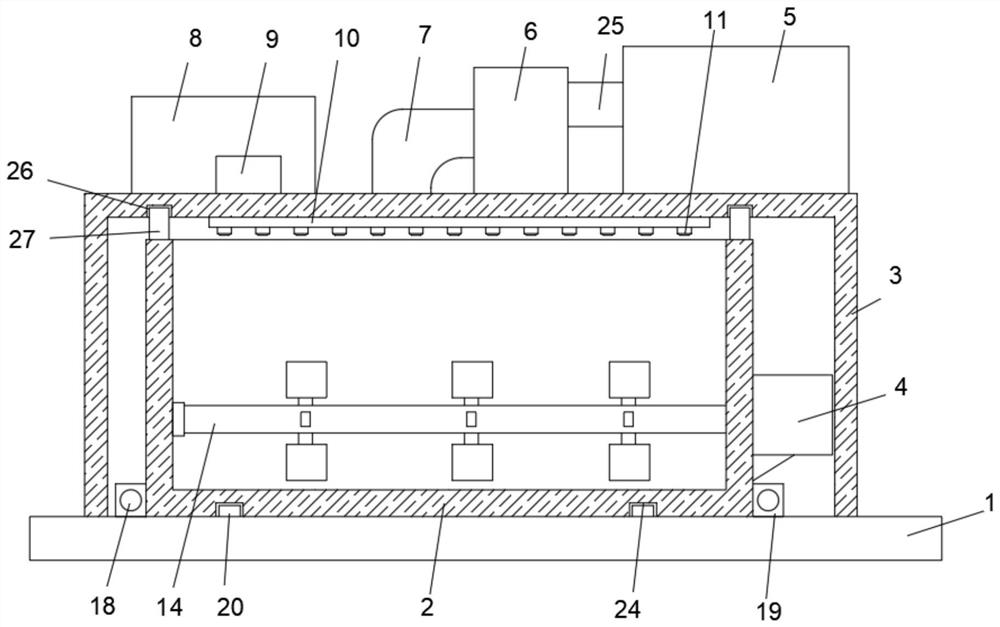

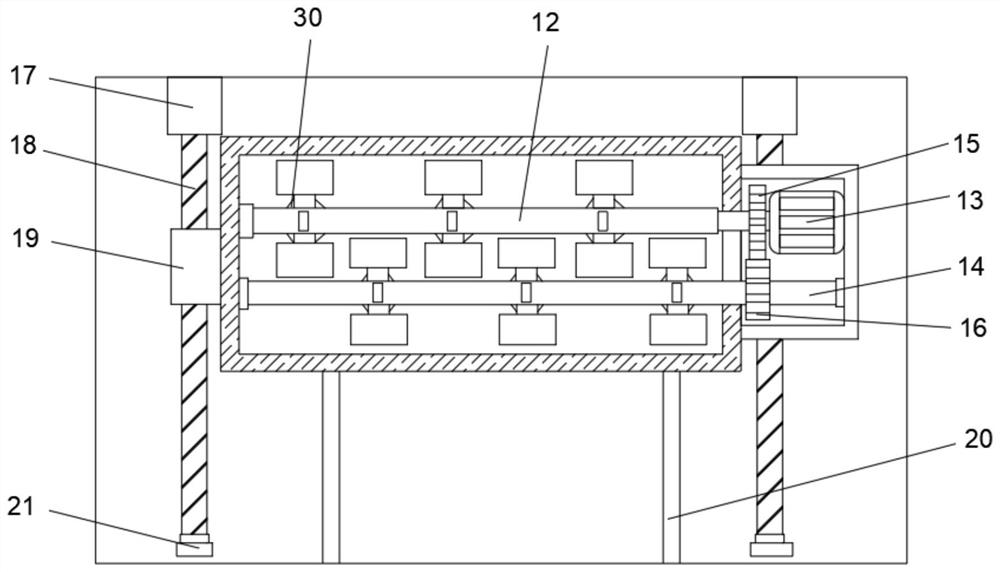

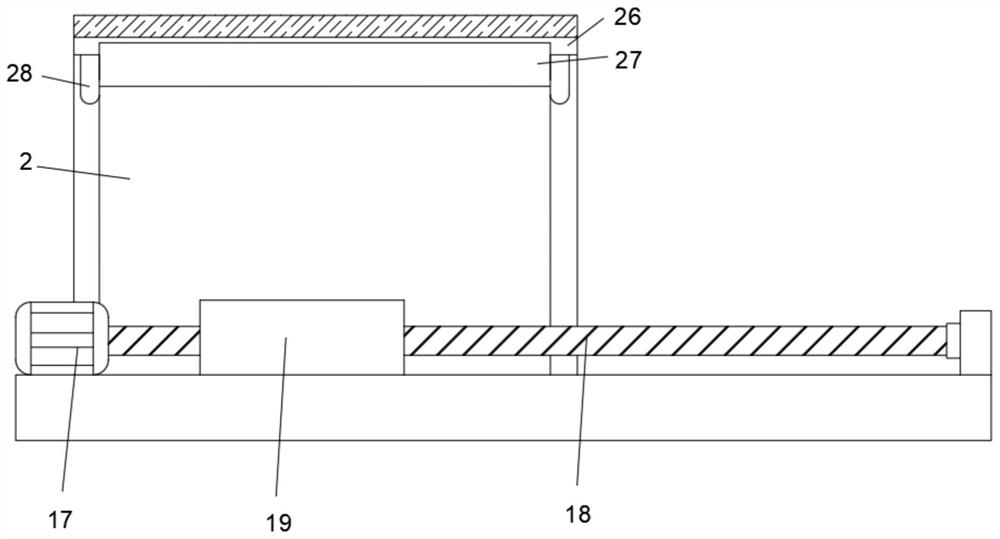

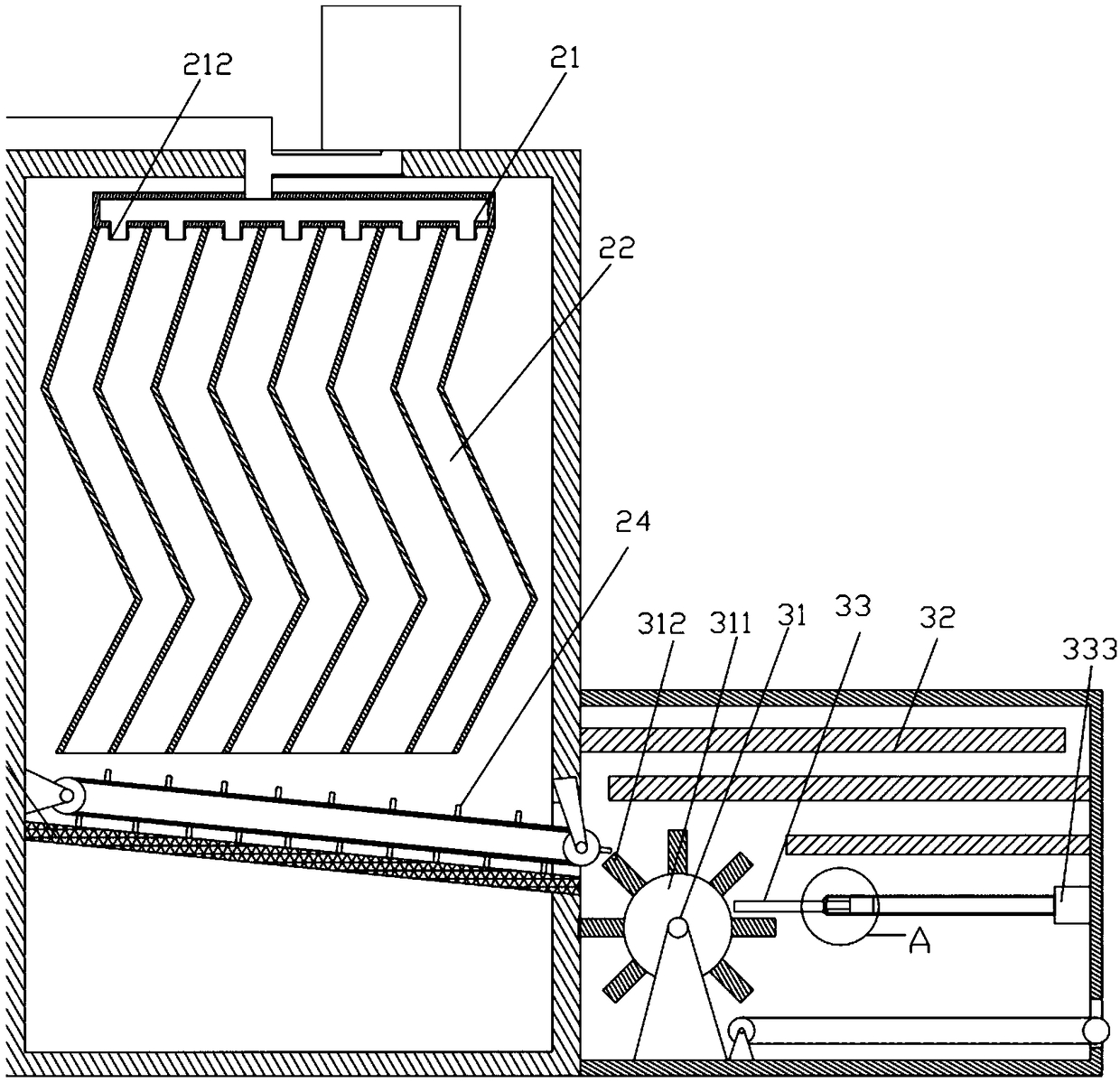

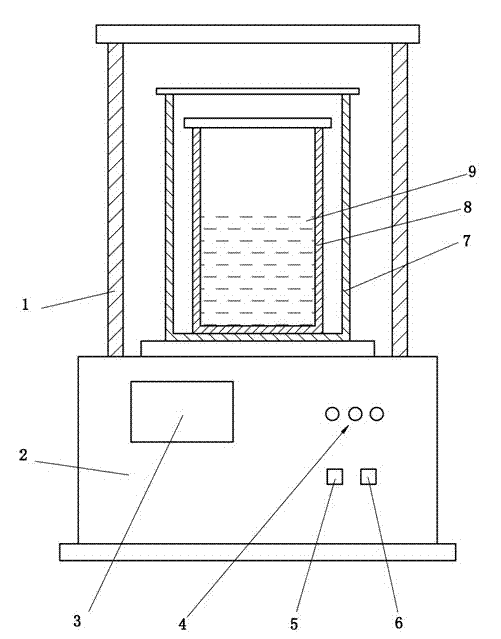

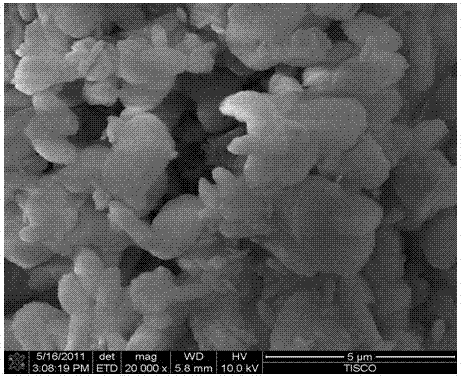

Totally-enclosed organic waste fermentation composting machine

InactiveCN112441849APromote decompositionPrevent leakageBio-organic fraction processingOrganic fertiliser apparatusAgricultural engineeringElectric machinery

The invention provides a totally-closed organic waste fermentation composting machine. The totally-closed organic waste fermentation composting machine comprises a base, a fermentation tank and a closed hood, wherein the fermentation tank and the closed hood are both located on the upper surface of the base, the closed hood is fixedly connected with the upper surface of the base, the fermentationtank is located in the closed hood, a driving box is fixedly connected to one side of the outer wall of the fermentation tank, a first motor is fixedly connected to the inner side wall of the drivingbox, the driving end of the first motor extends into the fermentation tank and is fixedly connected with a first rotating shaft, and the end, away from the first motor, of the first rotating shaft isrotationally connected with the inner side wall of the fermentation tank. According to the invention, traditional composting or groove-type composting is developed into totally-closed production, an occupied area is reduced, a harmless treatment process is accelerated, organic matter decomposition is accelerated to achieve the purpose of rapidly preparing the organic fertilizer, house constructionand ground hardening construction are reduced, and harmful gas can be prevented from leaking to cause pollution by adopting closed treatment.

Owner:YANGZHOU FUWATER CONSTR MASCH MFG CO LTD

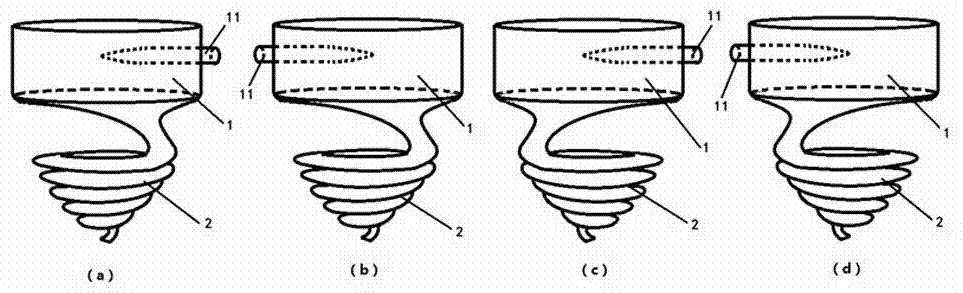

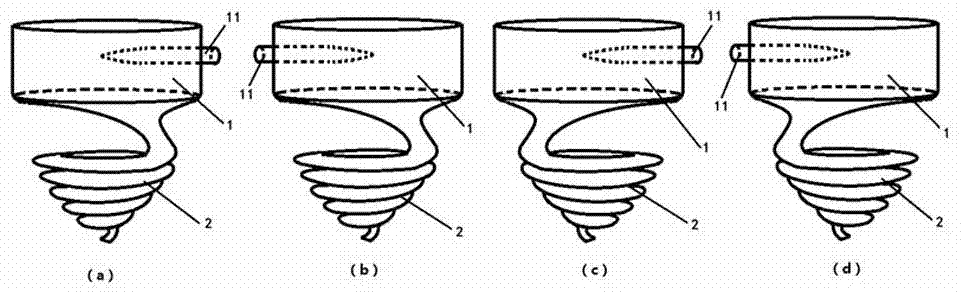

Vortex emulsion method and device

The invention discloses a vortex emulsion method and device. According to the invention, two or several fluids (liquids or gases) such as oil and water, which cannot be mixed, simultaneously flow through a vortex generator to be mixed, and then are discharged after doing centripetal vortex motion, so that an emulsion is generated. The vortex generator comprises a main container and a vortex tube; the cross section of the main container is circular; a tangential feed hole is arranged on the circumference of the main container; the bottom end of the vortex tube is provided with a discharge hole; the vortex tube and the main container form a hopper-shaped structure. A to-be-emulsified fluid together with other liquid such as water flows in from the lateral feed hole of the main container and forms mixed fluid; then the mixed fluid flows in the vortex tube in a special centripetal vortex manner and then interferes zero-point energy of vacuum to generate a centripetal vortex internal pressure energy field; original molecules or molecular groups in the to-be-emulsified fluid and the other liquid such as water are opened via the vortex internal pressure energy field, and then the emulsion with new molecules or molecular groups is regenerated.

