Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216results about How to "Distribute stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-healing polymer material and preparation method thereof

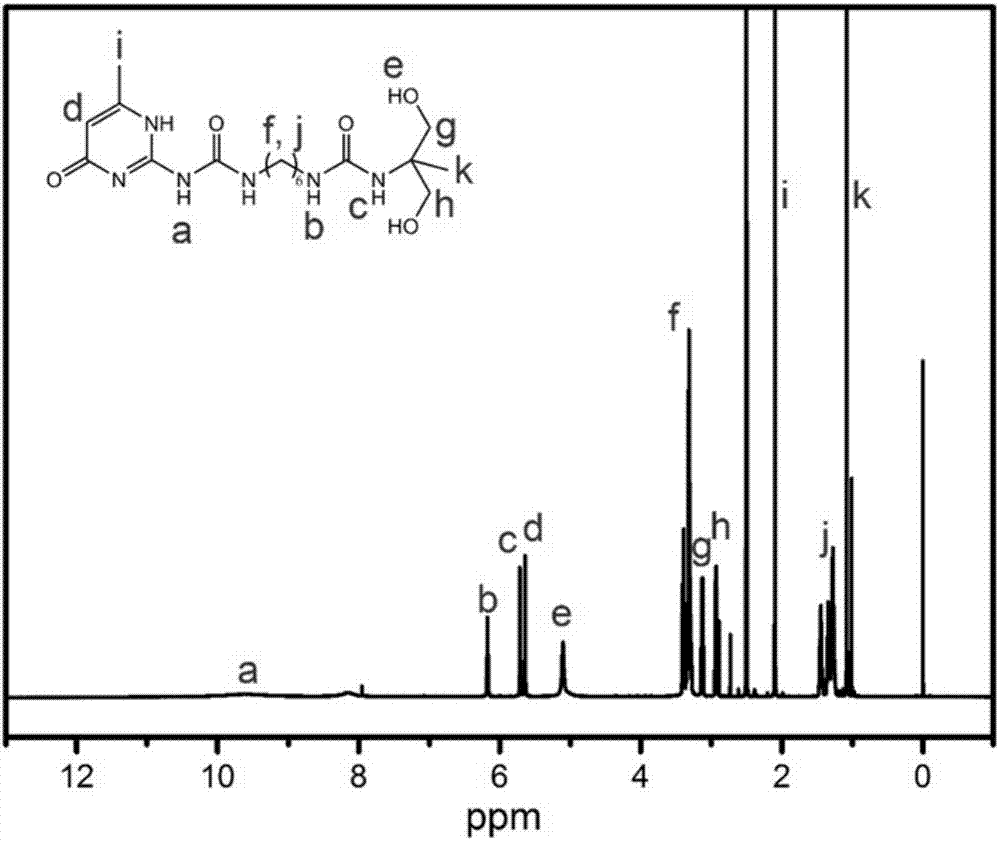

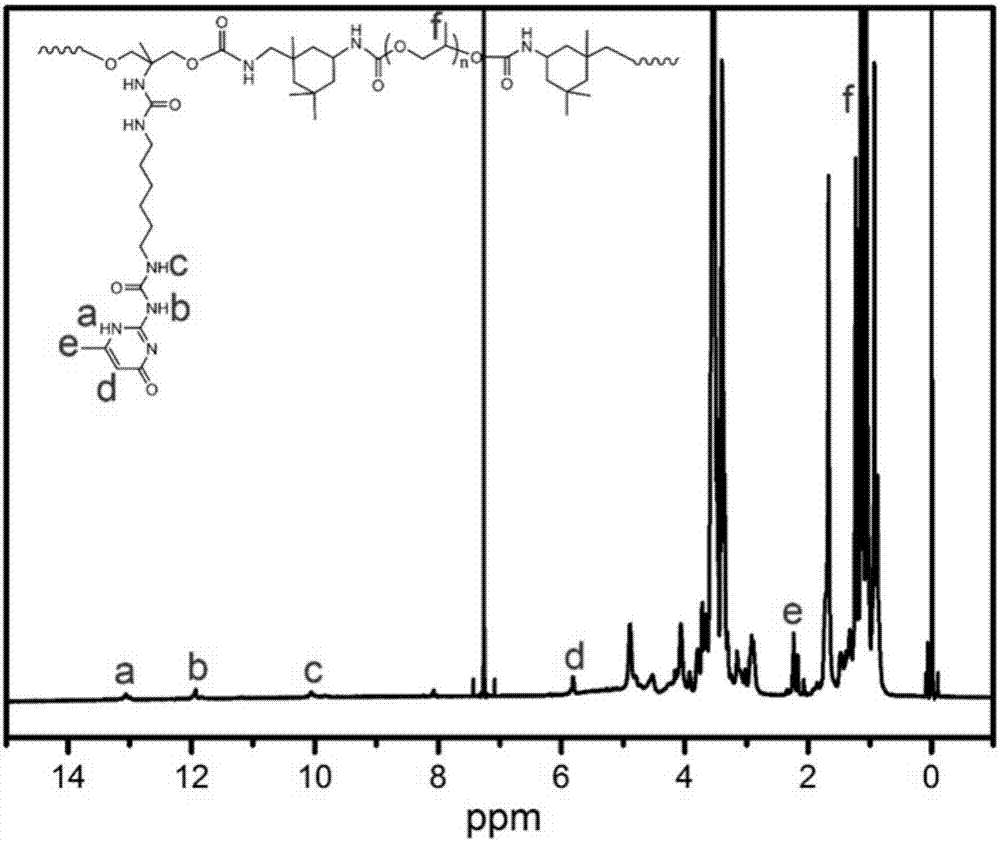

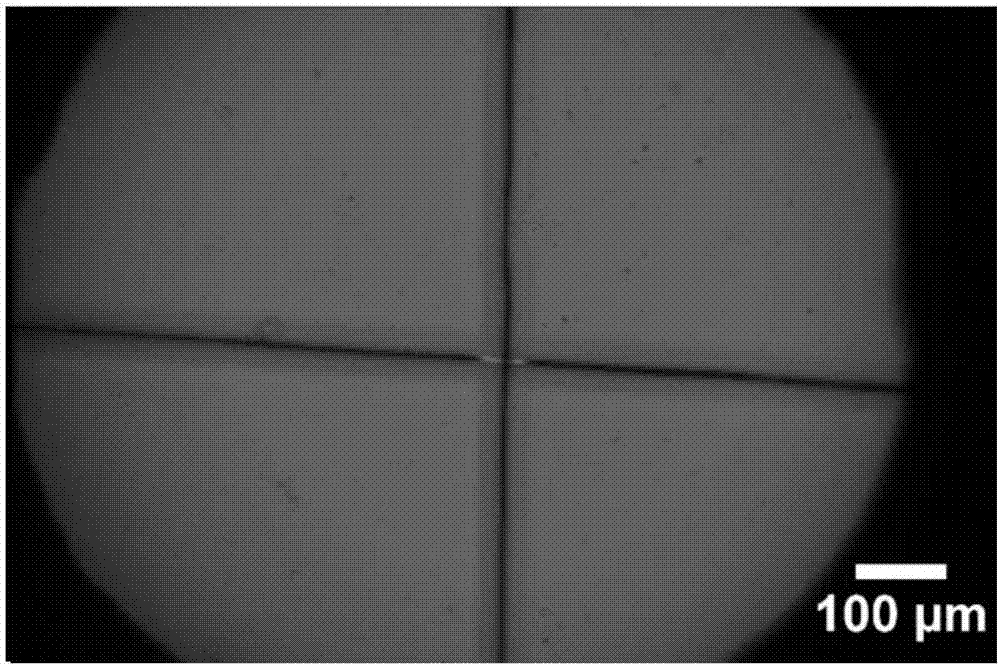

The invention discloses a self-healing polymer material and a preparation method thereof. The self-healing polymer material comprises at least one polyurethane polymer prepared by random copolymerization reaction of a low polymer dihydric alcohol, a chain extender and a first diisocyanate, wherein the chain extender comprises at least one multiple hydrogen bond chain extender. The invention further provides a preparation method of the self-healing polymer material. The method comprises the following steps: preparing a ureido pyrimidone type end-capping reagent or chain extender, and preparing the low-temperature rapid self-healing polymer material containing quadruple hydrogen bond groups on side chains and end groups by utilizing the random copolymerization reaction of the low polymer diglycol, the chain extender and the first diisocyanate. Compared with the traditional self-healing material, the self-healing material disclosed by the invention can realize repeated self-healing at the same position at a low temperature without adding a repair agent to the damaged part, and the self-healing polymer material is high in healing ability, excellent in mechanical property, excellent in material film-forming property and transparency, simple in process and low in cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

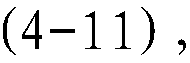

Flexible array substrate and preparation method thereof and display device

ActiveCN107634086AImprove stress uniformityReduce the chance of breakageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

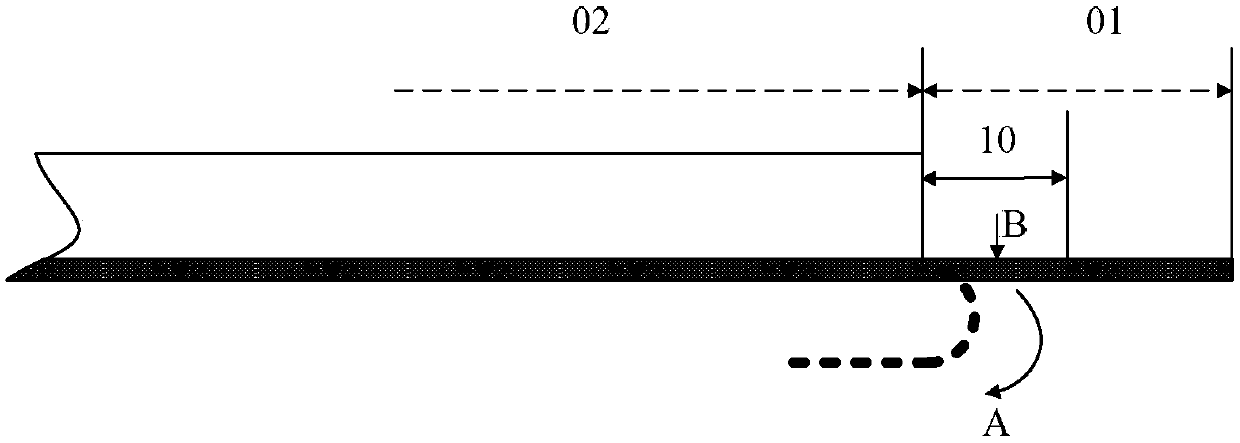

An embodiment of the invention provides a flexible array substrate and a preparation method thereof and a display device and relates to the display technical field. The probability of breakage of signal lines in a bending region due to bending can be reduced. The flexible array substrate comprises a display region and a wiring region. The wiring region comprises a bending region adjacent to the display region. The bending region comprises signal lines arranged on a substrate and a protection layer. The protection layer is arranged at one side, away from the substrate, of the signal lines; andthe orthographic projection of the protection layer on the substrate and the orthographic projection of the signal lines on the substrate have an overlapped region, and Young modulus of the protectionlayer is larger than or equal to Young modulus of the signal lines.

Owner:BOE TECH GRP CO LTD +1

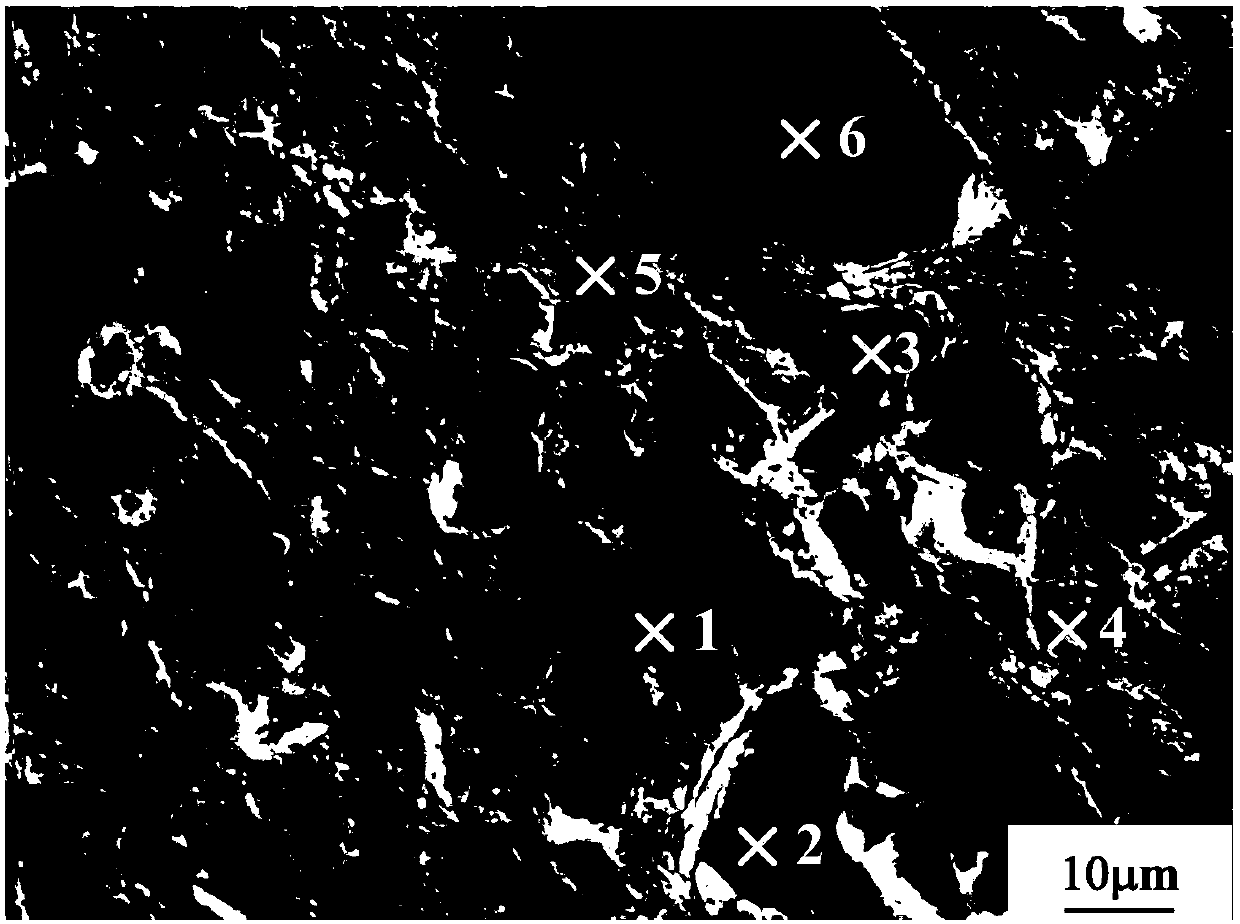

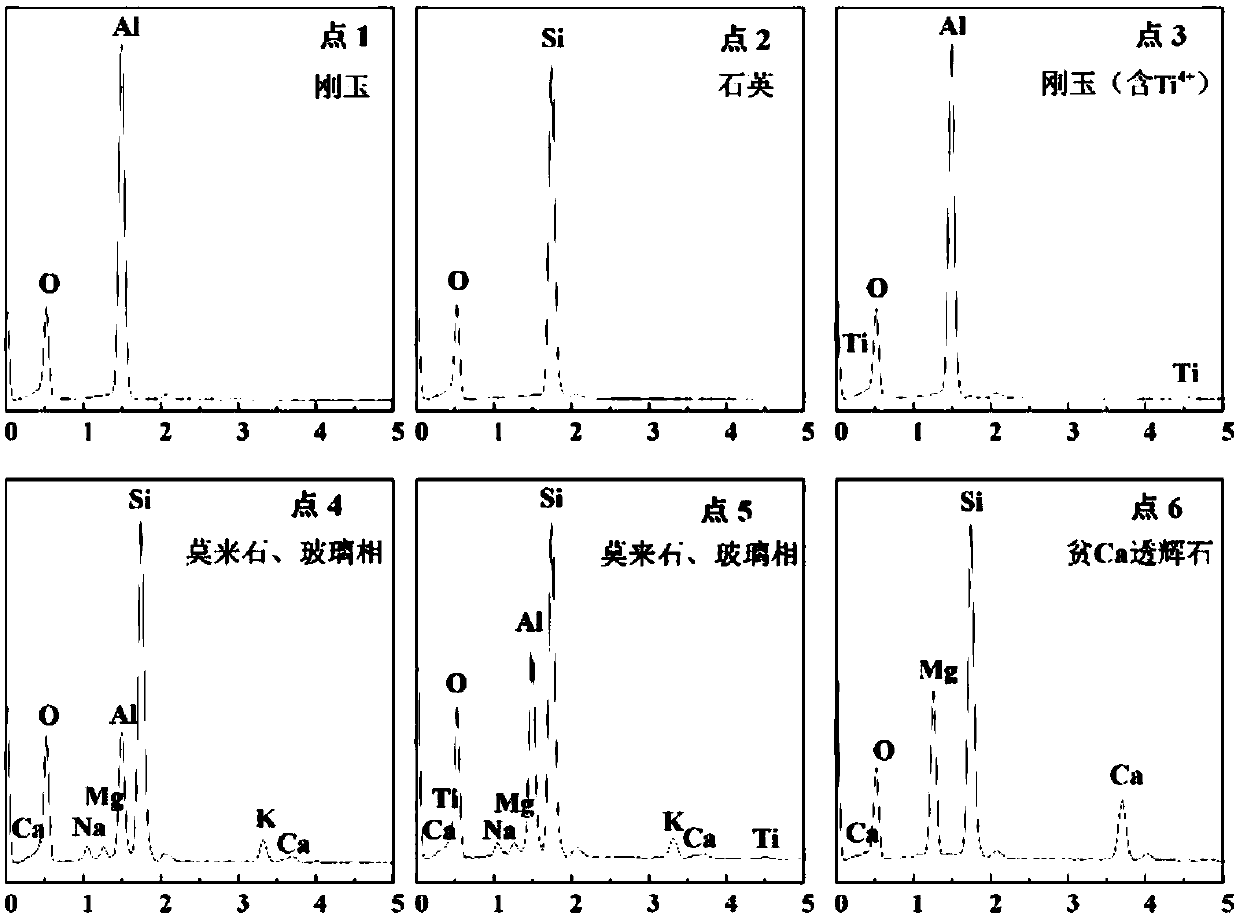

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

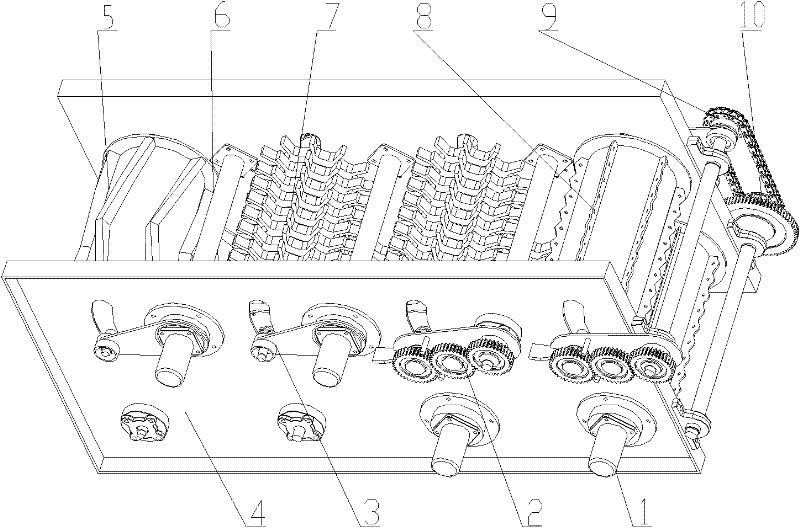

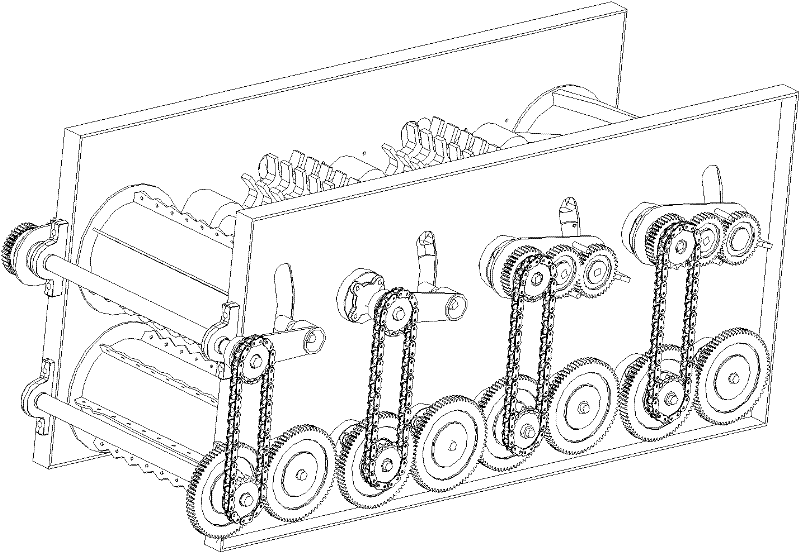

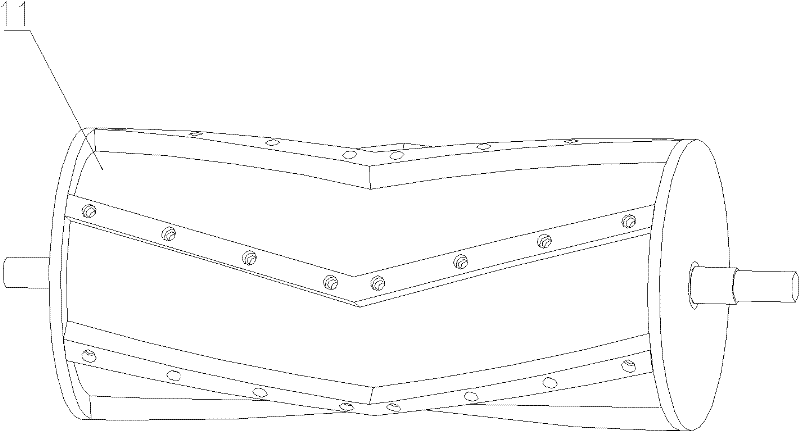

Leaf-peeling system of combine harvester of whole stalk type canes

The invention provides a leaf-peeling system of a combine harvester of whole stalk type canes. Flexible strip-shaped objects arranged according to a certain rule are arranged on the surface of a conveying roller device, and flexible leaf peeling elements and spacer bushes are evenly arranged on the surface of a leaf peeling roller device at intervals, so as to realize the uniform conveying and leaf peeling operation of canes in batches, thus the leaf peeling dirt percentage and the broken rate of cane stems can be effectively lowered, and the dispersing and conveying effects of the cane stems are enhanced; and in addition, as the flexible strip-shaped objects arranged on the surface of the conveying roller device, and the flexible leaf peeling elements of the leaf peeling roller device are made of elastic materials, and are in flexible contact with the cane in the leaf peeling process, the collision damage rate of the cane can be reduced.

