Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good prospects for industrialization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

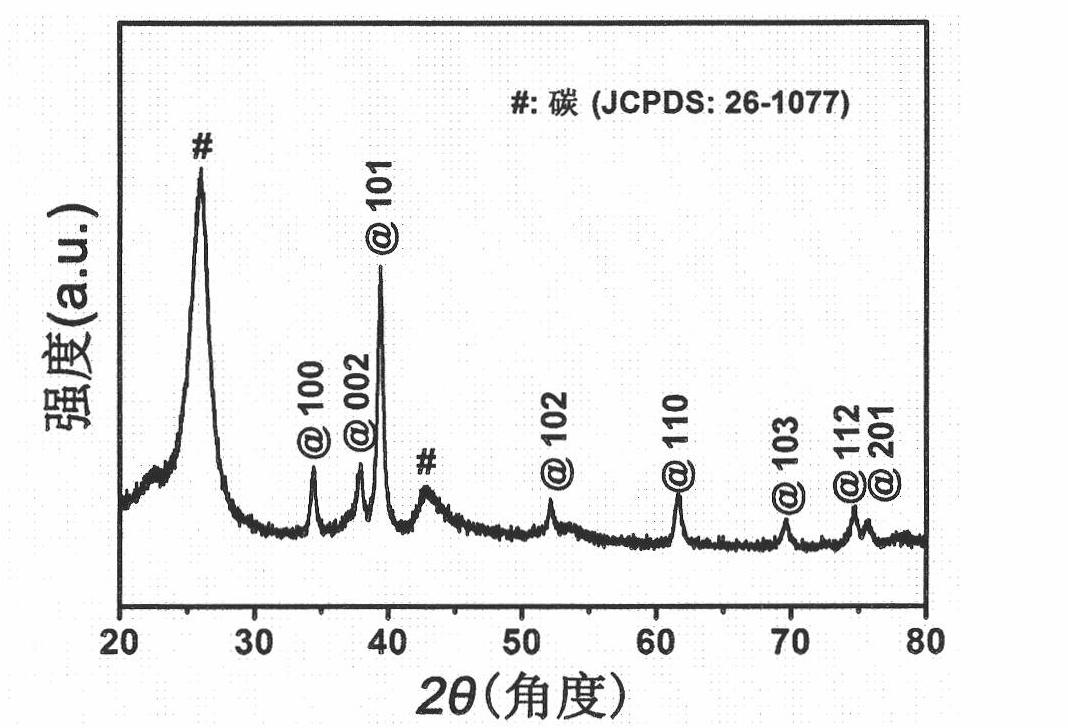

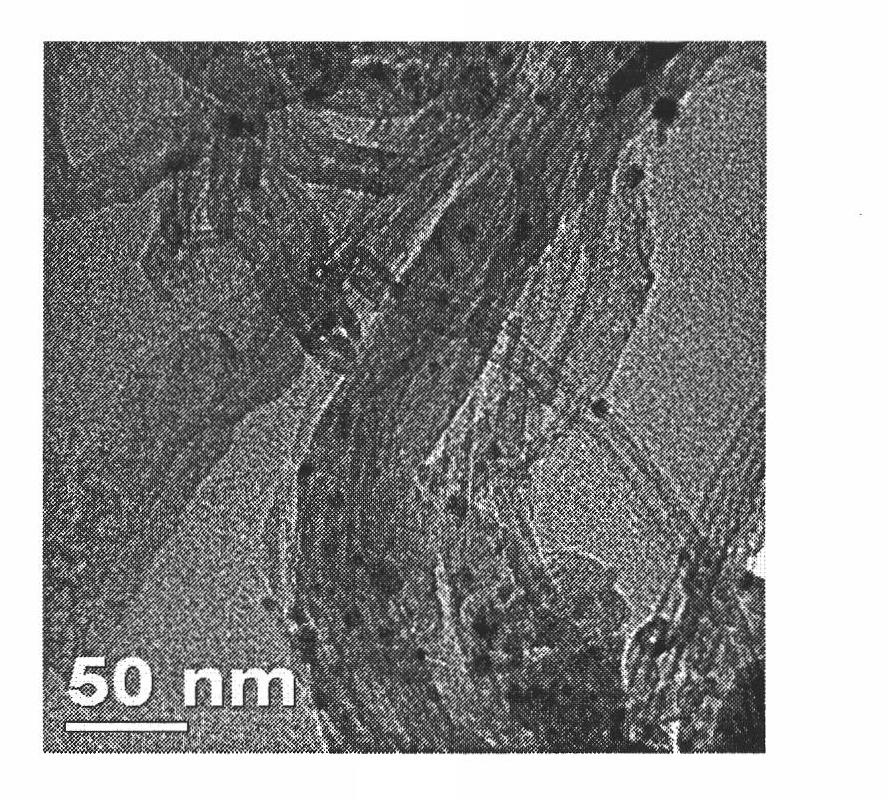

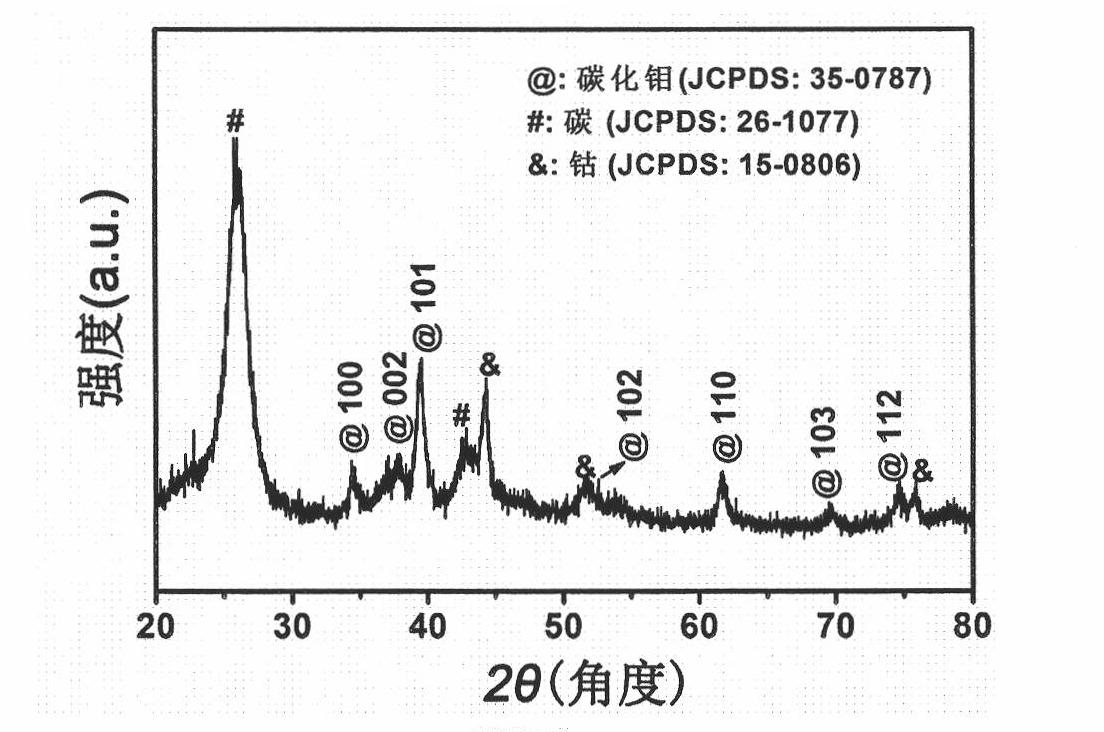

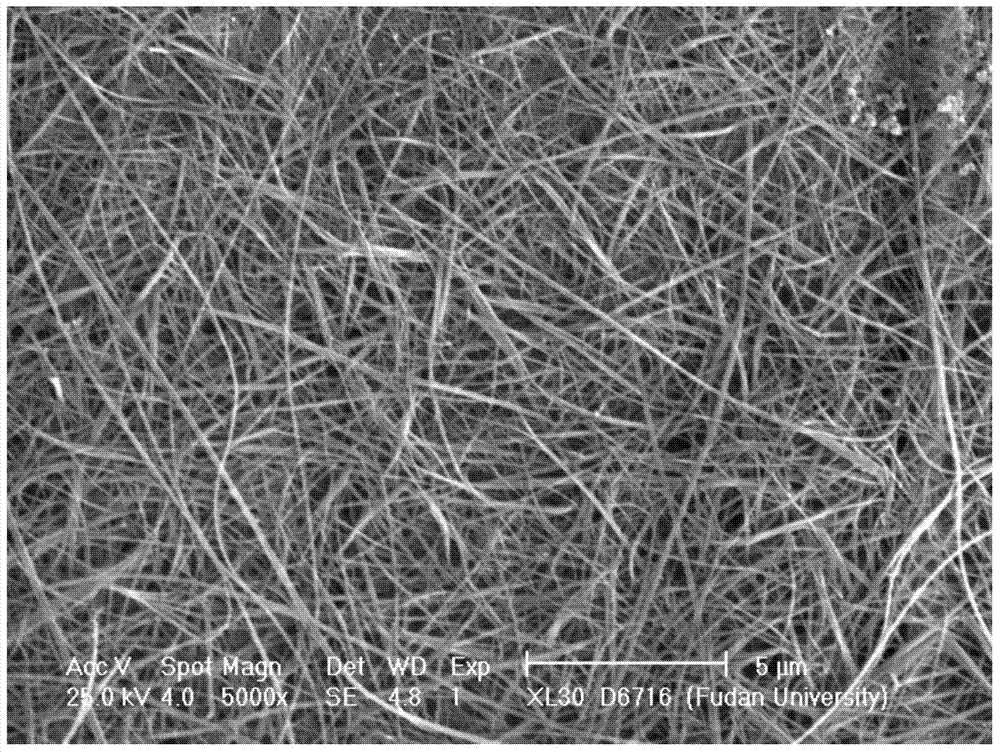

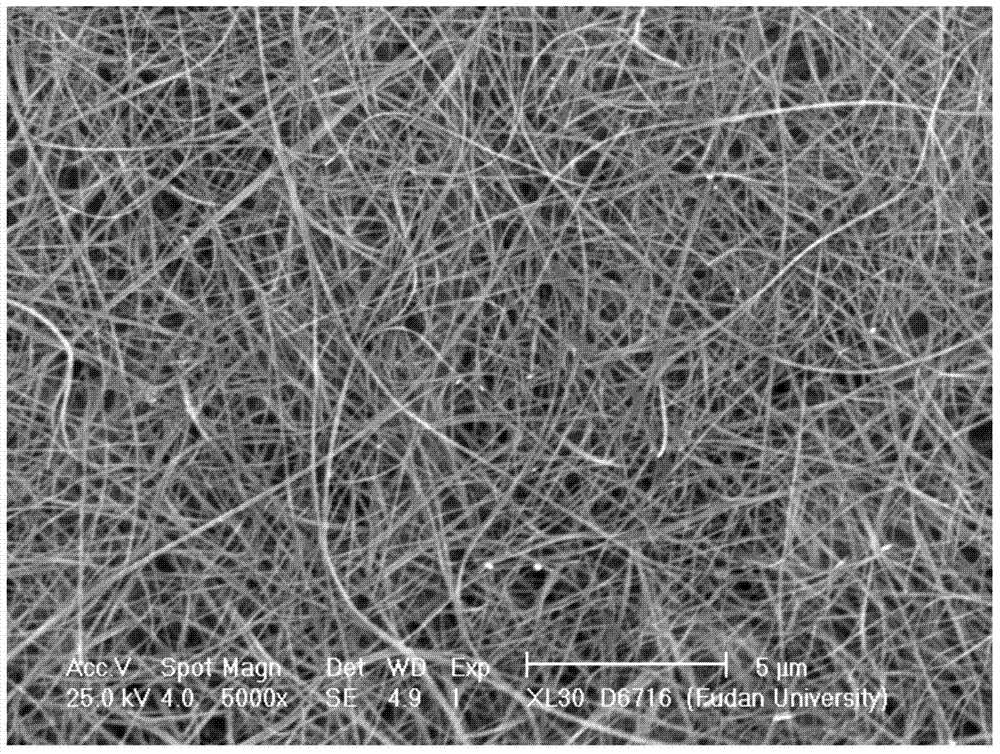

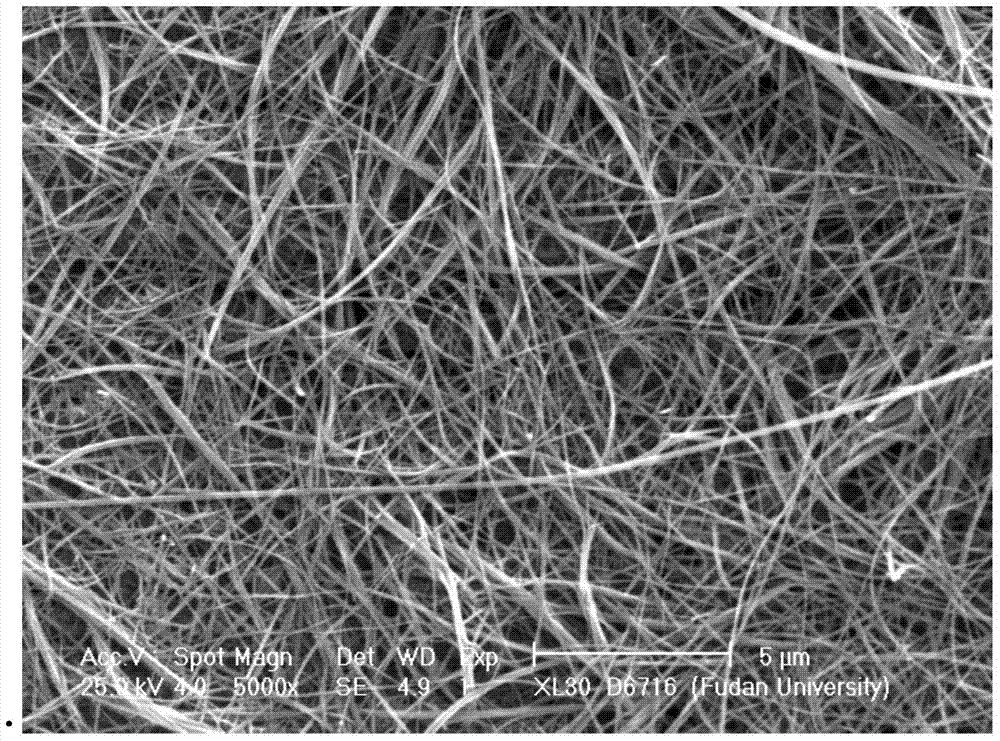

Synthetic method of load type molybdenum carbide catalyst

InactiveCN101829588AFacilitated DiffusionLarger than surfaceHydrogenPhysical/chemical process catalystsCarbon nanotubeMolybdenum carbide

The invention relates to a synthetic method of a load type molybdenum carbide catalyst, which belongs to the field of catalytic materials and comprises the steps of: dispersing organic-inorganic mixed molybdenum oxide-polyaniline used as precursors in H2O / EtO; drying after mixing with carriers, such as carbon nanotubes and the like; and then roasting at an inert atmosphere to obtain the load typemolybdenum carbide catalyst. In the load process, other metal salts can also be added to modify the molybdenum carbide catalyst to obtain a metal modified load type molybdenum carbide catalyst. The molybdenum carbide catalyst prepared by the invention has the advantages of large external surface area, less surface carbon deposition, abundant catalytic performance of precious metal and the like, and can be used for conveniently modifying the catalyst. The loading molybdenum carbide catalyst has important application in various catalytic reactions.