Owner:彭伟明

Electric garlic mashing device

The invention discloses an electric garlic mashing device which is characterized in that a plastic cylinder is of a double-layer hollow structure, a battery and a switch are arranged in an interlayer of the plastic cylinder, a separating plate provided with small holes is arranged at the middle position of an inner layer of the plastic cylinder, a cutting device is arranged at the middle position of the separating plate, a plurality of telescopic rods are arranged below the separating plate, and a closed circuit is formed by the battery, the switch, the cutting device and the telescopic rods. The upper end of each telescopic rod is connected with the inner layer of the plastic cylinder and a certain angle is formed, the other end of each telescopic is provided with a metal ball, a filter mesh is arranged on the bottom portion of the inner layer of the plastic cylinder, and a container used for collecting mashed garlic is arranged below the plastic cylinder. According to the electric garlic mashing device, the purpose of making garlic to mashed garlic rapidly is achieved, and the electric garlic mashing device is convenient to use, labor-saving and rapid.

Owner:殷乐

Method of producing organic high-calcium fertilizer from Sedum aizoon and straw

PendingCN109704821ASimple preparation processConducive to straw utilizationBio-organic fraction processingOrganic fertiliser preparationFertilizerCorn stover

The invention discloses a method of producing an organic high-calcium fertilizer from Sedum aizoon and straw and relates to a preparation method of high-calcium fertilizer by using the Sedum aizoon and straw. The method includes: 1) preparing an enzyme solution; 2) preparing a mixture from the Sedum aizoon and the like; 3) spraying the enzyme solution uniformly on the mixture in the step 2), and fermenting the mixed raw materials in a container for 30 days at 30-40 DEG C to prepare a fermented raw material; 4) crushing corn straw; 5) spraying water to the crushed corn straw; 6) composting theraw materials, wherein the corn straw, sprayed by water, and the fermented raw material are blended. The method solves the problems that a technology in the prior art is complex in process and requires a large number expensive devices, and limits production of fertilizers by using the Sedum aizoon and straw. The invention also solves a problem that the high-calcium fertilizer, produced in the prior art, is high in cost.