Owner:SOUTH CHINA AGRI UNIV

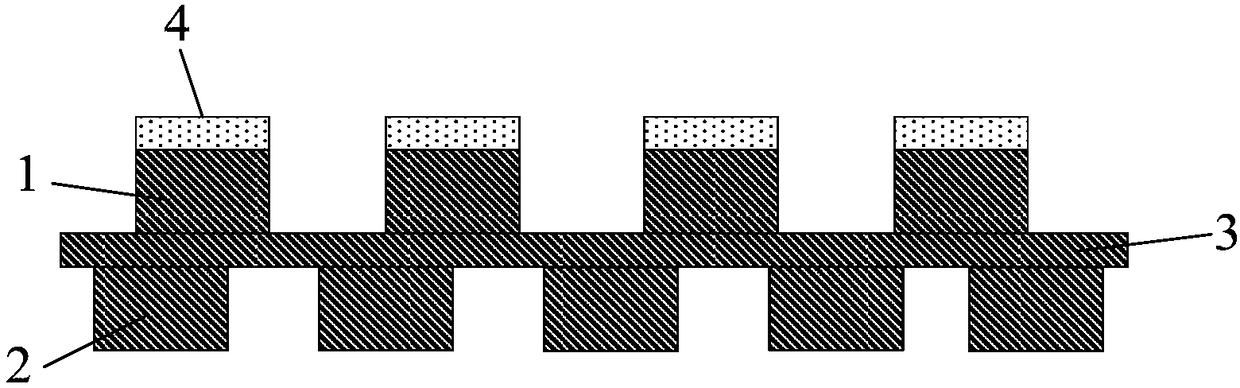

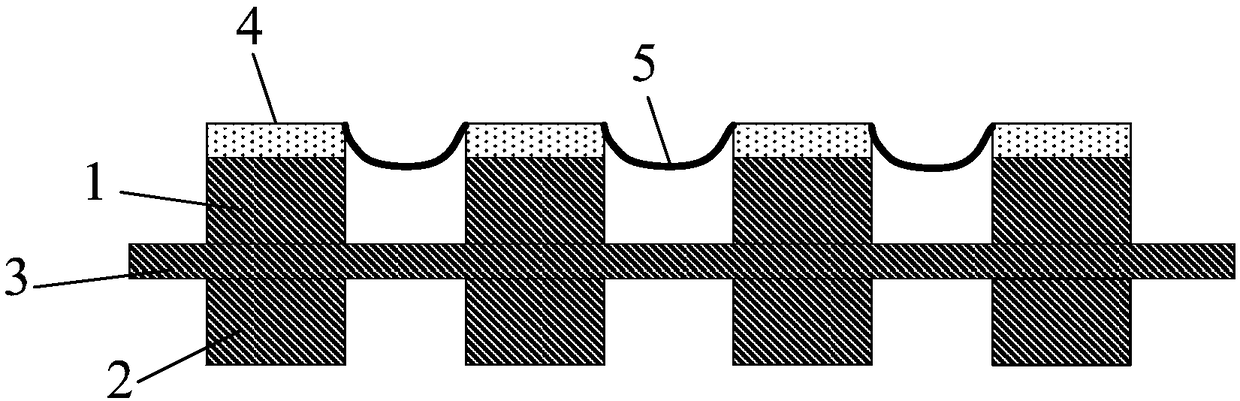

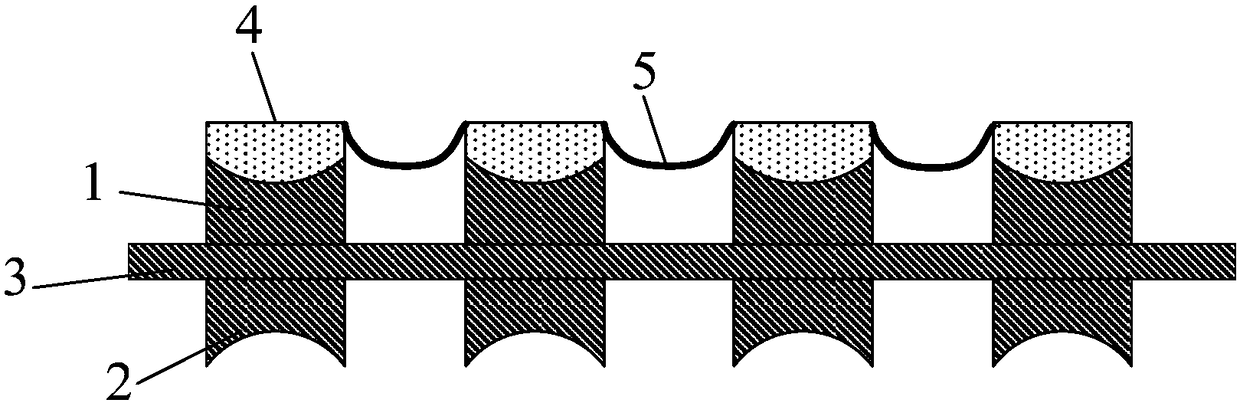

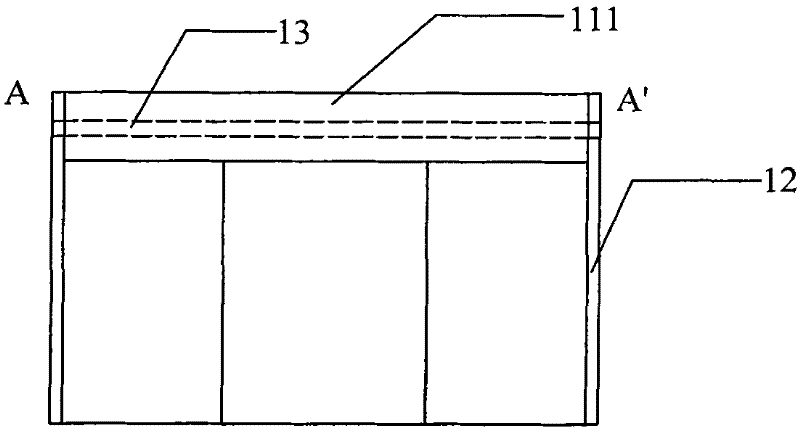

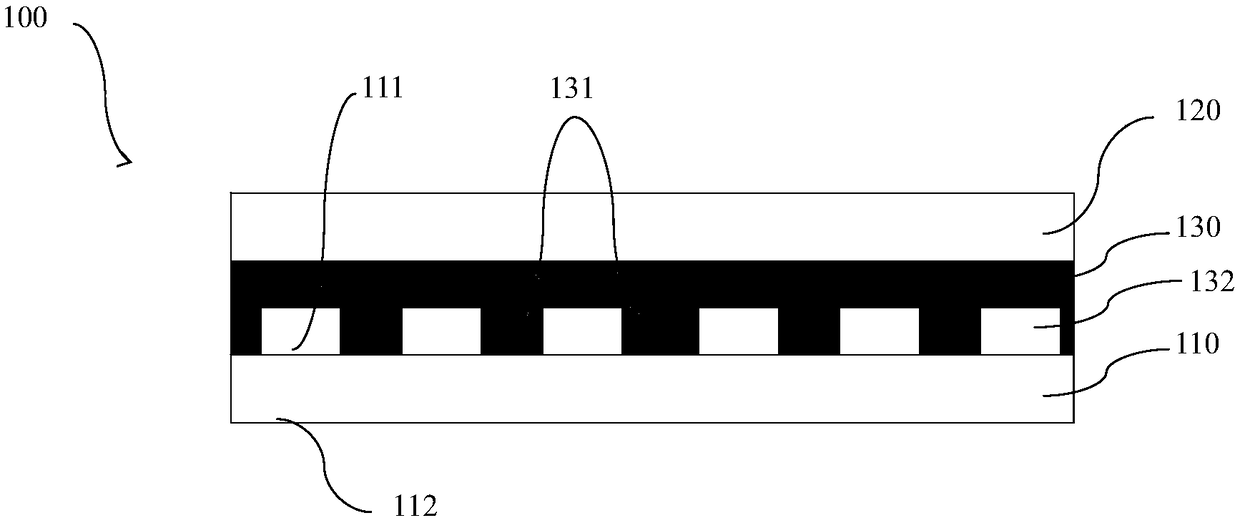

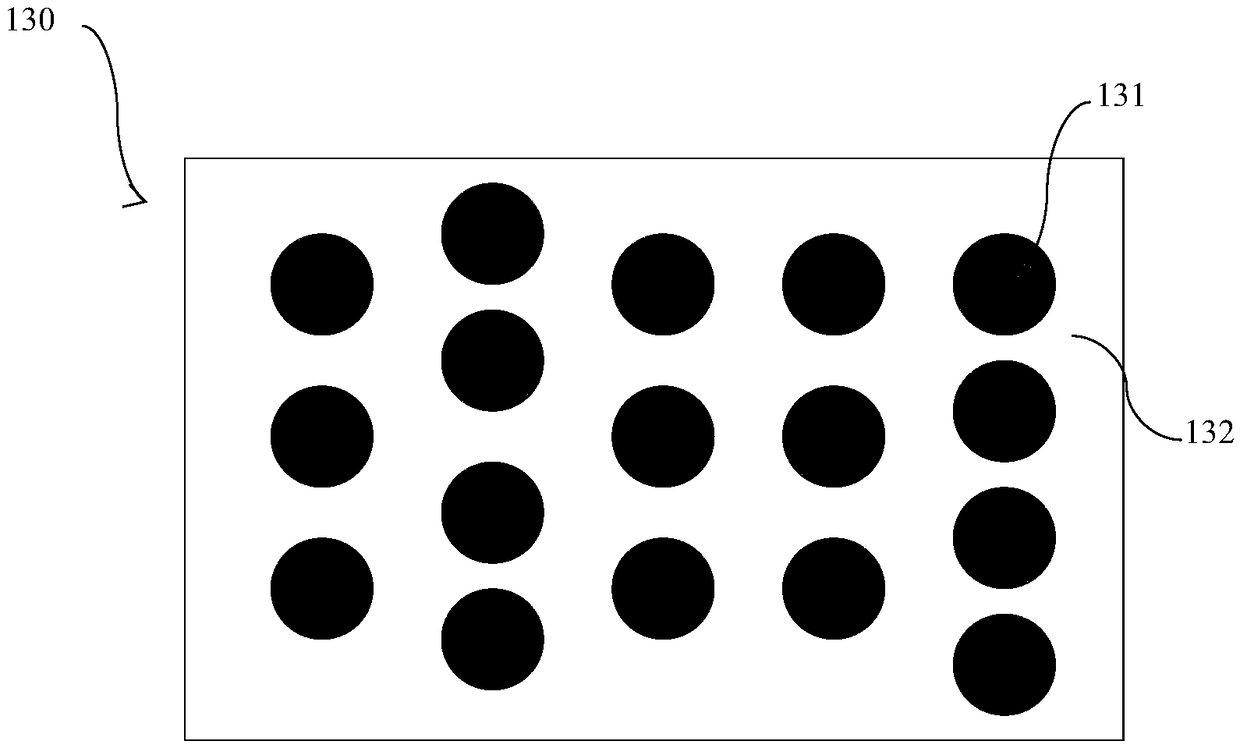

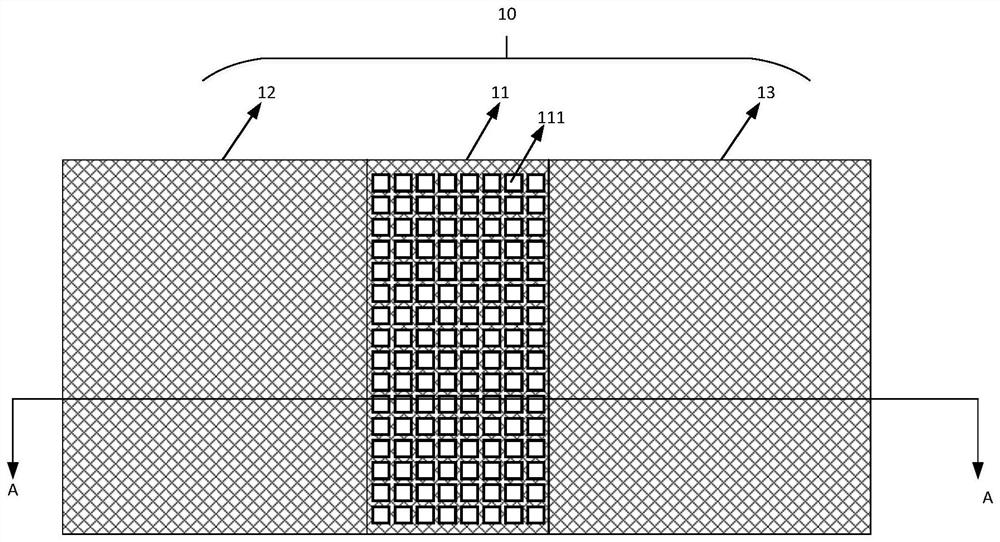

Elastically deformable display substrate, preparation method thereof and display device

InactiveCN108269501AEnhance resilienceImprove tensile propertiesIdentification meansDisplay deviceInterconnection

The invention provides an elastically deformable display substrate, a preparation method thereof and a display device, belongs to the technical field of flexible display and can solve the problem thatthe normal display is influenced by the fact that conventional display devices extend and deform to a certain degree with stretching of the substrates. A plurality of first bulges on the first side of a deformable layer of the display substrate and display devices on the first bulges can also be called an interconnection island structure, and second bulges are further arranged on a second side ofthe deformable layer and used for relieving and dispersing stress of the first bulges on the deformable layer. Therefore, normal display affected by damage of contact surfaces between the display devices and the first bulges due to stress on the first bulges is effectively prevented, that is, the display devices can display normally whether in the stressed stretching state, the unstressed state or the deformation restored state by means of the second bulges. The display substrate is suitable for various display devices.

Owner:BOE TECH GRP CO LTD

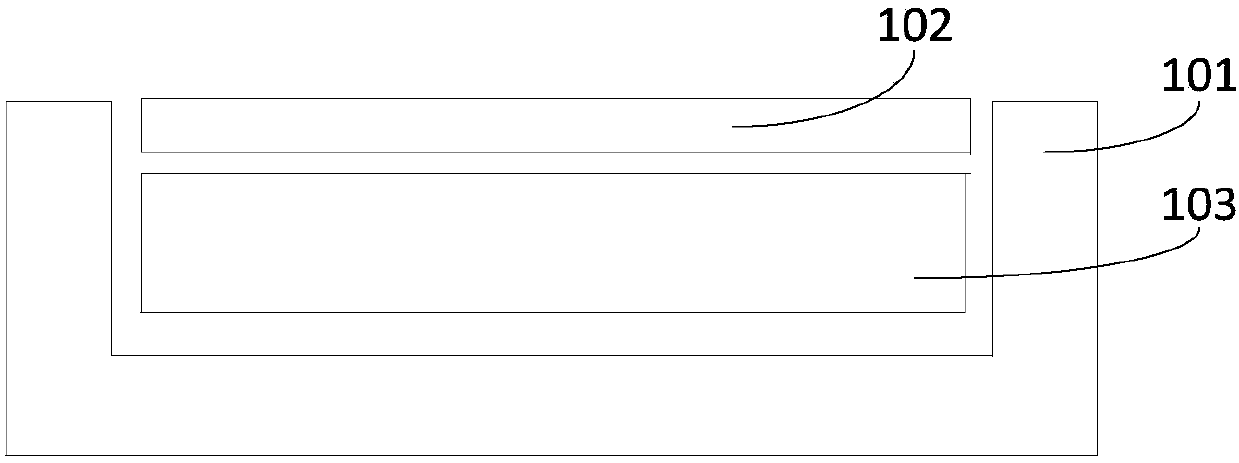

Flexible display module and preparation method thereof

InactiveCN107871453AMeet bending needsAvoid bending requirementsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayComputer science

The embodiment of the invention provides a flexible display module and a preparation method thereof. The problem that an existing flexible display module is likely to lose efficacy after being bent issolved. The flexible display module comprises a flexible glass layer and a display panel arranged in the flexible glass layer.

Owner:YUNGU GUAN TECH CO LTD

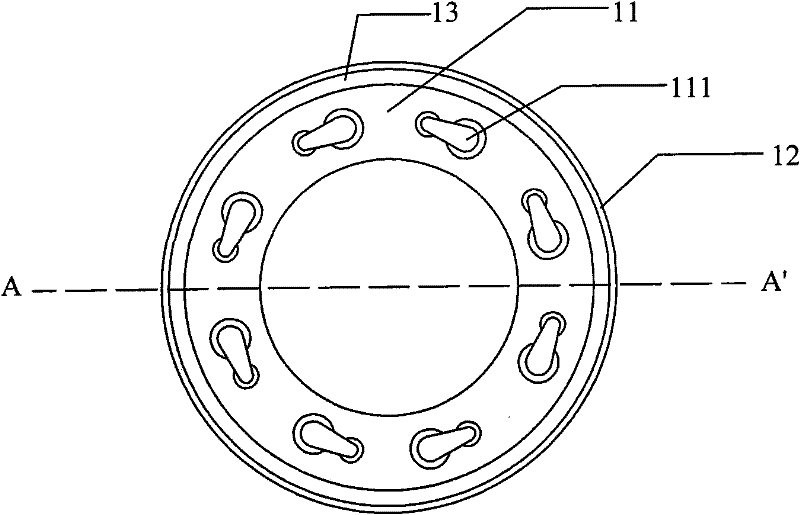

Method for strengthening and repairing tubular pile head

The invention provides a method for strengthening and repairing a tubular pile head. The method comprises the following steps: cleaning broken and loose concrete, exposing main reinforcement for 3 to 4cm, regulating the main reinforcement to ensure that the main reinforcement is vertical to the ground; sawing off the broken pile head, and flat sawing the pile head; washing float ash and dust on the surface of the concrete, drying the concrete, and covering a pile cap with the same specification on the pile head; connecting the exposed main reinforcement with the pile cap, and placing a pallet matched with the pile cap in an inner cavity of the tubular pile; connecting the pallet with the pile cap; and finally, filling epoxy resin concrete in a cavity formed by the pallet, an annular end plate and the inner wall of the tubular pile, and continuously connecting the epoxy resin concrete with a sunk pile after curing in 4 hours. The pile cap comprises the annular end plate, wherein a cylindrical steel hoop is sleeved on the annular end plate; the surface of the annular end plate and the end surface of the cylindrical steel hoop are coplanar, and the annular end plate and the cylindrical steel hoop are connected; the annular end plate is provided with end plate screw holes; and the connection of the exposed main reinforcement and the pile cap is to weld the exposed main reinforcement onto the end plate screw holes one by one.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

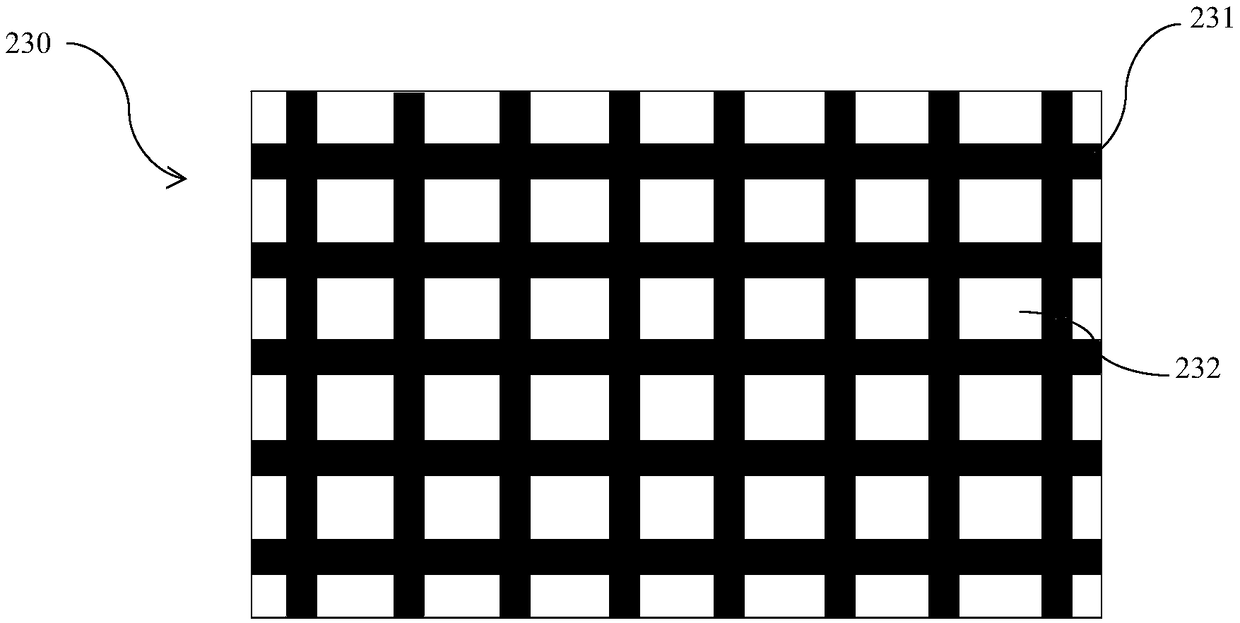

Cover plate and manufacturing method thereof, flexible display module and electronic equipment

ActiveCN109326220AImprove shear resistanceImprove chip resistanceInput/output processes for data processingIdentification meansEngineeringFlexible display

The invention provides a cover plate for a flexible screen and a manufacturing method thereof, a flexible display module and electronic equipment, wherein, the cover plate comprises: a base plate; a first cladding layer covering the first surface of the base plate; a first adhesive layer which adheres the first cladding layer with the base plate and forms a hollow structure between the base plateand the first cladding layer through at least one first bulge arranged on the first surface of the first adhesive layer. The invented cover plate effectively improves the anti-cracking intensity through the buffering action and the stress dispersing action of the bulges.

