Decomposition characteristic test system for solid fluidization exploitation of marine non-diagenetic hydrate and method

A technology of solid-state fluidized mining and characteristic testing, which is applied in the direction of measuring devices, fuel oil testing, and analyzing materials, can solve the problems of non-diagenetic hydrate fragmentation and flow decomposition that cannot be represented, and achieve the goal of improving the accuracy of experimental testing and enhancing simulation capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

[0022] see figure 1 , figure 2 .

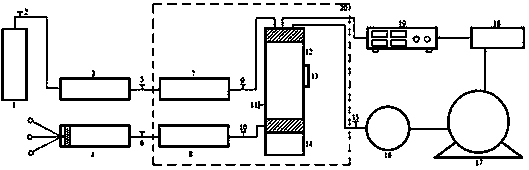

[0023] The test device for the decomposition characteristics of marine non-diagenetic hydrate solid fluidization mining consists of a methane gas source 1, an air compressor 3, an advection pump 4, a gas intermediate container 7, a solution intermediate container 8, a high-pressure reactor 12, a back pressure controller 16, Gas flowmeter 17, computer 18 with data acquisition software, temperature and pressure monitor 19, and constant temperature gas bath box 20 are composed.

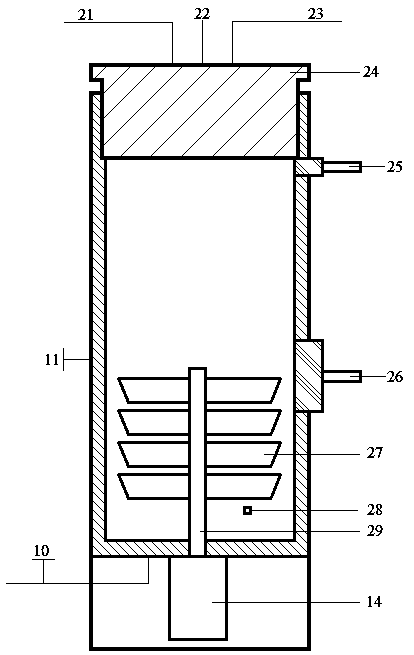

[0024] The top of the high-pressure reactor 12 is equipped with a reactor probe 24, which is connected to the booster valve 9 and the gas intermediate container 7 through the gas injection pipeline 21, connected to the temperature and pressure monitor 19 through the pressure monitoring pipeline 22, and connected to the temperature and pressure monitor 19 through the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com