Owner:杨印辉

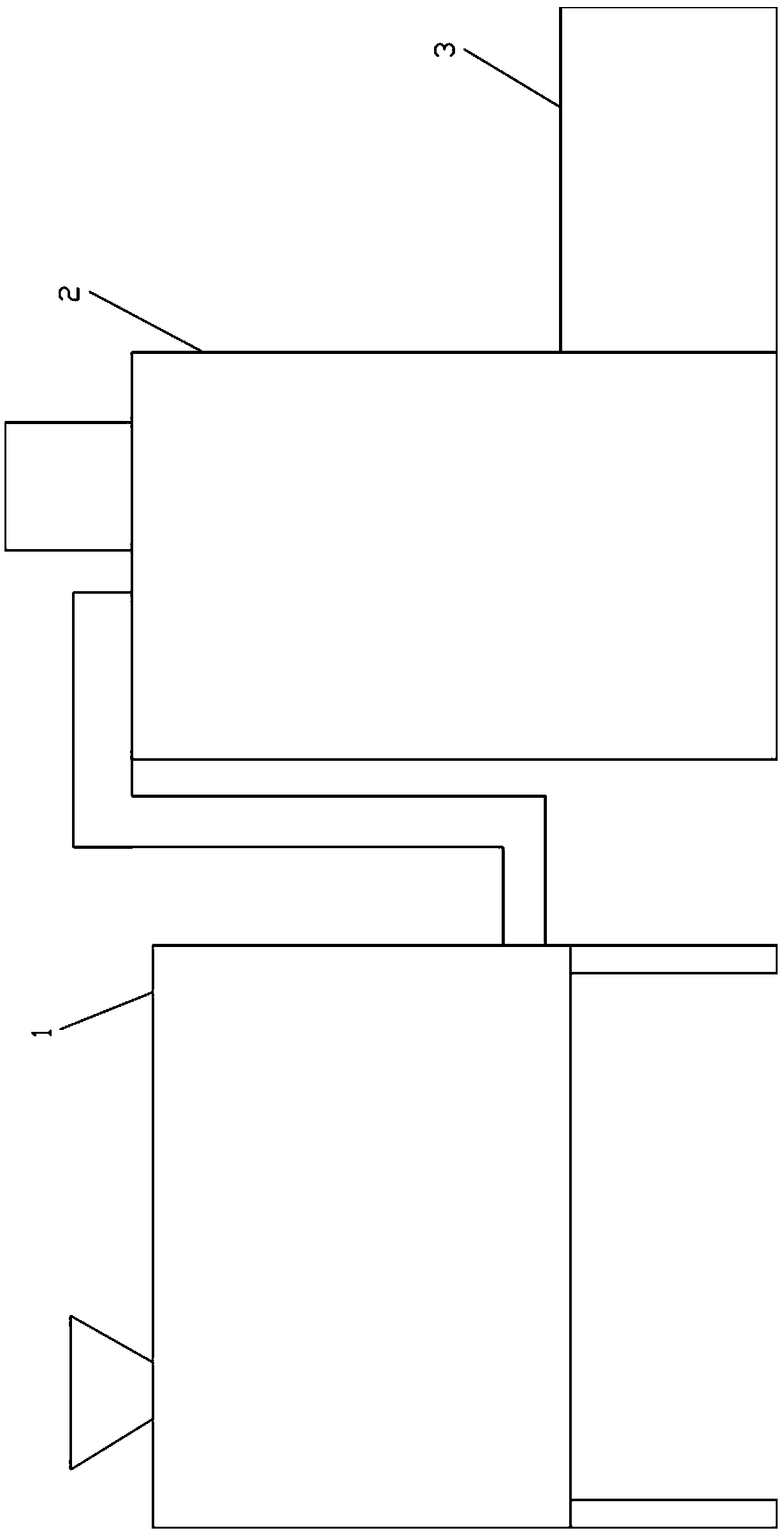

Well-drilling waste mud treatment equipment

InactiveCN108726839AAccelerateImprove efficiencySludge treatment by de-watering/drying/thickeningDehydrationWaste management

The invention discloses well-drilling waste mud treatment equipment. The well-drilling waste mud treatment equipment comprises a dilution mechanism, a flocculation mechanism and a drying mechanism, wherein the dilution mechanism is connected with the flocculation mechanism; the flocculation mechanism is connected with the drying mechanism; the dilution mechanism is used for adding water into thickwaste mud and diluting the waste mud, so that flocculation treatment is conveniently carried out on the waste mud; the flocculation mechanism is used for carrying out dehydration treatment on the diluted waste mud to realize solid-liquid separation; the drying mechanism is used for carrying out drying and shaping treatment on separated solids so that generated mud blocks are convenient to transport and treat. By adopting the structure, the waste mud can be very effectively treated into the small mud blocks and the efficiency of preparing the mud blocks from the waste mud is improved; meanwhile, the transportation efficiency of the waste mud is also improved.

Owner:崔九香

Preparation method of redissolved fish head thick soup stewing powder bag

PendingCN111264824AIncrease added valueEnrich market product formsFood scienceBiotechnologyNutritive values

The invention discloses a preparation method of a redissolved fish head thick soup stewing powder bag. The preparation method comprises the following specific operation steps: cleaning, pretreating, pickling, frying and boiling fish heads to obtain fish head soup, filtering the fish head soup to obtain filtrate, preparing fish head thick soup stewing by virtue of an evaporation and concentration technology, performing spray drying to obtain fish head thick soup powder, matching with a seasoning bag, and redissolving to obtain delicious fish head thick soup. Freshwater fish head by-products canbe effectively utilized, the problem that a common thick soup stewing is short in shelf life is solved, fishy smell is reduced, the content of amino acids in the soup is high, and t the soup has highnutritional value.