Owner:BEIJING VISIONOX TECH

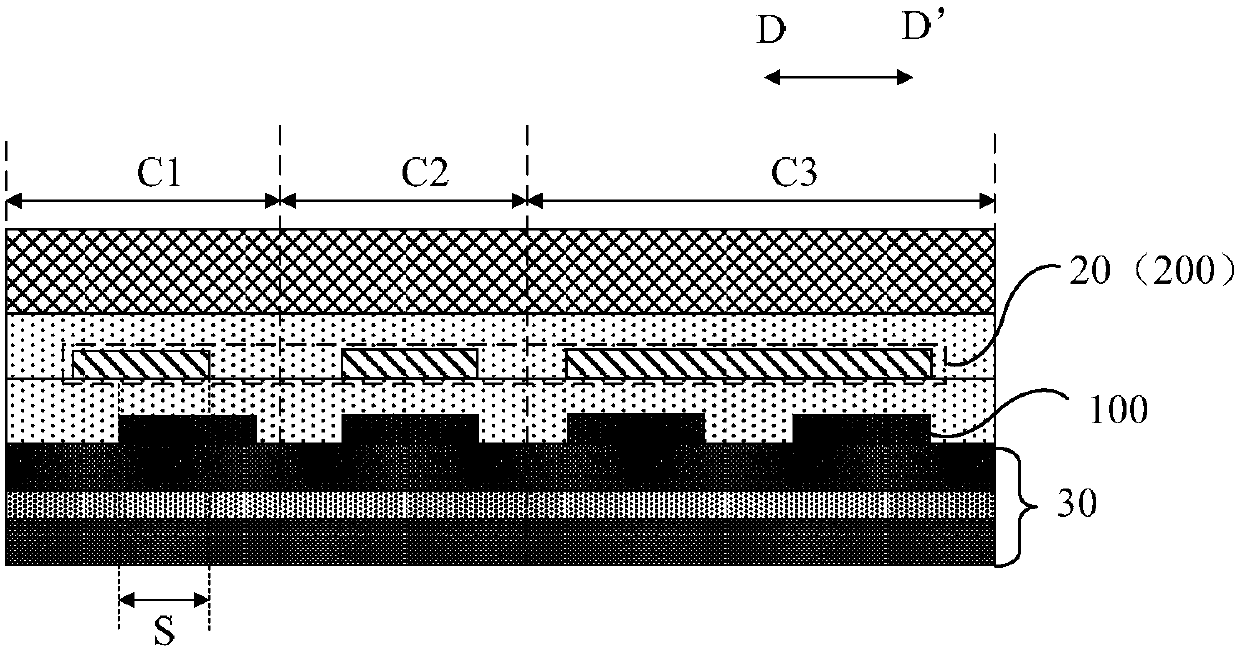

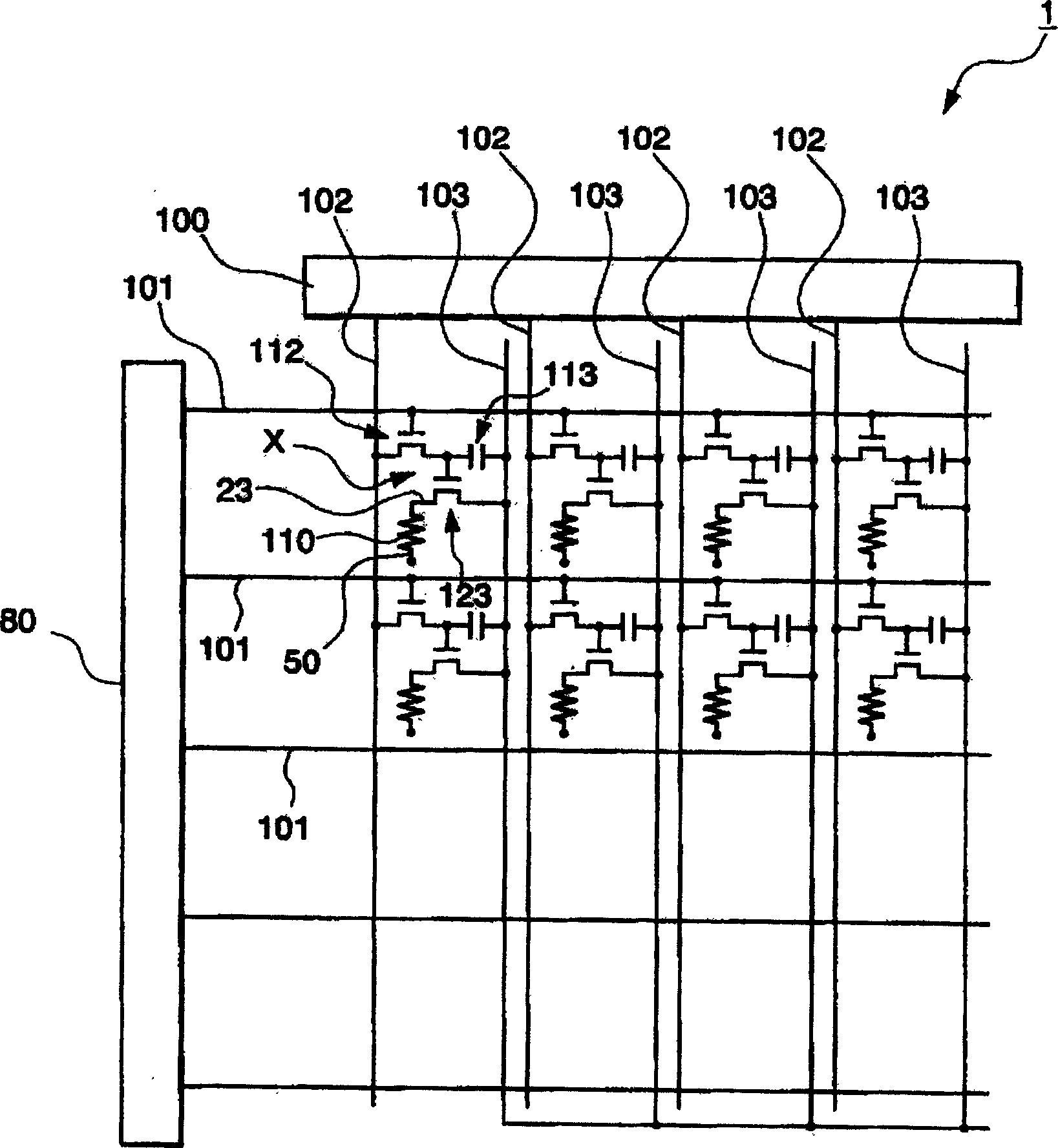

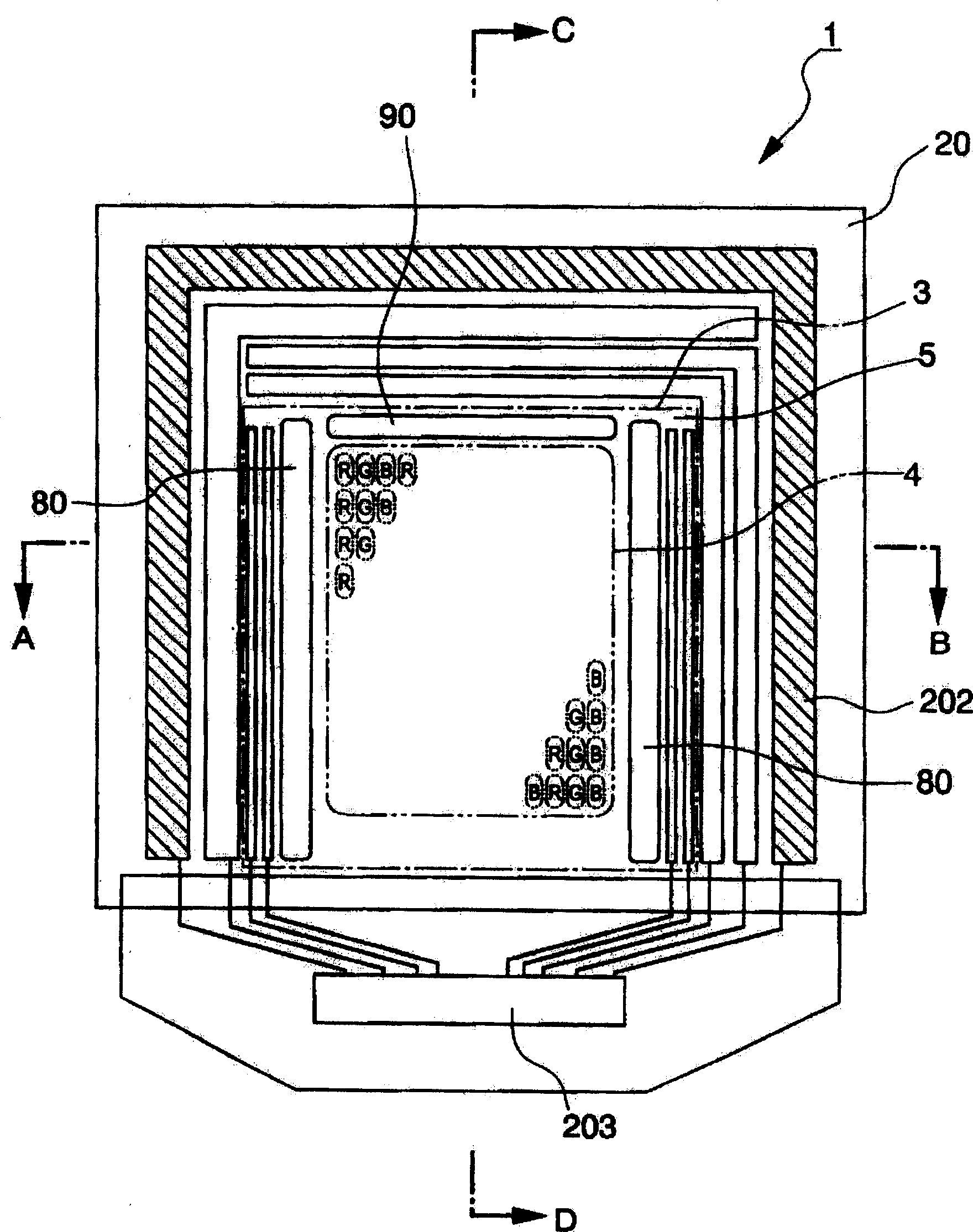

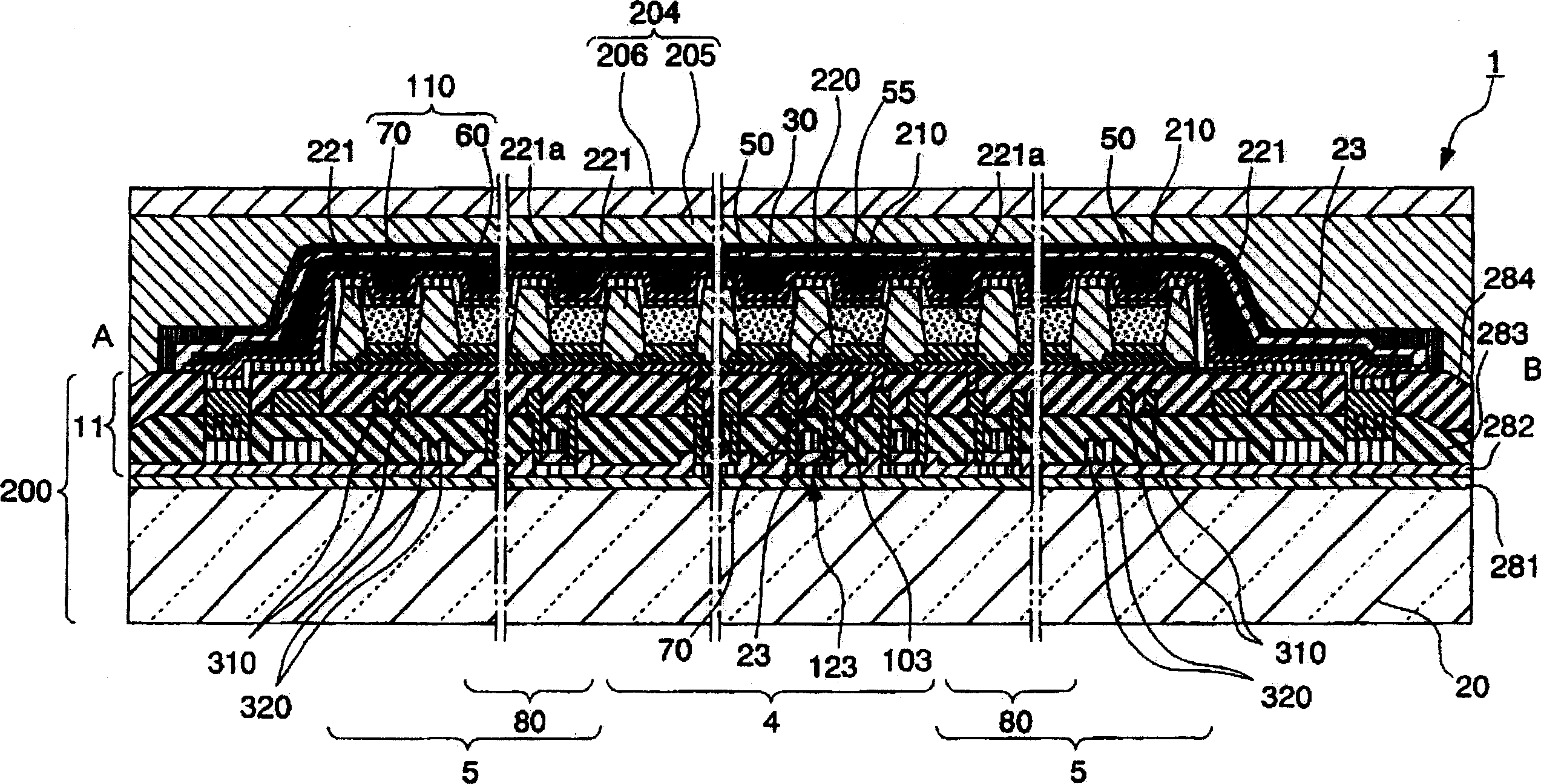

Method of manufacturing organic electroluminescent device and organic electroluminescent device

ActiveCN1764335AIncreased precision and freedomDistribute stressSemiconductor/solid-state device detailsElectroluminescent light sourcesOrganic electroluminescenceSolvent

The invention provides a method for manufacturing an organic electroluminescent device, comprising a plurality of first electrodes on a substrate (20), a light-emitting functional layer arranged correspondingly to the formation positions of the first electrodes, and a layer covering the light-emitting function. A method for manufacturing an organic electroluminescent device for a second electrode of the layer, comprising: a buffer layer forming step of forming a buffer layer (210) while covering the second electrode; and forming a buffer layer (210) covering the second electrode. The process of the gas barrier layer ( ) 30, the buffer layer forming process includes: a coating process of coating a coating material having a monomer / oligomer material and a curing agent without using a solvent under a vacuum atmosphere, and making the coating material The thermal curing process of curing to form a buffer layer. According to the method of manufacturing an organic EL device of the present invention, sufficient luminescence characteristics or luminescence lifetime can be obtained and generation of non-luminescence regions can be suppressed. The present invention also provides an organic electroluminescent device.

Owner:SEIKO EPSON CORP

Nanofiber flocculus with sandwich structure and preparation method of nanofiber flocculus

ActiveCN111485329ASmall diameterLarge diameterElectro-spinningNon-woven fabricsPolymer scienceSpinning

The invention relates to a nanofiber flocculus with a sandwich structure. The nanofiber flocculus is provided with a bottom layer, a middle layer and an upper layer with the longitudinal volume density being changed, the bottom layer and the upper layer are compact fiber layers, and the middle layer is a fluffy fiber layer; fibers, making contact with each other, in the nanofiber flocculus are crosslinked; the volume density of the compact fiber layers is 30-40 mg / cm3; the volume density of the fluffy fiber layer is 5-20 mg / cm3; and the compression resilience ratio of the nanofiber flocculus reaches 90% or above, and the CLO value is 2-4 clo. The nanofiber flocculus is prepared through an electrospinning technique, a polymer and a cross-linking agent are dissolved and dispersed in a solvent firstly, and sufficient stirring is conducted to obtain a spinning solution; and then continuous electrospinning is conducted under a specific humidity condition to obtain a composite nanofiber layer with the longitudinal volume density being changed, the composite nanofiber layer is subjected to crosslinking heat treatment, and the nanofiber flocculus is obtained.

Owner:DONGHUA UNIV

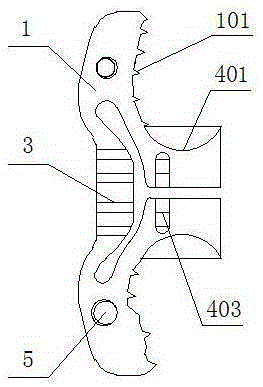

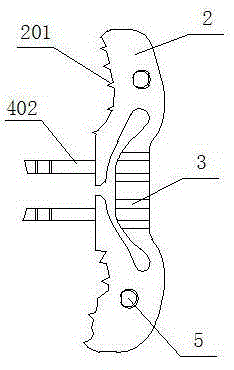

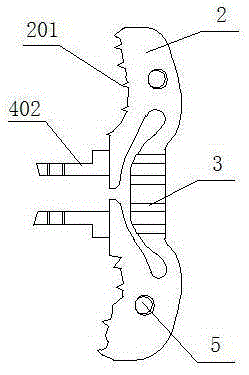

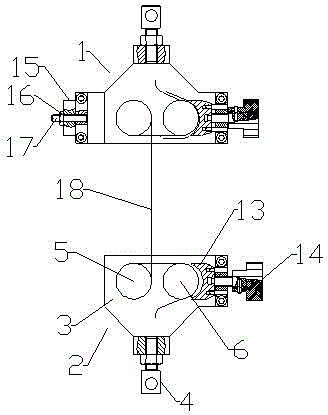

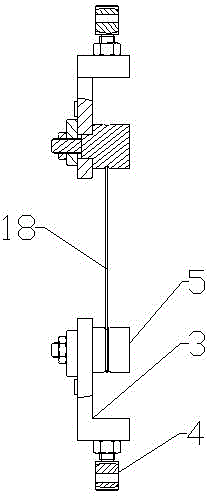

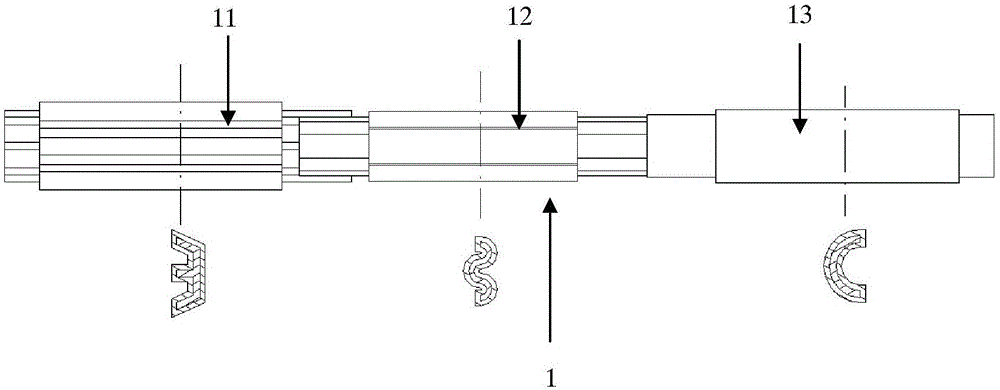

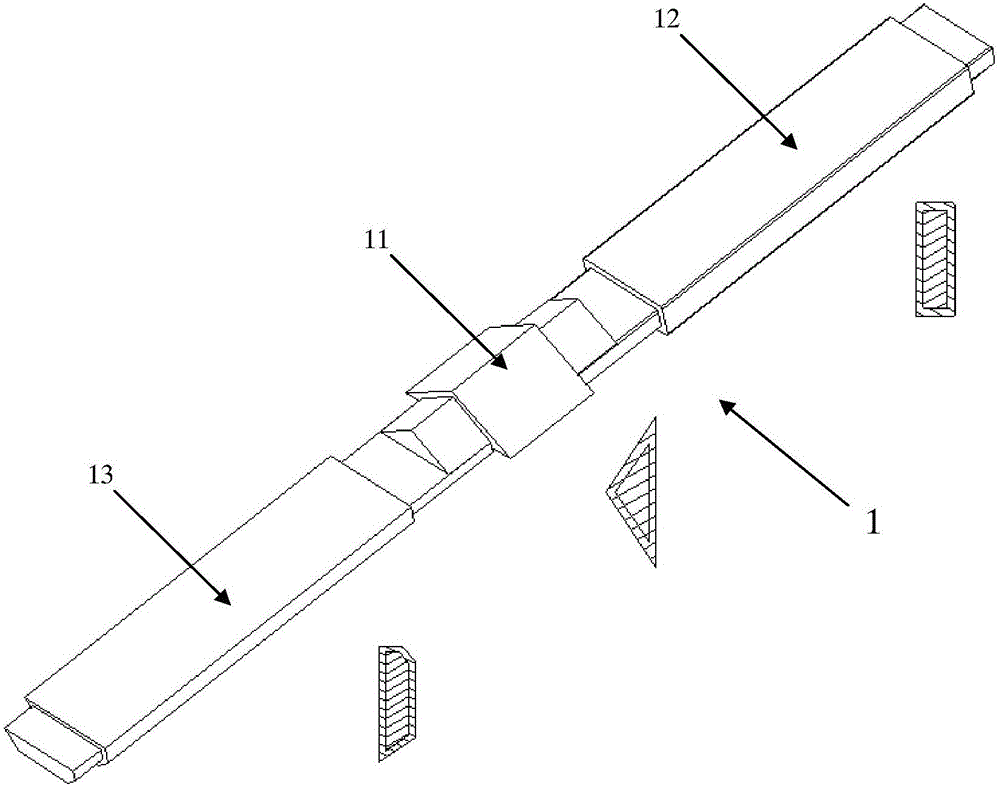

Stabilizer used between spine plates

ActiveCN105193524ASimple structureDistribute stressSpinal implantsLumbosacral angleBiomedical engineering

The invention relates to a stabilizer used between spine plates, and belongs to the technical field of medical instruments, particularly, human insertions. The stabilizer comprises an opening fixing plate, a buckle fixing plate and elastic structures, wherein the elastic structures are respectively arranged at the middle parts of the opening fixing plate and the buckle fixing plate; the opening fixing plate and the buckle fixing plate are connected through a clamping device, and are further fixed through movable inserting plates; the elastic structures comprise U-shaped structures and torsion structures. The stabilizer can realize elastic stability of stretching, bending, side bending and rotating of spine operation sections as well as dynamic stability of circumduction formed by multidirectional activity synthetic action, has the characteristics of being disperse in stress, convenient to implant and strong in matching ability with spinous process thickness and spine interval, and can be used for cases with oversize lumbosacral angles, over short spinous processes or undersize spine intervals; the problem that in the conventional various fixture techniques applied to the dynamic spinous processes, the supraspinal ligaments need to be excised or incised, the fixing is unreliable, the activity in various directions cannot be elastically limited, the matching ability with the spinous processes is poor, and negative damage in the operation is large are solved.

