Method of manufacturing organic electroluminescent device and organic electroluminescent device

An electroluminescence device and a technology for a manufacturing method, which are applied in the manufacture of organic electroluminescence devices and the field of organic electroluminescence devices, can solve the problems of generating non-light-emitting regions, unable to obtain light-emitting characteristics and light-emitting life, and achieve improved accuracy and Effects of degrees of freedom

Active Publication Date: 2006-04-26

SEIKO EPSON CORP

View PDF4 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0011] However, the inventors of the present invention have confirmed that even if the technology described in the above-mentioned patent documents is adopted, even if a buffer layer is provided, sufficient light-emitting characteristics and light-emitting life cannot be obtained, and non-light-emitting regions and the like are generated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0298] Hereinafter, the present invention will be described more specifically by way of examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity at room temperature | aaaaa | aaaaa |

| Viscosity at room temperature | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Login to View More

Abstract

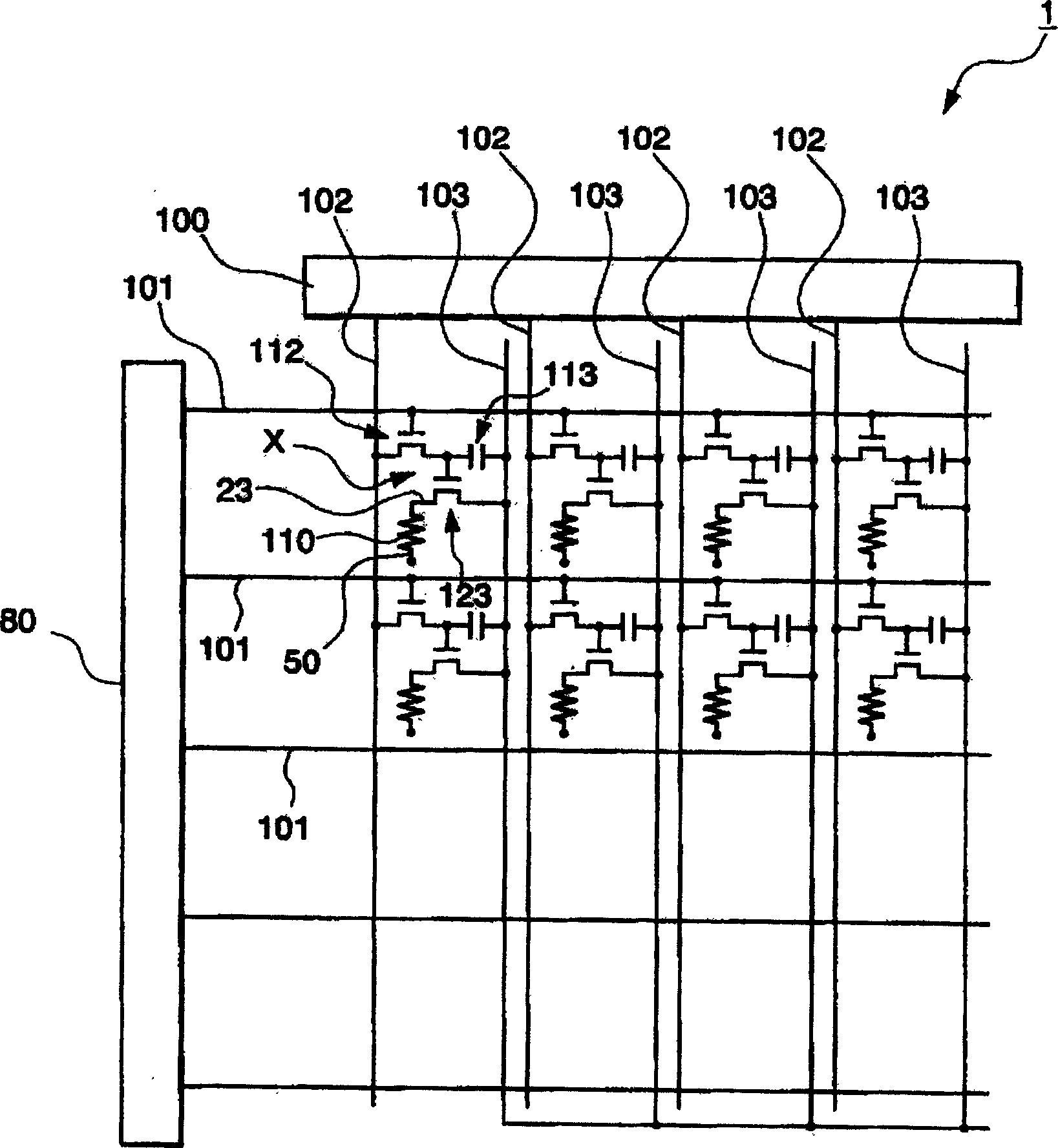

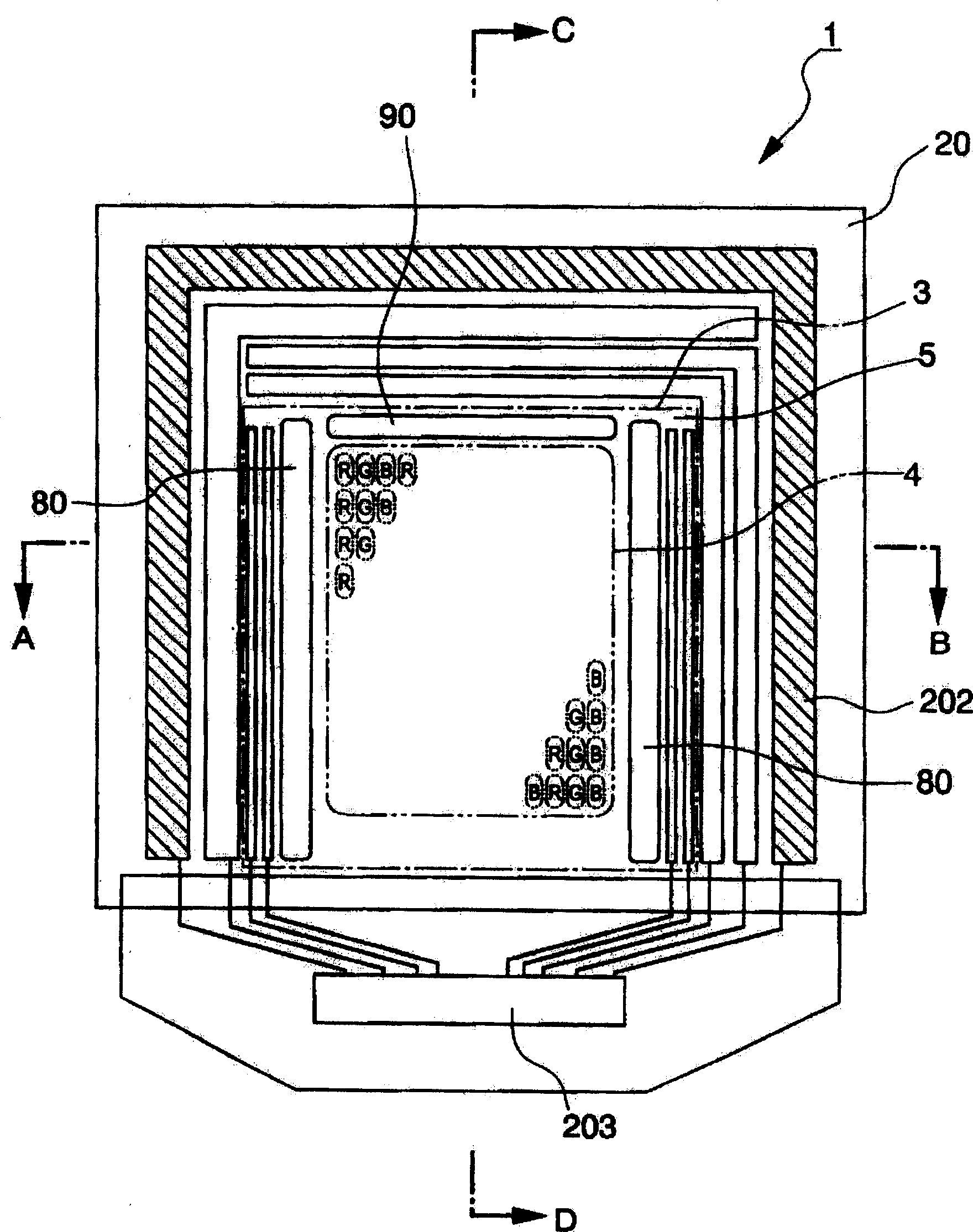

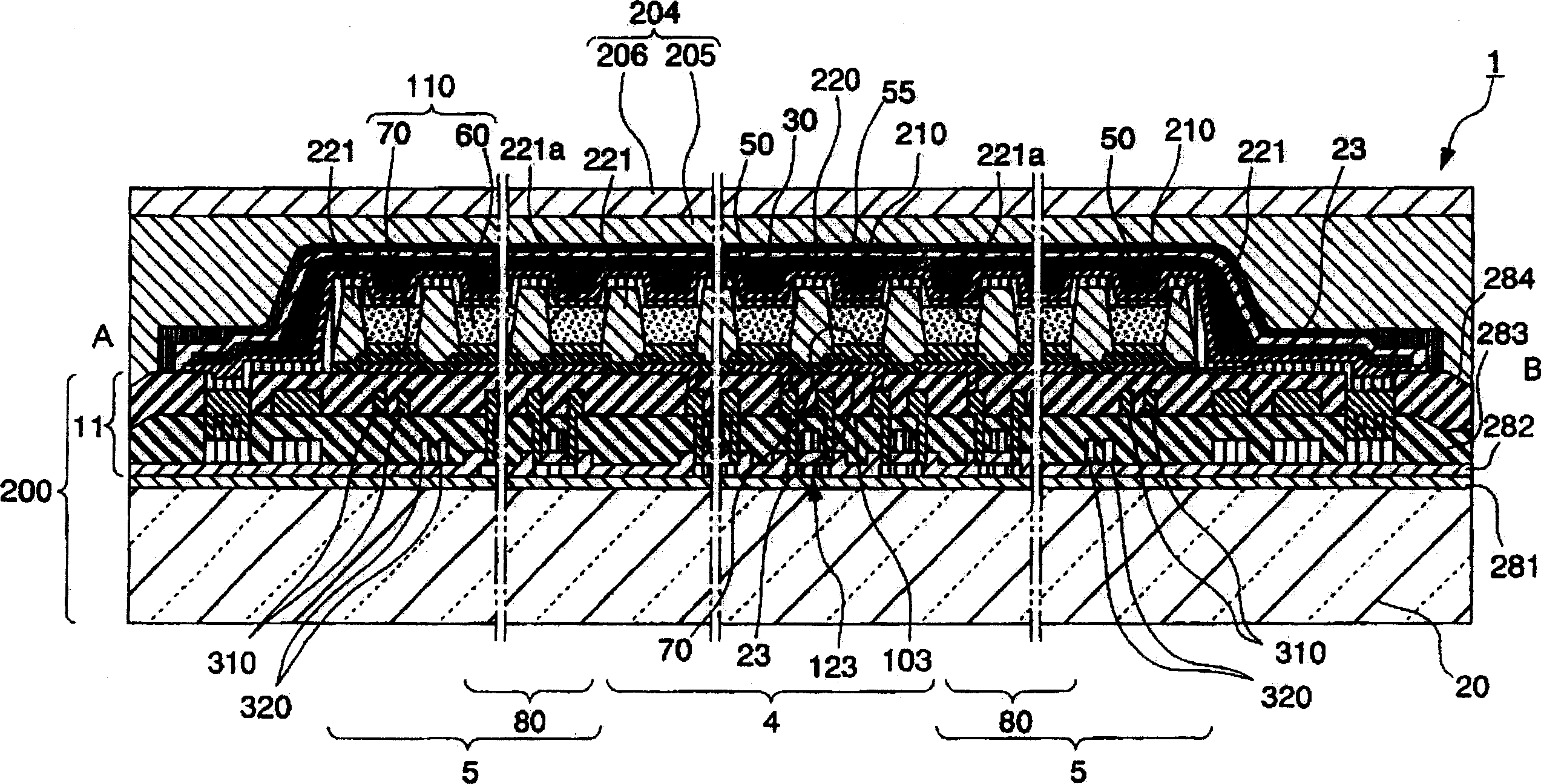

The invention provides a method for manufacturing an organic electroluminescent device, comprising a plurality of first electrodes on a substrate (20), a light-emitting functional layer arranged correspondingly to the formation positions of the first electrodes, and a layer covering the light-emitting function. A method for manufacturing an organic electroluminescent device for a second electrode of the layer, comprising: a buffer layer forming step of forming a buffer layer (210) while covering the second electrode; and forming a buffer layer (210) covering the second electrode. The process of the gas barrier layer ( ) 30, the buffer layer forming process includes: a coating process of coating a coating material having a monomer / oligomer material and a curing agent without using a solvent under a vacuum atmosphere, and making the coating material The thermal curing process of curing to form a buffer layer. According to the method of manufacturing an organic EL device of the present invention, sufficient luminescence characteristics or luminescence lifetime can be obtained and generation of non-luminescence regions can be suppressed. The present invention also provides an organic electroluminescent device.

Description

technical field [0001] The present invention relates to a method for manufacturing an organic electroluminescent device and an organic electroluminescent device. Background technique [0002] In recent years, an organic electroluminescent device (hereinafter, referred to as an organic EL device) having a light-emitting functional layer has been known. Such an organic EL device generally has an organic light-emitting layer between an inorganic anode and an inorganic cathode. Furthermore, in order to improve the hole injection property or electron injection property, a configuration in which an organic hole injection layer is arranged between an inorganic anode and an organic light-emitting layer, or a configuration in which an electron injection layer is arranged between an organic light-emitting layer and an inorganic cathode has been proposed. . [0003] Here, the electron injection layer, which has material properties that easily release electrons, easily reacts with moi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05B33/10G09F9/30H01L21/00H01L23/00H01L29/04H05B33/04

CPCH10K59/8722H10K59/873H10K59/87H05B33/10H05B33/22H10K50/84H10K50/844H10K50/8426

Inventor 林建二野泽陵一山内幸夫

Owner SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com