Owner:JIANGXI NORMAL UNIV

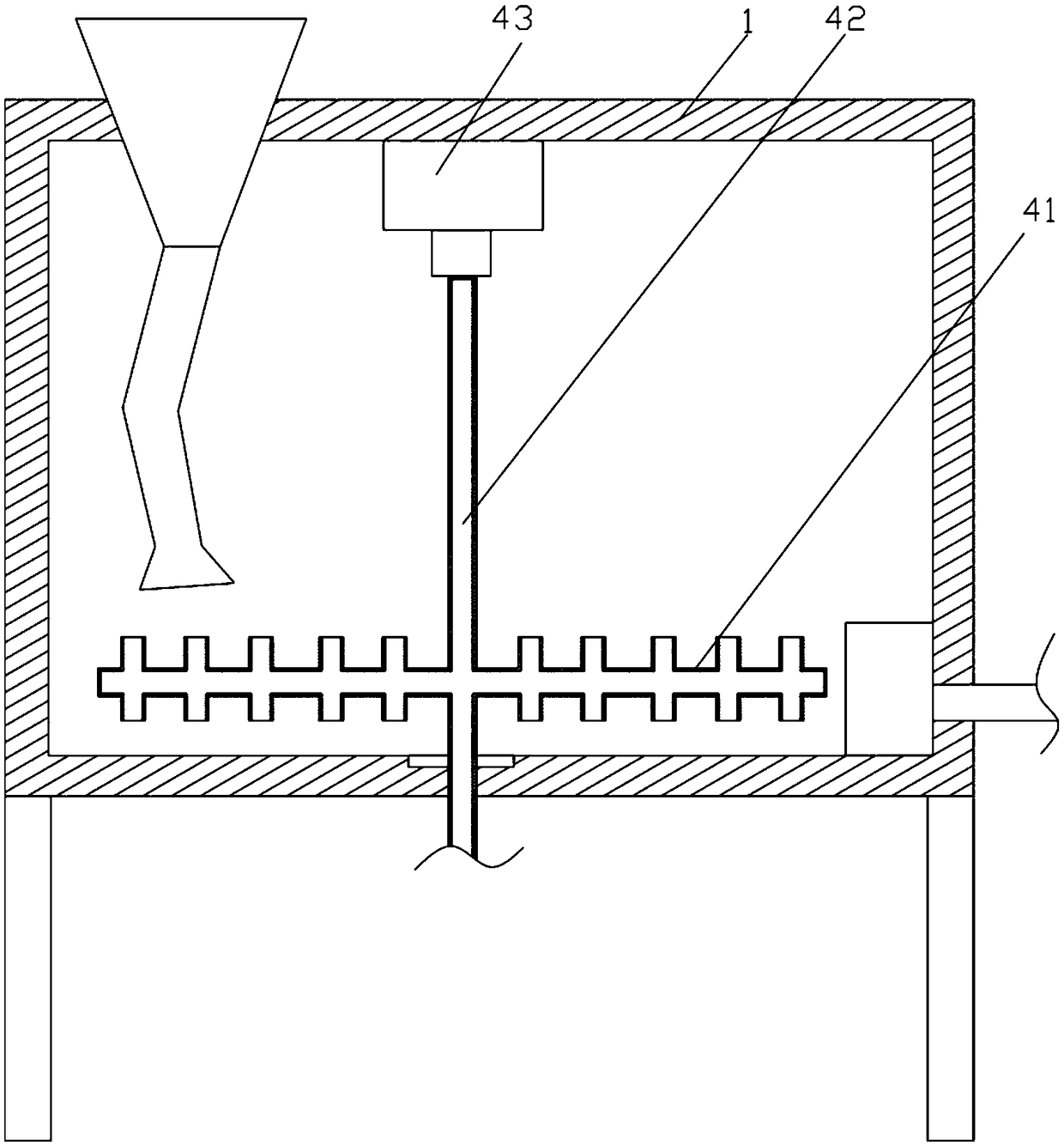

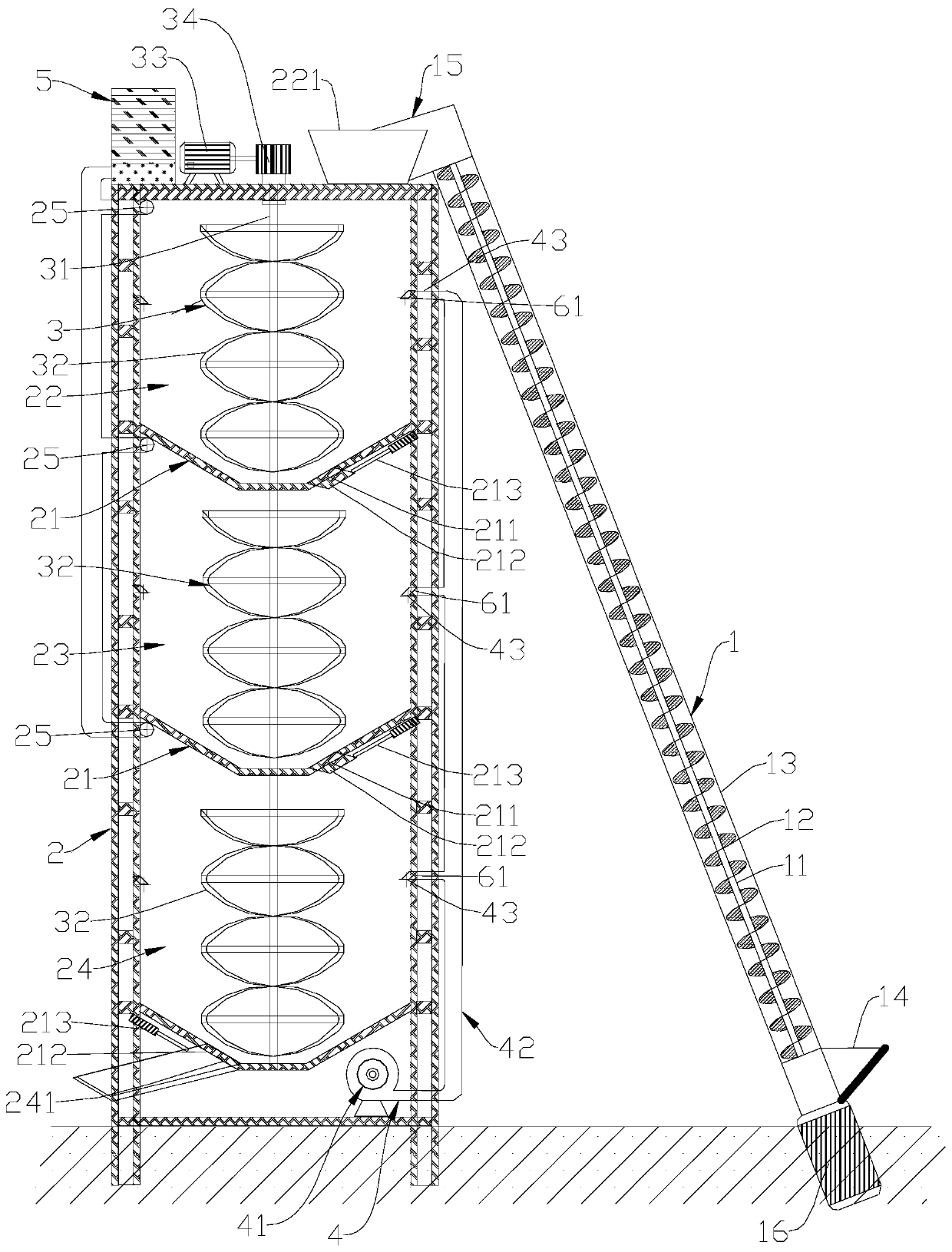

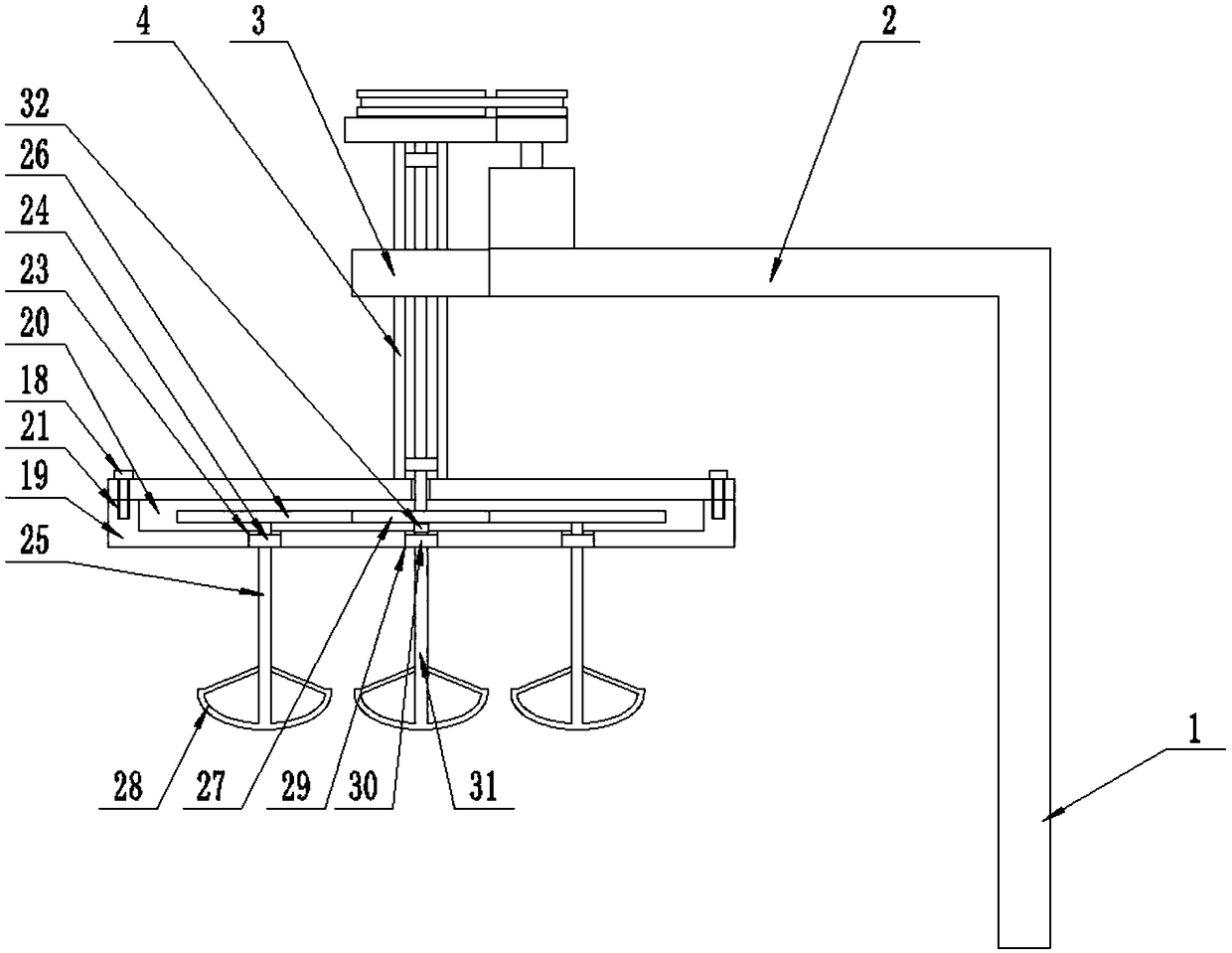

Three-dimensional composting treatment machine

InactiveCN110452036ASpeed up fermentationMade quicklyOrganic fertiliser preparationPulp and paper industryOrganic fertilizer

The invention relates to a three-dimensional composting treatment machine, which comprises a feeding device, a fermentation bin, a stirring device, an aeration device and a purification device. The feeding device transmits that waste to be treated to the top of the fermentation bin; baffles are arranged at intervals from top to bottom in the fermentation bin, and the fermentation bin is divided into a primary bin, an intermediate bin, and a lower bin arranged from top to bottom. The baffle is recessed downwardly and provided with an openable feeding opening, so that the waste to be treated entering the fermentation bin from the top can fall down step by step, and the bottom of the lower bin is provided with a discharge opening. The stirring device stirs the waste materials to be processedin the primary bin, the intermediate bin and the lower bin, and the aeration device respectively aerates in the primary bin, the intermediate bin and the lower bin, so as to ferment the waste materials to be processed; the purification device is respectively communicated with the primary bin, the intermediate bin and the lower bin to collect the exhaust gas for post-treatment discharge. Through stirring, aeration and multi-stage fermentation treatment, the composting fermentation speed is accelerated, and the bio-organic fertilizer is quickly prepared, which is used as resources, more environmental protection is obtained, and the treatment efficiency is improved.