Owner:BIODA DIAGNOSTICS WUHAN

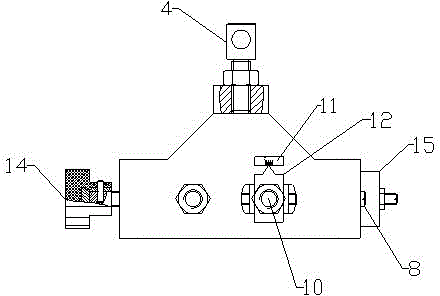

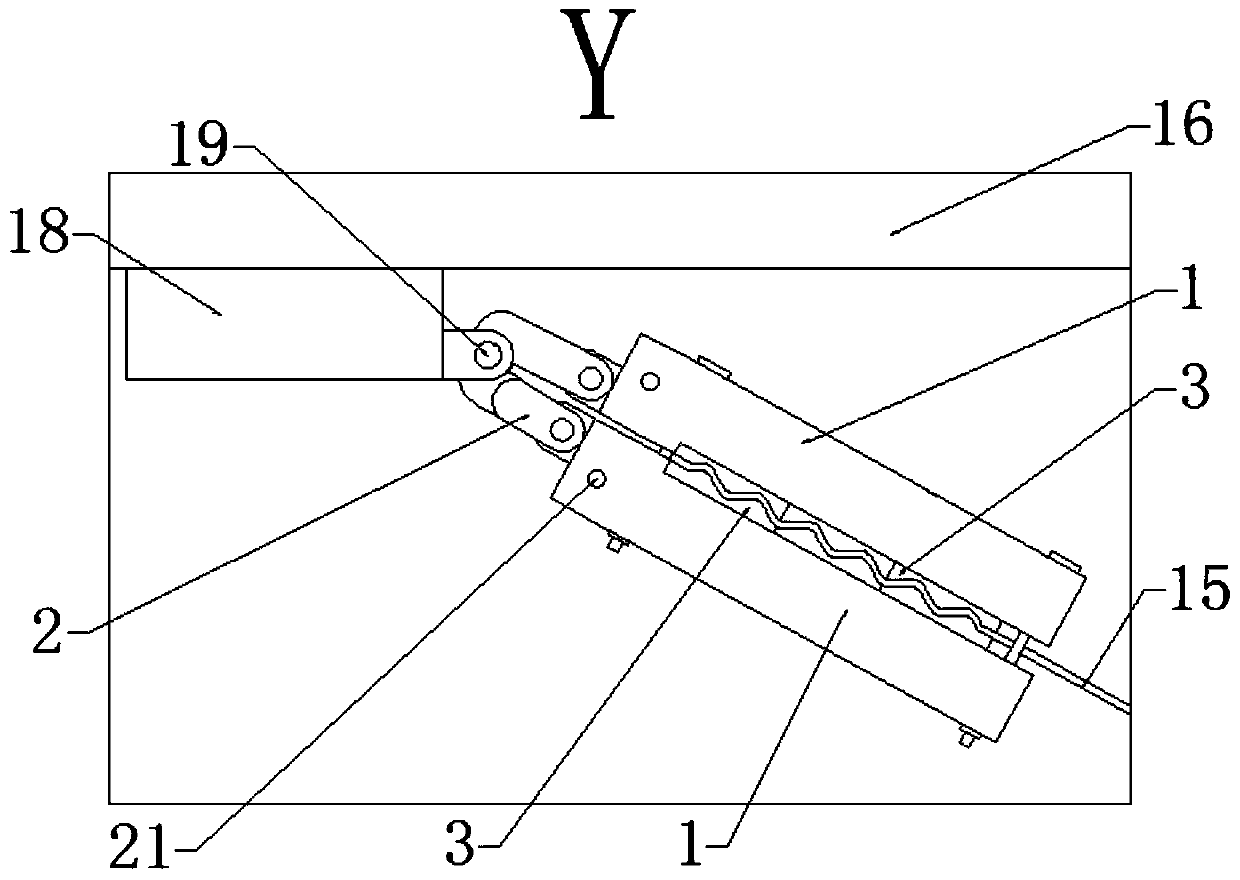

Coaxiality-adjustable winding type tensile fixture

Owner:JINAN RUISHENG MACHINERY

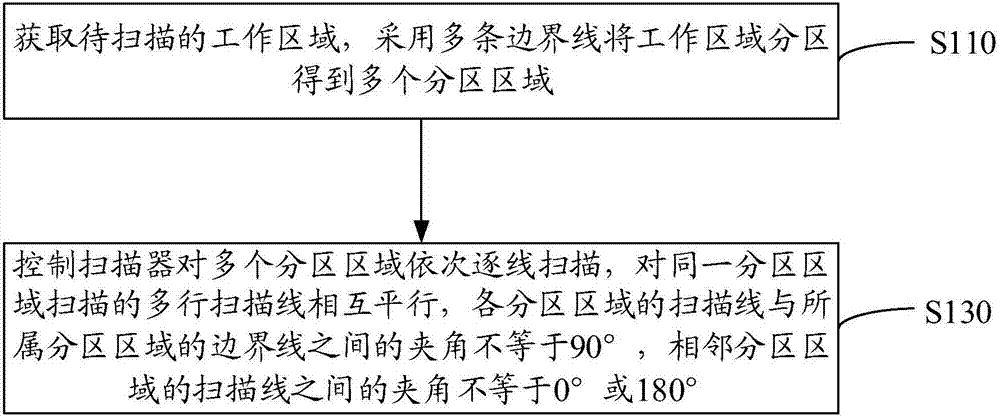

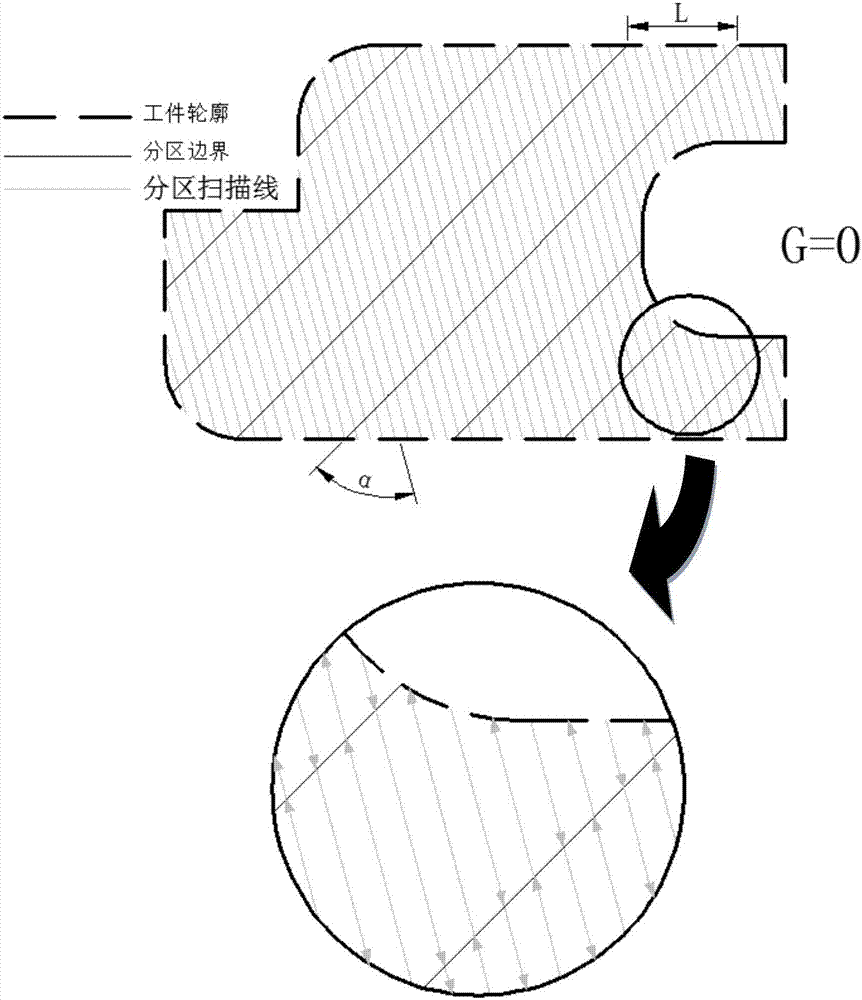

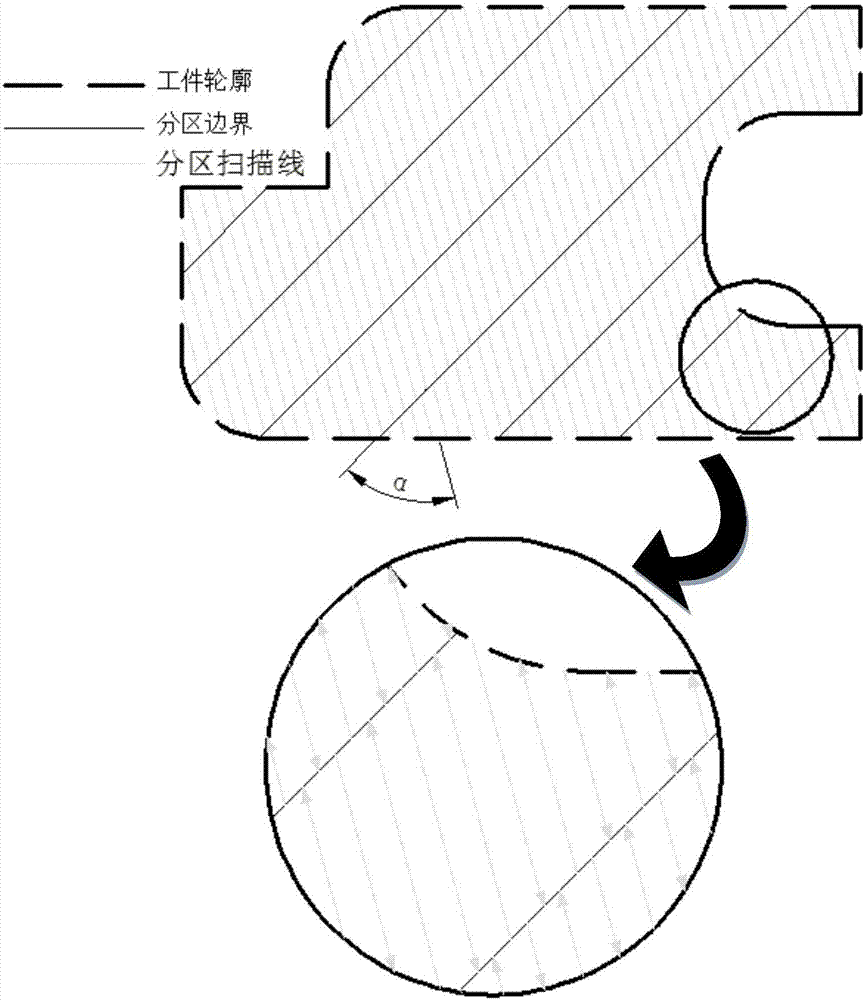

Laser scanning method, readable storage medium and laser scanning control device

ActiveCN107953552ADistribute stressGood scan effectAdditive manufacturing apparatusAdditive manufacturing with solidsScan lineClassical mechanics

The invention relates to a laser scanning method, a readable storage medium and a laser scanning control device. The laser scanning method comprises the steps that a work area to be scanned is acquired, and a plurality of boundary lines are applied to partition the work area into a plurality of partition areas; a control scanner is used to sequentially scans line by line for the multiple partitionareas, wherein, a plurality of scanning lines scanning the same one of the partition areas are parallel to each other; and included angles between the scanning lines of each of the partition areas and the boundary lines of the partition areas are not equal to 90 degree, and the included angles between the scanning lines of each two adjacent partition areas are not equal to 0 degree or 180 degree.According to the laser scanning method, the readable storage medium and the laser scanning control device, the partition scanning can be realized to enable the stress generated by the laser scanningto be more dispersed, so that the problems of the buckling deformation or the cracking of the scanned workpiece are not prone to be caused, and the scanning effect is good.

Owner:HUNAN FARSOON HIGH TECH CO LTD

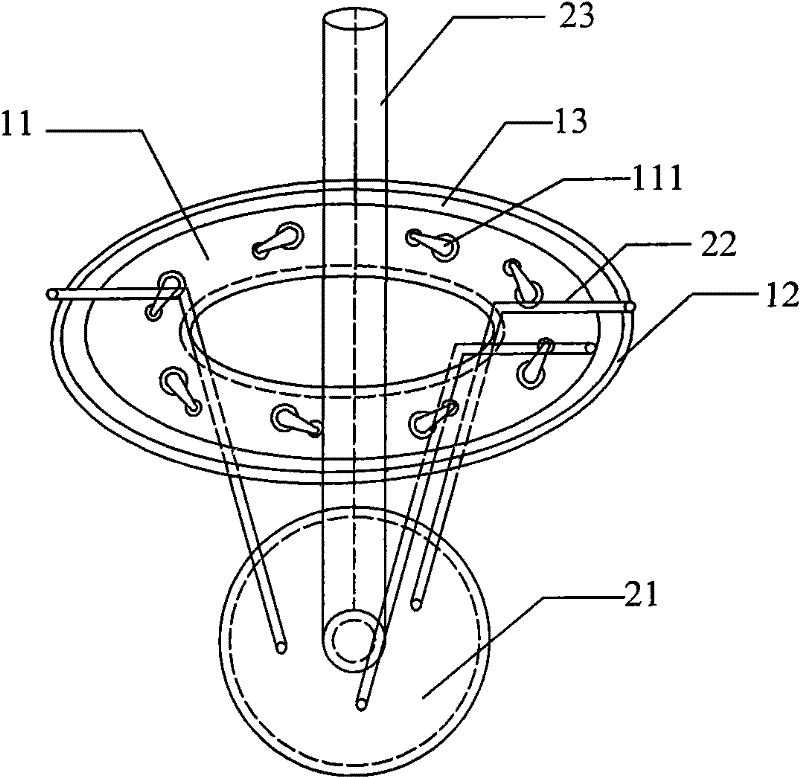

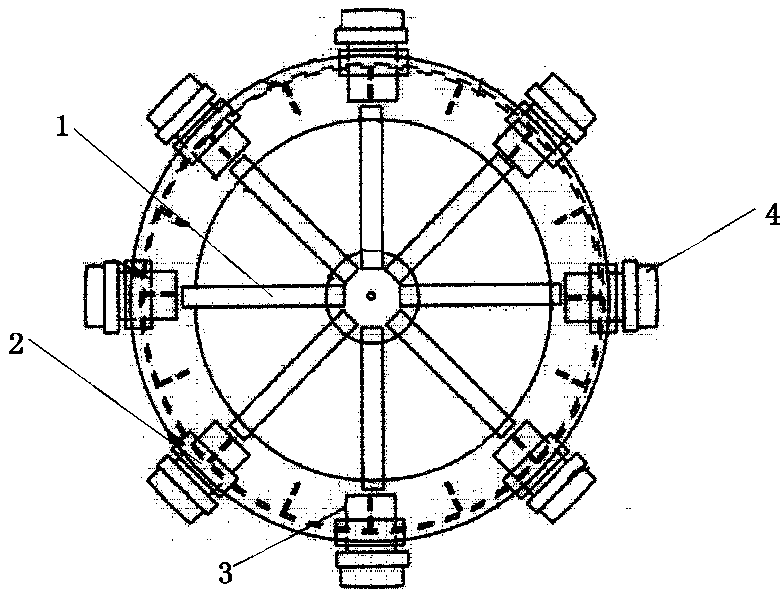

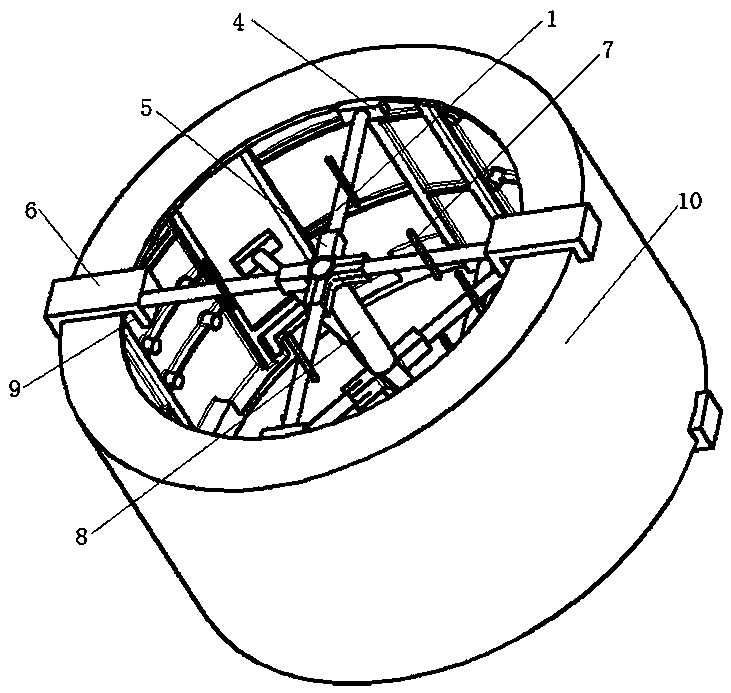

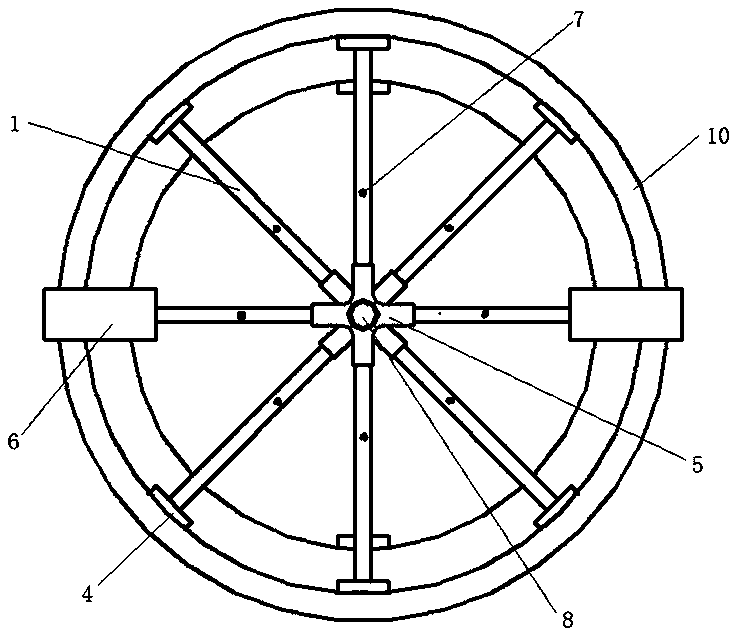

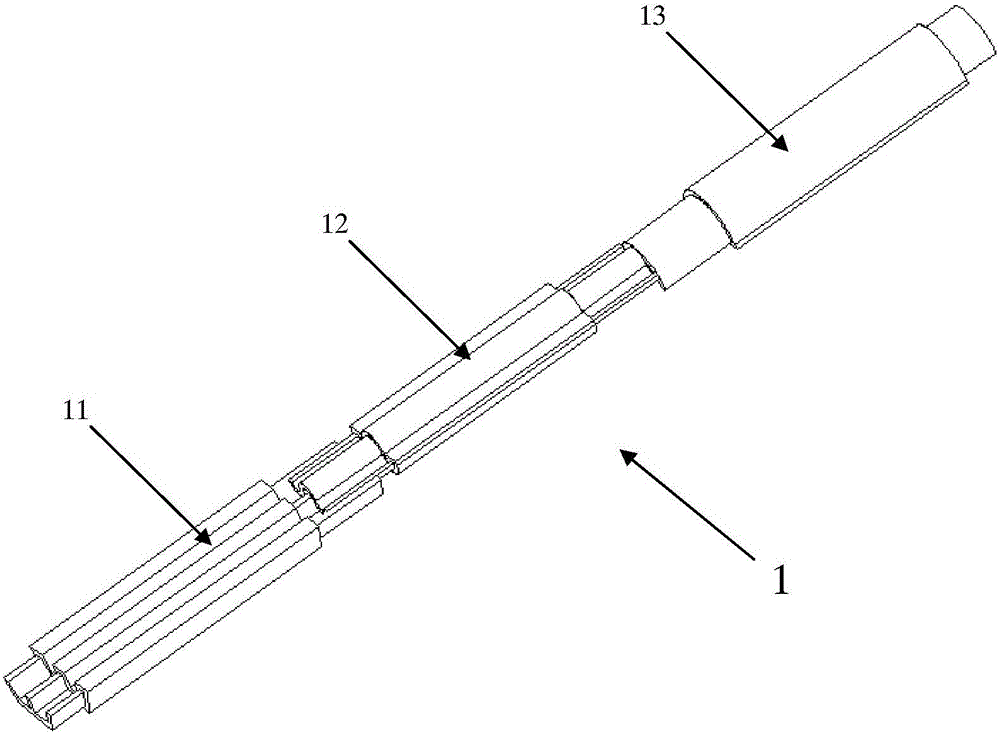

Correcting method for roundness of casting and correcting tool adopting same

PendingCN107617654AImprove the correction effectDistribute stressShaping toolsCorrection methodMaterials science

The invention relates to a correcting method for the roundness of a casting and a correcting tool adopting the same. The correcting method for the roundness of the casting comprises the following steps that firstly, the roundness of the casting is measured, the deformation amount and deformation position of the casting are determined; secondly, the casting is preheated with the temperature being smaller than the aging temperature through a heating device; thirdly, the correcting tool for the roundness of the casting clamps the casting, the deformation part of the casting is adjusted to enablethe roundness of the casting to reach the required range; and fourthly, the casting and the correcting tool for the roundness of the casting are put into the heating device together and cooled to theindoor temperature along with the heating device. After the casting is subjected to low-temperature aging treatment, the deformation part of the casting is adjusted to enable the size of the casting to reach the predetermined required range, and the casting is cooled along with the heating device, so that the stress is dispersed, and the correcting effect of the roundness of the casting is good.

Owner:洛阳乾中新材料科技有限公司

Special-shaped cable and preparation method thereof

ActiveCN106653163ADoes not affect operationReduced eddy current effectDetails of conductive coresManufacturing wire harnessesAbnormal shapedConsumables

The invention discloses a special-shaped cable and a preparation method thereof. The conductive core of the special-shaped cable is composed of at least two conductive core segments in an end-to-end way, wherein the cross sections of the conductive core segments are different in shape. The conductive core segments are externally wrapped by an insulating layer. The contour of the insulating layer is fit with the conductive core segments. The cable has great bending performance and can also be greatly fit with a vehicle body so that consumables can be saved and the safety performance can be greatly enhanced. The cable is made of the aluminum or aluminum alloy conductive cores so that the vehicle body is enabled to be light-weighted, and the production cost of the motor vehicle can be reduced. The preparation method of the special-shaped cable comprises the steps of manufacturing the conductive core segments, connection of the conductive core segments and manufacturing of the insulating layer so that the production efficiency and the productivity can be effectively enhanced according to different production requirements and the production cost can be reduced.

Owner:长春捷翼汽车科技股份有限公司

Design method for unbonded prestress and steel-concrete combined reinforcement of concrete box girder

ActiveCN106120574AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningSteel jacketPre stress

The invention discloses a design method for unbonded prestress and steel-concrete combined reinforcement of a concrete box girder. The design method comprises the following steps of I, determining a combined reinforcing structure: determining the unbonded prestress and steel plate-concrete combined structure of the box girder to be reinforced wherein the combined reinforcing structure comprises a steel jacket box formed by a base steel pate, two longitudinal side steel plates and two end part plugging steel plates, and a plurality of unbonded prestressed reinforcing bars are arranged in the steel jacket box; II, determining structural parameters for reinforcing the front box girder; and III, determining structural parameters of the combined reinforcing structure in the process comprising the following steps of initializing the parameters, calculating theoretical maximum thickness of the reinforcing steel plates, determining the thickness of the reinforcing steel plates and the thickness of concrete, and determining the height of the longitudinal side steel plates and the width of the base steel plate. The method disclosed by the invention is simple in steps, reasonable in design, convenient to realize, and good in using effect, the structural parameters of the combined reinforcing structure of a bridge can be simply, conveniently and quickly determined, and the designed combined reinforcing structure of the bridge is economical and practical and good in reinforcing effect.

Owner:XIAN HIGHWAY INST

Flexible lining plate and flexible display panel

PendingCN112863349ADistribute stressExtended service lifeIdentification meansStructural engineeringMechanical engineering

The embodiment of the invention provides a flexible lining plate and a flexible display panel. The flexible lining plate comprises a bending area and supporting areas on the two sides of the bending area. A plurality of hole structures are arranged on the first surface of the bending area; wherein the orthographic projection areas of the opening of the hole structure and the bottom of the hole structure on the first surface are different. In the embodiment of the invention, the area of the orthographic projection of the opening of the hole structure and the area of the orthographic projection of the bottom of the hole structure on the first surface are different, so that the area of the cross section of the hole structure parallel to the first surface is variable, the stress borne by the bending area can be better dispersed by the hole structure, and the service life of the bending area is prolonged.

