Method for rapidly manufacturing organic fertilizer and feed mineral element additive

A technology of organic fertilizers and mineral elements, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as time-consuming and incomparable economic costs, and achieve saving fertilizer consumption, preventing fertilizer loss, and high fertilizer retention capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

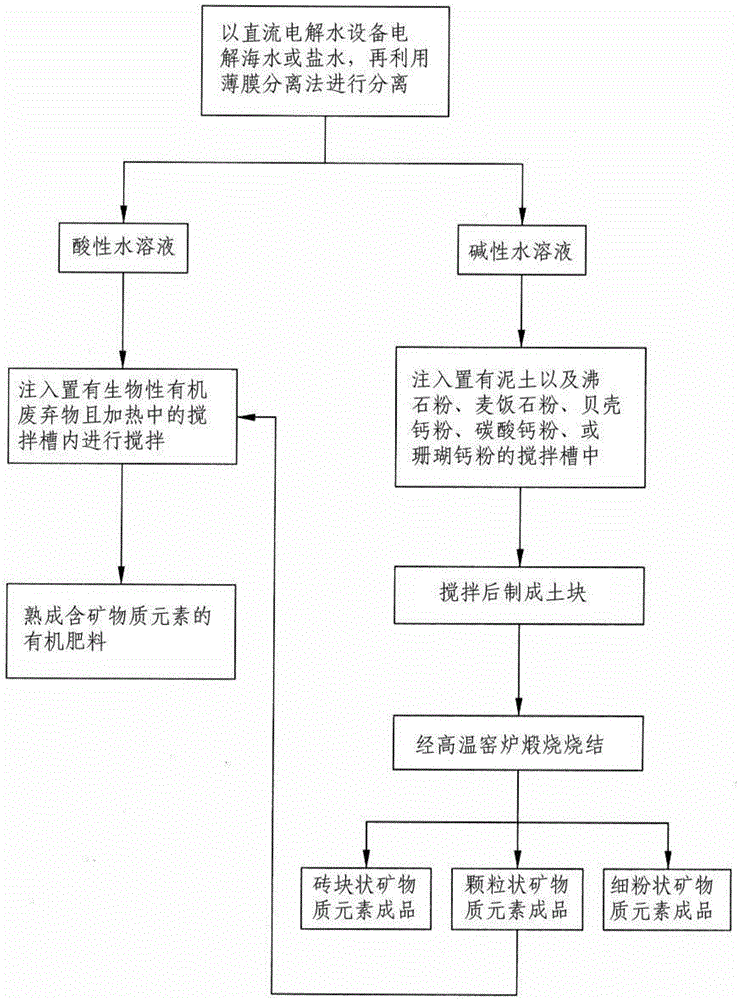

[0040] figure 1 The flow chart of the present invention is used for further specifying the method that the present invention can manufacture organic fertilizer and feed mineral element addition rapidly, comprising:

[0041] (1) Seawater or brine can be electrolyzed by direct current electrolyzed water equipment, and then acidic aqueous solution and alkaline aqueous solution can be separated by membrane separation method;

[0042] (2) inject the acidic aqueous solution into the stirring tank that is placed with biological organic waste and stir;

[0043] (3) mature organic fertilizer containing mineral elements;

[0044] (4) Inject the alkaline aqueous solution into the mixing tank with earth and zeolite powder, medical stone powder, shell calcium powder, calcium carbonate powder or coral calcium powder;

[0045] (5) Make soil block after stirring;

[0046] (6) Calcined and sintered in a high-temperature kiln;

[0047] (7) Make brick-shaped, granular or fine powdered minera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com