Owner:深圳市如茵生态环境建设有限公司

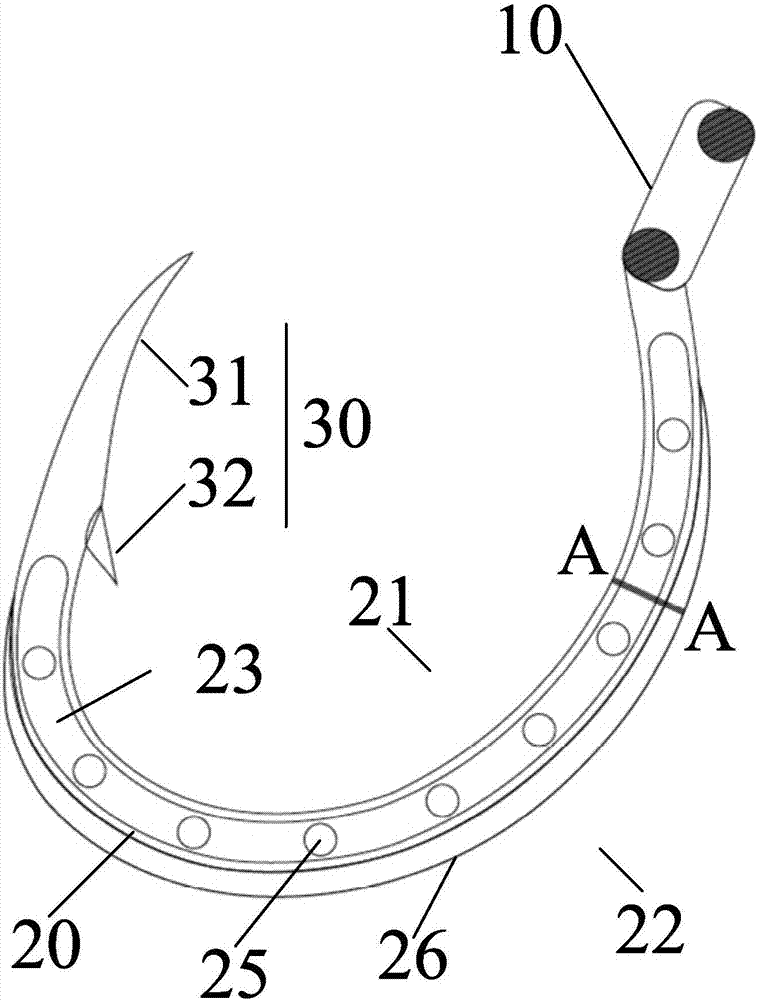

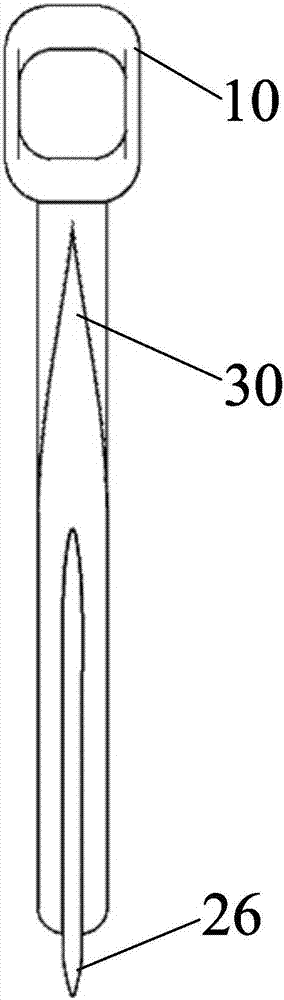

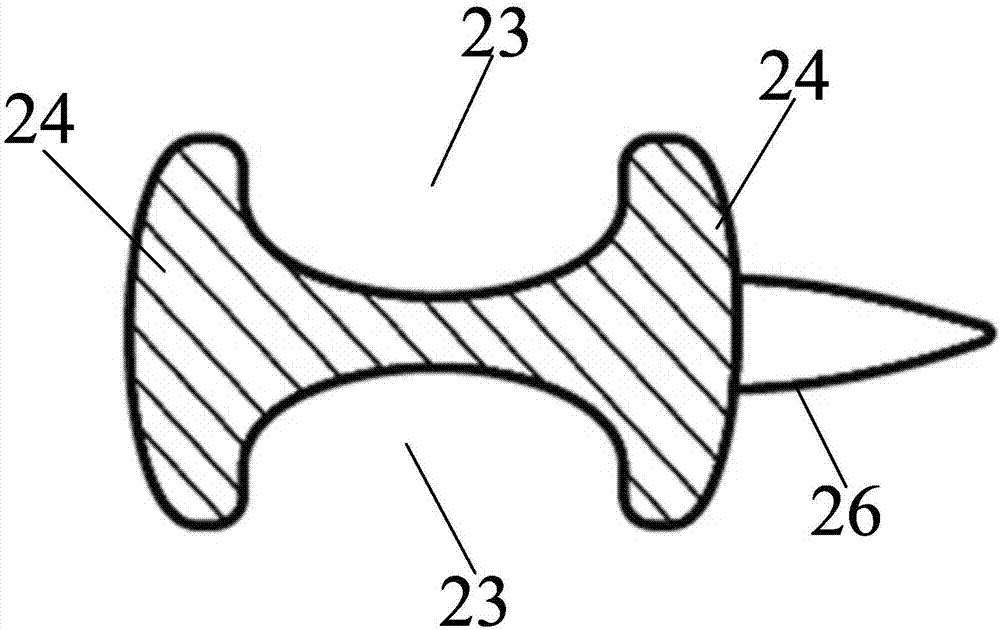

Fishhook and manufacturing method thereof

The invention relates to a fishhook, which is used for fishing, and comprises a thread binding part, a main body part and a hook tip part. The thread binding part, the main body part and the hook tip part are sequentially connected; the main body part is a flat arc-shaped body; flat surfaces of two sides of the main body part respectively comprise a main body groove; the cross section of the main body part is in an I shape. The fishhook provided by the invention is various and exquisite in shape, high in structuredness, and longer in service life.

Owner:鄱阳县黑金刚钓具有限责任公司 +1

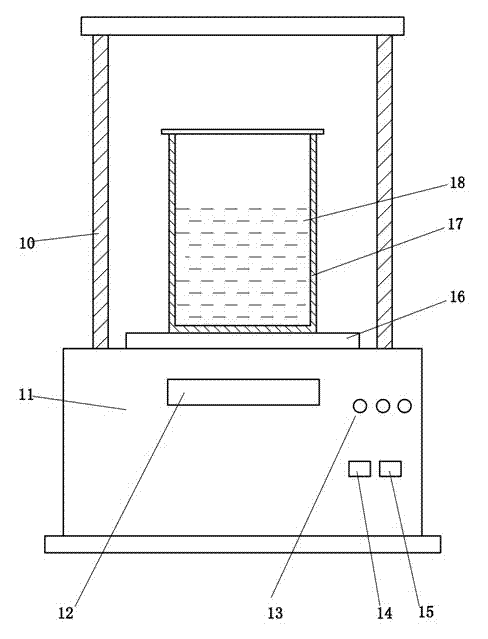

Fast preparation method of ferrous microporous composite molecular sieves

InactiveCN102774850BMade quicklyAdvancedMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveNitrate

The invention relates to a fast preparation method of ferrous microporous composite molecular sieves. According to the method, firstly, single molecular sieves are prepared in a reaction kettle, then, ferric nitrate is doped, heating and crystallization are carried out in a heating furnace, high-temperature roasting is carried out in a rotating furnace, ferrous microporous composite molecular sieve powder products are fast prepared, and the prepared ferrous microporous composite molecular sieve powder body particles are dispersive-molecule crystals containing 10-membered rings and 12-membered rings, the diameter of the powder particles is 2 to 5mum, the powder particles can be matched with various chemical substances to be used as catalysts, and the method provided by the invention belongs to a very ideal method for fast preparing the ferrous microporous composite molecular sieves.