Owner:BOE TECH GRP CO LTD +1

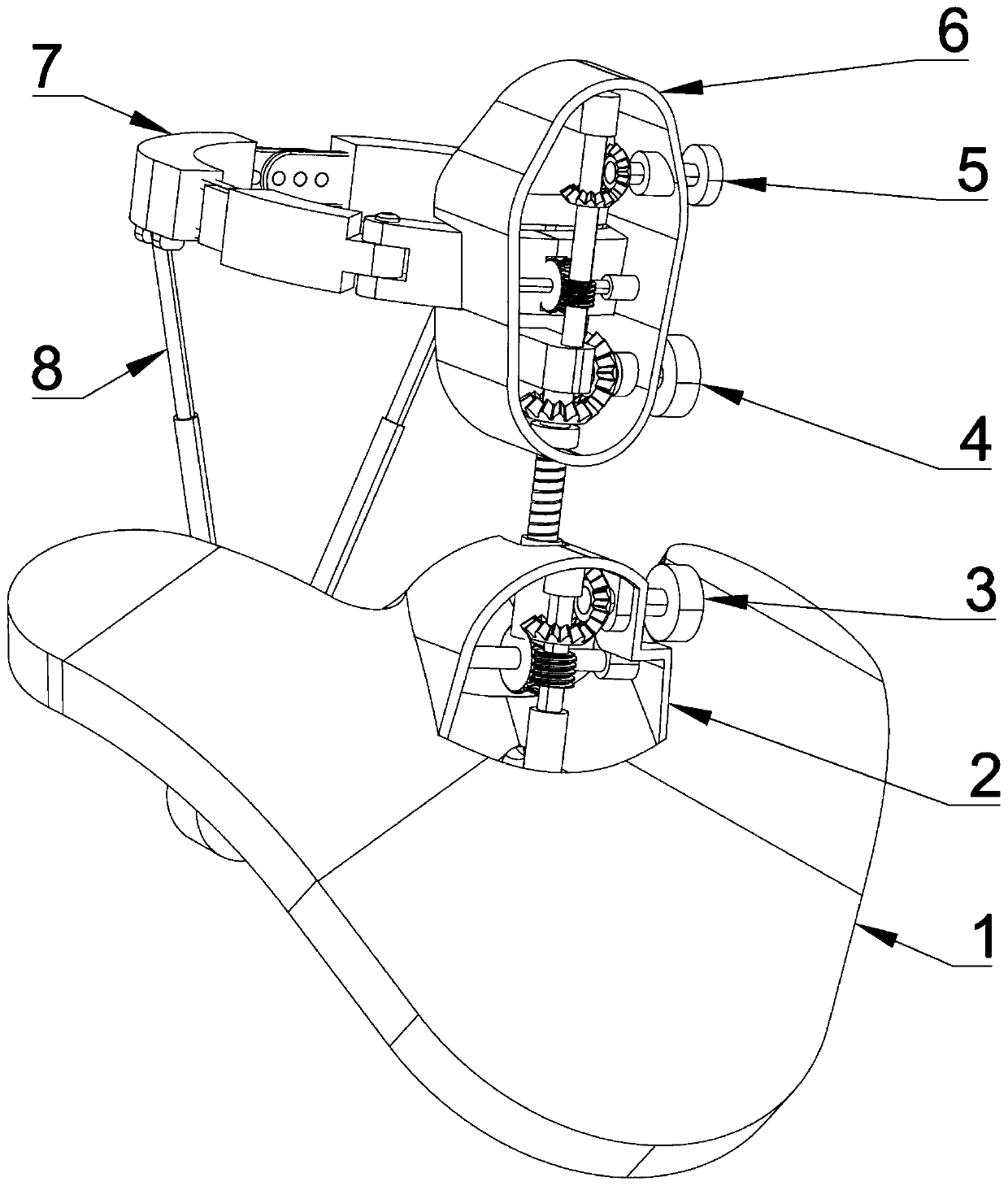

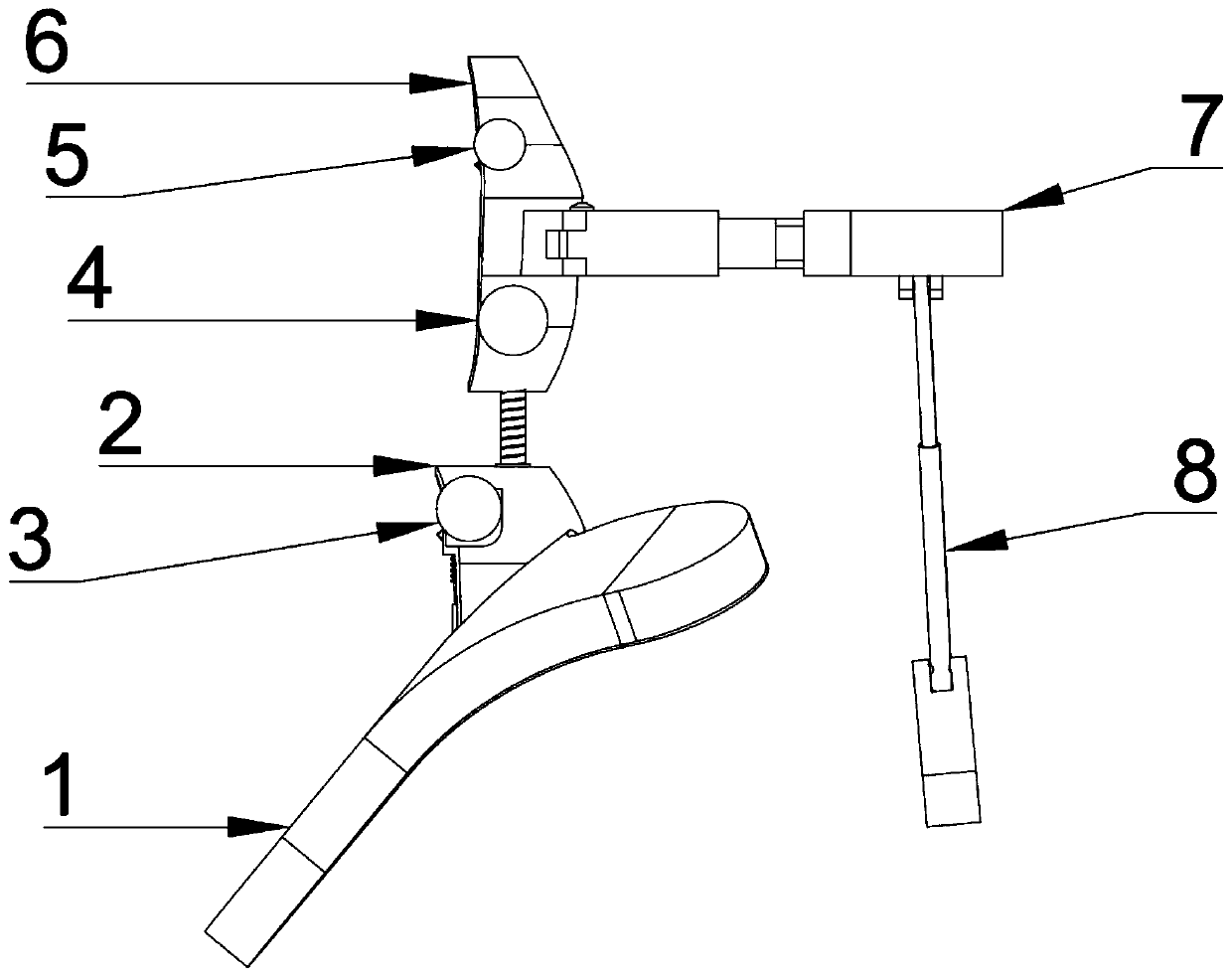

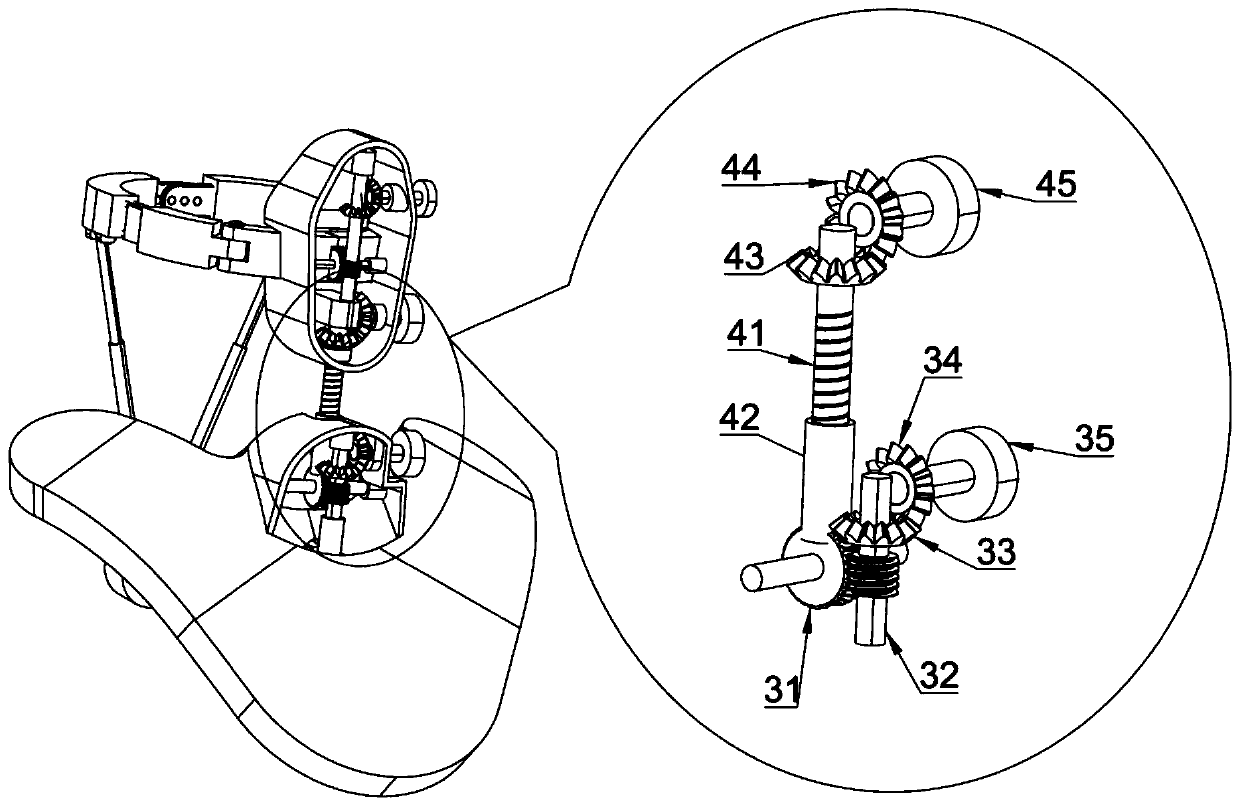

Cervical spondylosis traction cervical collar capable of realizing personalized adjustment

InactiveCN109846589AEasy to expandEasy to adjust the lengthChiropractic devicesFractureCervical spondylosisPhysical medicine and rehabilitation

The invention discloses a cervical spondylosis traction cervical collar capable of realizing personalized adjustment. The cervical collar is technically characterized by consisting of a shoulder frame, a jaw support, a front support frame, an upper shell sleeve, a lower shell sleeve, and a height adjusting device, a bracket angle adjusting device and a jaw support angle adjusting device which arepositioned behind the neck. The shoulder frame is supported by the shoulder of the human body; the jaw support is used for lifting the head; one end of the height adjusting device is connected into the upper shell sleeve, the other end is connected into the lower shell sleeve, and the length is adjustable; the jaw support angle adjusting device is used for adjusting the pitching angle of the jaw support; the bracket angle adjusting device is used for adjusting the pitching angle of the height adjusting device; the lower shell sleeve is fixedly connected to the shoulder frame; and the front support frame is positioned in front of the neck, one end of the front support frame is connected to the lower part of the jaw support, and the other end abuts against the sternum part of the human body.The cervical collar can quantitatively adjust the strength and the angle of the supporting, adjust the size according to individual conditions, improve the comfort degree, and meet the individualizedtreatment requirement of cervical spondylosis traction physiotherapy.

Owner:王嘉熙

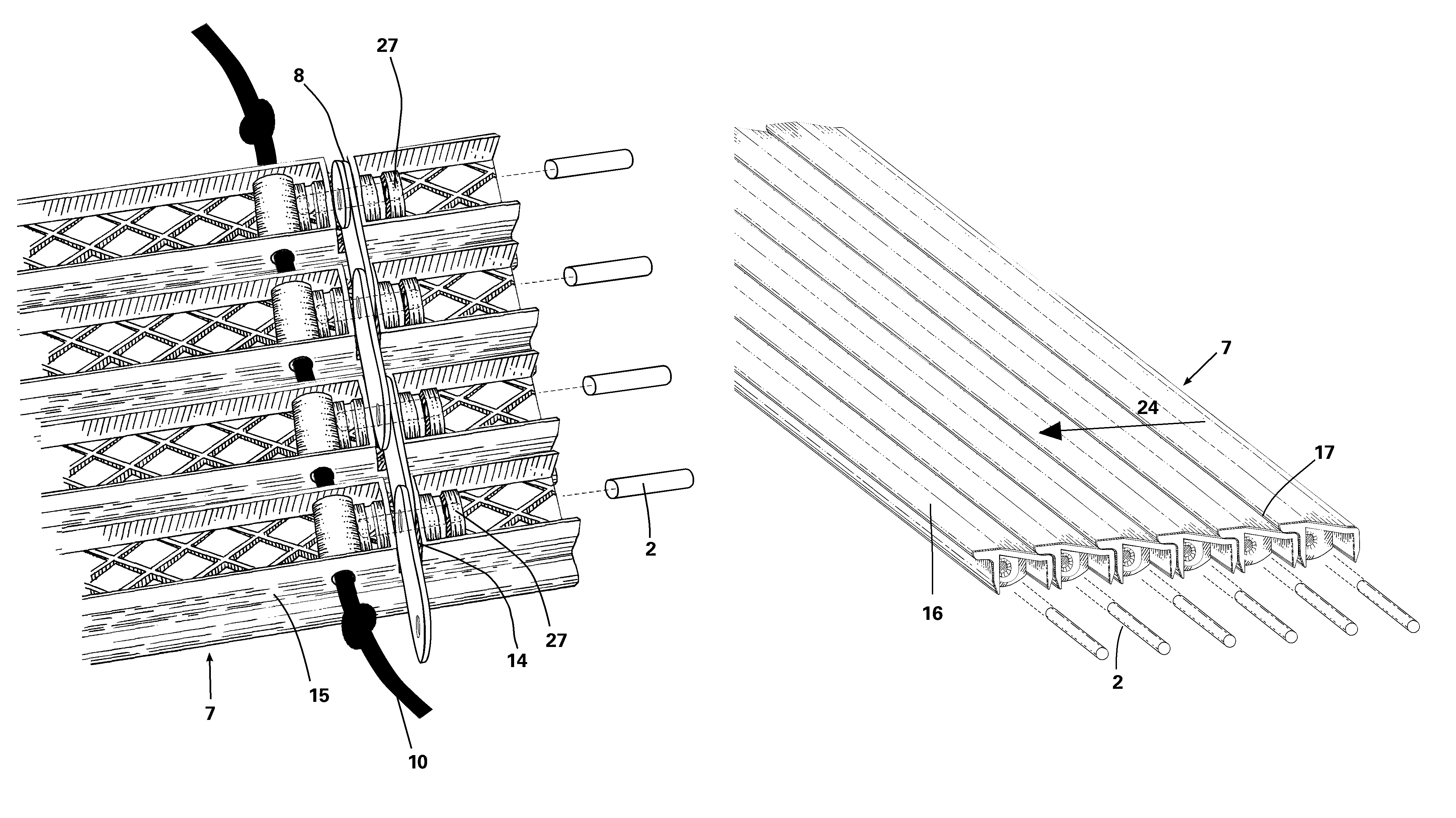

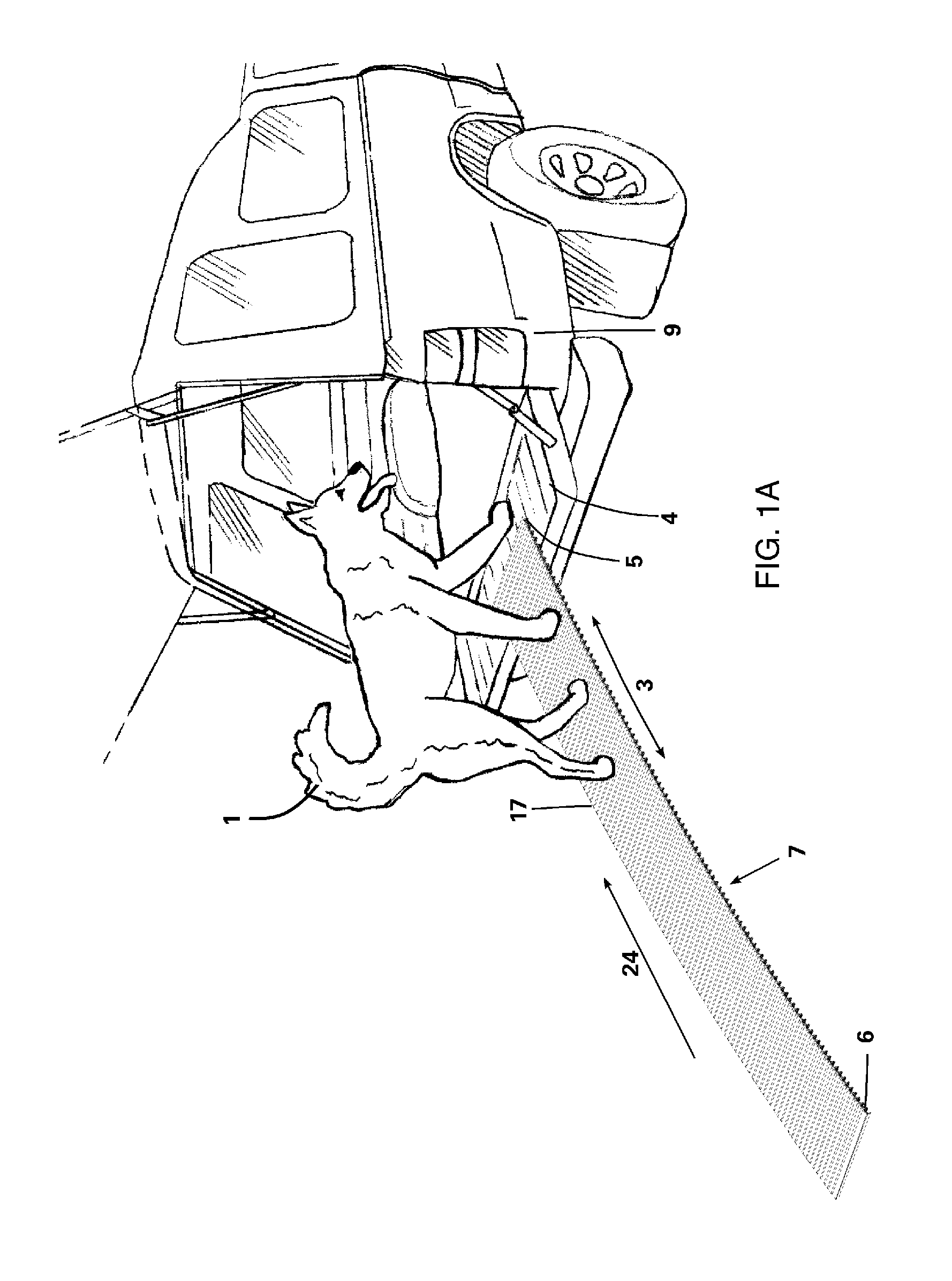

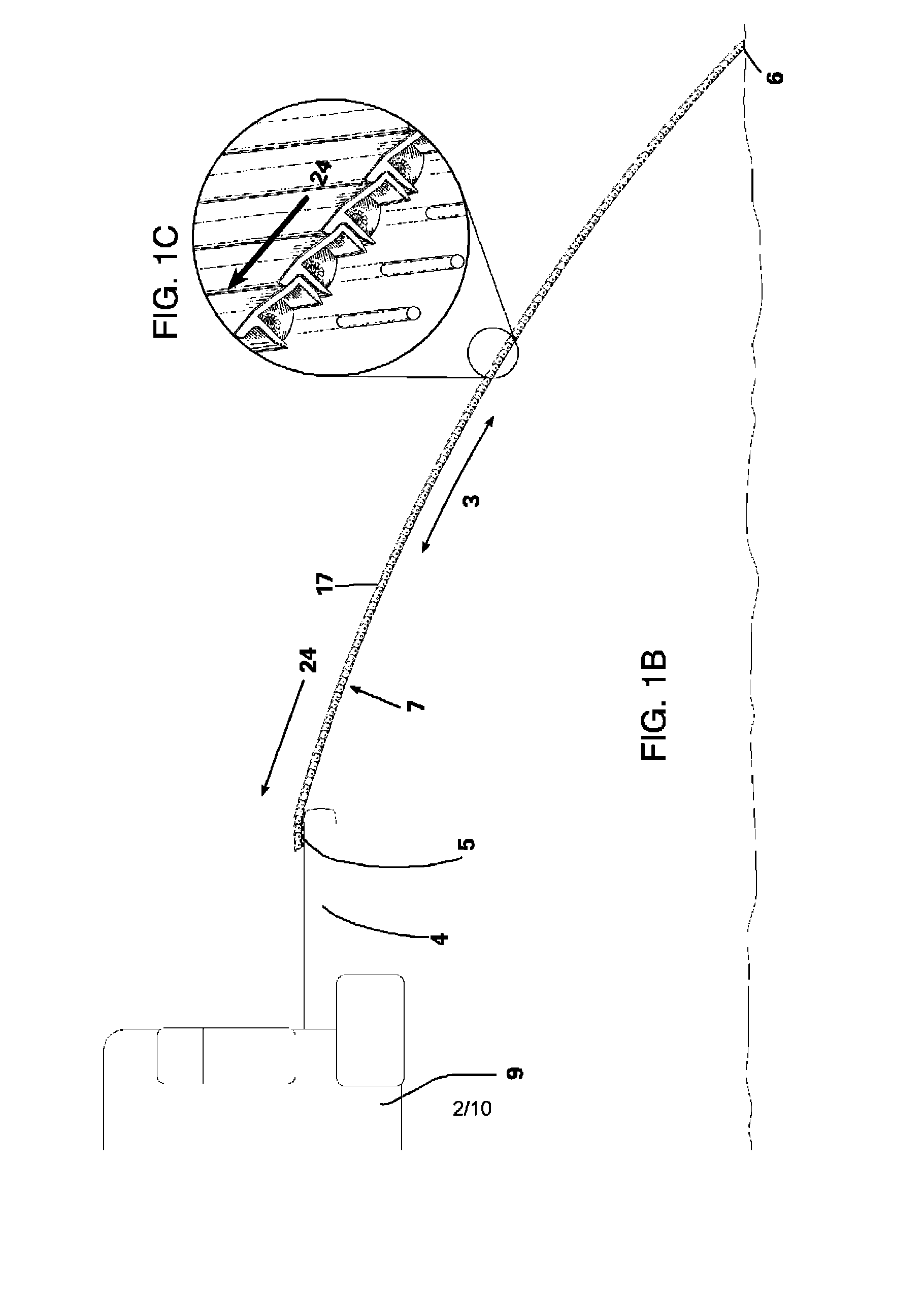

Multi tread segmented self deploying roll up ramp

InactiveUS7958586B1Quickly and efficiently deployQuick and easy deploymentBridgesLoading/unloadingEngineeringUltimate tensile strength

A roll out multi-tread ramp design supported by its arched design and the preferably identical shape and angle of each of its multiple treads abutting one another creating a surface area that distributes stress from weight placed on the surface of the ramp. Oblong links comprise preferably two holes per link and hold each tread that abut one another together, a cylindrical pin inserts snugly through an end of each ramp tread, passes through the link hole, then preferably re-enters tread of the ramp which connects multiple treads together and creates strength when weight is placed on ramp and allows the ramp to be rolled up. Ramp length is adjustable by using varying numbers of treads in each ramp assembly. An elastic cord runs through all treads to assist with self-deployment of ramp and assists in holding ramp treads in place.