Owner:FUDAN UNIV

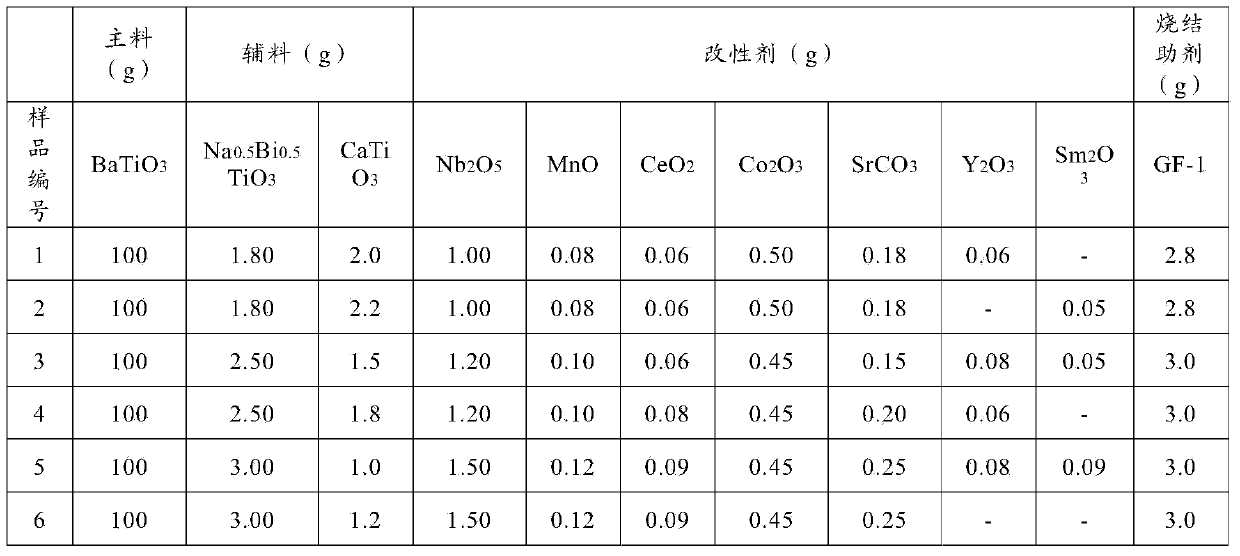

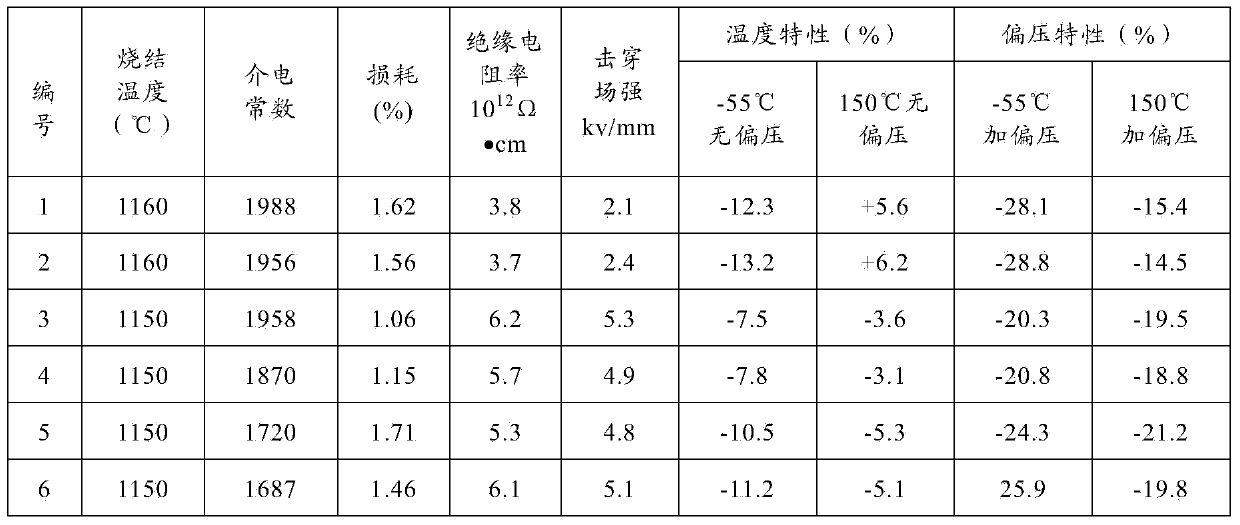

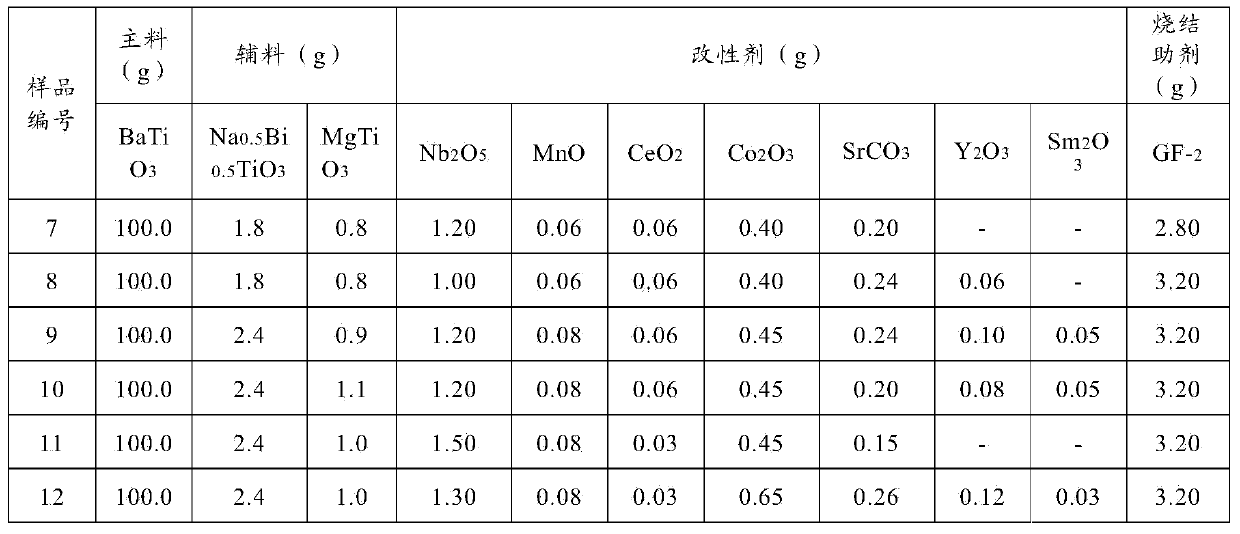

X8R type MLCC medium material with bias voltage characteristic and stable temperature for medium temperature sintering

The invention provides an X8R type MLCC medium material with bias voltage characteristic and stable temperature for medium temperature sintering. The X8R type MLCC medium material comprises a main material, a secondary material, a modifier and a sintering aid. The X8R type MLCC medium material with stable temperature is simple in preparation process, can realize medium temperature sintering and has the performances that relative dielectric constant at room temperature is 1700-1950, loss at room temperature is less than or equal to 1.5%, insulation resistivity at room temperature is more than or equal to 5*10<12>ohm.cm, breakdown voltage is more than or equal to 5kv / mm, temperature characteristic meets X8R requirements and capacitance of the X8R MLCC medium material is more than or equal to -25% and less than or equal to +15% when a direct-current bias voltage is applied in 2kv / mm, so that the X8R type MLCC medium material has a good industrialization prospect.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