Owner:TAIYUAN UNIV OF TECH

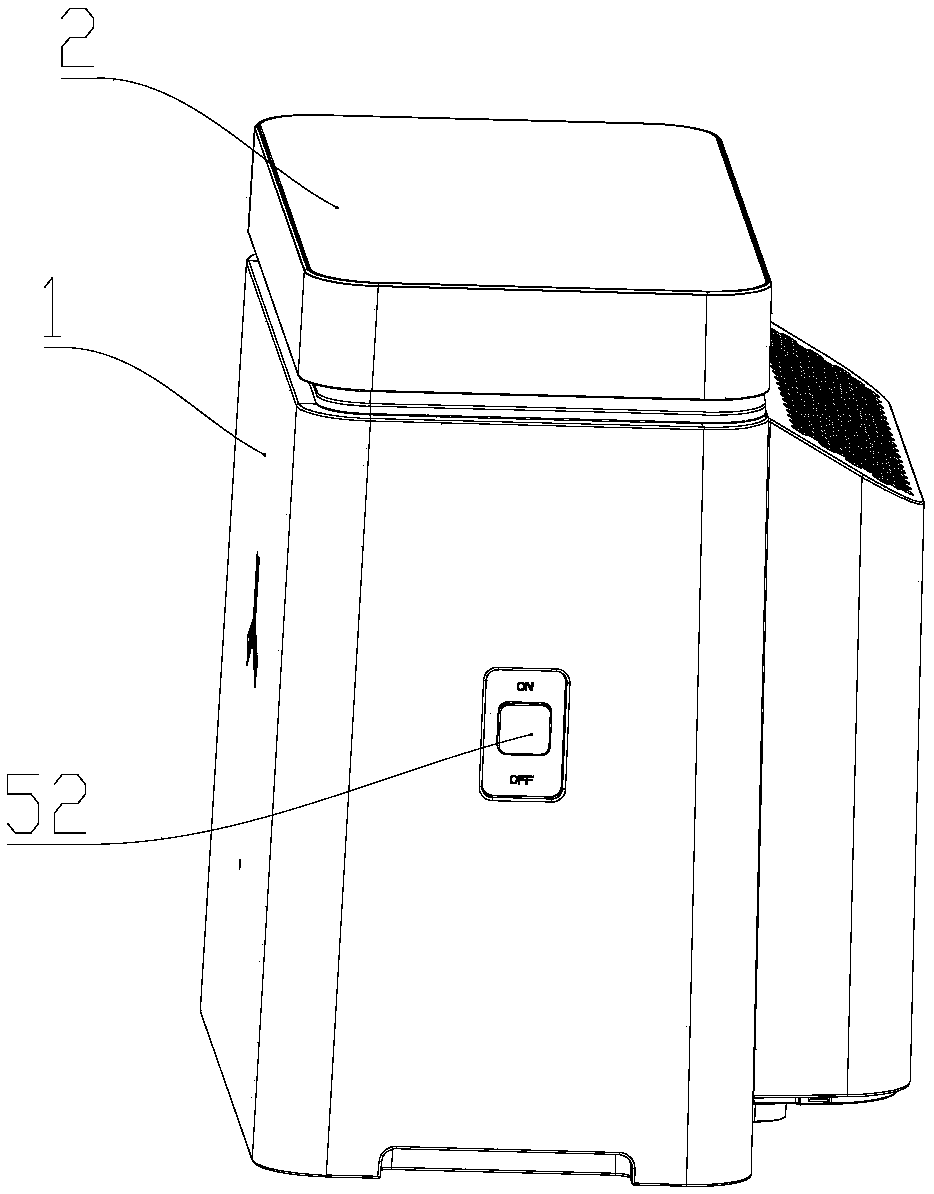

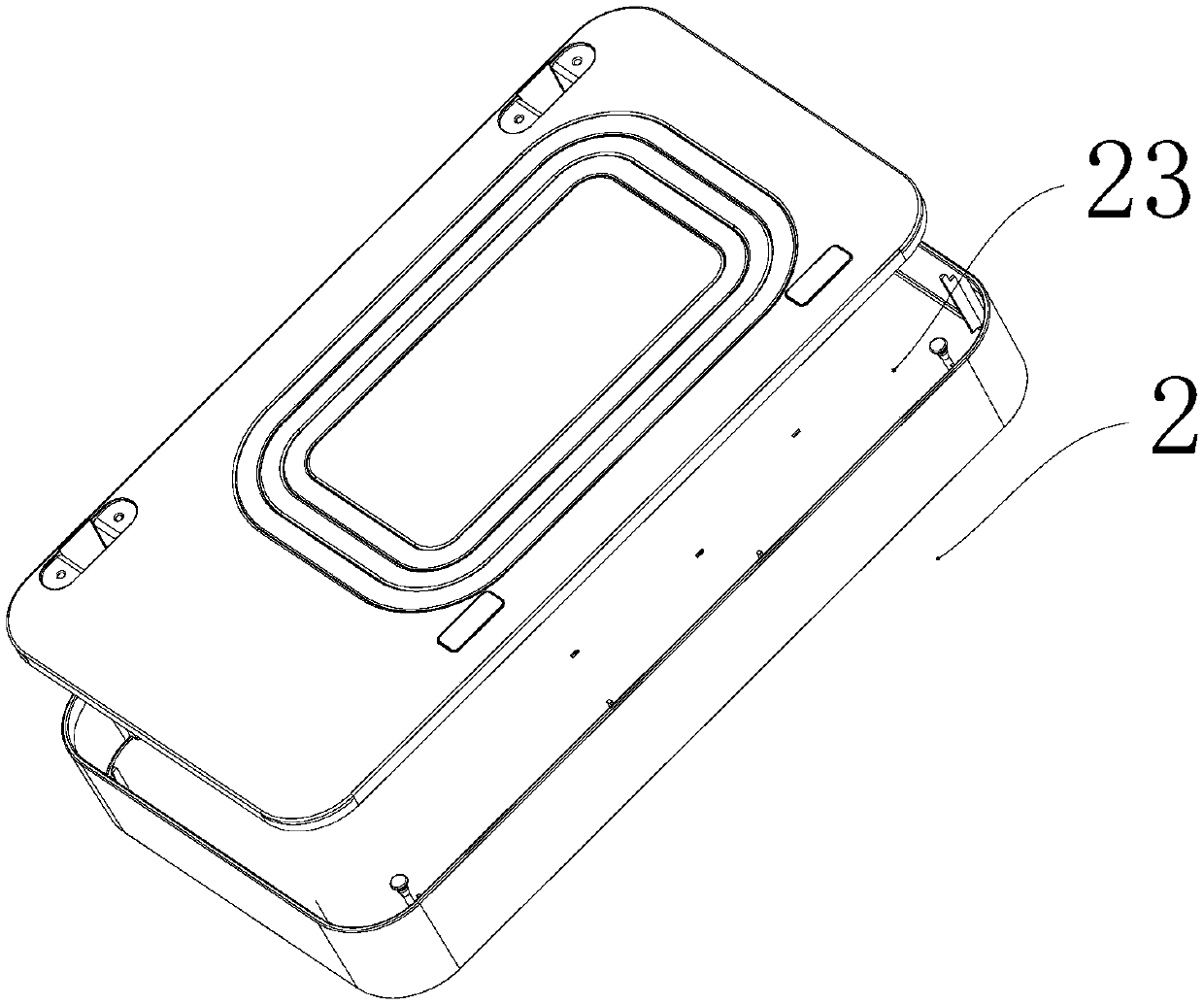

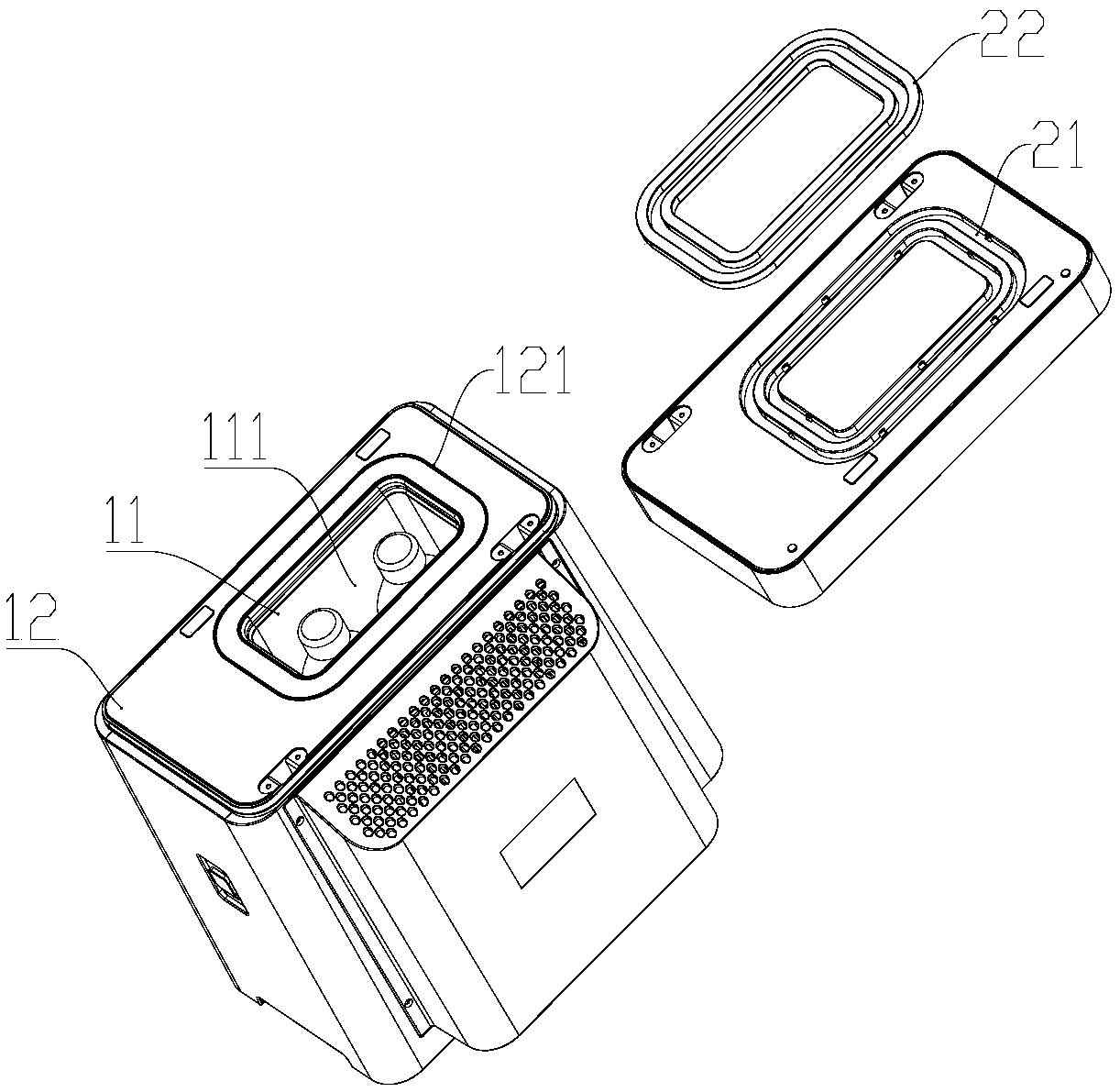

Portable smoothie refrigerator

PendingCN109539661ASimple structureEasy to carryDomestic refrigeratorsMachines using electric/magnetic effectsEngineeringRefrigeration

The invention belongs to the technical field of refrigeration, and provides a portable smoothie refrigerator. The portable smoothie refrigerator comprises a refrigerator body, a cover body, a refrigeration and cooling assembly and a control assembly. The refrigerator body comprises an inner container and an outer shell. The inner container is provided with containing space used for containing canned drinks, and a first insulating layer is arranged between the inner container and the outer shell. The cover body is arranged at the upper end of the refrigerator body in a manner of being capable of being opened and closed. A second insulating layer is arranged in the cover body, a sealing grove is formed in the cover body, a sealing ring is arranged in the sealing groove, and a sealing protrusion cooperating with the sealing groove is arranged on the outer shell. The refrigeration and cooling assembly sequentially comprises an inner conduction part, a semiconductor chilling plate and an outer conduction part from inside to outside, wherein the inner conduction part, the semiconductor chilling plate and the outer conduction part are in contact. Meanwhile, the control assembly is arranged in the refrigerator body and comprises a circuit board and a control chip arranged on the circuit board, and the circuit board is electrically connected with the semiconductor chilling plate. The portable smoothie refrigerator is simple in structure and convenient to carry, canned carbonate drinks can be rapidly made into smoothies, and practicality is high.