Owner:CARTER CYNTHIA D

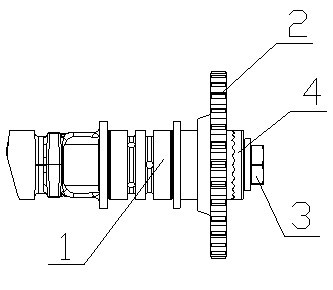

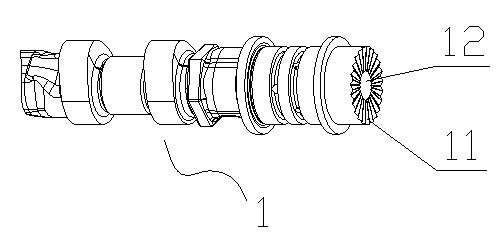

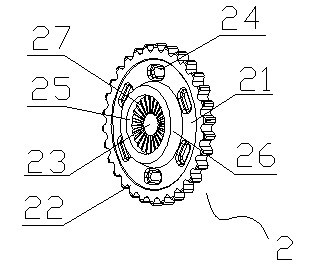

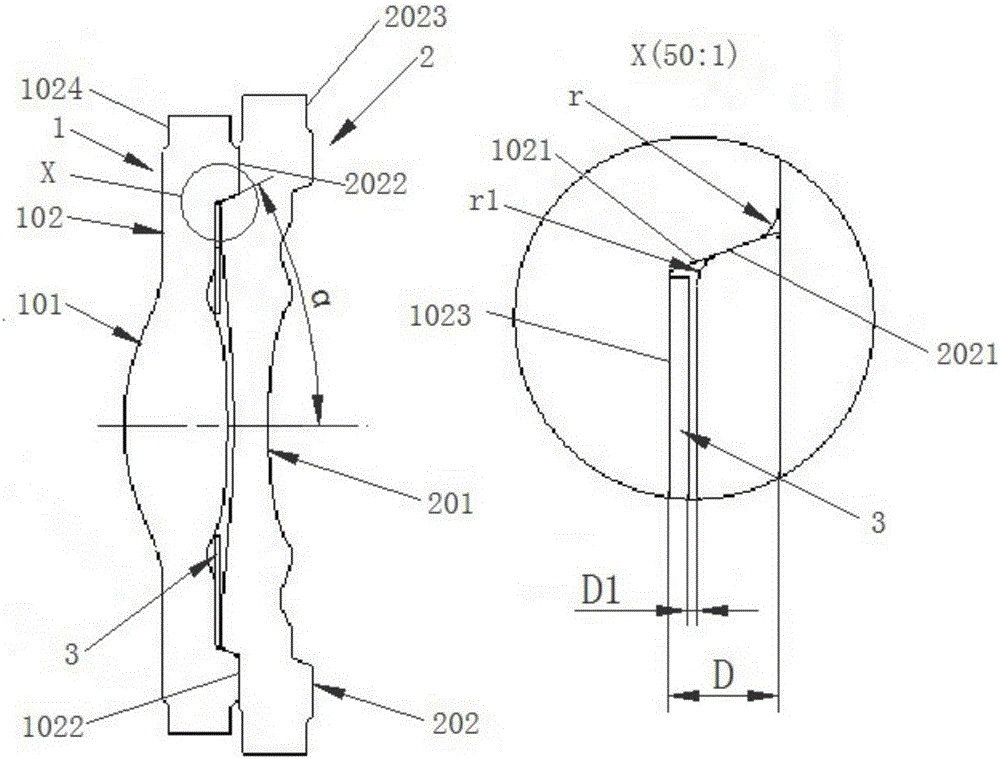

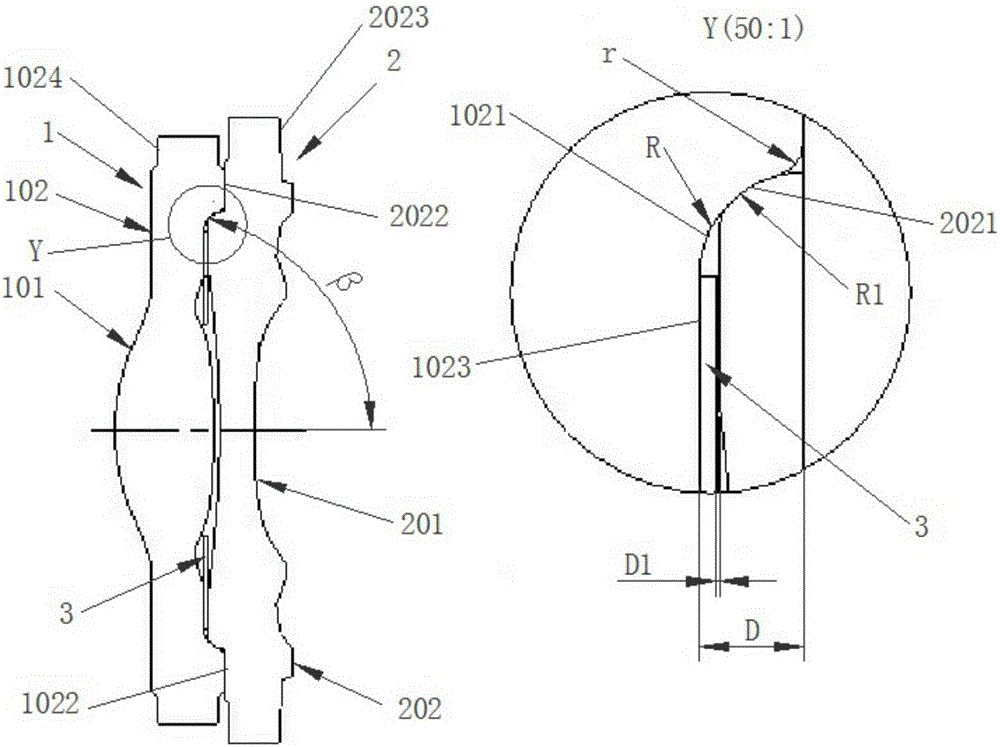

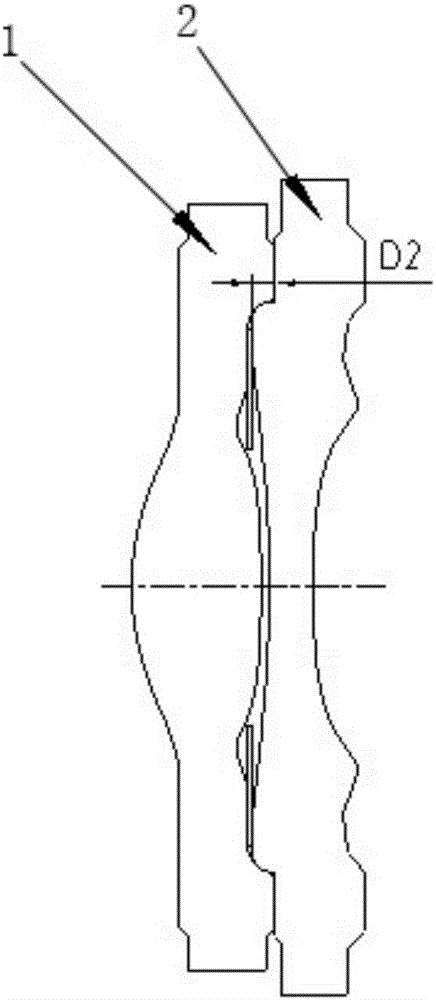

Installation structure for cam shaft and timing gear

ActiveCN102146818AGuaranteed StrengthNot easy to looseValve arrangementsPortable liftingStress concentrationGear wheel

The invention aims to provide a durable installation structure for a cam shaft and a timing gear. The structure can position accurately and is convenient to install. The installation structure for the cam shaft and the timing gear comprises the cam shaft, the timing gear and a bolt, and is characterized in that the surface of one end part of the cam shaft is provided with radial splines; the center of the end part is provided with an axial screw hole for installing the bolt; the middle of the timing gear is provided with shaft holes, one side of the timing gear is provided with radial splines which are matched with and engaged with the splines of the cam shaft, the timing gear is fixed at the end part of the cam shaft in a tightening mode through the bolt; and the splines of the timing gear are in fit connection with the splines of the cam shaft, thus the installation is convenient and the work efficiency is improved. By using the installation structure, not only can the timing gear be positioned, but also stress generated when the timing gear and the cam shaft rotate can be dispersed, thereby eliminating stress concentration and prolonging service life.

Owner:CHERY AUTOMOBILE CO LTD

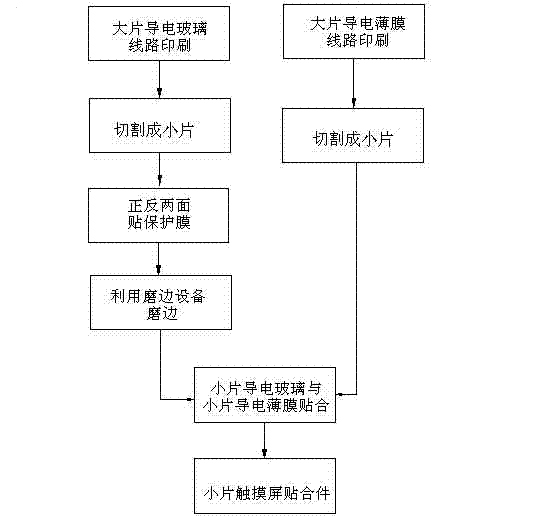

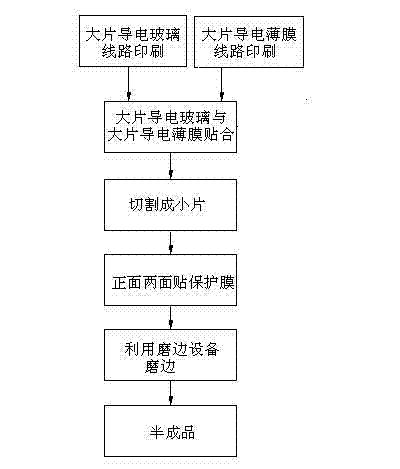

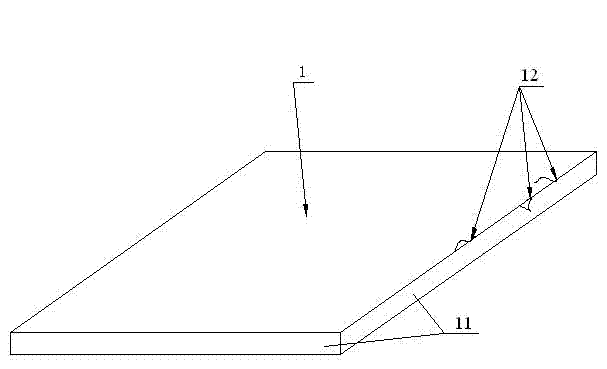

A method of manufacturing touch screen bonding parts

InactiveCN102298464ALow costImprove drop resistanceInput/output processes for data processingTouch panelEngineering

The invention relates to a manufacturing process of a touch screen bonding part. The bonding part is formed by bonding conductive glass and a conductive film. A touch screen uses a small bonding part, and a large bonding part contains a plurality of uncut small bonding parts. Fittings; in the process of making the fittings, the edging equipment is used to grind the cutting surface of each edge of the conductive glass in the small fittings into a frosted curved surface. The touch screen laminating part produced by the invention avoids the problems of stress concentration points and poor drop resistance in the cut surface of the ITO conductive glass substrate in conventional laminating parts. After the touch screen is made by using the invention, the stress when the touch screen falls can be effectively dispersed, and the qualified rate of products in the production of the touch screen can be improved. At the same time, because no strengthened glass substrate is used, the production cost is greatly reduced.

Owner:NANJING WALLY ELECTRONICS TECH

Optical lens group

The invention relates to an optical lens group which comprises a first lens and a second lens, wherein an optical axis of the first lens and an optical axis of the second lens are superposed; the radius of the second lens is more than that of the first lens; the first lens comprises a first optical part and a first mounting part; the second lens comprises a second optical part and a second mounting part; the first mounting part comprises a first buckling surface, a first bearing surface and a third bearing surface; the second mounting part comprises a second buckling surface and a second bearing surface which can cooperate with the first buckling surface and the first bearing surface; the vertical distance between the third bearing surface and the first bearing surface is D, and D is more than or equal to 0.08 mm and less than or equal to 0.5 mm. The optical lens group is stable in structure, realizes automatic centering and is favorable for rotational symmetry of image quality.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

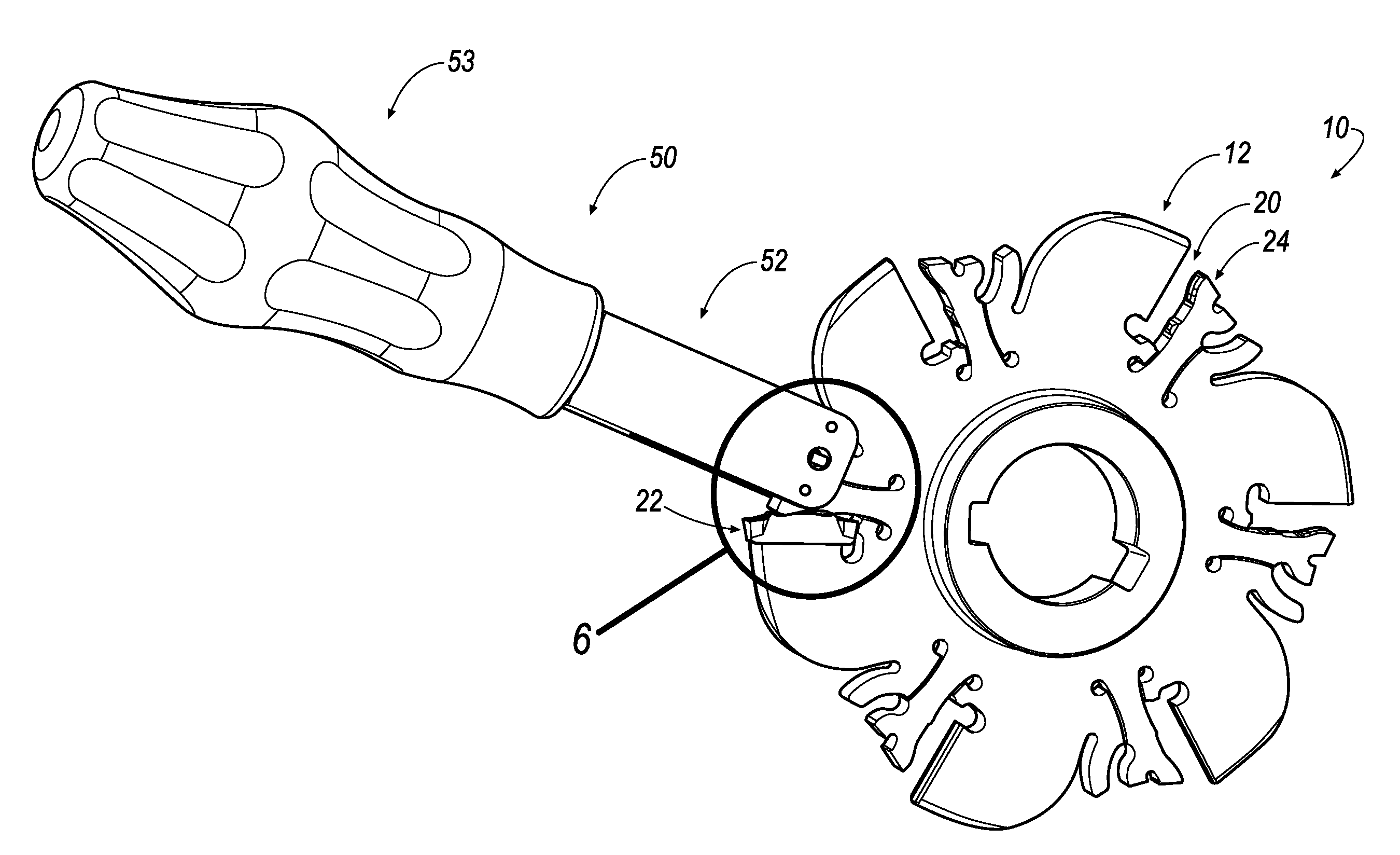

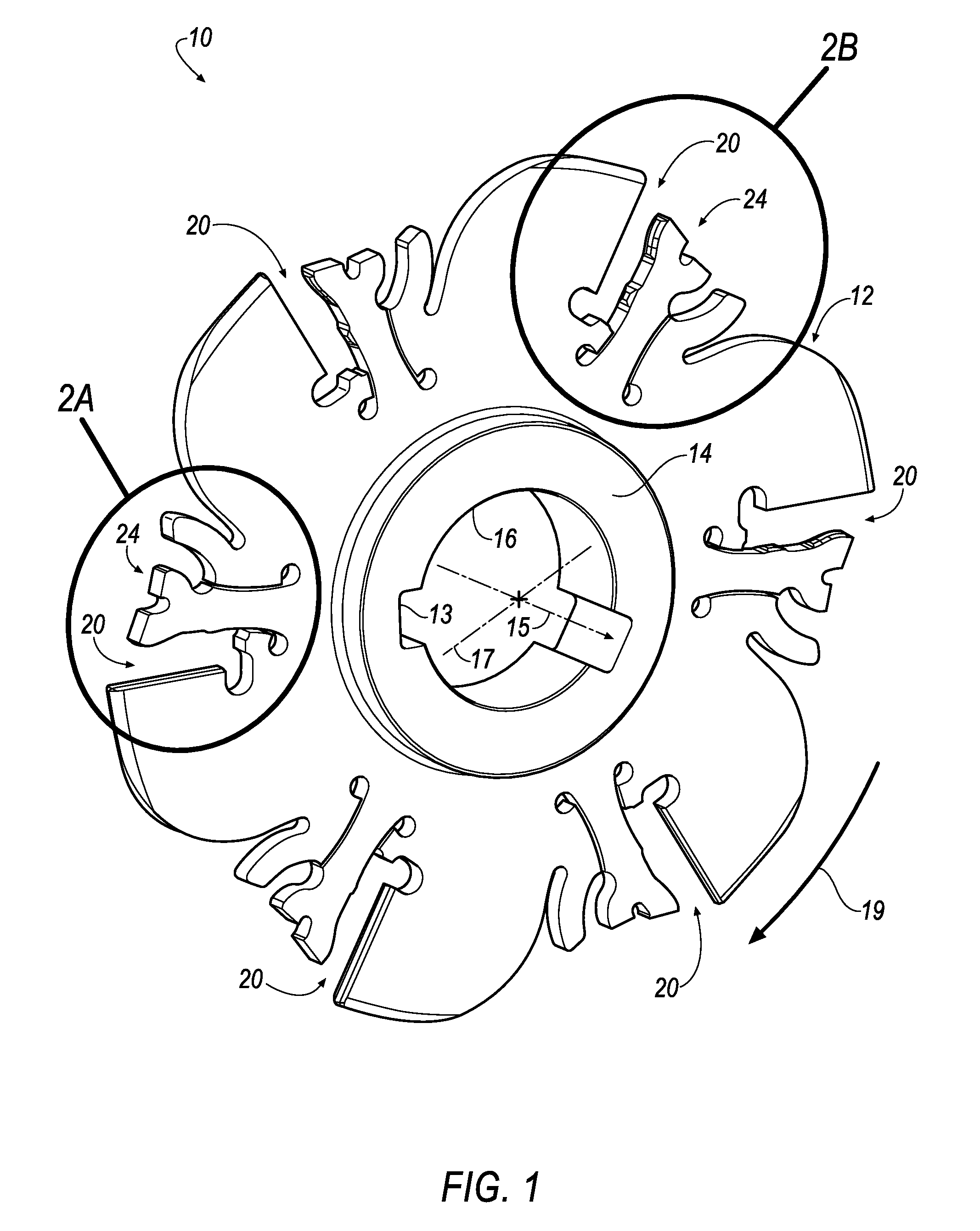

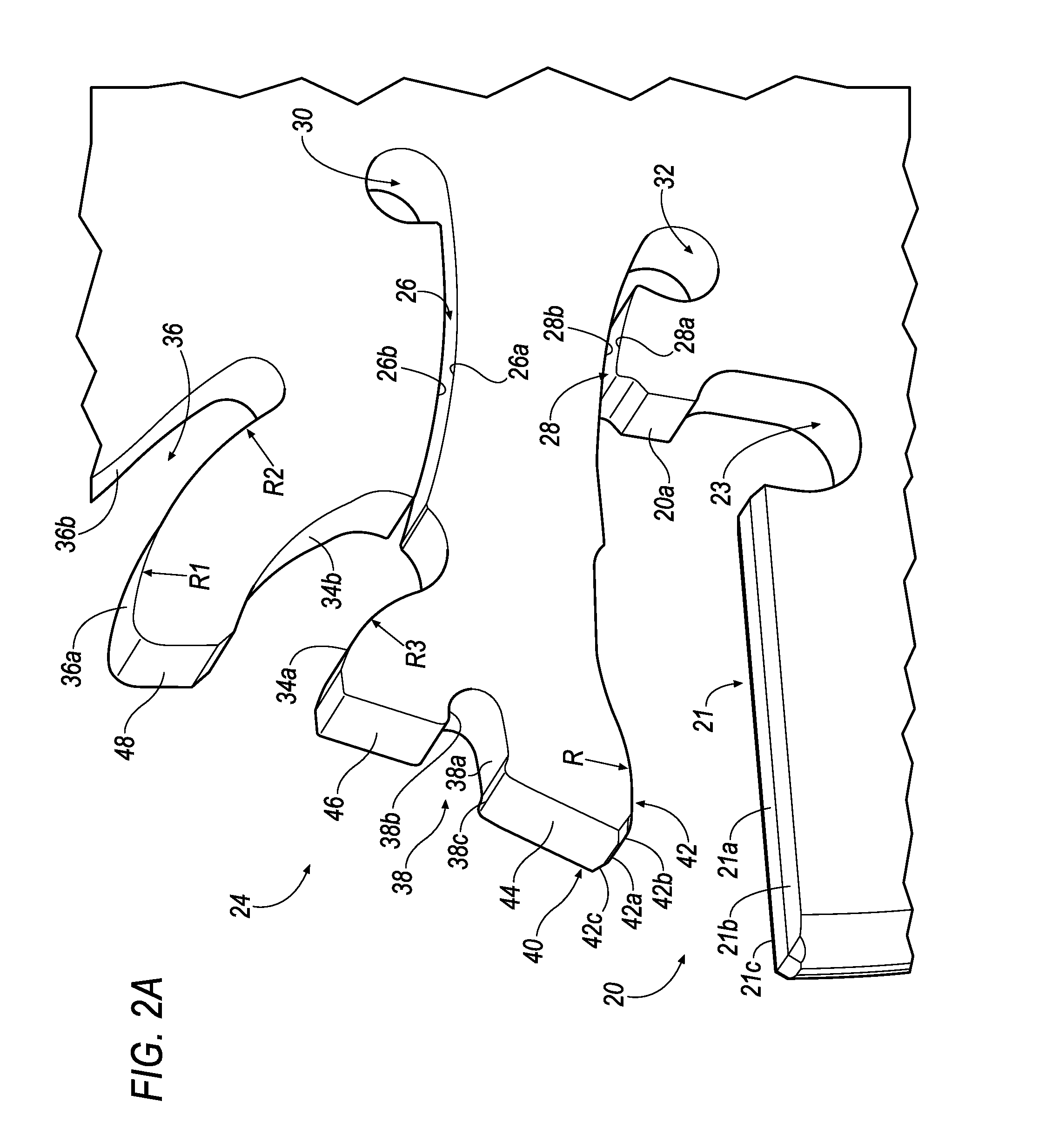

Slotting cutter, cutting insert and tool therefor

A slotting cutter includes a disc-like cutter body rotatable in a predetermined direction on a central axis perpendicular to a plane of the cutter body. The cutter body includes a stop slot, an upper cam slot and a lower slot. A plurality of pockets adapted to receive a cutting inset are formed about a perimeter of the body. A cantilevered clamping member includes a bottom surface with a pair of clamping surfaces that engage a pair of angled clamping surfaces on a top surface of the cutting insert during operation. A wrench is provided to lift the cantilevered clamping member for inserting, indexing or removing the cutting insert from the slotting cutter. The wrench includes two fixed pins and a floating pin that prevents the cantilevered clamping member from bending too far and limiting the useful life of the slotting cutter.

Owner:KENNAMETAL INC

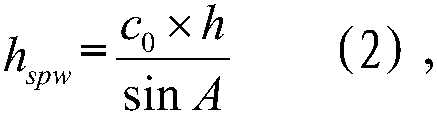

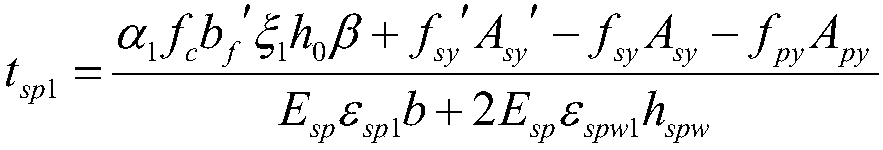

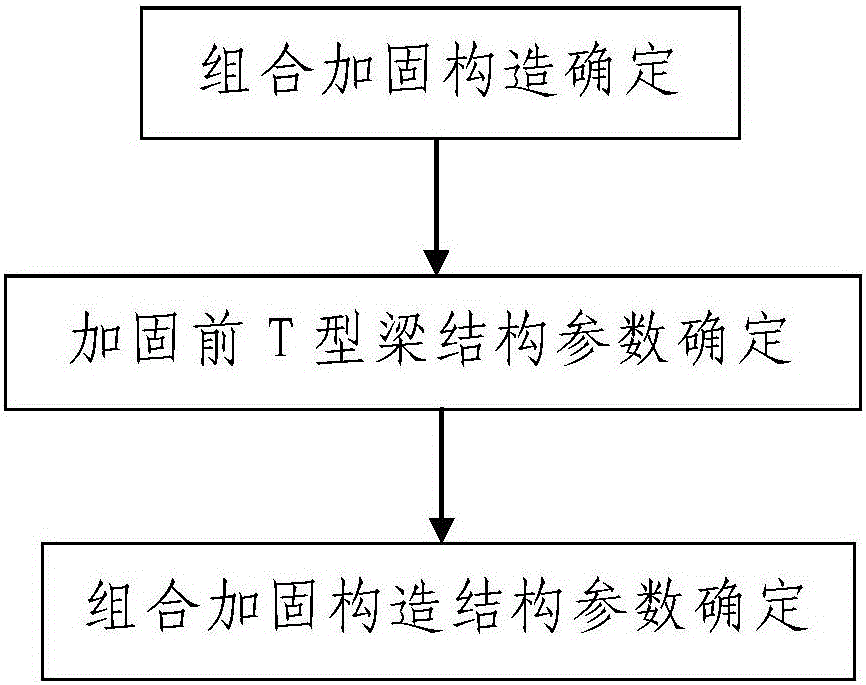

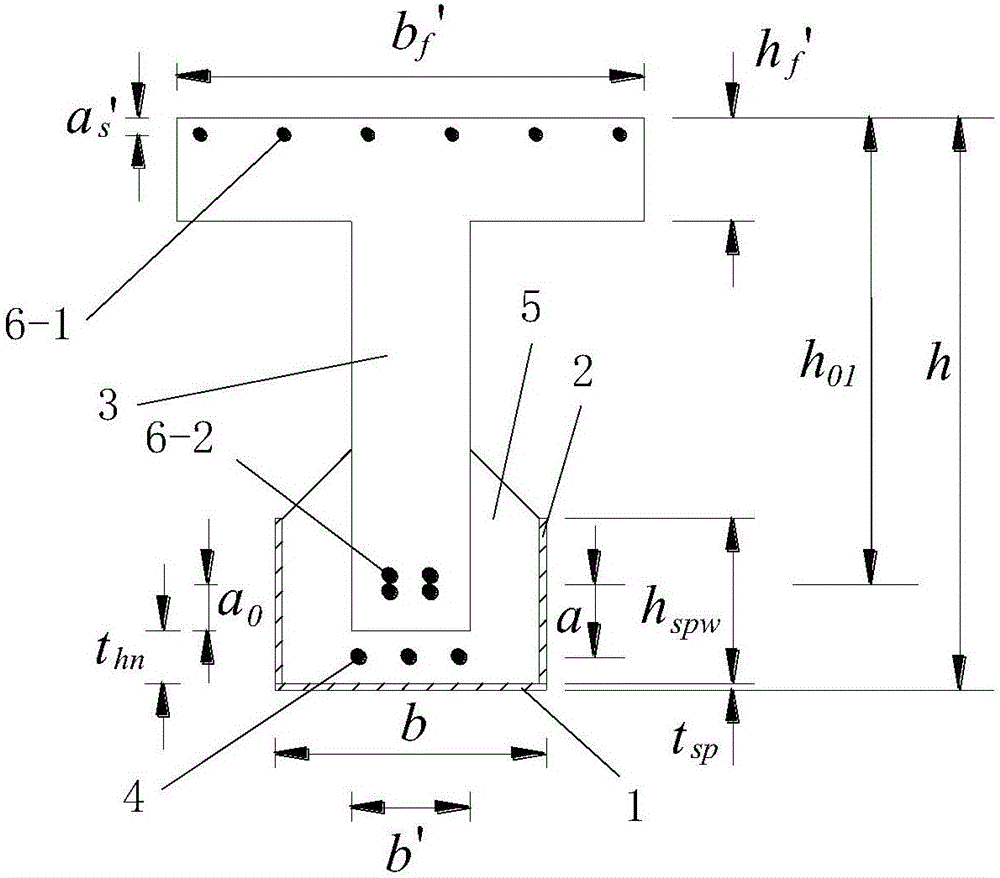

Unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams

ActiveCN105839551AThe method steps are simpleReasonable designBridge erection/assemblyBridge strengtheningRebarSteel plates

The invention discloses an unbonded prestress and steel-concrete composite reinforcement design method for concrete T-shaped beams. The unbonded prestress and steel-concrete composite reinforcement design method includes steps of firstly, determining unbonded prestress and steel plate-concrete composite reinforcement structures for the reinforcement T-shaped beams; secondly, determining structural parameters of the T-shaped beams prior to reinforcement; thirdly, determining structural parameters of the composite reinforcement structures, to be more specific, initializing the parameters, computing the maximum theoretical thicknesses of reinforcement steel plates, determining the thicknesses of the reinforcement steel plates and the thickness of concrete and determining the heights of longitudinal side steel plates and the widths of bottom steel plates. Each composite reinforcement structure comprises the corresponding bottom steel plate, the two longitudinal side steel plates and a steel bushing case, each steel bushing case comprises two end blocking steel plates, and a plurality of unbonded prestress reinforcing steel bars are arranged in each steel bushing case. The unbonded prestress and steel-concrete composite reinforcement design method has the advantages that the steps are simple, the unbonded prestress and steel-concrete composite reinforcement design method is reasonable in design and convenient to implement, good service effects can be realized, the structural parameters of the bridge composite reinforcement structures can be easily, conveniently and quickly determined, the bridge composite reinforcement structures designed by the aid of the unbonded prestress and steel-concrete composite reinforcement design method are economical and practical, and good reinforcement effects can be realized by the bridge composite reinforcement structures.