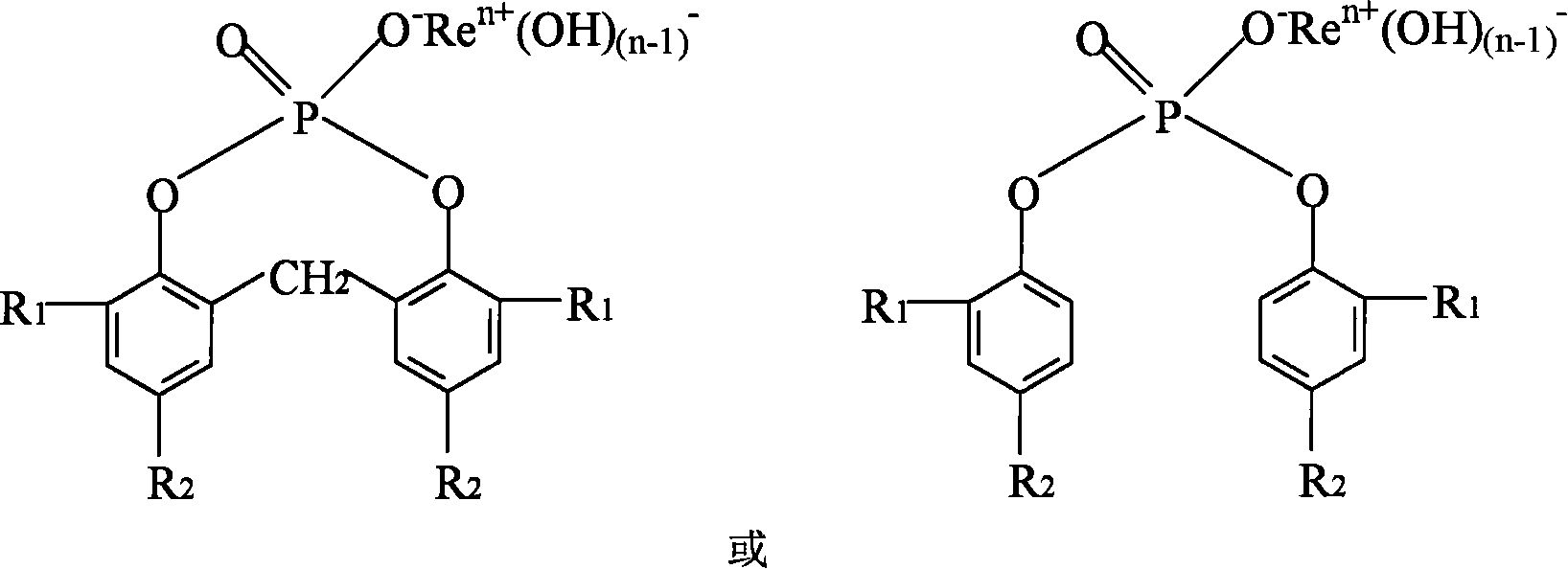

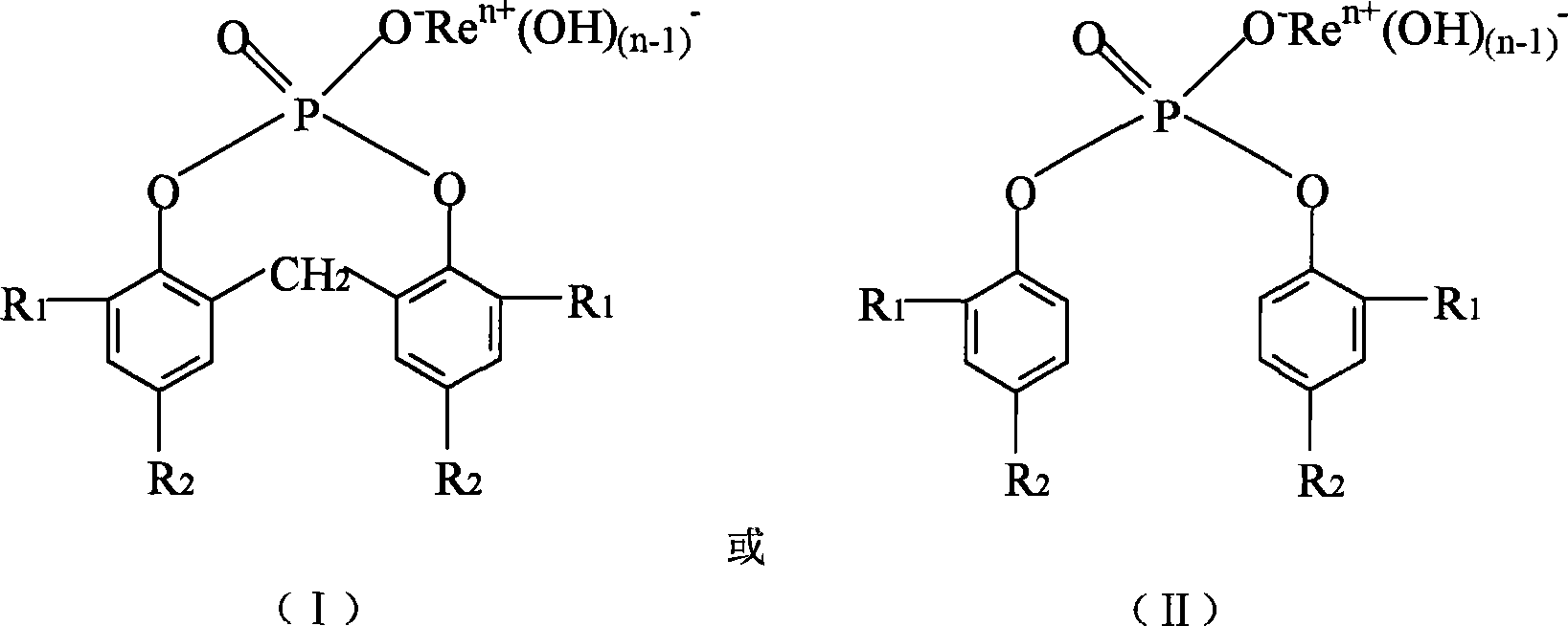

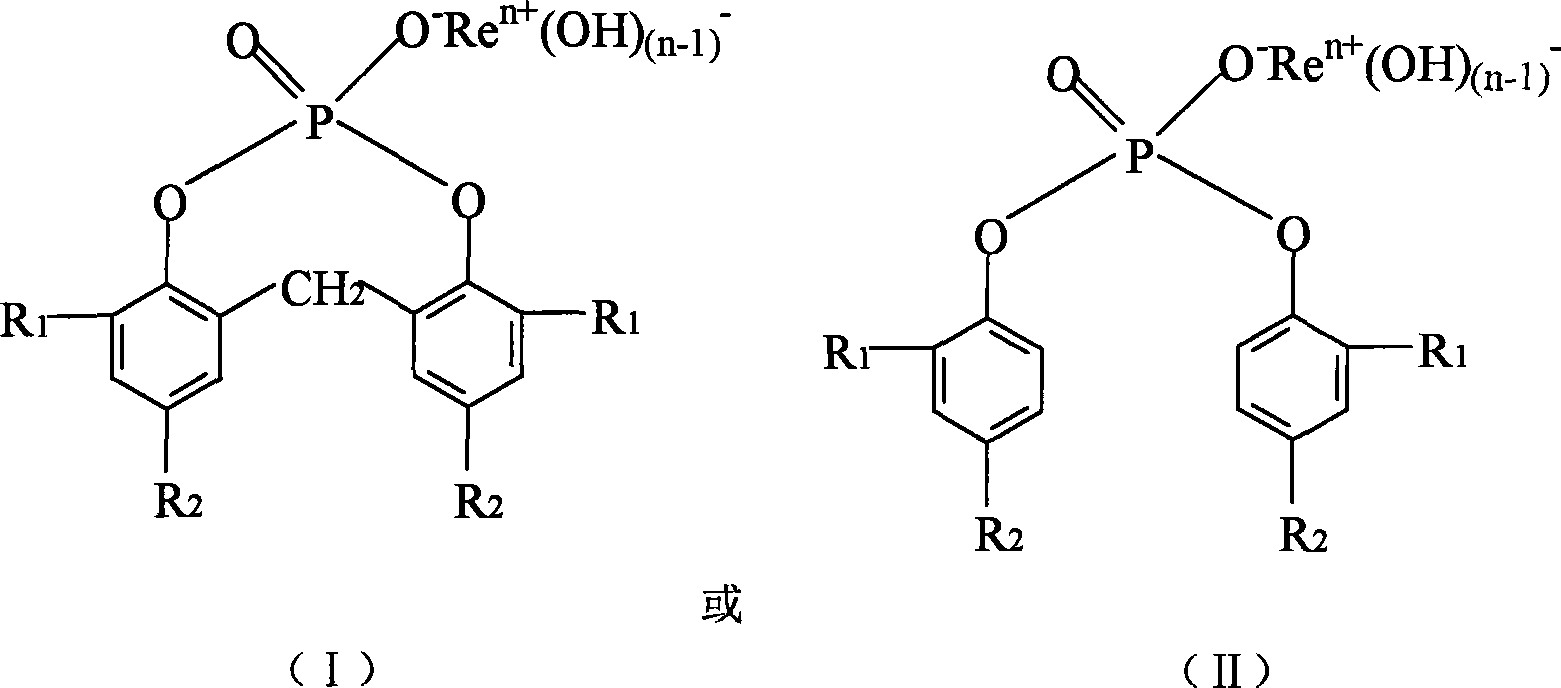

Organic phosphate rare earth salt nucleater, synthesis method and application thereof

InactiveCN101054387AStrong industrial operabilityComply with the design requirements of the structureGroup 3/13 element organic compoundsRare-earth elementPhosphate

The present invention relates to nucleating agent of crystallized polymer and its synthesis process which comprise: dissolving substituted diaryl phosphoric acid containing substituted alkyl R1 and R2 in alcosol, adding the alkaline liquor step by step and stirring under heating condition, adding stepwisely rare-earth salt chloride aqueous solution, filtering, drying and crushing, obtaining final product. The present invention introduces light rare earth element in organic phosphate, mainly lanthanum, cerium, to form organic phosphate rare earth salt. The inventive product is nontoxic, safe and stable. The nucleating effect of the inventive product is invariable. The inventive product has relatively high crystal form conversion and nucleating agent which can be used in general plastic and engineered plastic.

Owner:广东华南精细化工研究院有限公司 +1

Recovery treatment method of waste lubrication oil

The invention discloses a recovery treatment method of waste lubrication oil.The recovery treatment method includes the steps that firstly, a flocculant is added into the waste lubrication oil, stirring is performed, centrifugal separation is performed, and upper-layer oil is collected; then, the upper-layer oil is subjected to membrane separation, and lower-layer oil is collected; finally, an adsorbent is added into the lower-layer oil, stirring is performed, centrifugal separation is performed, upper-layer oil is taken, and thus recovery of the waste lubrication oil is completed.The recovery treatment method of the waste lubrication oil is simple, easy to implement, low in regeneration cost and environmentally friendly, base oil of the recovered waste lubrication oil is high in quality and meets the requirement for performance indexes of base oil in the HVI S150 standard, and good development prospects are achieved.

Owner:SHANGHAI INST OF TECH

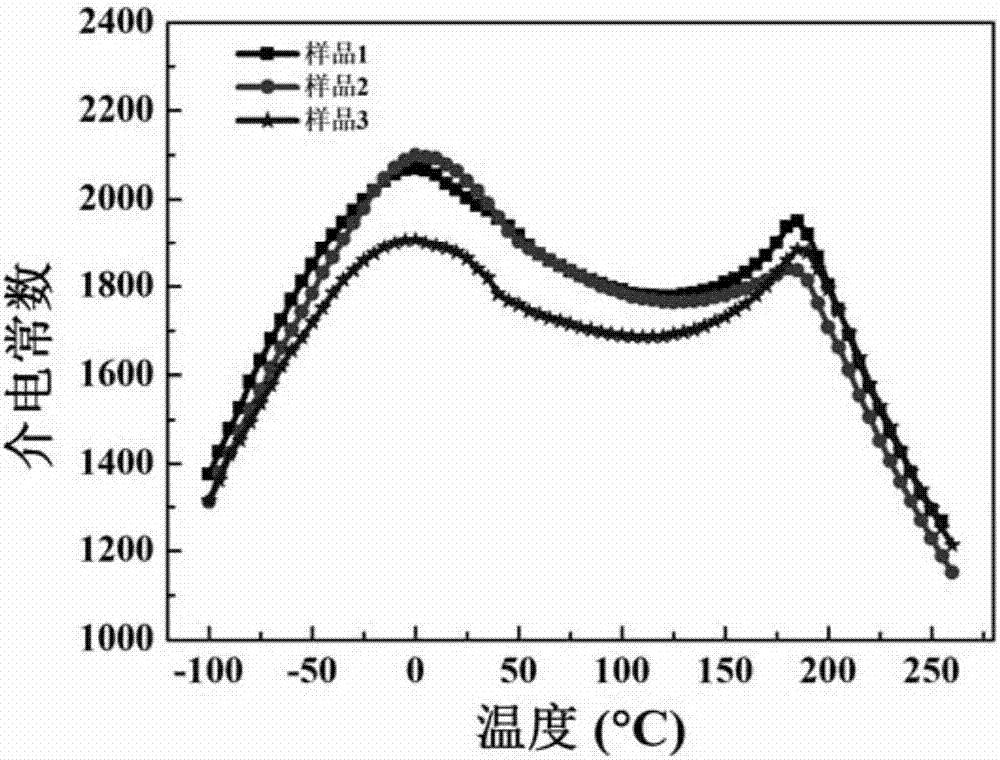

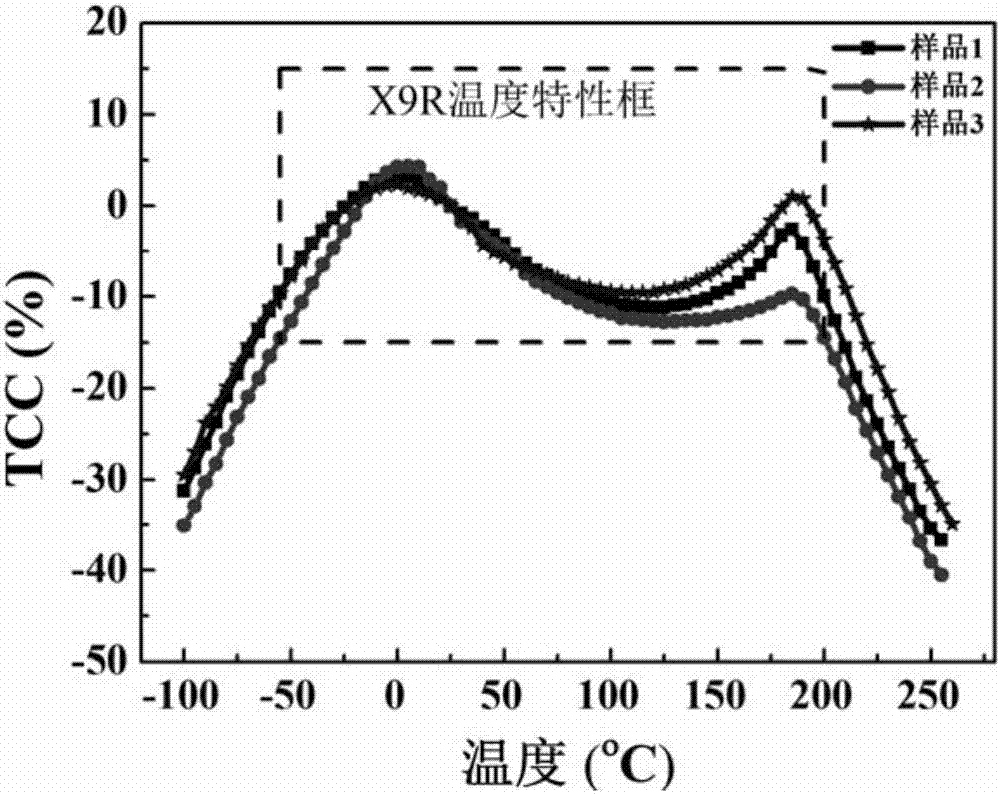

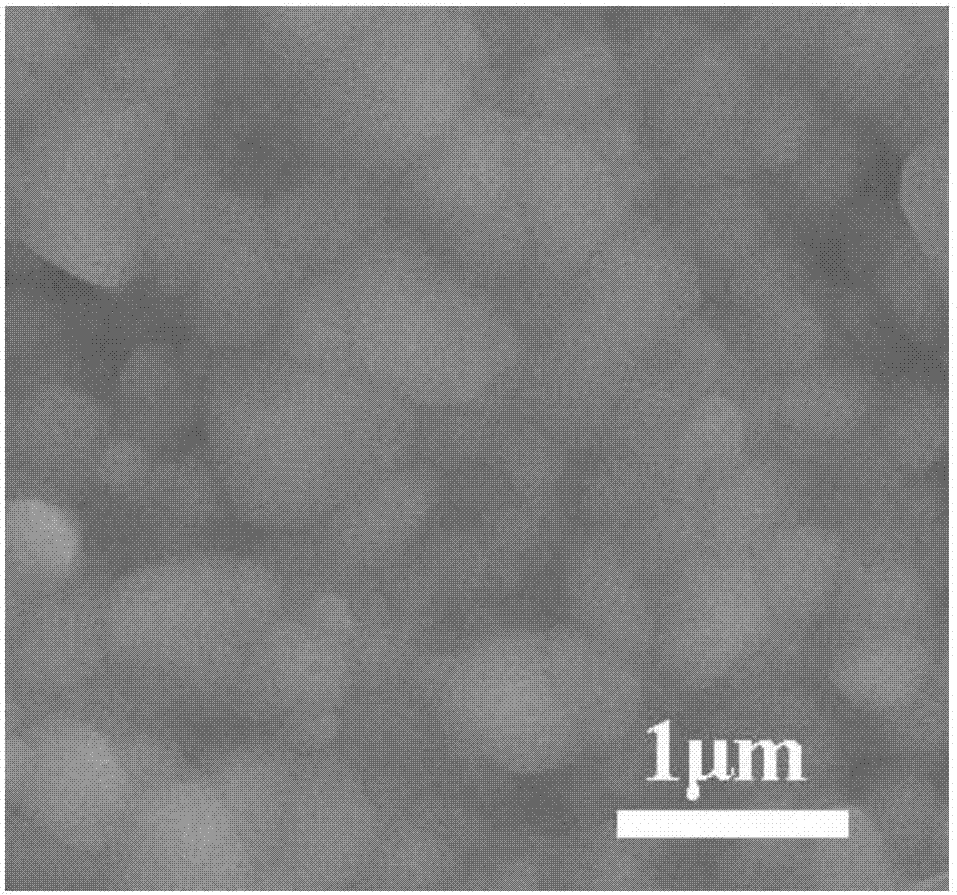

Anti-reduction X9R ceramic capacitor dielectric material and preparation method thereof

InactiveCN107512906AImprove temperature stabilityHigh Curie temperatureFixed capacitor dielectricDielectricDopant

The invention discloses an anti-reduction X9R ceramic capacitor dielectric material and a preparation method thereof. A complex has a molecular formula of 0.90BaTiO3-0.10Bi0.5A0.5TiO3, wherein A represents Na or K. The anti-reduction X9R type ceramic capacitor dielectric material comprises the complex and a secondary dopant. The secondary dopant comprises MnO2, a component A and a component B. The component A is Nb2O5 and / or Ta2O5. The component B is at least one of CeO2, CaZrO3 and MgO. A mass ratio of the secondary dopant to the complex is 0.5 to 2.0: 100. The preparation method comprises mixing the complex and the secondary dopant, carrying out ball milling, drying and sieving to obtain ceramic material powder, tabletting the ceramic material powder, and carrying out sintering in a reducing atmosphere furnace to obtain the anti-reduction X9R ceramic capacitor dielectric material. The dielectric material has good temperature stability, satisfies (delta C / C25) less than or equal to + / -15% at -55 to 200 DEG C and has a high dielectric constant and good reliability. The preparation method has simple processes, realizes a low cost and is harmless for the environment.