Owner:深圳天辰天亿科技有限公司

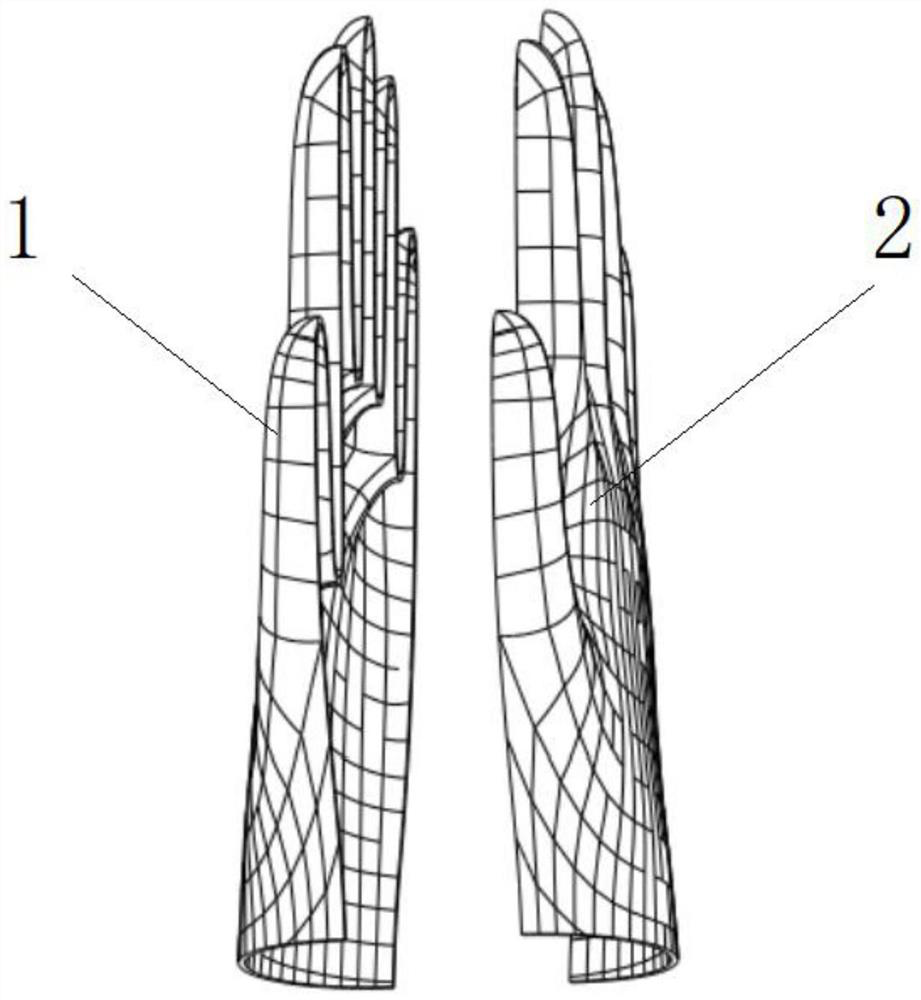

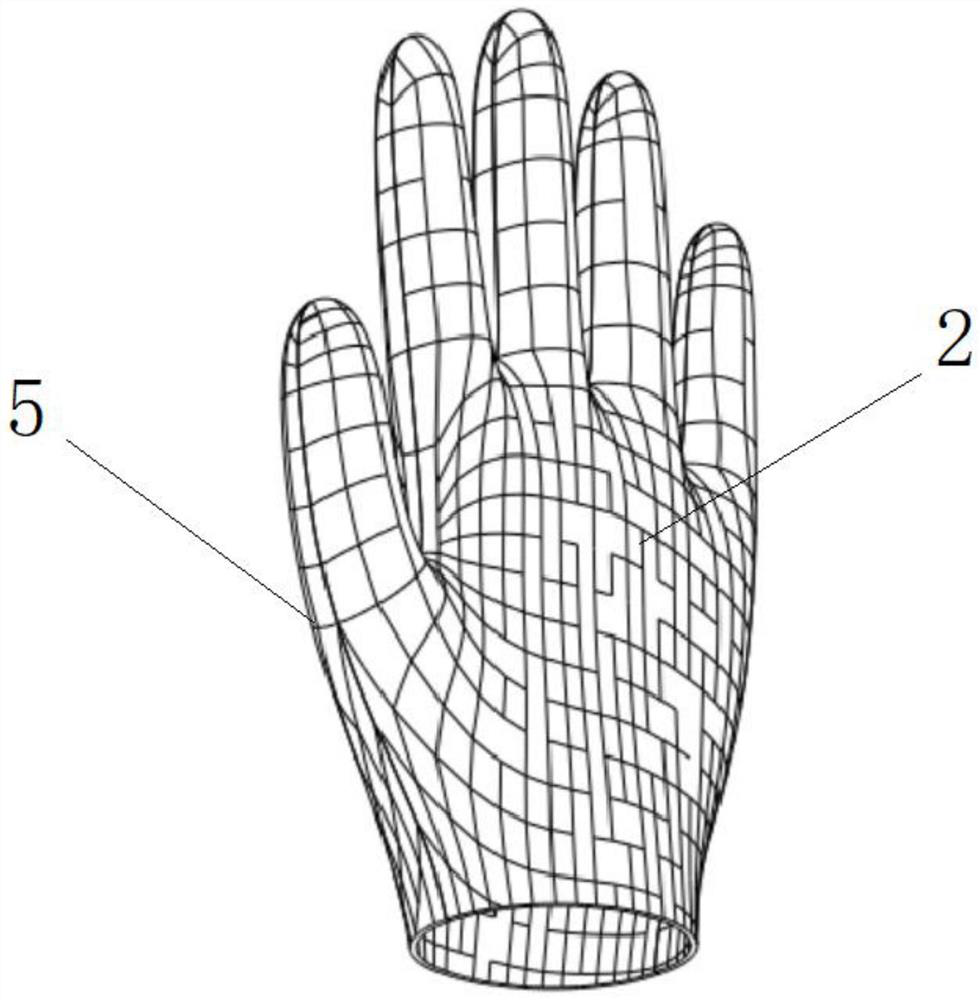

Metal-based ceramic glove mold and preparation method thereof

PendingCN114368098AImprove yieldReduce processing costsDomestic articlesCoatingsCeramicVitreous enamel

The invention discloses a metal-based ceramic glove mold and a preparation method thereof, the metal-based ceramic glove mold comprises an upper mold and a lower mold, the upper mold and the lower mold comprise a metal plate and an enamel layer, the metal plate is made of an aluminum alloy or a composite alloy material with the aluminum alloy as a matrix, and the upper mold and the lower mold are fixed through brazing welding. The hand mold has the advantages of a metal mold and a ceramic mold, the advantages are organically combined, the service life can be prolonged, secondary recycling can be achieved, the requirement for reducing the production cost is met, enamel is evenly sprayed to the surface of a metal matrix through an enamel treatment means to form an enamel layer, a pure metal mold can be effectively replaced, the manufacturing cost is low, and the production efficiency is high. And the internal metal matrix can be used for improving the heat conduction performance of the mold, the internal metal matrix can be reused for enamel treatment and spraying even if the surface ceramic is damaged, a new glove mold is rapidly manufactured, recycling is easy, and the cost is low.

Owner:梅刚

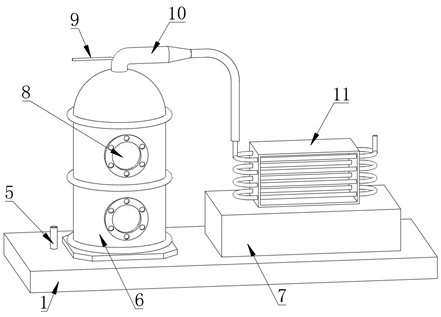

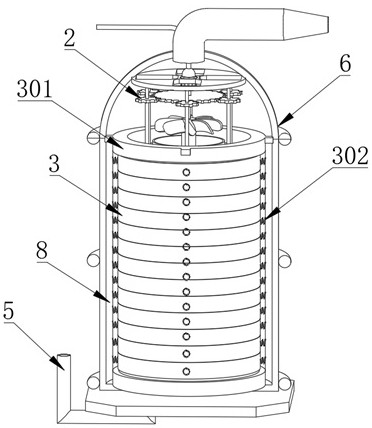

Integrated marine seawater desalting device

ActiveCN114590857ASpeed up circulationIncrease the water vapor pressure differenceGeneral water supply conservationSeawater treatmentEnvironmental engineeringMechanical engineering

The invention relates to the technical field of seawater desalination, in particular to an integrated marine seawater desalination device which comprises a bottom plate, an evaporation tower and a placement plate are fixedly connected to the upper surface of the bottom plate, a condenser is fixedly connected to the upper surface of the placement plate, and a steam inlet and outlet pipeline is fixedly connected to the upper end of the evaporation tower. The tail end of the steam inlet and outlet pipeline is connected to a connector of the condenser, a seawater inlet pipeline fixedly penetrates through the steam inlet and outlet pipeline, a cleaning assembly is further arranged on the inner wall of the lower end of the evaporation tower, and a discharging pipe is further fixedly connected to the lower end of the evaporation tower. Part of impurities remaining on the evaporation plate and the other part of impurities are shaken off to the bottom of the evaporation tower, a good foundation is provided for subsequent seawater desalination, the problem that the desalination efficiency is reduced in the continuous seawater desalination process of equipment is solved, and the practicability of the equipment is improved.

