Method for controlling content of nitrogen in oriented silicon steel

A technology of oriented silicon steel and control method, which is applied to the improvement of process efficiency, electric furnace, furnace, etc., can solve the problems of long process, lack of multi-batch supplementation, low nitrogen content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

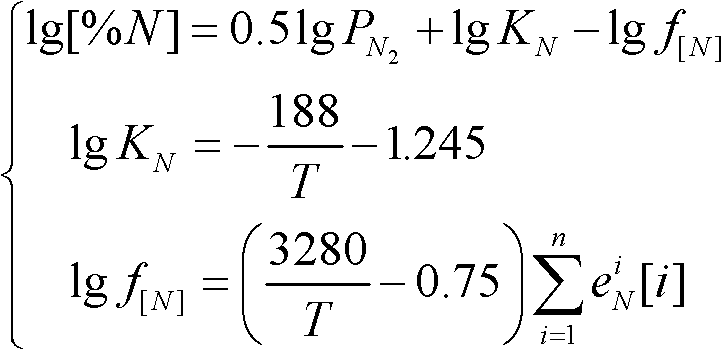

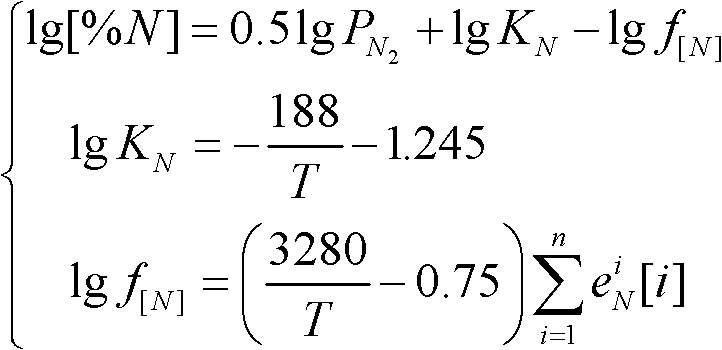

Method used

Image

Examples

Embodiment 1

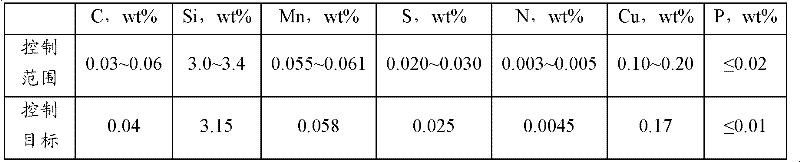

[0034] The equipment adopts a 50kg vacuum induction furnace with a power supply of 160KW, a rated voltage of 380V, a maximum temperature of 1700°C, and a frequency of 2500Hz. Furnace load 40kg, smelting 1 furnace of oriented silicon steel QX1 ([N]≤0.005wt%), the composition control range and target requirements are shown in Table 1, and the raw material ingredients are shown in Table 2 (excluding carbon and aluminum for deoxidation) . Among them, the chemical composition of pure iron is Mn: 0.042wt%, N: 0.037wt%, P: 0.0086wt%, S: 0.035wt%, Cu: 0.034wt%, others are Fe and trace impurities; ferrosilicon nitride The nitrogen content is 26wt%.

[0035] Table 1 The composition control range and control target of grain-oriented silicon steel QX1

[0036]

[0037] Table 2 Raw material ingredients for smelting grain-oriented silicon steel QX1

[0038] pure iron

the carbon

copper ...

Embodiment 2

[0053] The equipment adopts a 50kg vacuum induction furnace with a power supply of 160KW, a rated voltage of 380V, a maximum temperature of 1700°C, and a frequency of 2500Hz. The furnace load is 40kg, and one furnace of oriented silicon steel QX2 ([N]=0.008wt%-0.009wt%) is smelted. The composition control range and target requirements are shown in Table 5, and the raw material ingredients are shown in Table 6 (not included in the deoxidation use). carbon and aluminum).

[0054] Table 5 Component control range and control target of grain-oriented silicon steel QX2

[0055]

[0056] Table 6 List of raw materials for smelting grain-oriented silicon steel QX2

[0057]

[0058] Specific steps are as follows:

[0059] (1) Pure iron and carbon 12g are put into crucible, and aluminum, metal silicon, carbon, ferrous sulfide, tin, ferrosilicon nitride, metal manganese are put into vacuum hopper according to the order of alloy feeding;

[0060] (2) Vacuumize the furnace until th...

Embodiment 3

[0068] The equipment adopts a 50kg vacuum induction furnace with a power supply of 160KW, a rated voltage of 380V, a maximum temperature of 1700°C, and a frequency of 2500Hz. Furnace load 40kg, smelting 1 furnace of oriented silicon steel QX3 ([N]=0.006wt%-0.008wt%), its composition control range and target requirements are shown in Table 8, raw material ingredients are shown in Table 9 (not included in deoxidation) carbon and aluminum).

[0069] Table 8 The composition control range and control target of grain-oriented silicon steel QX3

[0070]

[0071] Table 9 Raw material ingredients for smelting grain-oriented silicon steel QX3

[0072]

[0073] According to the target composition of the oriented silicon steel QX3, at 1600°C, according to the nitrogen filling pressure calculation formula, the nitrogen filling pressure is 5.0KPa. Within the required composition range, the chemical composition of the finished steel QX3 is shown in Table 10.

[0074] Specific steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com