Owner:XIAN HIGHWAY INST

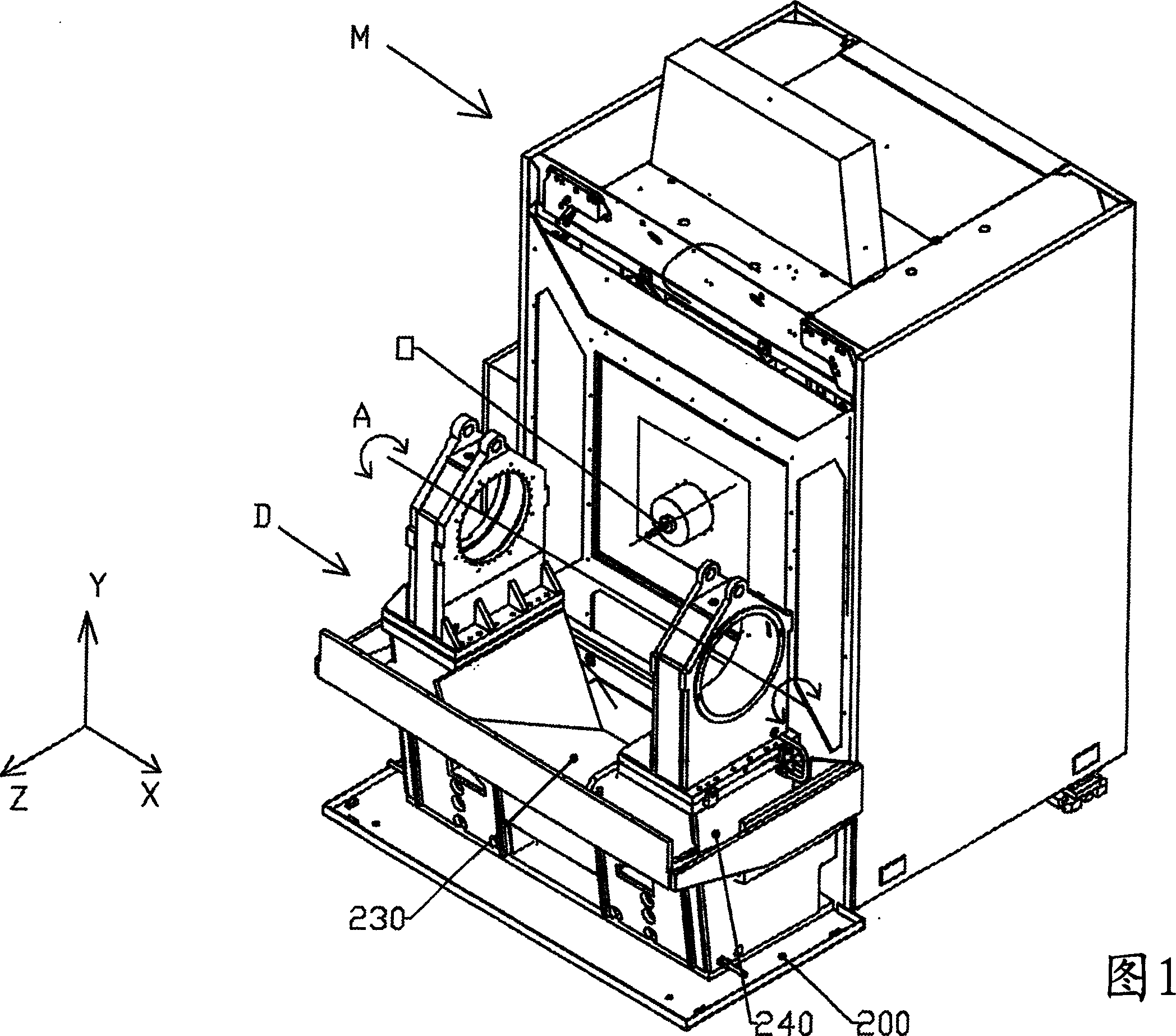

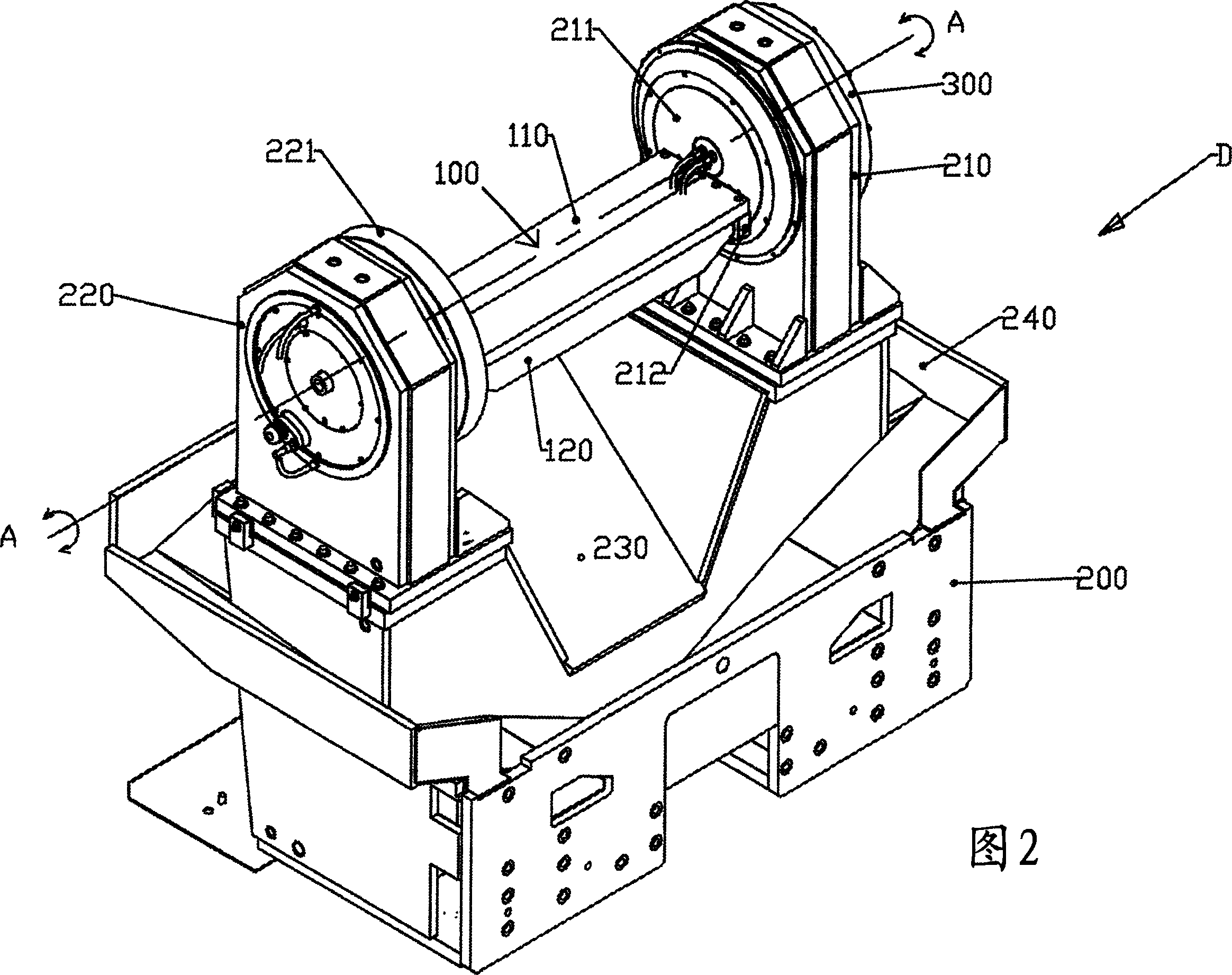

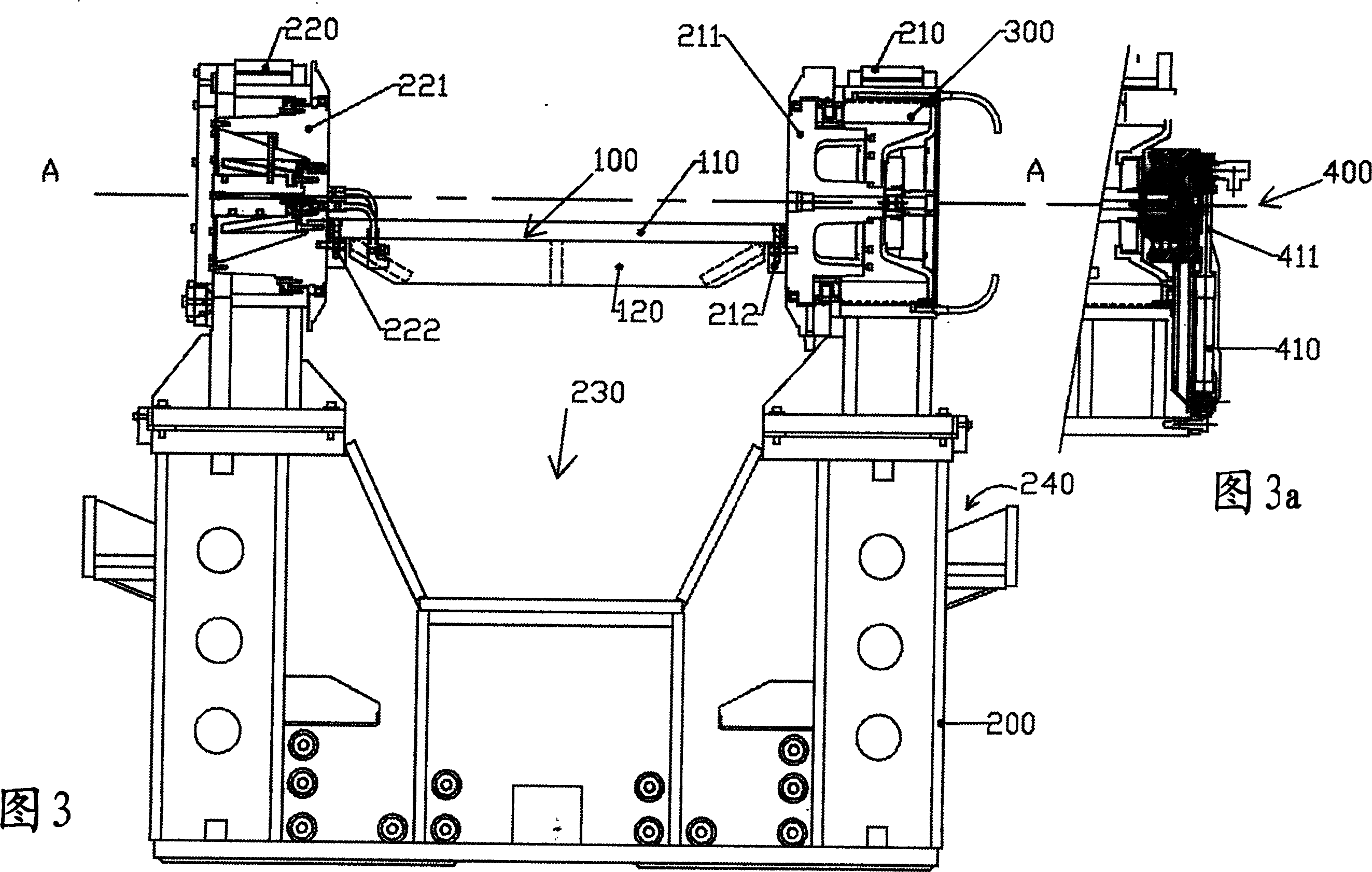

Versatile and modular workpiece holding device

InactiveCN1871101AEasy to implementEasy to handlePrecision positioning equipmentLarge fixed membersEngineeringAxial force

Owner:COMAU SYST FRANCE

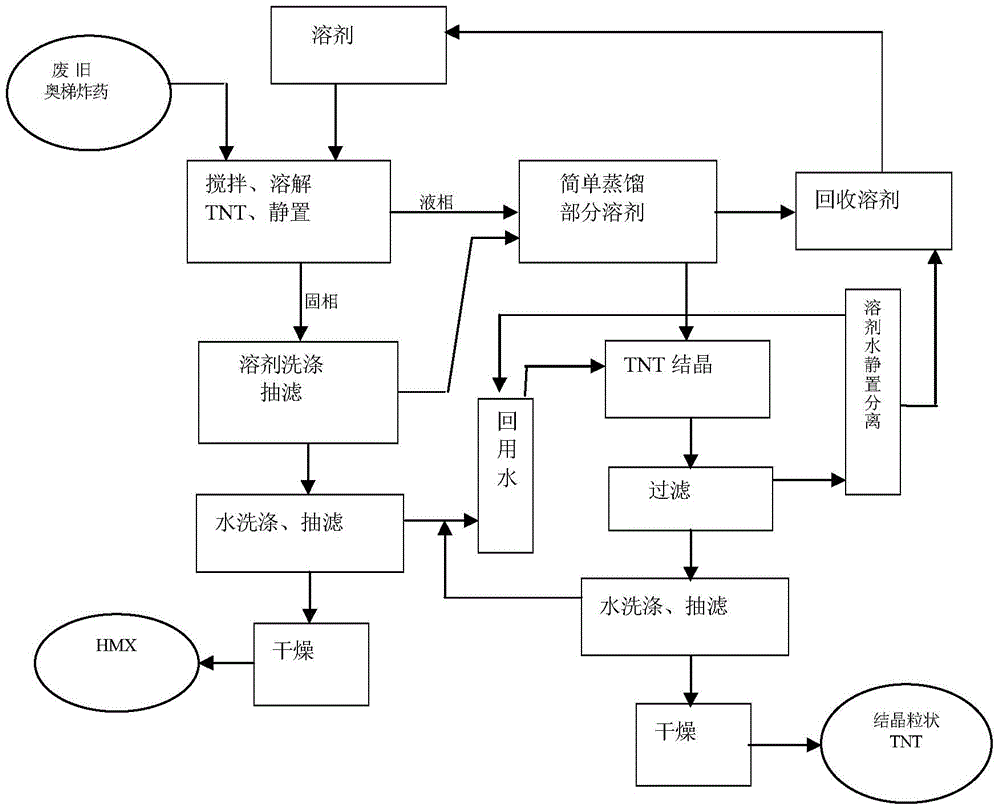

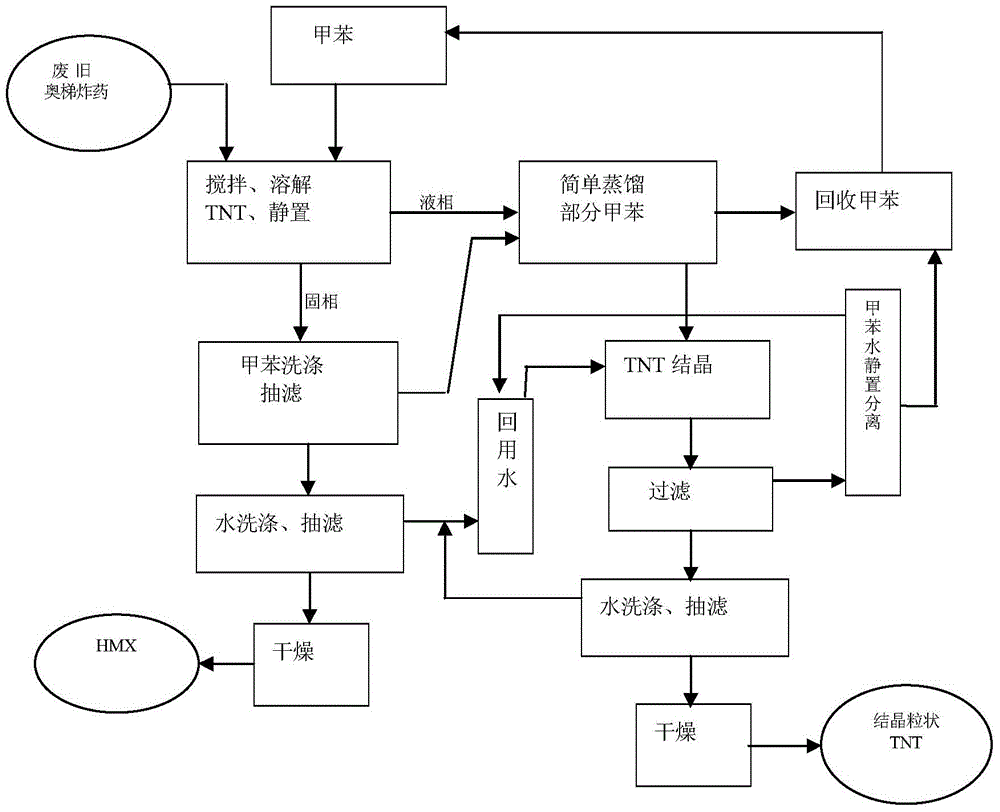

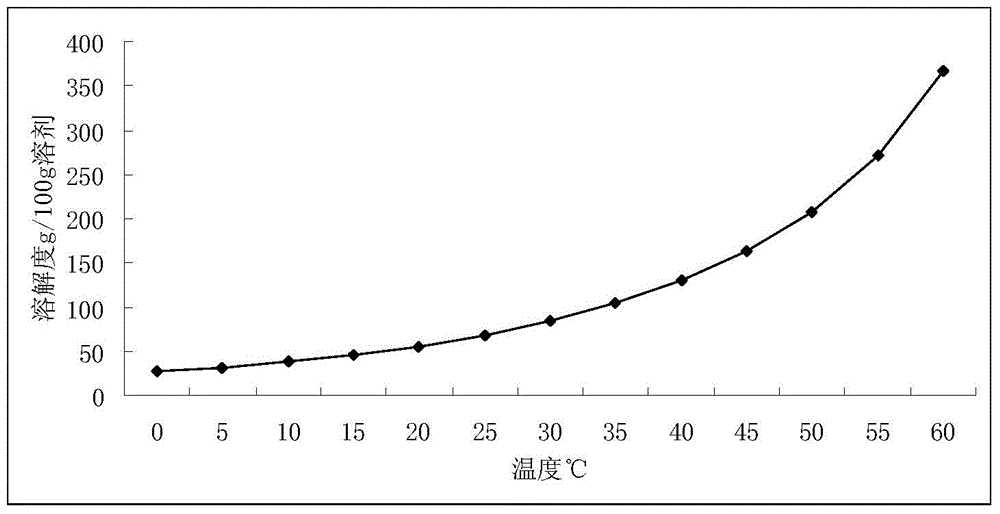

Waste HMX and TNT mixed explosive recovery method

InactiveCN104311501AHigh densityEasy to useOrganic chemistryOrganic compound preparationRecovery methodFiltration

The invention discloses a waste HMX and TNT mixed explosive recovery method. The method comprises the following steps: dissolving TNT in a waste HMX and TNT mixed explosive in an excess amount of toluene as a solvent, separating a solid phase HMX and a liquid phase toluene unsaturated solution of TNT; washing the solid phase in toluene, carrying out pumping filtration, washing by using water, carrying out pumping filtration, and drying to obtain an HMX product; and carrying out simple distillation on the liquid phase and the above toluene washing mother liquor to steam out parts of toluene, carrying out a cooling and water addition combined crystallization process to precipitate TNT crystals, filtering, washing the crystals by water, carrying out pumping filtration, and drying to obtain a crystallized granular TNT product. The total yield of the recovery treatment is 98.55%; and the method has the advantages of simple process, few species of used materials, complete recycling of the used solvent toluene, basic reuse of washing water, and realizing of energy saving and clean production.

