Magnesium/titanium laser melting braze welding method assisted by nickel-plated layer

A welding method and nickel coating technology, which is applied in the field of magnesium/titanium laser welding, can solve the problems of difficult metallurgical reaction, low joint strength, and difference in melting point, etc., and achieve the effect of facilitating wetting and spreading, low cost, and reducing alignment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

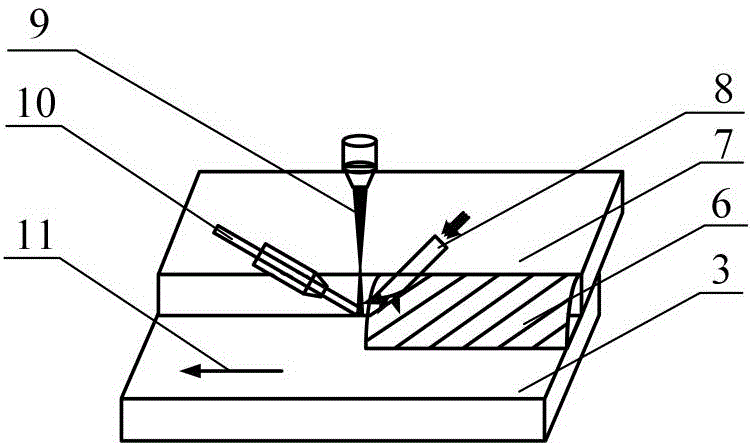

Method used

Image

Examples

Embodiment 1

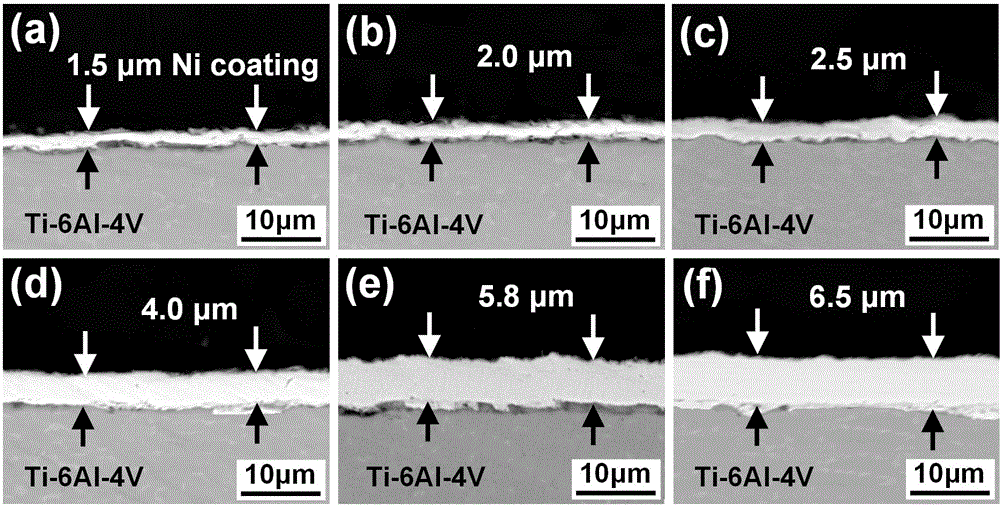

[0032]Example 1: The base materials are AZ31B magnesium alloy and Ti-6Al-4V titanium alloy, and the size is 100×50×1 mm.

[0033] (1) Plate treatment: Use hydrochloric acid with a mass fraction of 36 to 38%, hydrofluoric acid with a mass fraction of 40%, and pickling solutions with a volume fraction of 15% hydrochloric acid, 5% hydrofluoric acid, and 80% distilled water to clean titanium Plate for 2 to 3 minutes, then rinse with alcohol and dry for use; use an angle grinder to polish the magnesium plate to remove the oxide film;

[0034] (2) Titanium plate electroplating process: according to the mass concentration of NiSO 4 ·6H 2 O 200 g / L, NaCl 10 g / L, H 3 BO 3 32 g / L, Na 2 SO 4 72 g / L, MgSO 4 ·7H 2 O 60 g / L is equipped with electroplating solution, the nickel plate is used as the anode, and the titanium plate is used as the cathode. During electroplating, the pH value is controlled at 5.0, the temperature is 35°C, the magnetic stirrer rotates at 250 r / min, and the ...

Embodiment 2

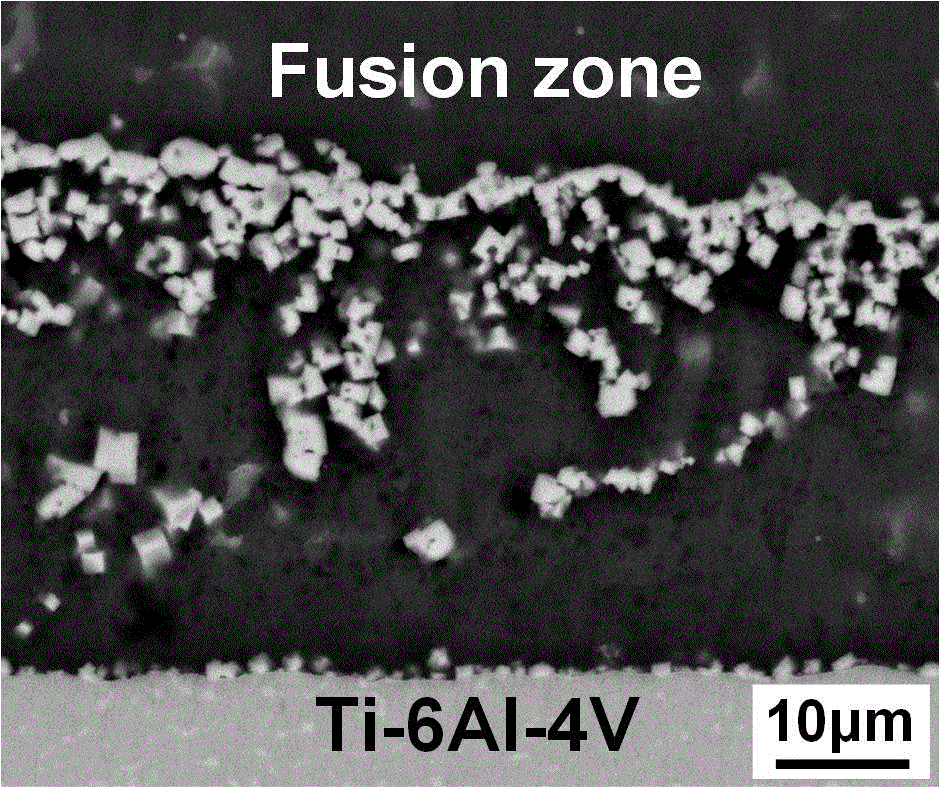

[0039] The difference between this embodiment and embodiment 1 is that the electroplating time is 60 min, and the others are the same as embodiment 1. The thickness of the obtained nickel coating is about 2 μm, and the scanning electron microscope photo of the nickel-plated titanium plate cross section is shown in image 3 As shown in part (b), the tensile test results of the magnesium / titanium joint show that the fracture occurs at the interface, and the joint strength is 211 N / mm.

Embodiment 3

[0041] The difference between this embodiment and embodiments 1 to 2 is that the electroplating time is 180 min, and the others are the same as embodiments 1 to 2. The thickness of the obtained nickel coating is about 6.5 μm, and the scanning electron microscope photo of the nickel-plated titanium plate cross section is as follows: image 3 As shown in part (f), the tensile test results of the Mg / Ti joint showed that the fracture occurred in the weld, and the joint strength was 220 N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com