Owner:TSINGHUA UNIV

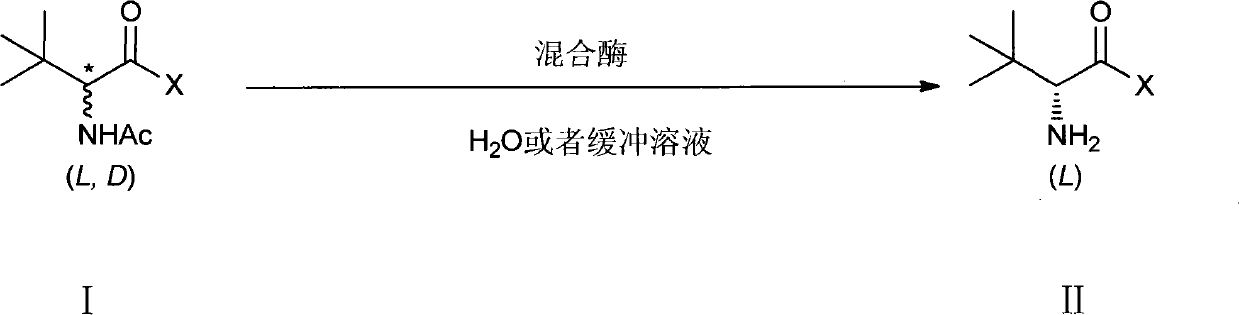

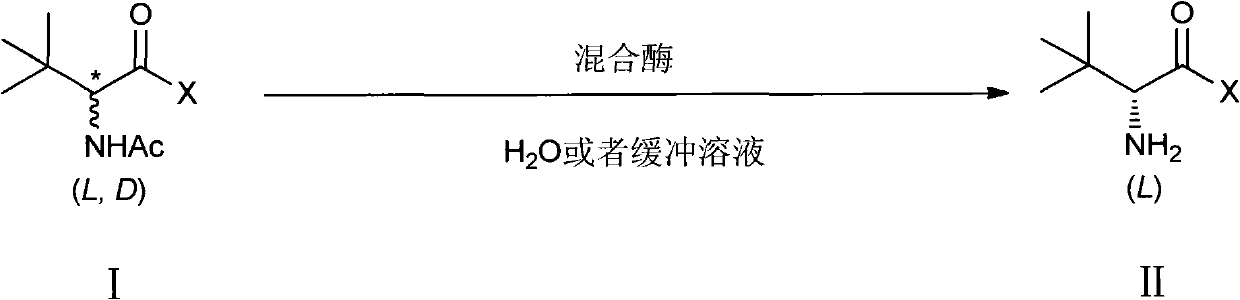

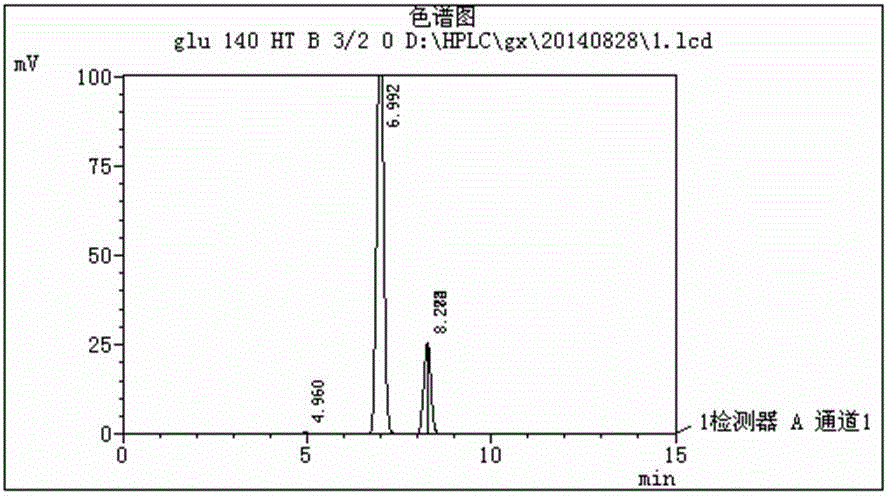

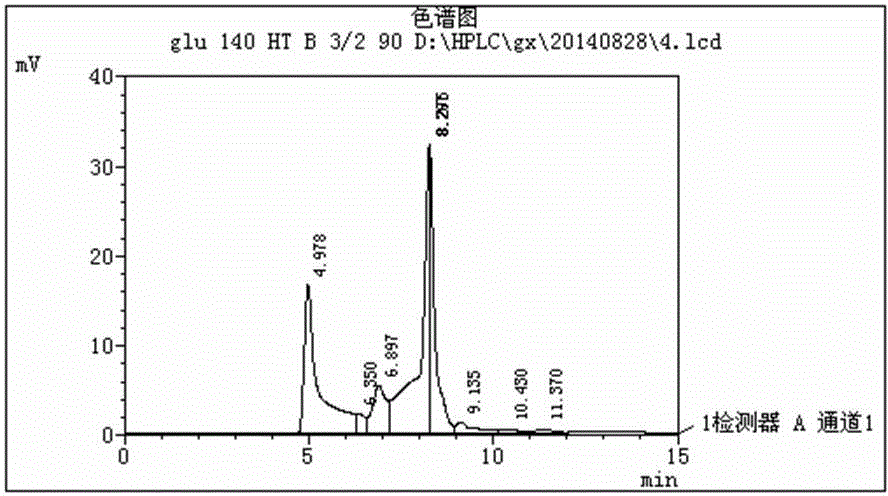

Method for preparing L-tertiary leucine compound by two enzyme system

The invention relates to a method for preparing a chiral compound based on splitting by adopting a biological enzyme preparation, in particular to a method for preparing an L-tertiary leucine compound by a two enzyme system. The method prepares the chiral L-tertiary leucine compound of the formula III by using the reaction of an N-acylating tertiary leucine compound of the formula II in water or a buffer solvent at 15 to 60 DEG C in the presence of the two enzyme system. The biological enzyme is a mixed enzyme of an acylating amino acid racemase (alanine racemase) and a hydrolase; and the preparation reaction equation is as follows, wherein X is any group of OH, NH2, NR1R2 and OR3 (wherein R1, R2, R3 are a C1-C5 straight chain, a branch chain and a one, two or three-halogen substituted alkane respectively). The invention can be implemented at room temperature and ensures simple operation and no pollution, while remarkably lowering the production cost.

Owner:ZHEJIANG UNIV

Method for making negative electrode material of lithium ion cell

InactiveCN1705150APrevent oxidationQuality assuranceElectrode manufacturing processesActive material electrodesLithiumRare earth

A method for preparing negative pole material of lithium cell, which contains putting silicon, carbon, doped 0.01 % rareearth oxide La2O5 and Nd2O5 in high power ball mill, protected by Ar or N2 for preventing oxidation, the C : Si = 3 :1 -5 : 1, checking the abrading grain size every 20 hr until to 50-100nm to obtain high specific capacity and fine safety nano negative pole material.

Owner:潘树明

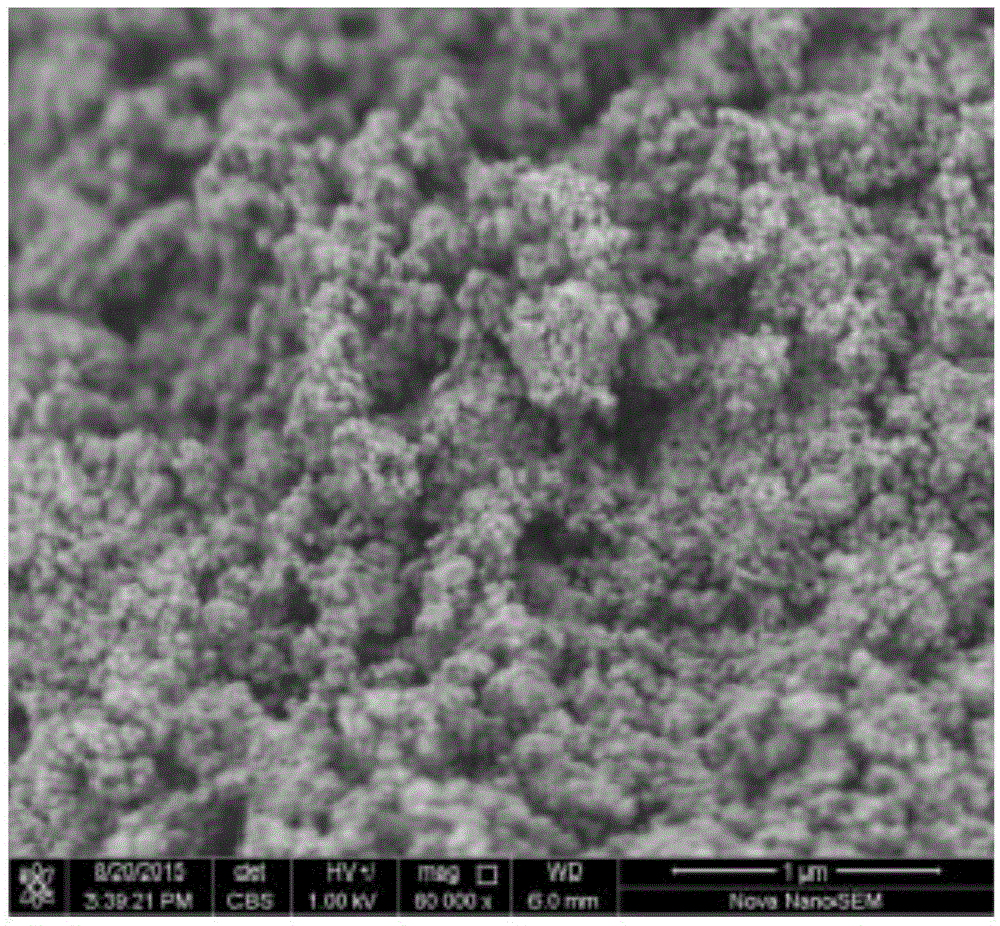

SnS2-C negative electrode nanocomposite and preparation method and application therefor

ActiveCN105406065ALarge specific surface areaImprove electrochemical performanceMaterial nanotechnologyCell electrodesMass ratioNanoparticle

The invention discloses an SnS2-C negative electrode nanocomposite and a preparation method and an application therefor. The composite negative electrode material consists of SnS2 nanoparticles and a carbon material wrapping the SnS2 nanoparticles; the grain diameter of the SnS2 nanoparticles is less than 100 nm, and the SnS2 nanoparticles are uniformly distributed in the carbon material; and the mass ratio of the SnS2 nanoparticles to the carbon material is 0.625-12.5:1. The preparation method for the SnS2-C negative electrode nanocomposite comprises the following steps: performing ball milling on stannic disulphide for the first time to obtain the SnS2 nanoparticles; adding the SnS2 nanoparticles into a glucose solution for performing ball milling for the second time to obtain a mixture; and drying the mixture and then performing thermal treatment on the dried mixture to obtain the SnS2-C nanocomposite. The SnS2-C negative electrode nanocomposite is high in circulation rate capability, high in capacity retention ratio, can be applied to the field of a lithium ion battery, and is bright in the application and industrial prospects.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

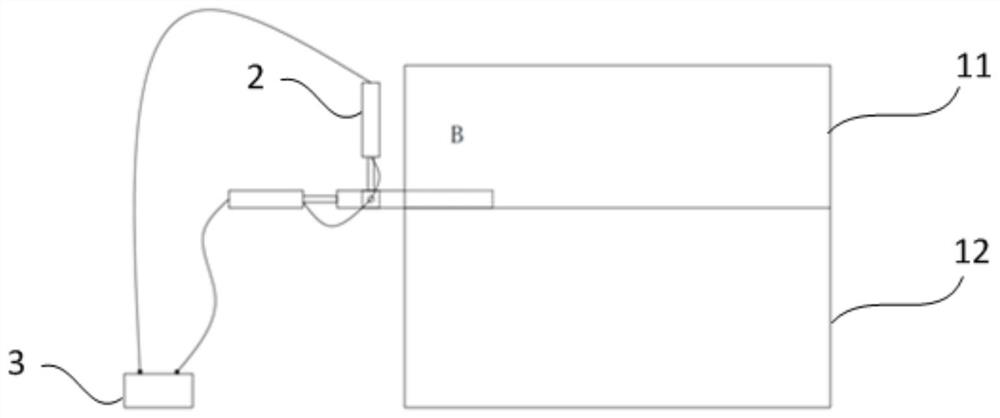

Method for preparing large-area perovskite solar cell based on spraying technology

InactiveCN105655489AEasy to prepareGood prospects for industrializationSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellElectrically conductive

