Laser annealing device and method

A laser annealing and laser technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of dual-laser IGBT annealing and low laser utilization, and achieve the effect of improving absorption efficiency, ensuring activation efficiency, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

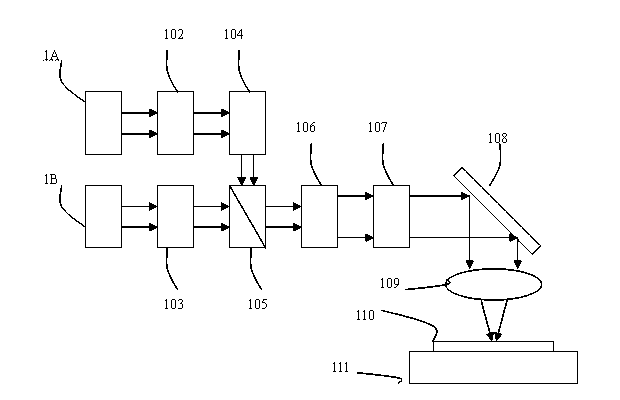

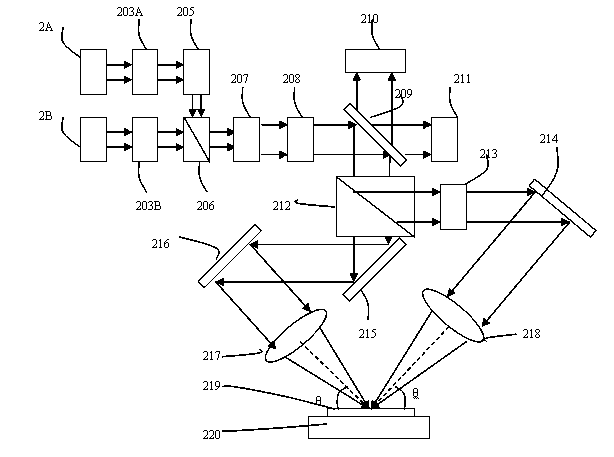

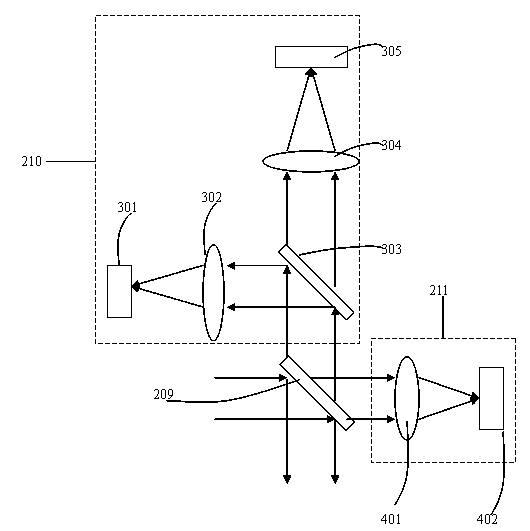

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] For ease of understanding, some relevant definitions are explained below:

[0028] When light travels through the surface of an optical component, such as a beamsplitter, at non-perpendicular angles, both reflection and transmission properties depend on polarization phenomena. In this case, the coordinate system used is defined by the plane containing the input and reflected beams. If the polarization vector of the ray is in this plane, it is called P polarization; if the polarization vector is perpendicular to this plane, it is called S. polarization. Any input polarization state can be expressed as a vector sum of S and P components.

[0029] When natural light is reflected and refracted on the dielectric interface, the reflected light and refracted light are generally partially polarized light. Only when the incident angle is a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com