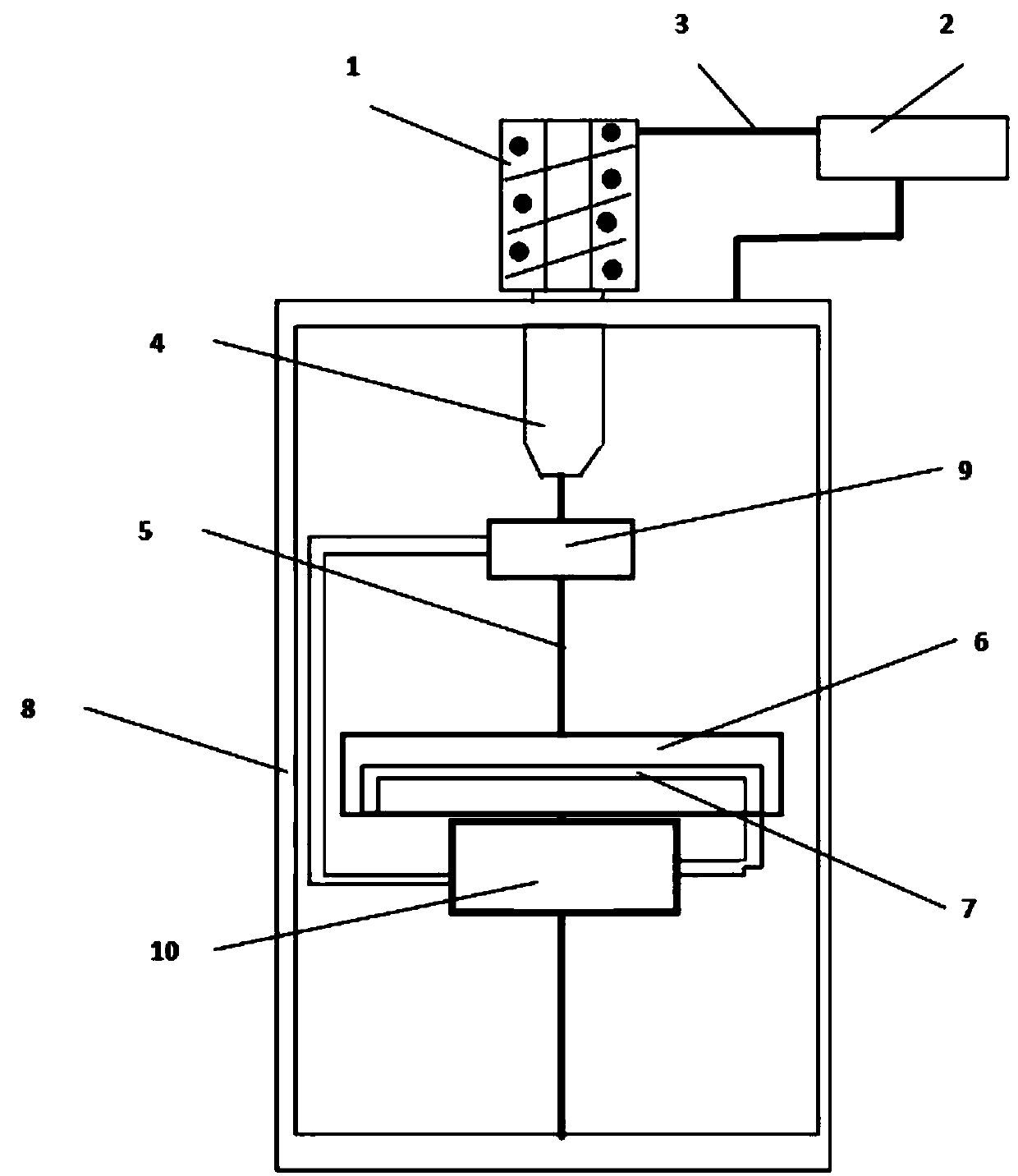

High-speed 3D printer with cooling system

A technology of 3D printer and cooling system, applied in 3D object support structure, additive manufacturing, processing drive device, etc., can solve the problem of low printing speed and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] First of all, it must be pointed out that this embodiment is only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

[0021] The printer 8 is connected with the spiral material extruding mechanism 1, and printing starts, and the nozzle of the printer and the heating device 4 start to work, and the nozzle of the printer and the nozzle of the heating device 4 are heated to a certain temperature to ensure that the printing material 3 melts when entering the nozzle. After the temperature of the nozzle is heated to a predetermined temperature, the spiral material extruding mechanism 1 starts to work to extrude the printing material 3 from the material box 2 and squeeze the printing material 3 into the printer nozzle and the heating device 4 . The printing material 3 melts in the printing head, and at the same time, the printing head moves on the XY plane to extrude the printing material 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com