CFRP sheet composite string beam structure reinforcement installation system

A system and sheet technology, used in building maintenance, construction, building construction, etc., can solve the problem of brittle fracture of carbon fiber reinforced composite materials, poor shear resistance of CFRP sheets, and failure to completely improve the stress of reinforced components, etc. problem, to achieve the effect of optimizing mechanical properties, simple structure, and avoiding uneven force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

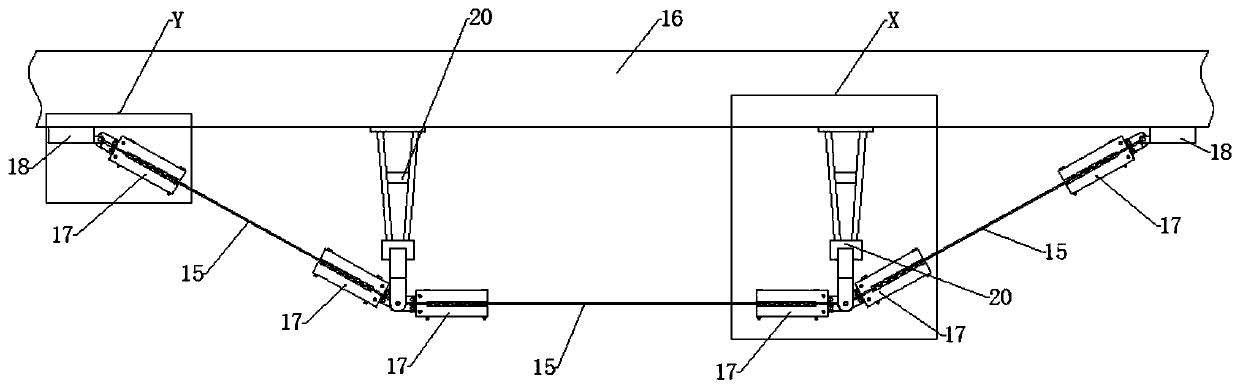

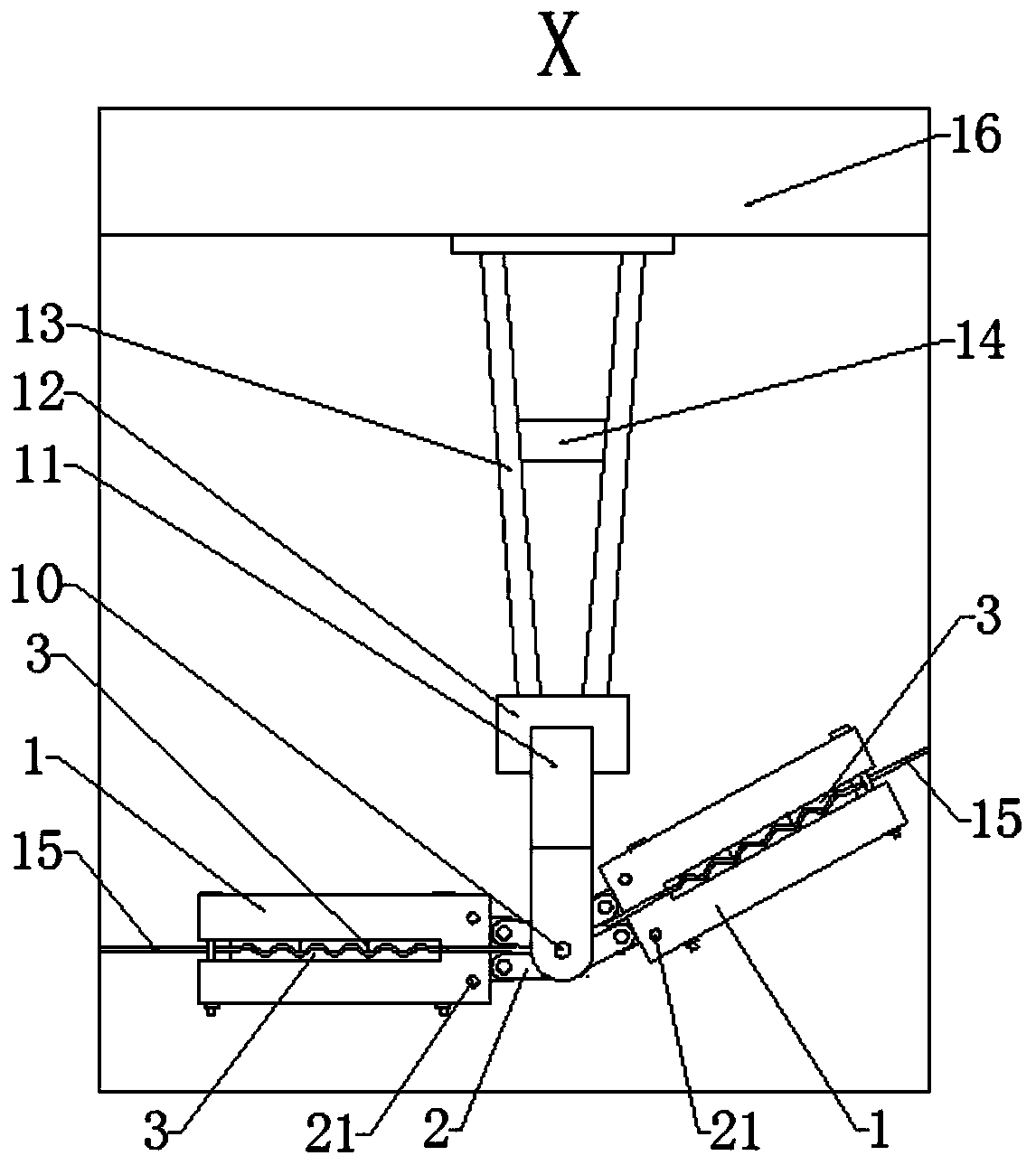

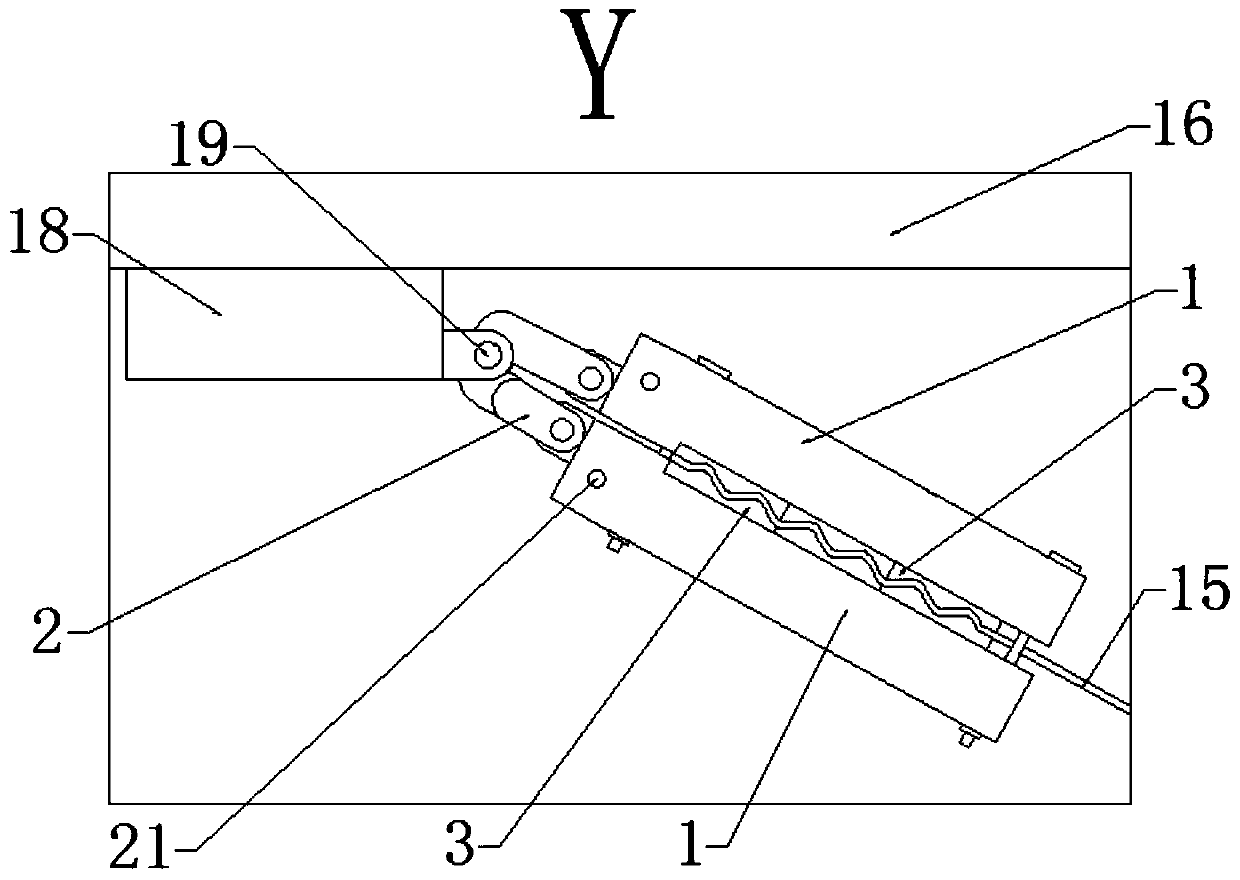

[0041] Such as Figure 1 to Figure 9 As shown, a CFRP sheet composite string beam reinforcement installation system mainly includes a beam body 16, n+1 CFRP sheets 15, n fixing brackets 20 and 2n+2 anchors 17, n is a positive value greater than or equal to 1 Integer, the beam body 16 is arranged horizontally, the fixed bracket 20 is vertically arranged on the lower surface of the beam body 16, and the lower end of the fixed bracket 20 is hinged with two anchors 17; the beam body 16 Two ends of the lower surface of the lower surface are also provided with two hinged seats 18, and the fixed brackets 20 are located between the two hinged seats 18, and all the fixed brackets 20 are arranged in sequence along the line direction of the two hinged seats 18. , the two hinged seats 18 are respectively hinged with one of the anchors 17, the CFRP sheet 15 is arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com