The invention discloses a method for preparing a large-area perovskite solar cell based on spraying technology. The method comprises the following steps: firstly putting a transparent conductive base on a platform and spraying an electronic transmission layer; and preparing a perovskite optical absorption layer by a continuous spraying method: firstly spraying a PbI2 solution on the electronic transmission layer, and heating for 30min at 70-90 DEG C; further spraying a CH3NH3I solution and heating for 120min at 90-110 DEG C; cooling to room temperature, washing with isopropyl alcohol and drying; spraying a hole conduction layer; and finally, spraying a silver nanowire / graphene to prepare a counter electrode. In the invention, the parameters of the spraying technology are adjusted to realize preparation of the large-area perovskite solar cell; and the preparation method is simple and easy to implement, can realize low-cost preparation of an efficient perovskite solar cell and has a good industrialization prospect.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

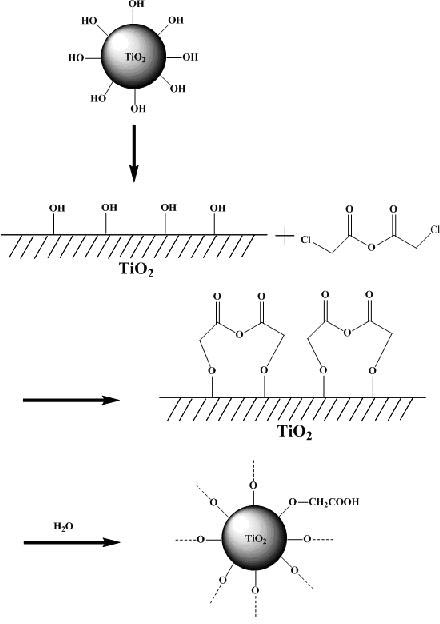

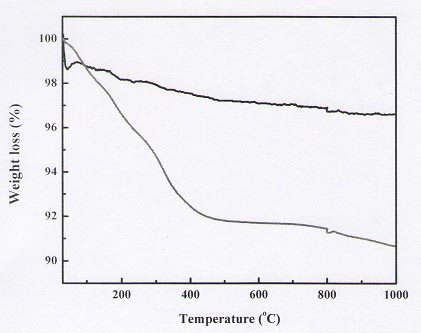

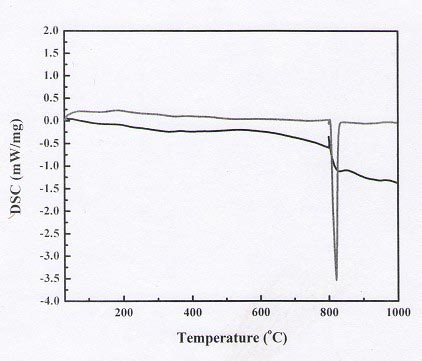

Modified titanium dioxide grain, super-hydrophilic transparent thin film and preparation method thereof

ActiveCN102311561AIncrease the amount addedHigh mechanical strengthEpoxy resin coatingsPigment physical treatmentHigh energyChloroacetic anhydride

The invention discloses modified titanium dioxide grain, a super-hydrophilic transparent thin film and a preparation method thereof. In the invention, a ball mill is used as a modification tool; chloroacetic anhydride is used as a modifier, is added into the titanium dioxide grain through a mechanical and chemical method and is bonded with a hydroxyl group on the surface of the titanium dioxide grain with a chemical bond through mechanical stirring, vibration and collision of ball milling of the ball mill; then the prepared grain is reacted with water in a high-energy ball mill so as to prepare the hydroxyl group-modified titanium dioxide grain; finally, the grain is added into polymer in a ball milling mode to prepare suspension; the suspension is coated on a glass slide and then thermal curing is performed to obtain the super-hydrophilic transparent thin film. The super-hydrophilic transparent thin film prepared by the invention has the advantages of superior wear resistance and heat resistance, high mechanical strength, high impact resistance capacity, optical performance, anti-ultraviolet capacity and convenience in cleaning.

Owner:YANGZHOU SPED CHEM

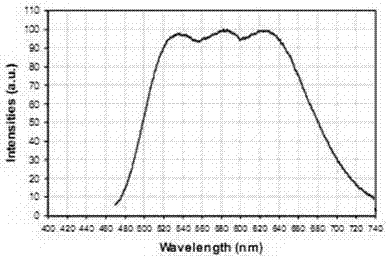

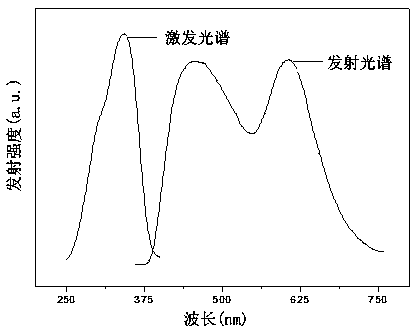

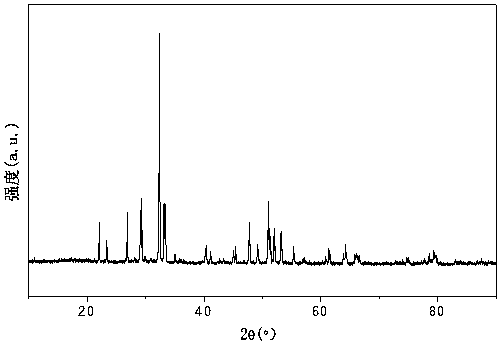

Multi-emission-peak LED (light emitting diode) white light fluorescent powder and preparation method thereof

InactiveCN102585805AGood colorSimple processGas discharge lamp usageLuminescent compositionsSolid state reaction methodLight-emitting diode

The invention relates to a multi-emission-peak LED (light emitting diode) white light fluorescent powder and a preparation method of the multi-emission-peak LED white light fluorescent powder. The chemical formula of the composition of the fluorescent powder is A2-xSiO4:(Eu<2+>x1, Eu<3+>x2), wherein A is one or more of Mg, Ca, Sr, Ba, Zn and Cd, 0<X1<2, 0<X2<2, 0<X<2, and X=X1+X2. The fluorescent powder can be prepared by high-temperature sintering in a reducing atmosphere by a solid-phase reaction method, and the technology is simple. The LED white light fluorescent powder disclosed by the invention is matched with a blue light LED chip; in a spectrum of an obtained white light LED, the fluorescent powder can be excited to generate a broad peak of 500-580nm and narrow-band red light within a range within 585nm to 760nm; and the fluorescent powder has the advantages of high color rendering property and high light luminous efficiency and can be used for preparing a white light LED light source.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

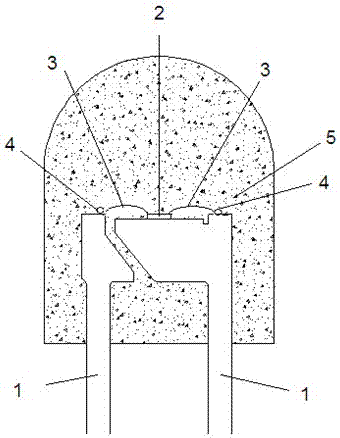

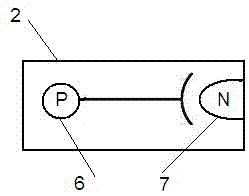

All-angle luminous light-emitting diode (LED) light source

InactiveCN103208578ARealization of full-angle lightingEasy to replaceSolid-state devicesSemiconductor devicesDie bondingLuminescence

The invention discloses an all-angle luminous light-emitting diode (LED) light source. The light source comprises two separated supports. A luminescence chip is fixed on a die bonding platform on the upper portion of one support; a P electrode and an N electrode on the surface of the luminescence chip are connected with leads on the two supports through bonding wires respectively; and a layer of outer sealing adhesive with fluorescent powder mixed covers the upper portions of the supports and outsides of the luminescence chip, the bonding wires and the leads. The LED light source is capable of achieving all-angle luminescence on space, close to luminescence forms of traditional light sources and capable of facilitating light source substitution and lamp design.

