Leaf-peeling system of combine harvester of whole stalk type canes

A combine harvester and leaf stripping technology, which is applied to harvesters, agricultural machinery and implements, and applications, can solve the problems of small contact between leaf stripping elements and sugarcane leaves, poor leaf stripping effect, and immature technology, and achieve reduction Effects of small sugarcane stalk collision damage, prolonging service life and improving leaf stripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

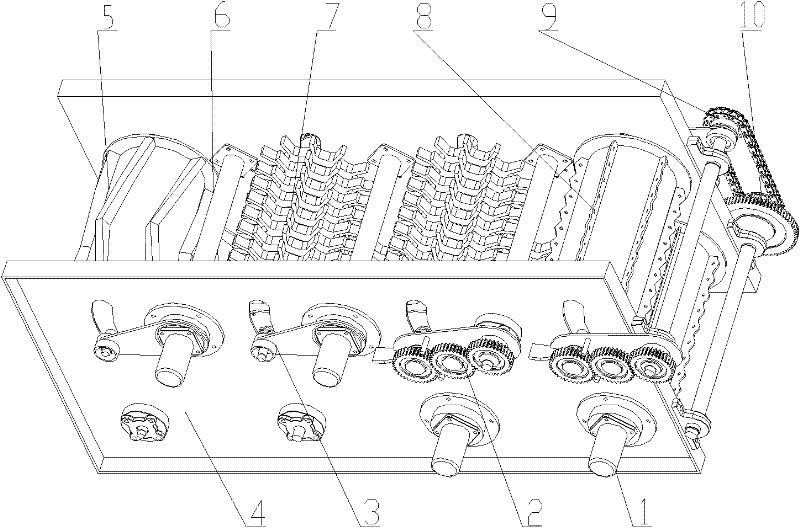

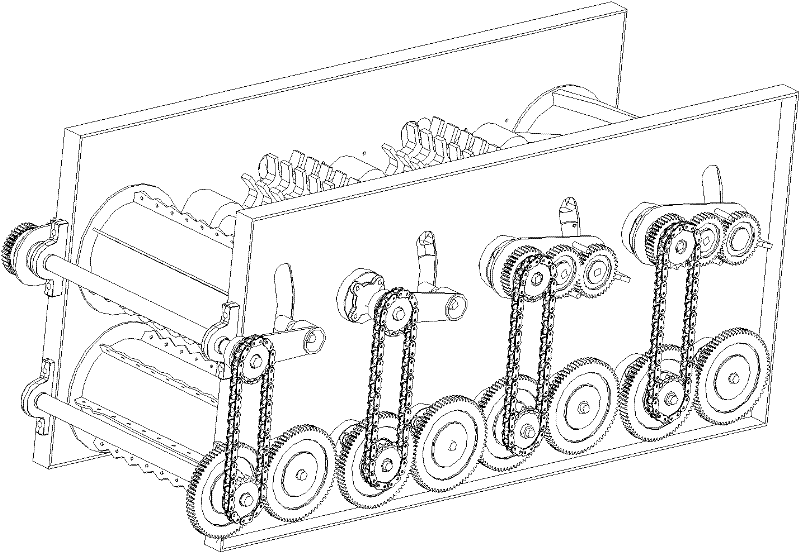

[0033] like figure 1 , figure 2 As shown, a whole stalk type sugarcane combine harvester leaf stripping system is mainly composed of a driving motor 1, a floating gear connecting plate 2, a floating connecting plate 3, a side plate 4, a conveying roller group 5, a driving shaft 6, and a leaf stripping roller group 7. The output drum group 8, the transmission chain 9 and the transmission gear 10 are composed.

[0034] The upper and lower rollers of conveying roller group 5, leaf stripping roller group 7 and output roller group 8 rotate oppositely under the drive of transmission chain 9 and transmission gear 10, and each roller group is driven by a drive motor 1. The side plate 4 has arc grooves, and the upper roller devices of the delivery roller group 5, the leaf stripping roller group 7 and the output roller group 8 can be driven by the floating gear connecting plate 2 and the floating connecting plate 3 around the drive shaft 6 in a circle. Float up and down in the arc gr...

Embodiment 2

[0046] This embodiment is the same as Embodiment 1 except the following features: the leaf stripping roller group is provided with four pairs of leaf stripping roller devices.

Embodiment 3

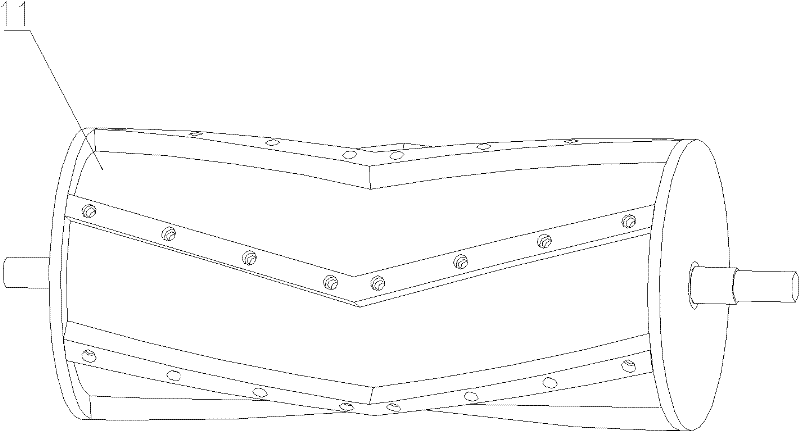

[0048] The structure of this embodiment is as Figure 10 As shown, it is the same as Embodiment 1 except for the following features: the rectangular strip-shaped protrusions of the leaf stripping cylinder device are arranged in a spiral interval in the radial direction of the cylinder, effectively increasing the contact times between the rectangular strip-shaped protrusions and sugarcane and frequency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com