Owner:GANSU YINGUANG CHEM IND GRP CO LTD

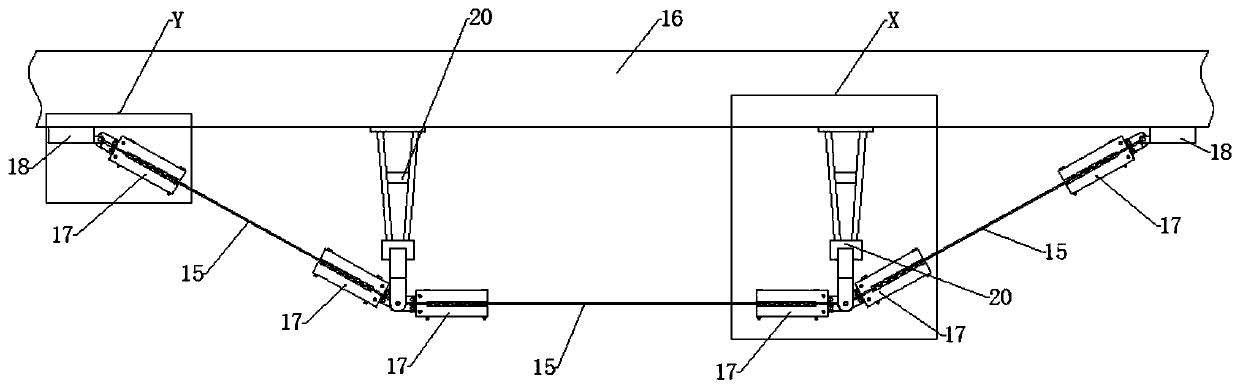

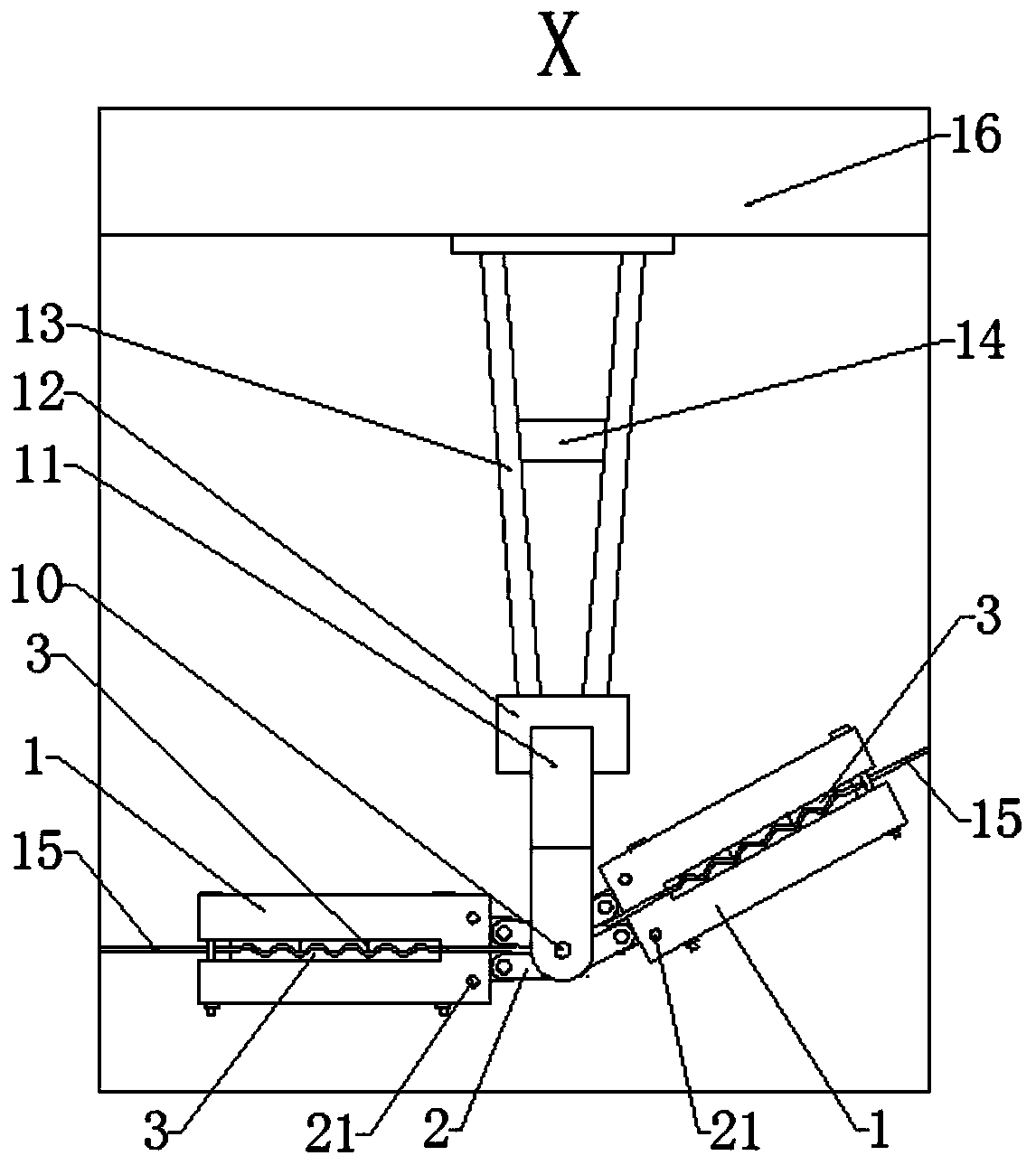

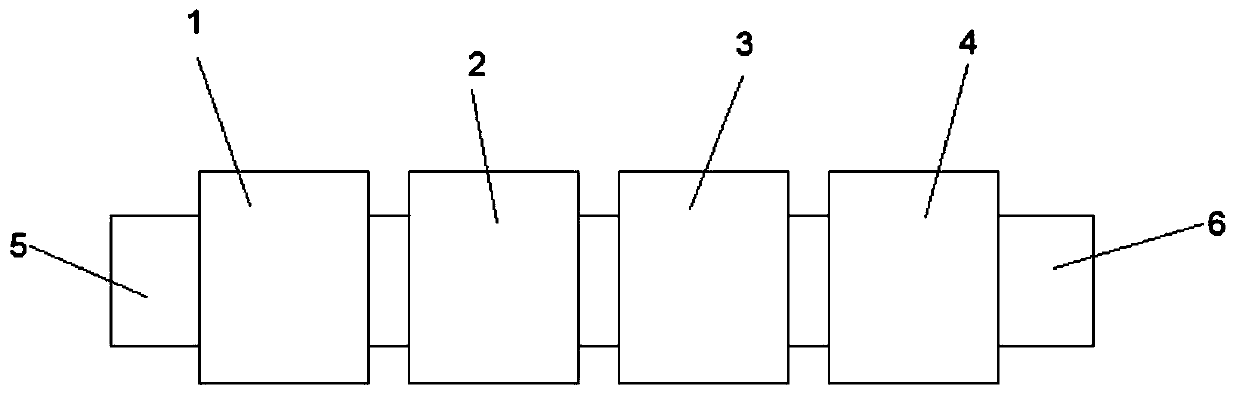

CFRP sheet composite string beam structure reinforcement installation system

The invention discloses a CFRP sheet reinforcement installation system. The CFRP sheet reinforcement installation system comprises a beam body, n+1 CFRP sheets, n fixed supports and 2n+2 anchorages, nis a positive integer greater than or equal to 1, the beam body is horizontally arranged, the fixed supports are vertically arranged on the lower surface of the beam body, two anchorages are hinged to the lower ends of the fixed supports, two hinged seats are further arranged at the two ends of the lower surface of the beam body, and the fixed supports are located between the two hinged seats. Anchorages are hinged to the two hinged seats correspondingly. CFRP sheets are arranged between the hinged seats and the adjacent fixed supports. CFRP sheets are further arranged between the two adjacent fixed supports, and the two ends of the CFRP sheets are clamped on the corresponding anchorages. The CFRP sheet reinforcement installation system has the remarkable effects that in the clamping andstretching process of the CFRP sheets, the stress of the CFRP sheets is dispersed, and the uniform stress of the CFRP sheets is ensured. Because the CFRP sheets can form any angle through hinge pieces, the CFRP sheets can be stretched along the straight line, and the shear failure of the CFRP sheets is avoided, and thus the bearing capacity of a reinforced member is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

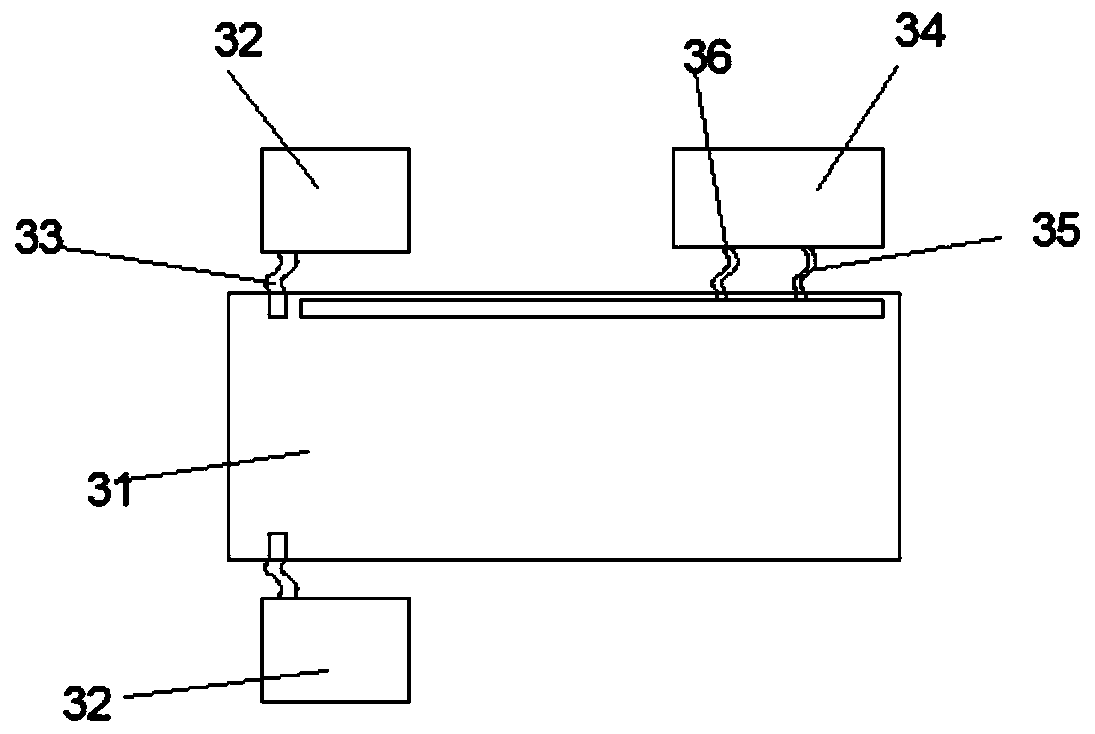

Laminating device and method applied to large-size battery assembly

PendingCN110370778AReduce the impactReduce shockLaminationLamination apparatusElectrical batteryPre cooling

The invention relates to a laminating device and method applied to a large-size battery assembly. The laminating device comprises a laminating cavity, a curing cavity, pre-cooling cavities and a cooling cavity which are connected sequentially, and the temperature in the pre-cooling cavities is higher than the temperature in the cooling cavity; and in the laminating process, the assembly is sequentially subjected to the four steps of laminating, curing, pre-cooling and cooling, wherein in the pre-cooling process, the assembly is cooled from 130-160 DEG C to 50-80 DEG C firstly and then placed into the cooling cavity to be cooled to 20-50 DEG C. The laminating device and method have the beneficial effects that the laminating device including the one or more pre-cooling cavities is adopted, through a stepped cooling method, the influences of quick cooling on large-size battery pieces are reduced, stress, caused by thermal expansion and cold contraction phenomena in the cooling process, ofthe surface of a silicon wafer is dispersed, impact borne by the surfaces of the battery pieces is buffered, the phenomena of laminating fragments and subfissure of the battery pieces are obviously reduced, the efficiency of assembly preparation is improved, and the qualified rate of assembly preparation is increased.

Owner:DONGFANG HUANSHENG PHOTOVOLTAIC (JIANGSU) CO LTD

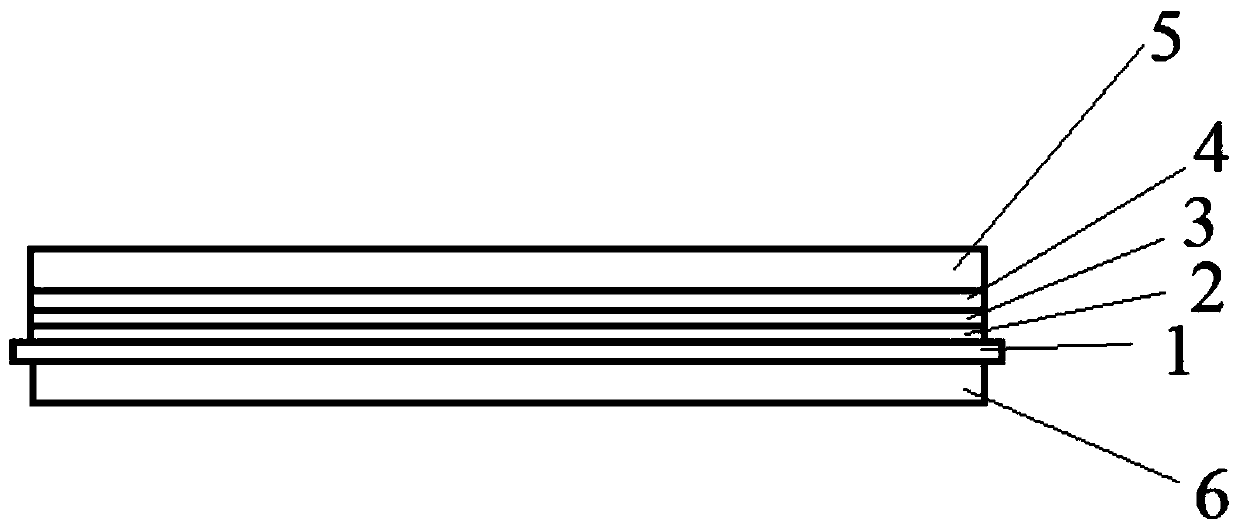

Foldable flexible cover plate and manufacturing method thereof

The invention discloses a foldable flexible cover plate and a manufacturing method thereof. The foldable flexible cover plate comprises an ultrathin glass substrate, and an adhesion enhancing platinglayer, a high polymer material layer and a ceramic functional layer which are sequentially stacked on the ultrathin glass substrate, wherein the high polymer material layer is formed by coating and baking a mixture at least consisting of transparent polyamide acid and a coupling agent at one time. The manufacturing method comprises the following steps: providing an ultrathin glass substrate, and forming an adhesion enhancing plating layer on the surface of one side of the ultrathin glass substrate; coating the surface of the adhesion enhancing plating layer with the mixture at least consistingof transparent polyamic acid and a coupling agent, and then carrying out baking-curing reaction to form a high polymer material layer at least consisting of transparent polyimide; and forming a ceramic functional layer on the high polymer material layer to obtain the foldable flexible cover plate. According to the invention, the foldable flexible cover plate with stronger mechanical property andgood bending property can be prepared.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

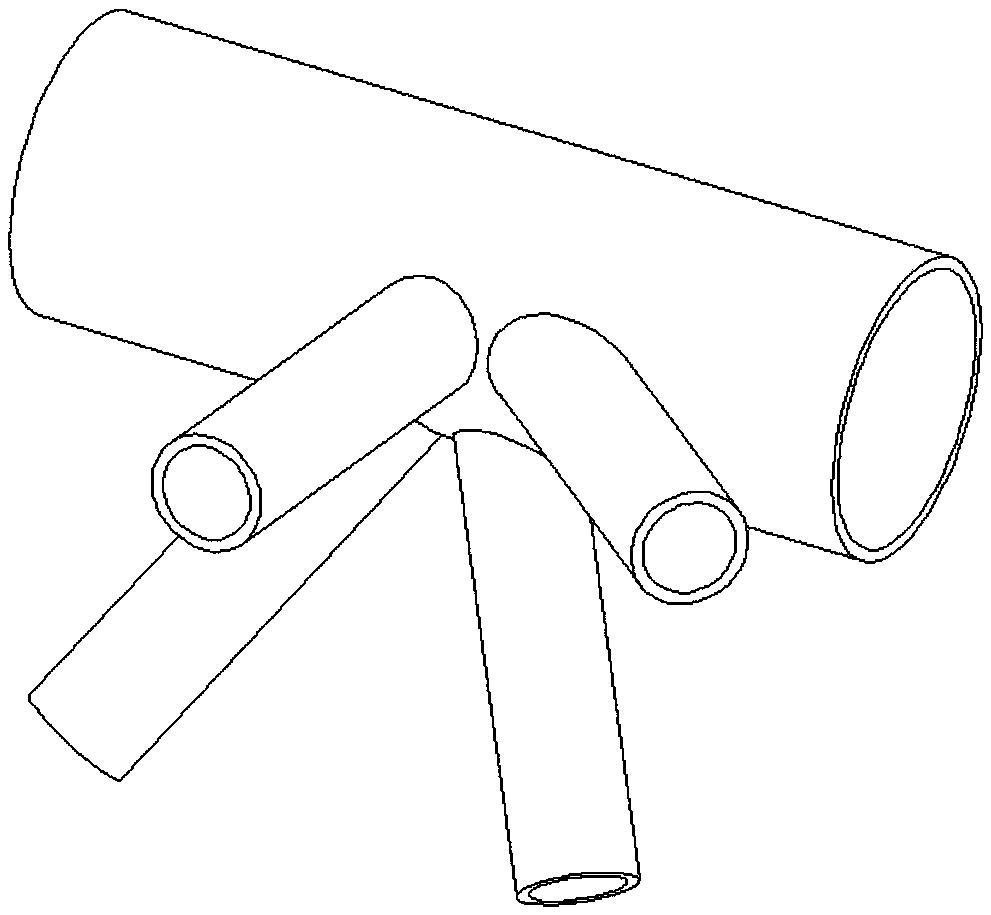

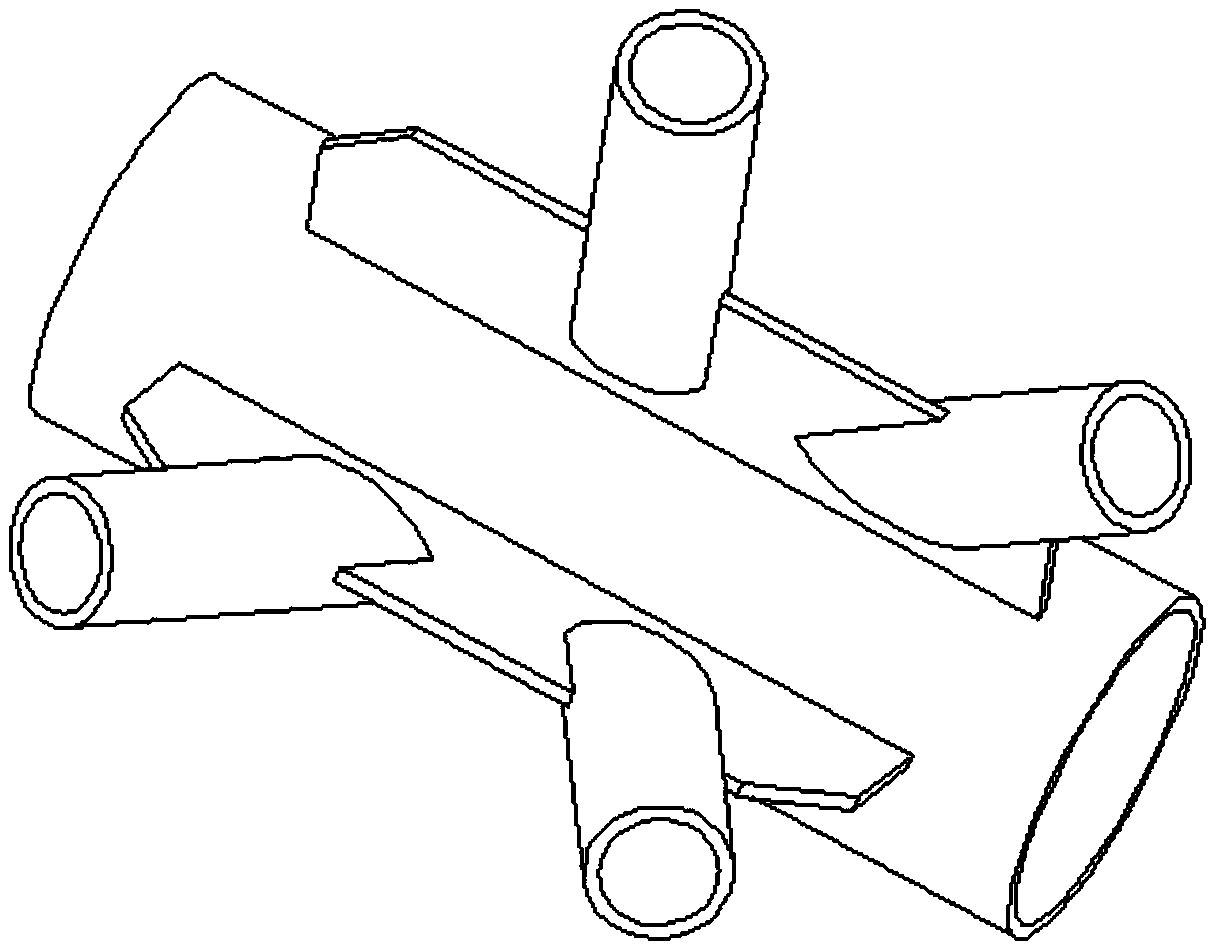

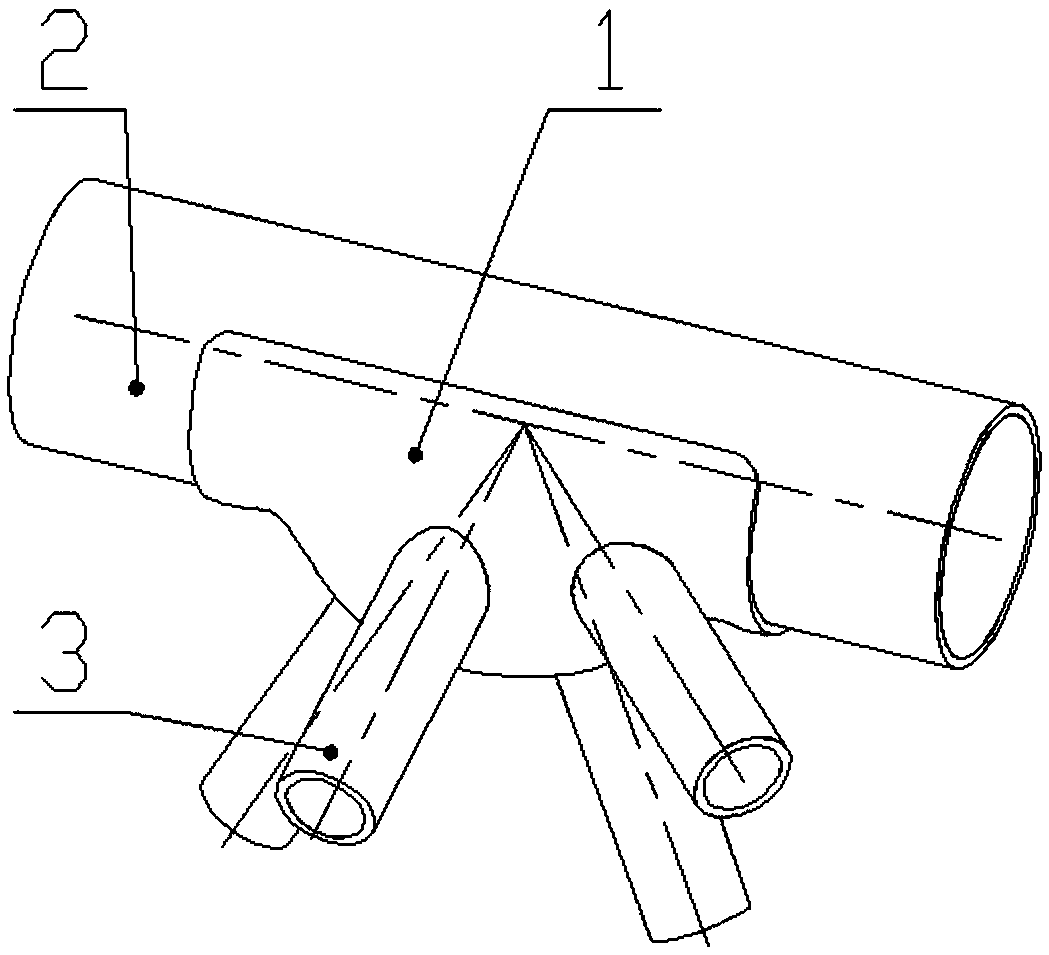

Containing-type node

ActiveCN105508355APrevent surface tearing problemsEasy to manufactureRod connectionsStress concentrationUltimate tensile strength

The invention provides a containing-type node, belonging to the technical field of mechanical connection parts. The containing-type node comprises a bent plate for connecting a main chord of a tube structure truss and a main chord part, wherein the bent plate comprises an edge part and a bulge part which protrudes in a bunch shape from the middle of the edge part; the outline of the edge part is matched with that of the main chord; and the edge part is wrapped on the main chord part. The containing-type node can effectively simplify the node structure, lowers the stress concentration, and enhances the strength and reliability, so that the truss structure which is usually lighter than the box-type structure by more than 30% can be widely adopted and is especially applied to the fields of hoisting and engineering machinery and heavy-duty mobile load.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com