Owner:HANGZHOU HANGKE OPTOELECTRONICS

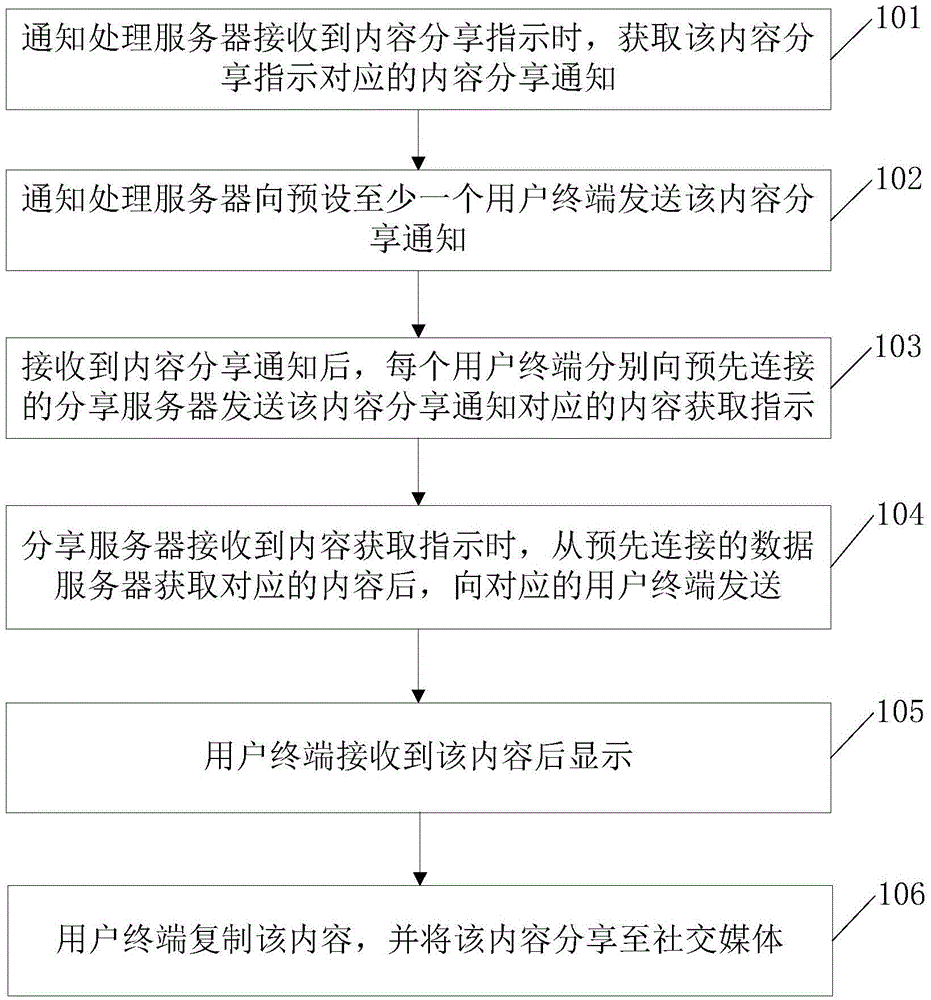

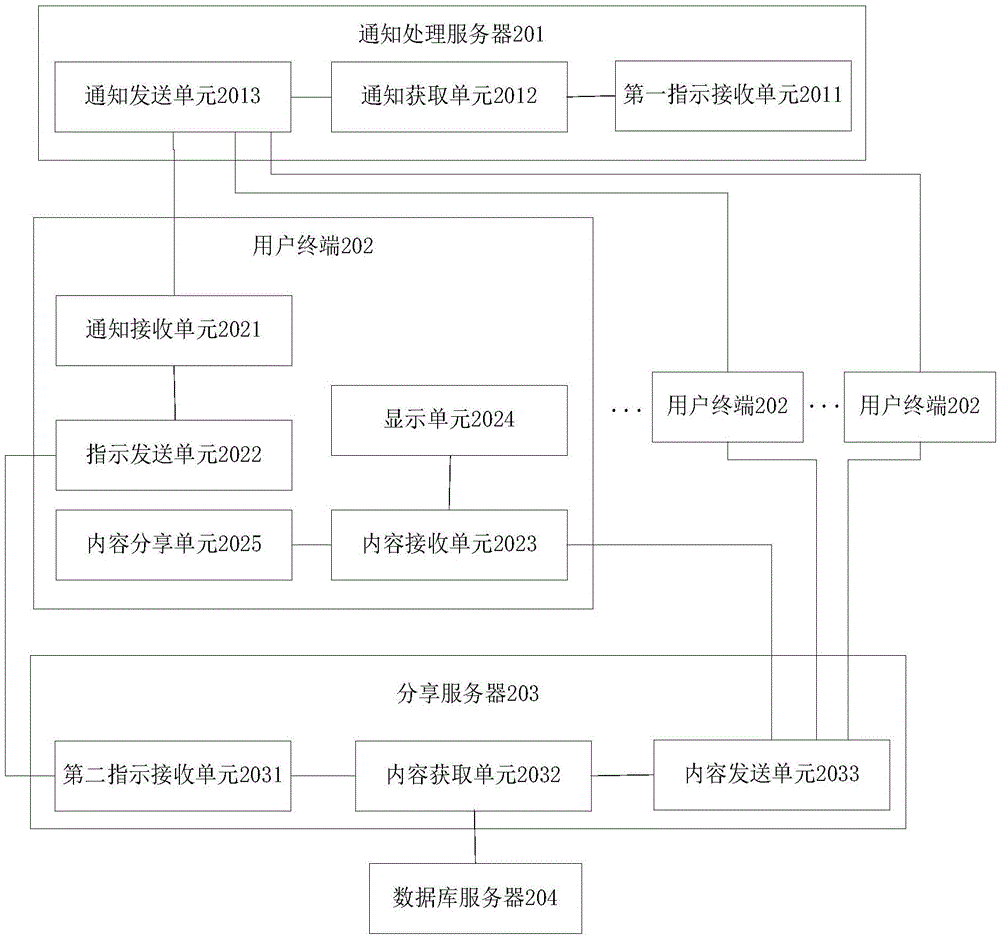

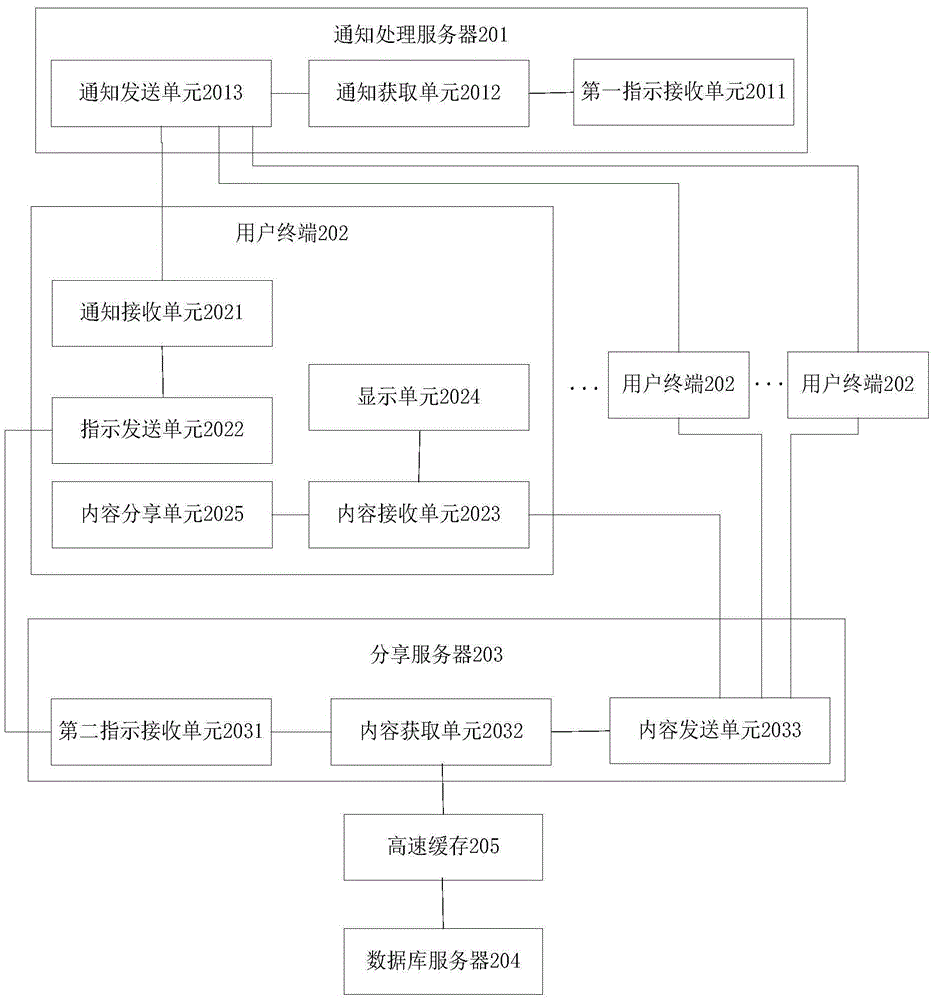

Content-sharing system and method

ActiveCN105592082ASolve the inconvenienceGreat application potentialDigital video signal modificationSelective content distributionSocial mediaDatabase server

The invention discloses a content-sharing system and method. The content-sharing system comprises a notification-processing server, at least one user terminal, a sharing server, and a database server. The content-sharing method comprises steps that S10, the notification-processing server, when receiving a content-sharing instruction, acquires a content-sharing notification corresponding to the content-sharing instruction; S20, the notification-processing server sends the content-sharing notification to the at least one preset user terminal; S30, after receiving the content-sharing notification, each user terminal sends a content-acquiring instruction corresponding to the content-sharing notification to the pre-connected sharing server; S40, the sharing server, when receiving the content-acquiring instruction, acquires the corresponding content from the pre-connected sharing server and then sends the content to the corresponding user terminal; S50, the user terminal receives and then displays the content; and S60, the user terminal copies the content and shares the content in a social media.

Owner:BEIJING WEIBOYI TECH CO LTD

Straw fiber doped polyaniline electromagnetic shielding material and preparation method of straw fiber doped polyaniline electromagnetic shielding material

InactiveCN106832918AImprove efficiencyHigh extraction ratePhysical treatmentVegetal fibresPeristaltic pumpFiber

The invention discloses a straw fiber doped polyaniline electromagnetic shielding material and a preparation method of the straw fiber doped polyaniline electromagnetic shielding material. The preparation method comprises the following steps: under the condition of -8 DEG C to 0 DEG C, dropwise adding an oxidation solution into a raw material solution containing a polyaniline monomer and straw fibers by adopting a peristaltic pump; slowly stirring; after dropwise adding, stopping stirring and continually reacting for 10h to 16h; after reacting, filtering and centrifuging and washing with absolute ethyl alcohol for 3 to 5 times; after drying in vacuum, preparing the straw fiber doped polyaniline electromagnetic shielding material. The preparation method of the shielding material is simple; raw materials are cheap and easy to obtain; the shielding material has high shielding efficiency, a wide range and good industrialized production prospect.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

Method for manufacturing nano silver wire

InactiveCN103894620APreparation conditions are easy to controlLow costNanotechnologyHydrofluoric acidSilver ion

The invention provides a method for manufacturing a nano silver wire. According to the method, a silver nitrate aqueous solution serves as a raw material, and the nano silver wire of one-dimensional growth is obtained by etching the silicon surface through hydrofluoric acid and restoring silver ions. The method is simple in preparation condition, low in process condition and cost, high in preparation efficiency, high in product quality and high in the yield, the purity of products is larger than 95 percent, and the method has good application and industrial prospects.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

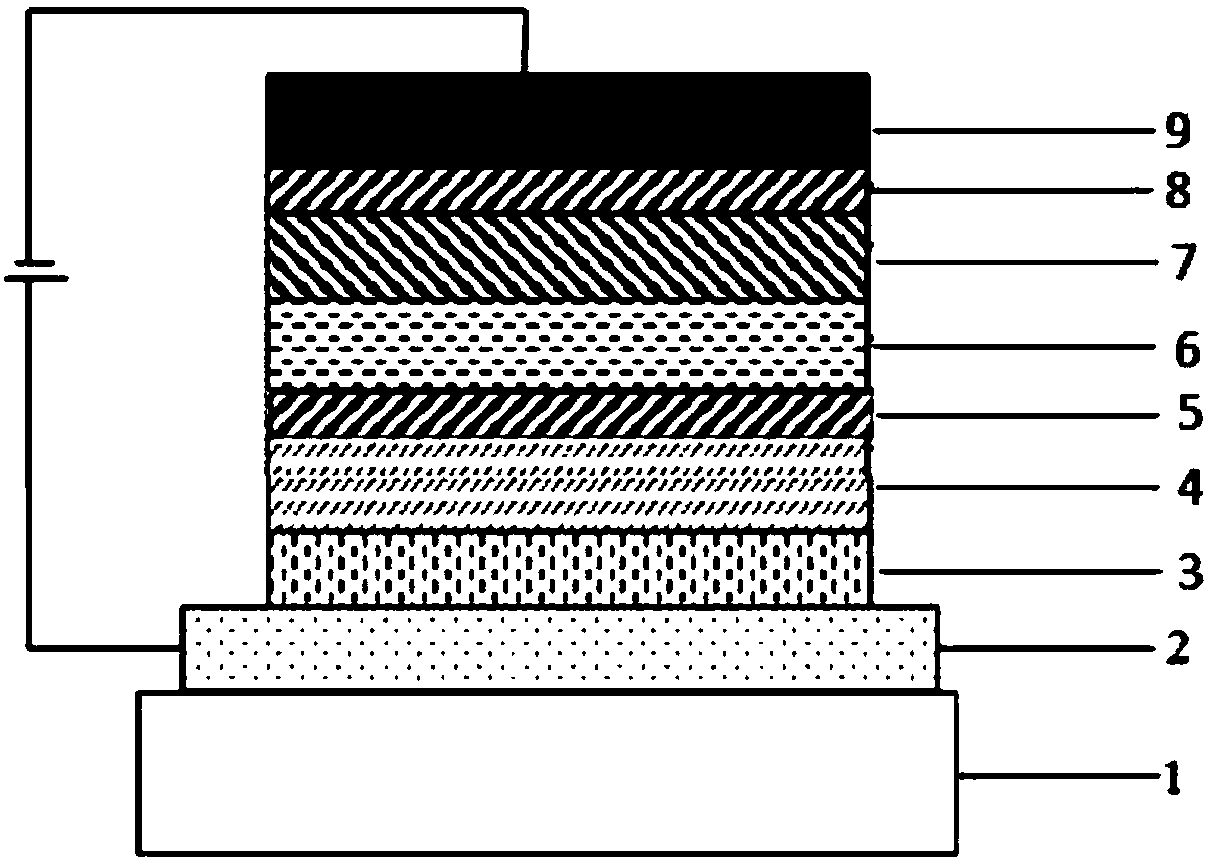

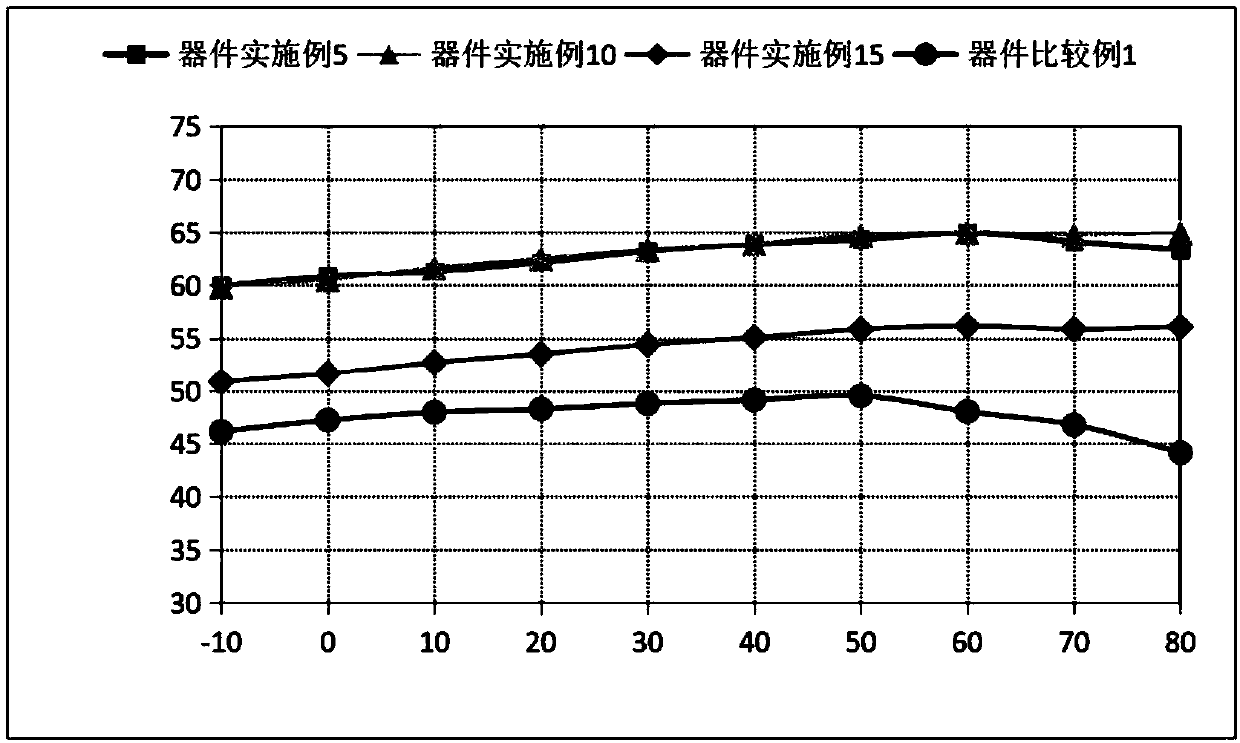

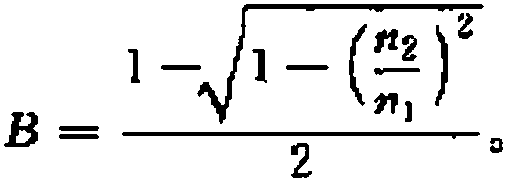

Compound with dibenzo-6-membered ring as core and application thereof in organic light emission diode device

ActiveCN109574989AReduce absorptionHigh refractive indexOrganic chemistrySolid-state devicesRefractive indexOrganic compound

The invention discloses a compound with a dibenzo-6-membered ring as a core and an application thereof in an organic light emission diode device. The organic compound contains the dibenzo-6-membered ring, and two benzene are connected by an alkylene group substituted by an oxygen atom, a sulfur atom, and a C1-10 linear chain or branched alkyl group, an aryl-substituted alkylene group, an aryl-substituted alkyl group or an aryl-substituted tertiary amine group. The compound of the invention has high glass transition temperature and molecular thermal stability; the compound is low in absorptionand high in refractive index in a visible light field, and can effectively improve the light extraction efficiency of an OLED device after being applied to a CPL layer of the OLED device; and the compound of the invention is shallow in HOMO energy level and high in hole mobility, can be used as a hole injection / transport layer material of the OLED device, and can effectively transfer holes to oneside of a light-emitting layer, thereby enhancing the recombination efficiency of the holes and electrons in the light-emitting layer, and the luminous efficiency and service life of the OLED device are further improved.

