Phase change memory device and method for manufacturing the same

a phase change memory and memory device technology, applied in the direction of bulk negative resistance effect devices, semiconductor devices, electrical equipment, etc., can solve the problems of poor sensing margin and high integration difficulty of phase change memory devices, and achieve the effect of quick cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]Hereafter, specific embodiments of the present invention will be described in detail with reference to the attached drawings.

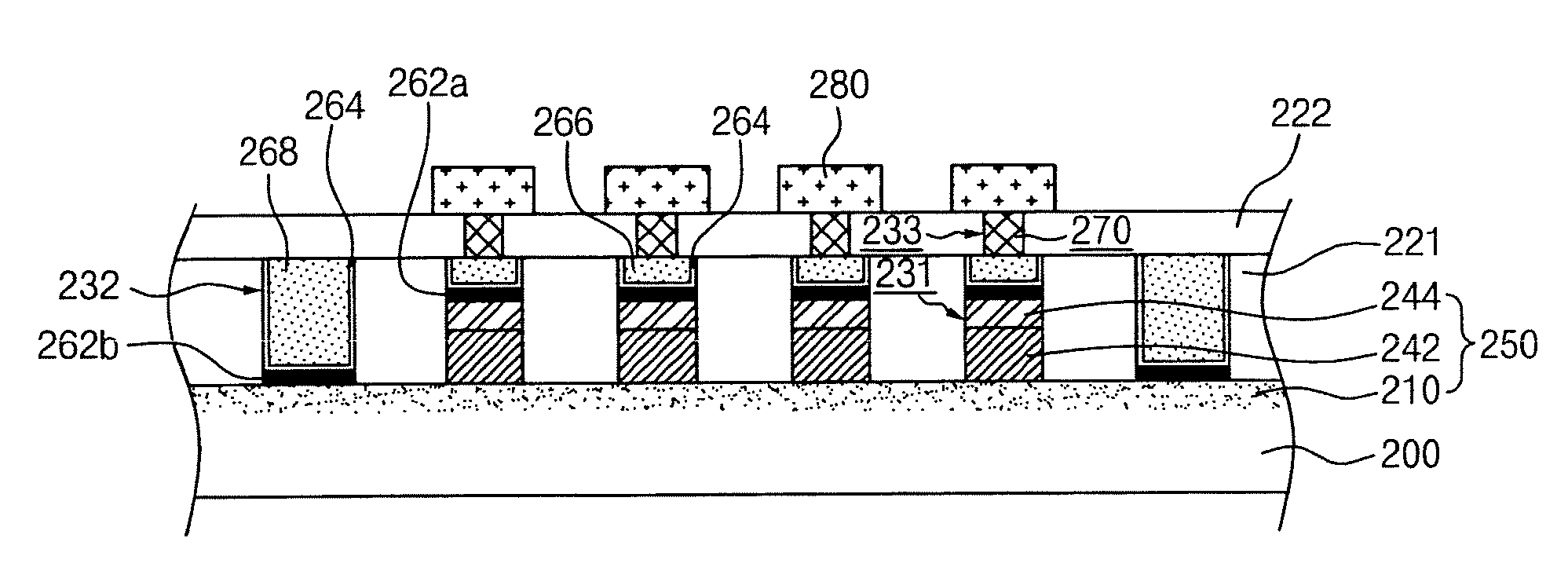

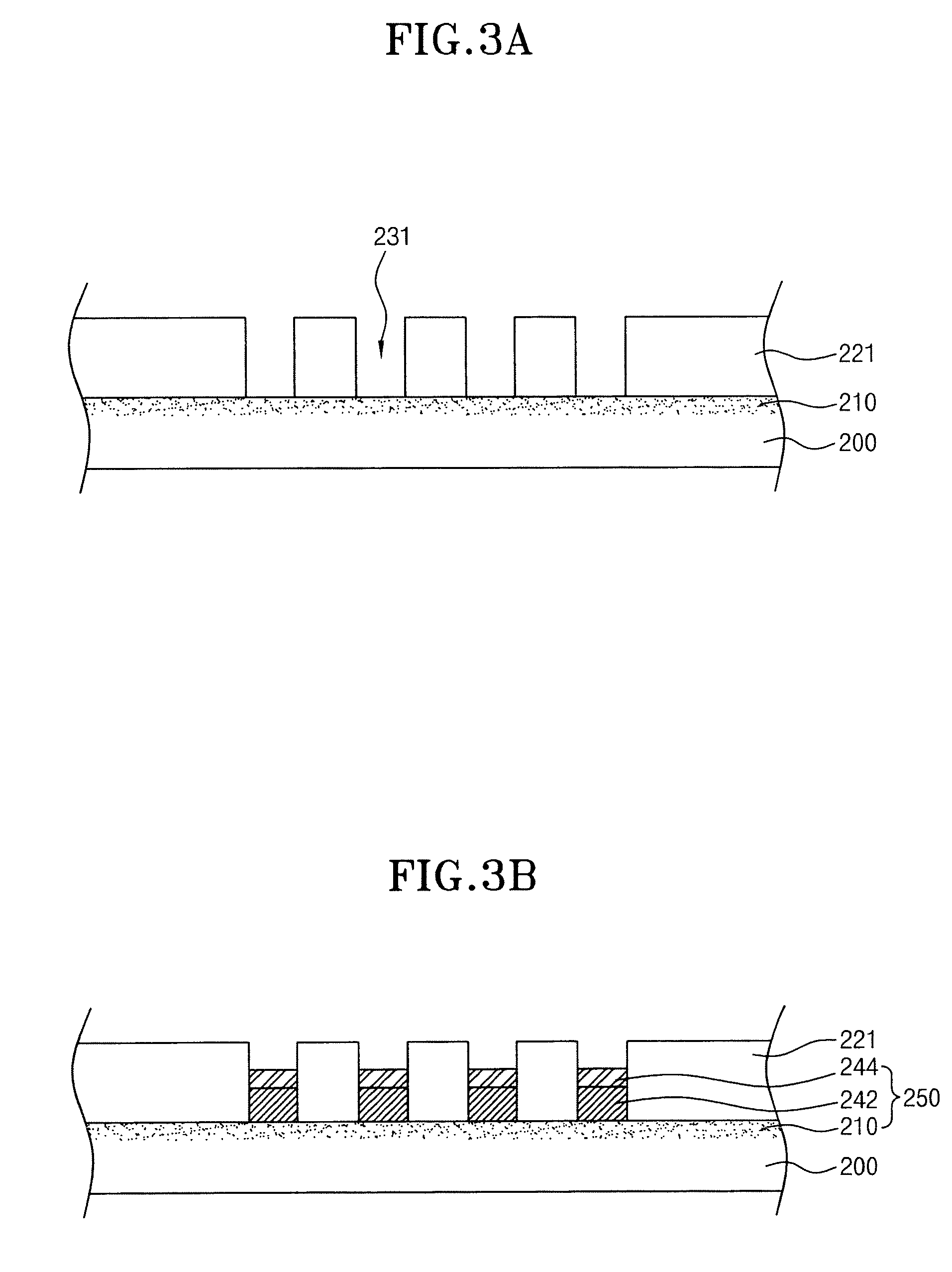

[0063]FIG. 2 is a cross-sectional view showing a phase change memory device in accordance with an embodiment of the present invention.

[0064]Referring to FIG. 2, a silicon substrate 200 is prepared. The silicon substrate 200 has a bar-type active region that comprises a plurality of phase change cell areas. An N-type impurity region 210 is formed in the surface of the active region of the silicon substrate 200. A first insulation layer 221 is formed on the silicon substrate 200 including the N-type impurity region 210. First contact holes 231 are defined in portions of the first insulation layer 221 corresponding to respective phase change cell areas. Second contact holes 232 are defined in portions of the first insulation layer 221 on both sides of the plurality of phase change cell areas to expose the N-type impurity region 210 formed in the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com