Owner:江苏汉盛海洋装备技术有限公司

Manufacturing method of active carbon

The invention discloses a manufacturing method of active carbon. The manufacturing method comprises charing and activation. Raw materials are burned and heated in a calciner, the raw materials are crushed, are fed into an activation furnace and are activated, wherein in activation, the raw materials are self-vaporized, the semi-finished product is recycled, and the activated product is cooled to form a finished product. In calcination, under specific high temperature and high pressure conditions, the raw materials are completely burned without contact with air, and the semi-finished product is crushed so that an active carbon adsorption capacity is improved. Activation is carried after calcination and in activation, the crushed active carbon is fed into the activation furnace, is vaporized at a high temperature and is bonded to oxygen in air so that activation is finished, and the product is cooled to form active carbon. The manufacturing method of active carbon utilizes any one of coal, cocoanut shell, straw and firewood as raw materials.

Owner:山阴县华晟活性炭有限公司

Stirring device capable of rapidly stirring silt for sediment stirrer

The invention discloses a stirring device capable of rapidly stirring silt for a sediment stirrer. The stirring device comprises a support. The support is fixedly mounted on the sediment stirrer; a stirring drive device is arranged on the support; a stirring device is arranged below the stirring drive device; a controller is arranged on an outer surface of the support; and a power output of the controller is electrically connected to a rotary motor. The stirring device capable of rapidly stirring silt for the sediment stirrer has the advantages of simple structure and strong practicability.

Owner:徐杨广

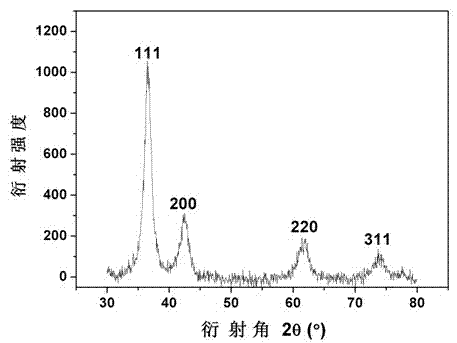

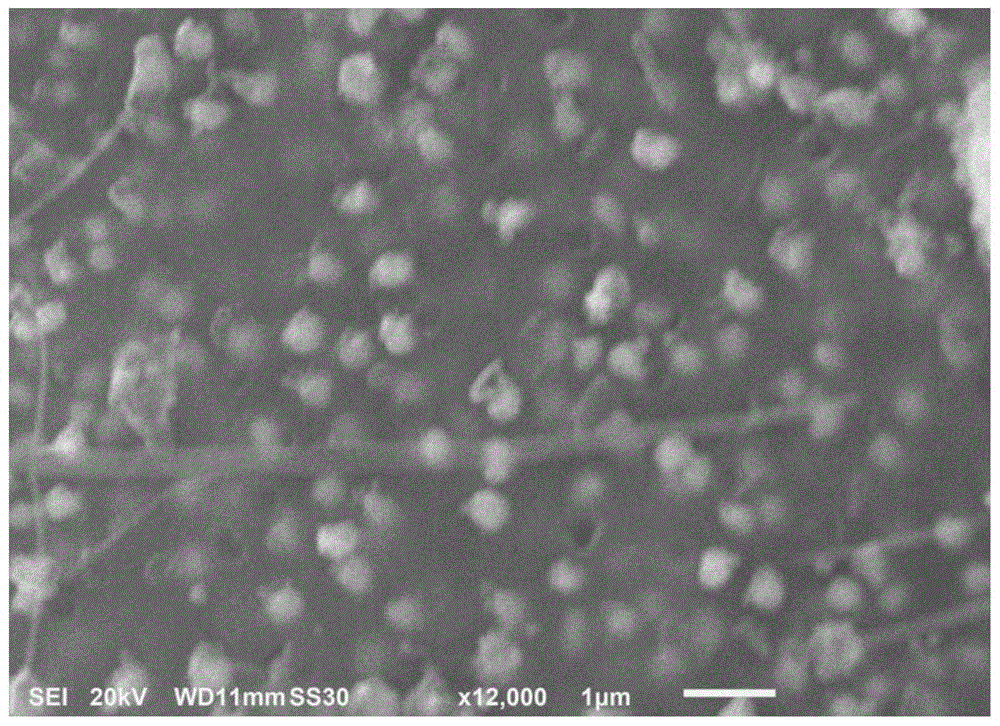

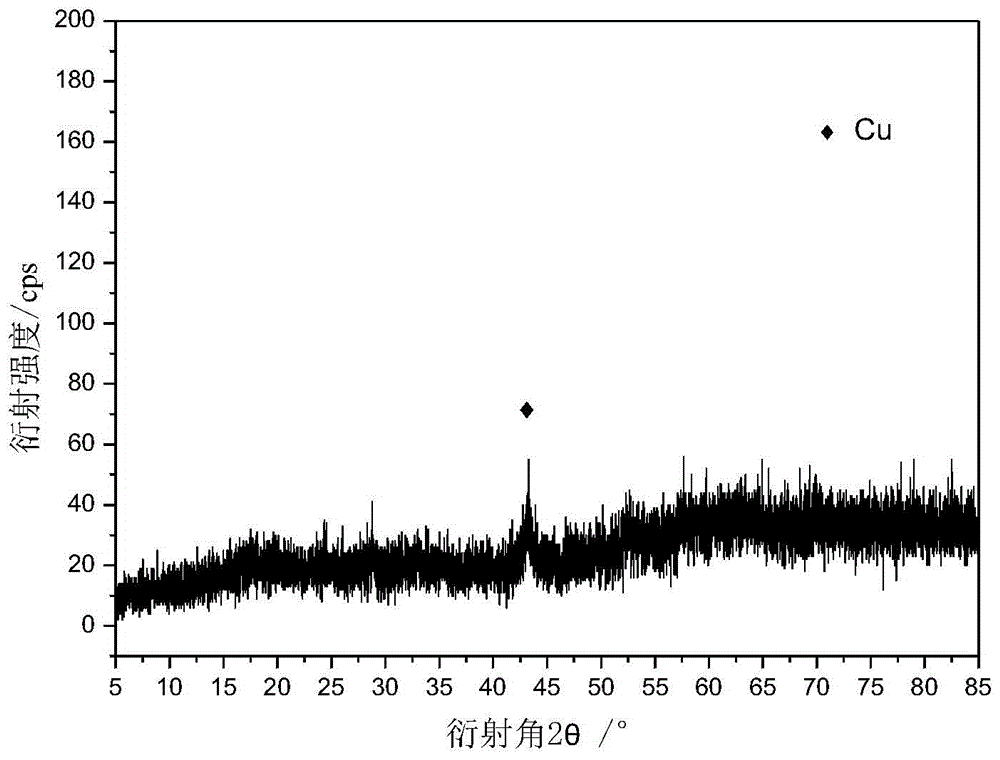

A rapid preparation method of resin-type carbon-supported copper catalyst

ActiveCN105233825BMade quicklyAdvancedMetal/metal-oxides/metal-hydroxide catalystsCopper nitrateRaw material

The invention relates to a rapid preparation method of a resin type carbon-loaded copper catalyst. The rapid preparation method aims at overcoming the defects existing in preparation of a resin type carbon-loaded copper catalyst. The rapid preparation method includes the steps that resin and copper nitrate are adopted as raw materials, and the resin type carbon-loaded copper catalyst is rapidly prepared through solution preparation, hydrochloric acid steeping, ultrasonic treatment, precursor preparation and gas shielded sintering. The preparation method is advanced in process, accurate and abundant in data, high in preparation speed and low in cost, the product is black powder, the powder particle diameter is smaller than or equal to 100 nm, the purity of the product reaches 99.5%, the reaction activity is high, the catalytic performance reaches 99.99%, and the method is an advanced method for rapidly preparing the resin type carbon-loaded copper catalyst.

Owner:TAIYUAN UNIV OF TECH

Shredded potato chip grater

The invention discloses a shredded potato chip grater which structurally comprises a bottom plate and a plurality of grating knives. The bottom plate is of a rectangular block-shaped structure, and a plurality of through holes are formed in the bottom plate and are of rectangular square through hole structures; the multiple through holes are uniformly formed in the bottom plate; the through holes are perforated through the upper surface and the lower surface of the bottom plate; the grating knives are mounted in the through holes, are in the shapes of semi-opening wedges and are internally of hollow structures, and sharp knife edge structures are arranged at openings in the upper ends of the grating knives; the arrangement directions of the multiple grating knives are consistent with one another. The shredded potato chip grater has the advantage that block-shaped potato blocks can be quickly grated to obtain shredded potato chips.

Owner:冉宏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com