Owner:JIANGSU SUNERA TECH CO LTD

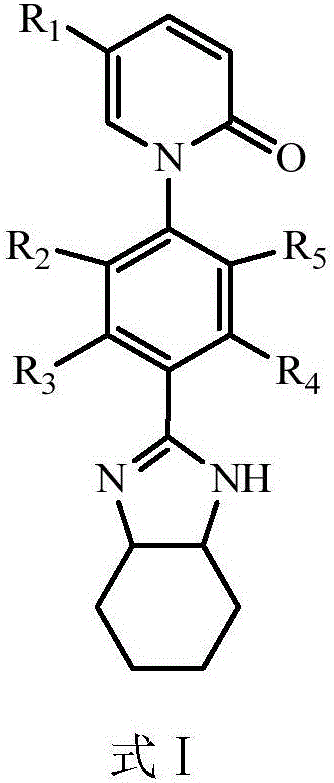

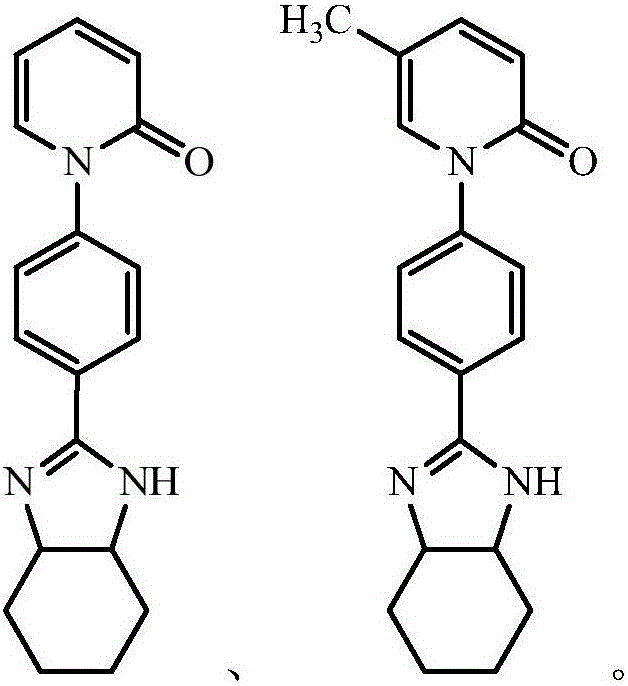

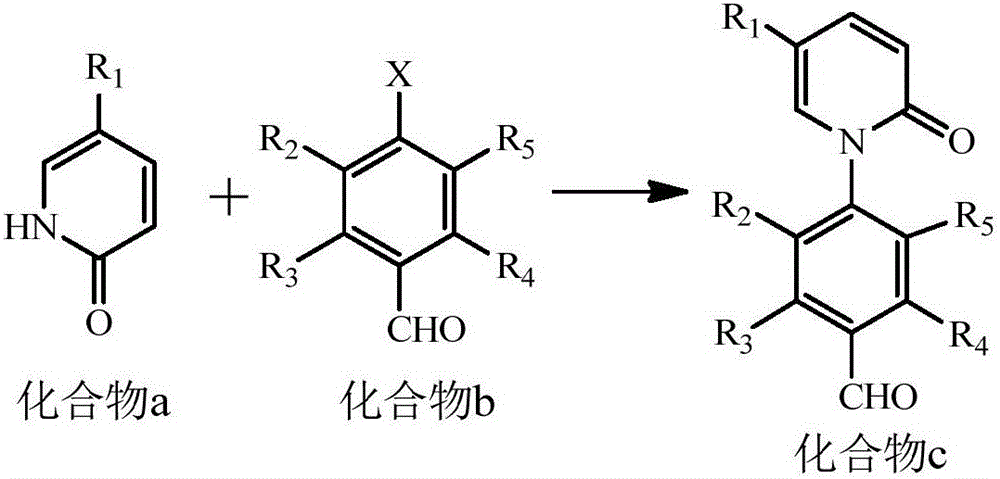

Pirfenidone derivative and preparation method thereof

InactiveCN106045971AGood prospects for industrializationOrganic active ingredientsOrganic chemistryPirfenidoneSolvent

The invention relates to a pirfenidone derivative and a preparation method thereof, and discloses a compound represented by a formula I or a pharmaceutically acceptable salt, crystal form, hydrate or solvate of the compound, wherein R1, R2, R3, R4 and R5 are respectively or simultaneously selected from H, halogen, hydroxyl, nitryl, carbonyl or C1-C8 alkyl. Compared with pirfenidone, the novel compound disclosed by the invention has a different ring structure; furthermore, the fibrosis resistant activity of the novel compound is obviously higher than that of pirfenidone; particularly, the suppression rate of the novel compound to fibroblast proliferation is 95 percent or above, which is increased by 10 times or more when compared with the suppression rate (8.15 percent) of pirfenidone; meanwhile, the suppression effect of the novel compound to fibroblast secretory fiber connection proteins is obviously better than that of pirfenidone, so that the novel compound has a good industrialization prospect. The formula I is shown in the description.

Owner:杨若一

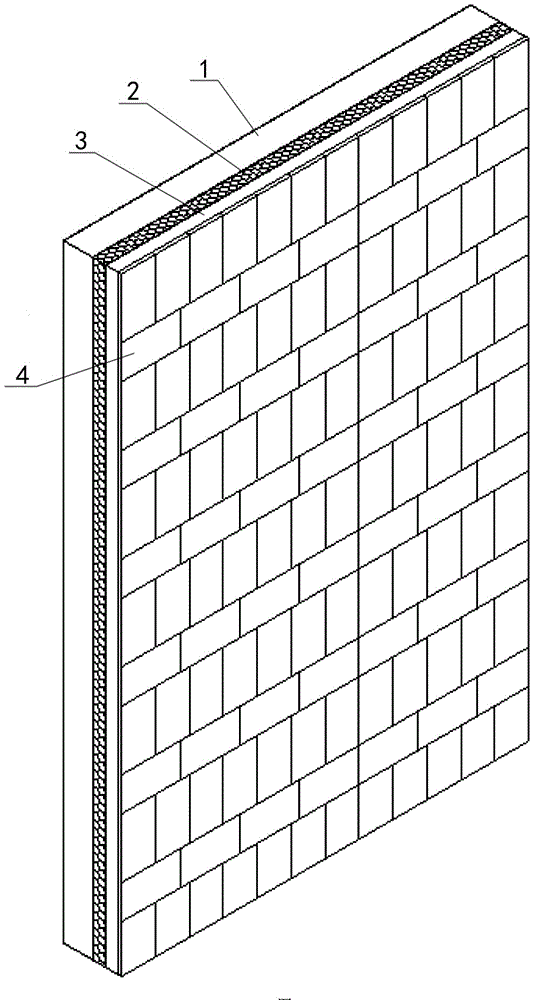

Integrated wallboard with heat retaining and decorative structure made of wasted red bricks and preparation method thereof

InactiveCN106760162ASatisfy preferencePromote the development of energy savingCovering/liningsBuilding componentsBrickProtection layer

The invention relates to an integrated wallboard with a heat retaining and decorative structure made of wasted red bricks and a preparation method thereof. The integrated wallboard comprises a recycled aggregate structure layer, a heat retaining layer, a mortar protection layer and a wasted red brick decorative layer, wherein the mixture of the recycled aggregate structure layer comprises wasted red brick coarse aggregate, wasted red brick fine aggregate, cement and water, and the wasted red brick decorative layer is formed by splicing wasted red brick slices. The mixture comprises the following components in parts by weight: 1.65-2.55 parts of wasted red brick coarse aggregate, 0.95-1.15 parts of wasted red brick fine aggregate, 1 part of cement and 0.38-0.45 part of water. Through the combination of the wasted red bricks and a fabricated low-rise building in a village, the invention provides the integrated wallboard with the heat retaining and decorative structure made of the wasted red bricks and the preparation method thereof. The integrated wallboard is mainly used for a fabricated residential structure in the village, and achieves the purposes of simple production process, low production cost, energy conservation and waste utilization.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Iron-contained type load catalyst polymerized by utilizing reverse atom to transfer free radical and its application

The present invention relates to an iron-contained type load catalyst for reverse atomic transfer free radical polymolization and its application. It uses high specific area cross-linked polyacrylic acid ion-exchange resin as load carrier of catalyst, and uses iron trihalide to make coordination and complexation to form load catalyst, the load catalyst and conventional azo initiator, monomer and solvent are formed into a solid-liquid reaction system according to a certain proportion, the system can be used for catalyzing controllable free radical polymerization. The catalyst has no need of using halid with strong poisonou property as initiator, after having been activated it can be circularly used.

Owner:SHANGHAI JIAO TONG UNIV

Application of synovial fluid neutrophil gelatinase-associated lipocalin in detection and diagnostic kit for prosthetic joint infection

InactiveCN108593923AImprove anti-interference abilityImprove stabilityBiological material analysisBiological testingFluorescenceSevere complication

The invention relates to an application of synovial fluid neutrophil gelatinase-associated lipocalin (NGAL) in detection and a diagnostic kit for prosthetic joint infection. Joint replacement is an effective treatment mode for treating joint disease at a terminal stage, and periprosthetic joint infection is a severe complication after joint replacement. The synovial fluid NGAL has high sensitivityand specificity for diagnosing the prosthetic joint infection. According to the invention, fluorescence particles are taken as a maker, and the diagnostic kit (a test paper strip) for the synovial fluid NGAL is prepared through an immunochromatography method. By using an immunofluorescence quantitative analyzer, quantitative detection and instant detection on a synovial fluid specimen can be carried out, and diagnosis of the prosthetic joint infection is realized. A synovial fluid NGAL detection reagent and the diagnostic kit have the advantages of simple usage, sensitive reaction, and high diagnosis accuracy.

Owner:THE FIRST AFFILIATED HOSPITAL OF FUJIAN MEDICAL UNIV

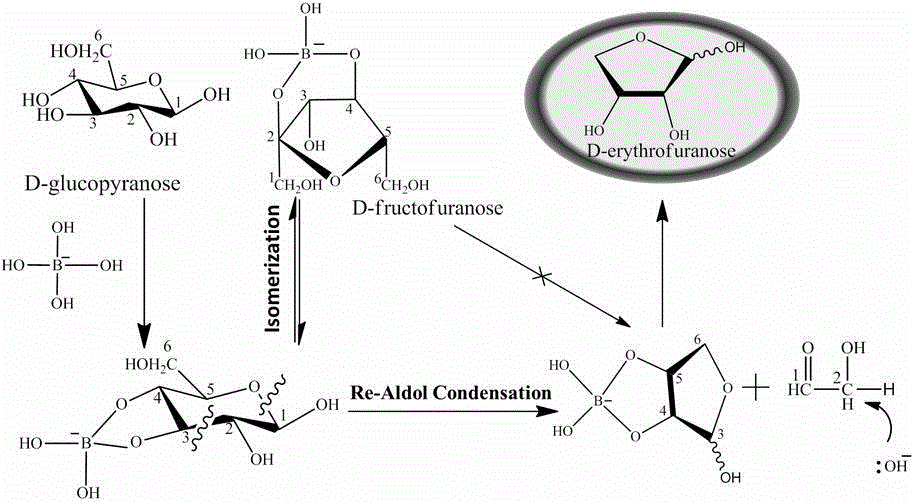

Method for preparing D-erythrose from biomass saccharides

InactiveCN104558063AWide range of choicesNarrow distributionSugar derivativesChemical industryChemical compoundFine chemical

The invention belongs to the technical field of biomass conversion and chiral synthesis and particularly relates to a method for preparing D-erythrose from biomass saccharides. According to the invention, the biomass saccharides are adopted as the raw materials, and under the aqueous phase condition and the alkaline environment, the raw materials are catalyzed to obtain the D-erythrose. The method is has the following characteristics: the type of the biomass saccharides is more, the initial concentration range of the biomass saccharides is wide, the heating manner is flexible, the basicity range of a catalyst is wide, and the single chirality of the catalyst is realized; the operation is simple and convenient, equipment is simple, energy is saved, the aftertreatment is convenient, and both the percent conversion and the selectivity are high. As the D-erythrose is regarded as one of important platform chemical compounds at present, a series of products with wide application ranges can be obtained through chiral conversion and achiral conversion, can serve as midbodies of fine chemical engineering and pharmacy, and has huge economical value and broad application prospects. Therefore, through the method for efficiently preparing a great amount of D-erythrose from the biomass saccharides, large-scale industrialized production is expected to realize.

