Quick preparation method for multi-shell cuprous oxide nano-spheres

A cuprous oxide and nanosphere technology, applied in copper oxide/copper hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems of large surface area, multi-shelled cuprous oxide nanospheres, low density and other problems, and achieve product The effect of high purity, good product morphology and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

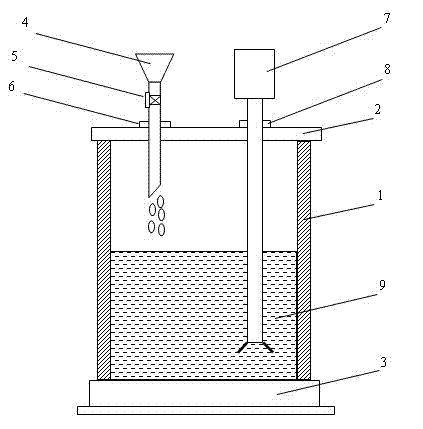

[0049] figure 1 As shown, it is a state diagram for the preparation of the cuprous oxide suspension, and the positions of each part must be correct, proportioned according to the amount, and operated in sequence.

[0050] The amount of the chemical substance required for the preparation is determined according to a preset range, with grams and milliliters as measurement units.

[0051] The preparation of the cuprous oxide suspension is carried out in a beaker, at normal temperature, adding a pH regulator and a reducing agent dropwise, and completing during the stirring process;

[0052] The beaker is a vertical cylinder, the lower part of the beaker 1 is fixed on the workbench 3, the upper part of the beaker 1 is the beaker cover 2; the upper left part of the beaker cover 2 is provided with a dripping funnel 4, and the dropping funnel 4 passes through the beaker cover 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com