Laminating device and method applied to large-size battery assembly

A technology for battery components and lamination devices, applied in the direction of lamination devices, lamination, electrical components, etc., can solve problems that affect battery components and pass rate, single cell increase, hidden cracks, etc., to reduce lamination Fragments and hidden cracks, improving efficiency and pass rate, buffering the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

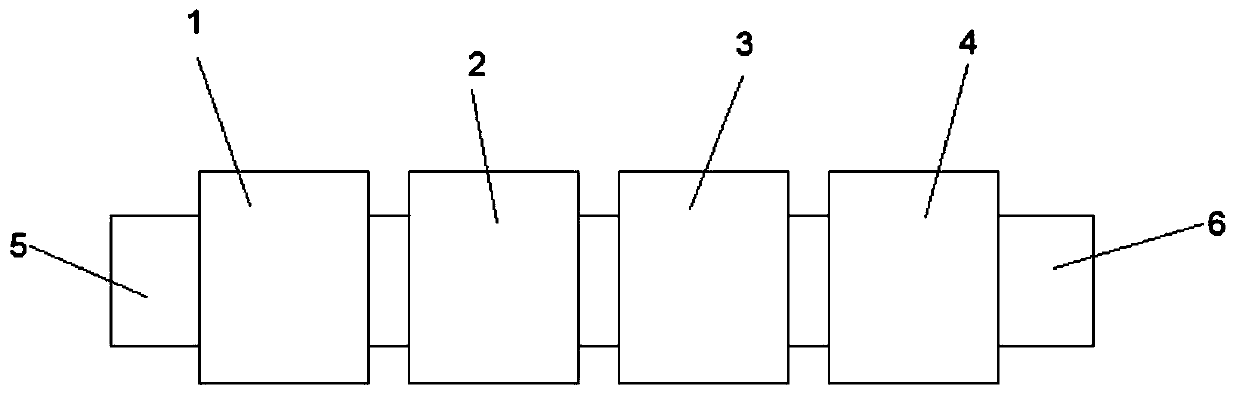

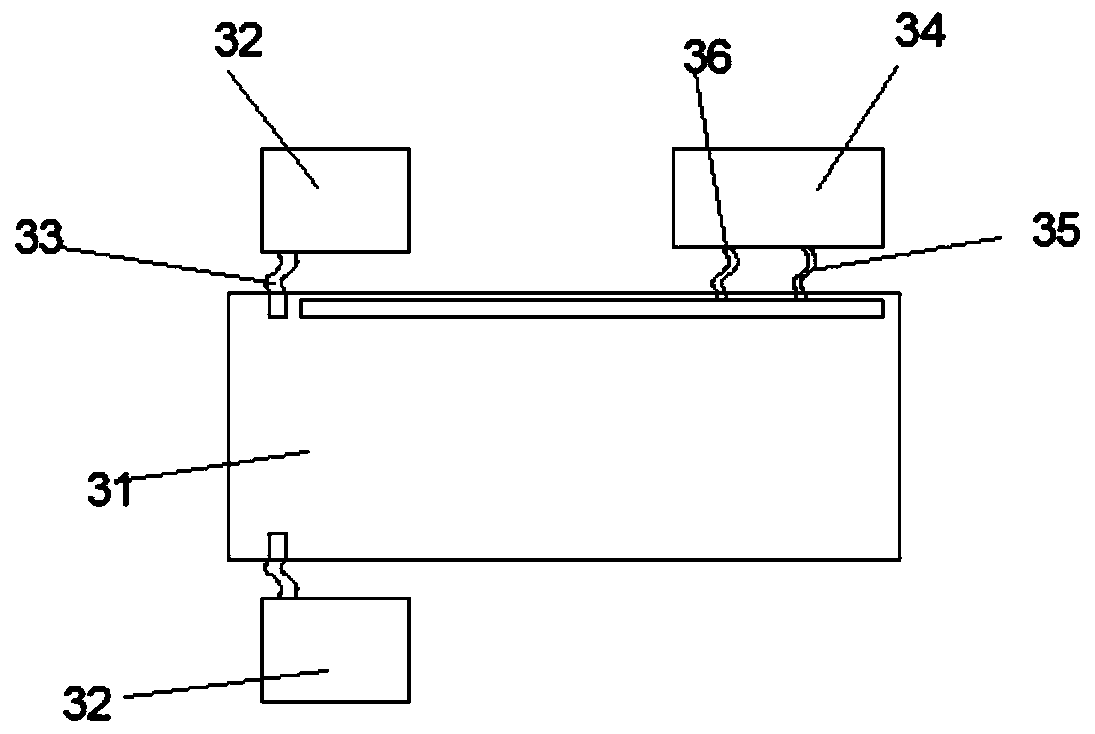

[0045] A lamination device applied to large-sized battery components, including a sequentially connected feeding table 5, a lamination chamber 1, a curing chamber 2, a pre-cooling chamber 3, a cooling chamber 4, and a discharge table 6, and the inside of the pre-cooling chamber 3 The temperature is 50-80°C, and the temperature in the cooling chamber 4 is 20-50°C. The pre-cooling chamber 3 and the cooling chamber 4 have the same structure; the pre-cooling chamber 3 includes a pre-cooling chamber 31, a refrigerator 34 and a vacuum pump 32, and the vacuum pump 32 communicates with the pre-cooling chamber 31 through a vacuum tube 33, and the pre-cooling chamber 31 is provided with a cooling chamber. The water circulation pipeline is specifically a cooling plate with a cavity inside. The cavity in the cooling plate is bent and arranged in a pipeline type. The water inlet pipe 35 and the water outlet pipe 36 at both ends of the cooling water circulation pipeline in the form of a cool...

Embodiment 2

[0048] A lamination device applied to large-sized battery components, comprising a sequentially connected feeding table 5, a lamination chamber 1, a curing chamber 2, a pre-cooling chamber 3, a cooling chamber 4, and a discharge table 6, and the pre-cooling chamber 3 includes For the first pre-cooling chamber and the second pre-cooling chamber, the temperature in the first pre-cooling chamber is 65-80°C, the temperature in the second pre-cooling chamber is 50-65°C, and the temperature in the cooling chamber 4 is 20-50°C. The structure of the first pre-cooling chamber, the second pre-cooling chamber and the cooling chamber 4 are the same; the structure of the cooling chamber 4 in the existing three-cavity automatic laminator can be adopted, and the temperature sensing device and the cooling device in each chamber are controlled by cooperation The temperature of each chamber. The lamination chamber 1 and the curing chamber 2 can also adopt the same structure as in the three-cavi...

Embodiment 3

[0050] A lamination method applied to large-scale battery components, including four steps of lamination, curing, pre-cooling and cooling. Firstly, the battery components are made by lamination and curing. Lower the component temperature to 50-80°C, and lower the component temperature to 20-50°C during the cooling phase.

[0051] The specific operation steps are as follows:

[0052] Step 1 Transfer the components into the lamination chamber, heat up to 130-160°C under vacuum, and laminate the components with a silica gel plate after the POE melts, keep the lower chamber evacuated, and place for lamination for 5-10 minutes;

[0053] Step 2: Transfer the component to the curing chamber, keep it in a vacuum environment at 130-160°C for curing, keep the lower chamber in vacuum, and keep curing for 5-10 minutes;

[0054] Step 3 Transfer the components to the pre-cooling chamber, keep the pre-cooling chamber at 50-80°C for pre-cooling, keep the lower chamber vacuumed, and keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com