Owner:FUDAN UNIV

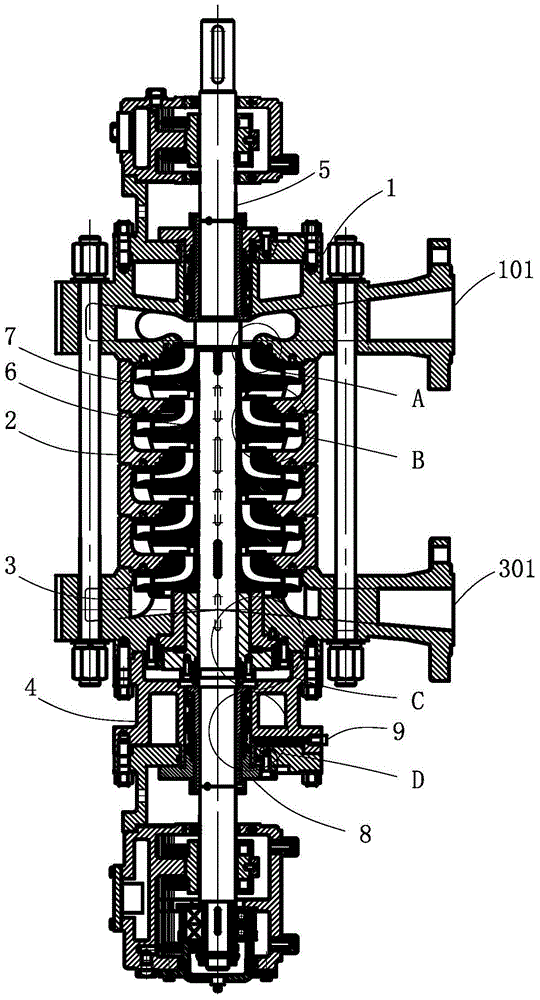

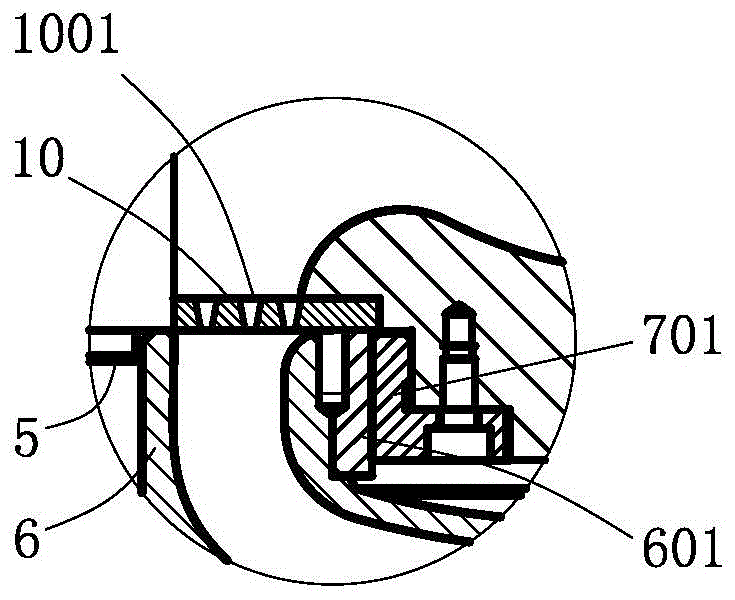

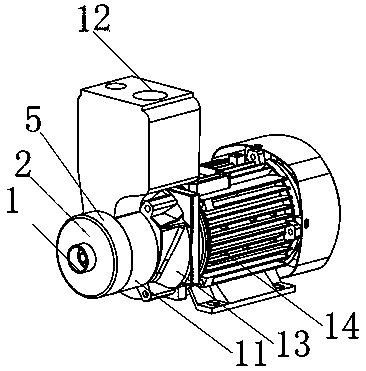

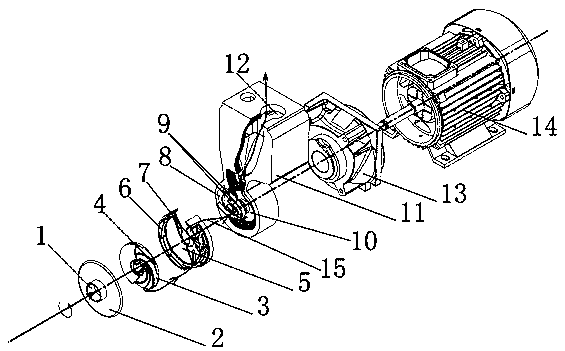

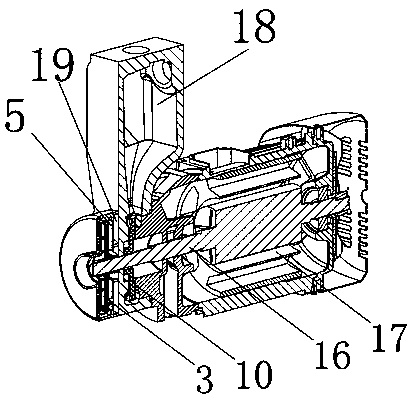

Novel multistage centrifugal pump

The invention discloses a novel multistage centrifugal pump, and belongs to the technical field of fluid pumps. The centrifugal pump comprises a pump body, and the pump body is internally provided with a transmission shaft in a rotating mode. The pump body comprises an intake segment, a middle segment and an output segment, and the middle segment is arranged between the intake segment and the output segment. The transmission shaft is fixedly provided with a plurality of impellers, and the middle segment is provided with guide vanes corresponding to the impellers. An intake sealing mechanism is arranged between the intake segment and the transmission shaft, and an output sealing mechanism is arranged between the output segment and the transmission shaft. An air filter plate is arranged between the intake segment and the first-stage impeller. The air filter plate is fixedly arranged on the pump body and provided with a plurality of through holes. The output segment is fixedly connected with a compensation shell. The transmission shaft penetrates out of the compensation shell. A compensation sealing mechanism for preventing liquid from leaking is arranged between the compensation shell and the transmission shell. By means of the novel multistage centrifugal pump, the technical problems that an existing multistage centrifugal pump is poor in sealing performance and low in output efficiency, and air bind is formed easily are solved, and the novel multistage centrifugal pump is widely applied to continuous conveying of fluid.

Owner:JIANGSU JIANGYUAN MASCH CO LTD

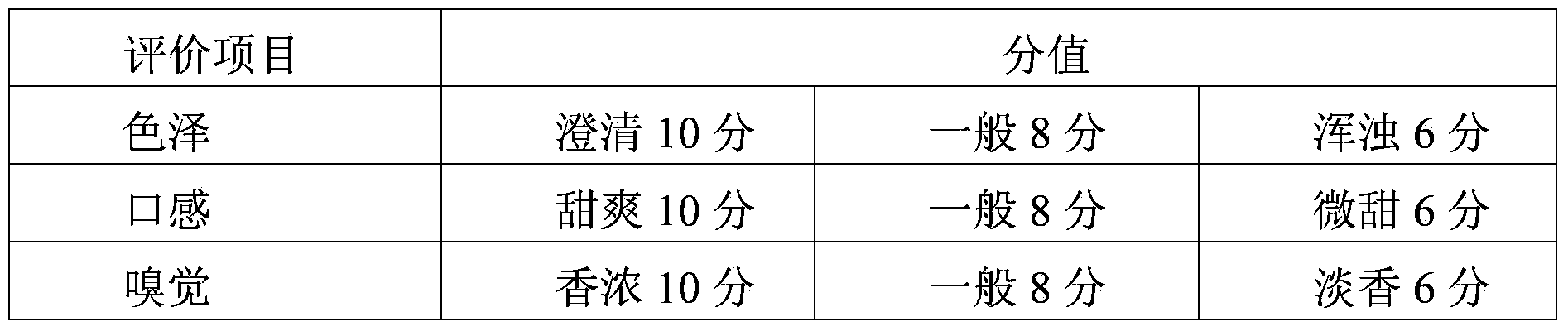

Sweet corn low-sugar composite type beverage and preparation method thereof

ActiveCN103519305AProspects for industrialization development are promisingGood prospects for industrializationNatural extract food ingredientsFood ingredient functionsBlood pressureWolfiporia extensa

The invention discloses a sweet corn low-sugar composite type beverage and a preparation method thereof. The sweet corn beverage is prepared by adding water into the following raw materials in percentage by mass in mode of soaking: 40-50% of sweet corn, 15-20% of the root of kudzu vine, 10-15% of poria cocos and 10-15% of chrysanthemum, wherein the ratio of the materials to water for soaking is (1:10)-(1:18). The preparation method of the sweet corn beverage comprises the following steps: washing sweet corn, subsequently mixing with chrysanthemum, the root of kudzu vine and poria cocos, adding water to soak and extract, filtering, taking the juice, blending, filling and sterilizing so as to obtain a product. According to the sweet corn low-sugar composite type beverage, sweet corn which is known as health-care product resource is adopted to be compounded with traditional Chinese medicine materials such as chrysanthemum and the root of kudzu vine according to the traditional Chinese medicine principle, a fragrant convenient beverage which can reduce fat and lose weight, adjust the blood pressure, tonify spleen and stomach, calm heart and nerve, expel wind and heat, inhibit cough and relieve pain is prepared, and the product has a good market prospect and is wide in future industrial development prospect.

Owner:HUNAN LIUYANG RIVER ECOLOGICAL AGRI TECH DEV GROUP

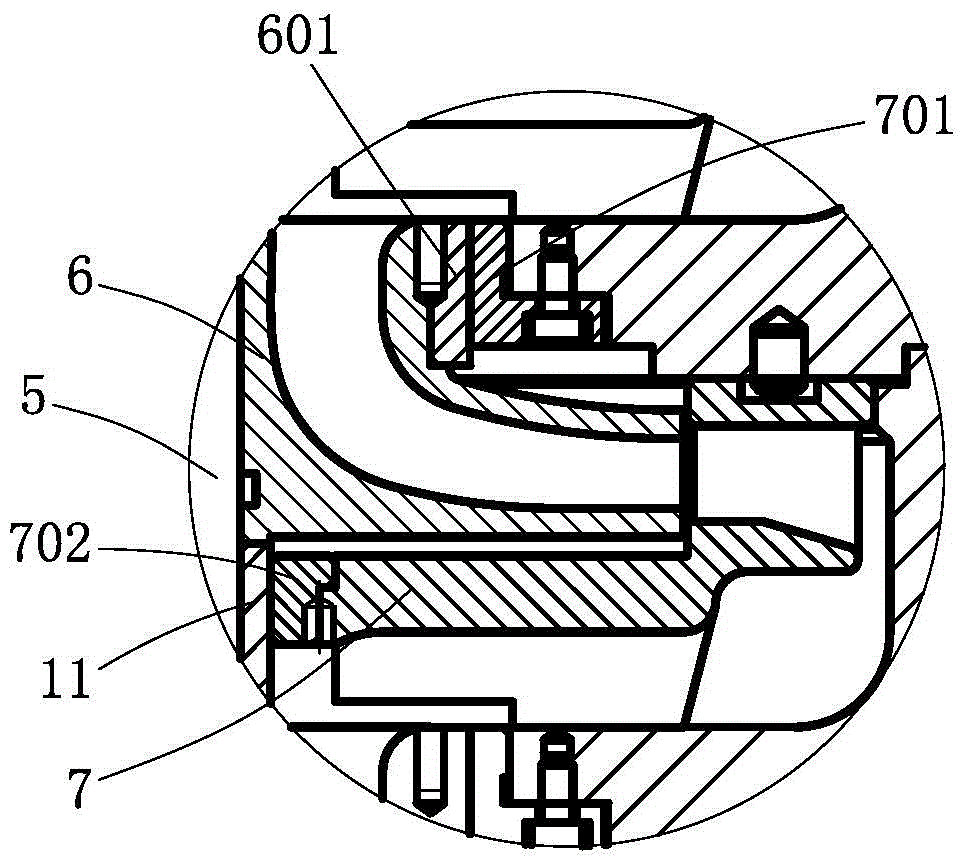

High-efficiency dual-stage centrifugal regenerative pump

PendingCN109667767AHigh feasibilityGood prospects for industrializationPump componentsPump installationsCentrifugal pumpDual stage

The invention discloses a high-efficiency dual-stage centrifugal regenerative pump. The high-efficiency dual-stage centrifugal regenerative pump comprises a first-stage centrifugal pump consisting ofa centrifugal impeller and a centrifugal guide blade, a second-stage regenerative pump consisting of a regenerative pump impeller and a regenerative pump body, and a transferring diversion cavity forconnecting the first-stage centrifugal pump with the second-stage regenerative pump; and the centrifugal impeller and the regenerative pump impeller are coaxially fixed on a pump shaft, and a motor isused for simultaneously driving the two impellers to rotate. According to the high-efficiency dual-stage centrifugal regenerative pump disclosed by the invention, through pressurizing of the first-stage centrifugal pump, the gas containing rate of inlet fluid of the regenerative pump can be effectively reduced, the inlet condition of the second-stage regenerative pump is improved, and the operation noise of the pump is reduced. Besides, through the organic combination of the first-stage centrifugal pump and the second-stage regenerative pump, the purpose that the two pumps have complementaryadvantages is achieved, the compact integral structure of the pump is reserved, and the volume of the high-efficiency dual-stage centrifugal regenerative pump compared with that of a conventional regenerative pump is not greatly changed.

Owner:浙江中杭水泵股份有限公司

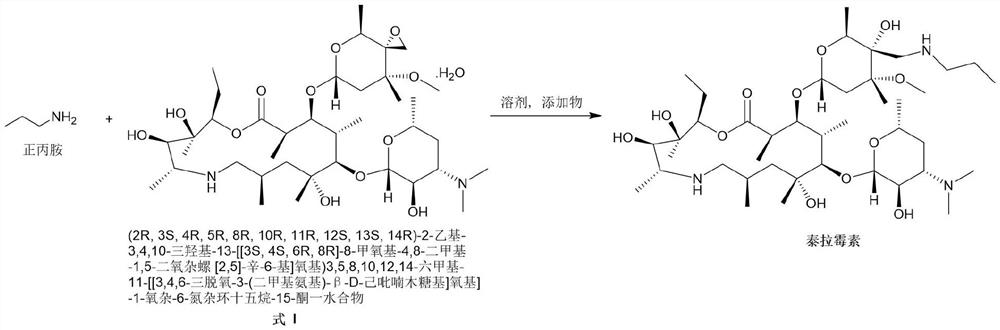

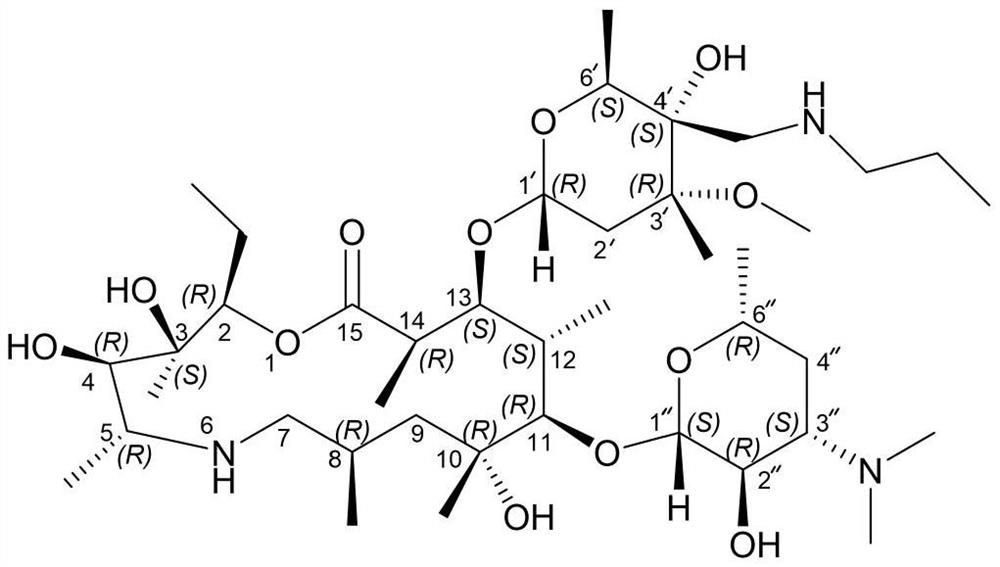

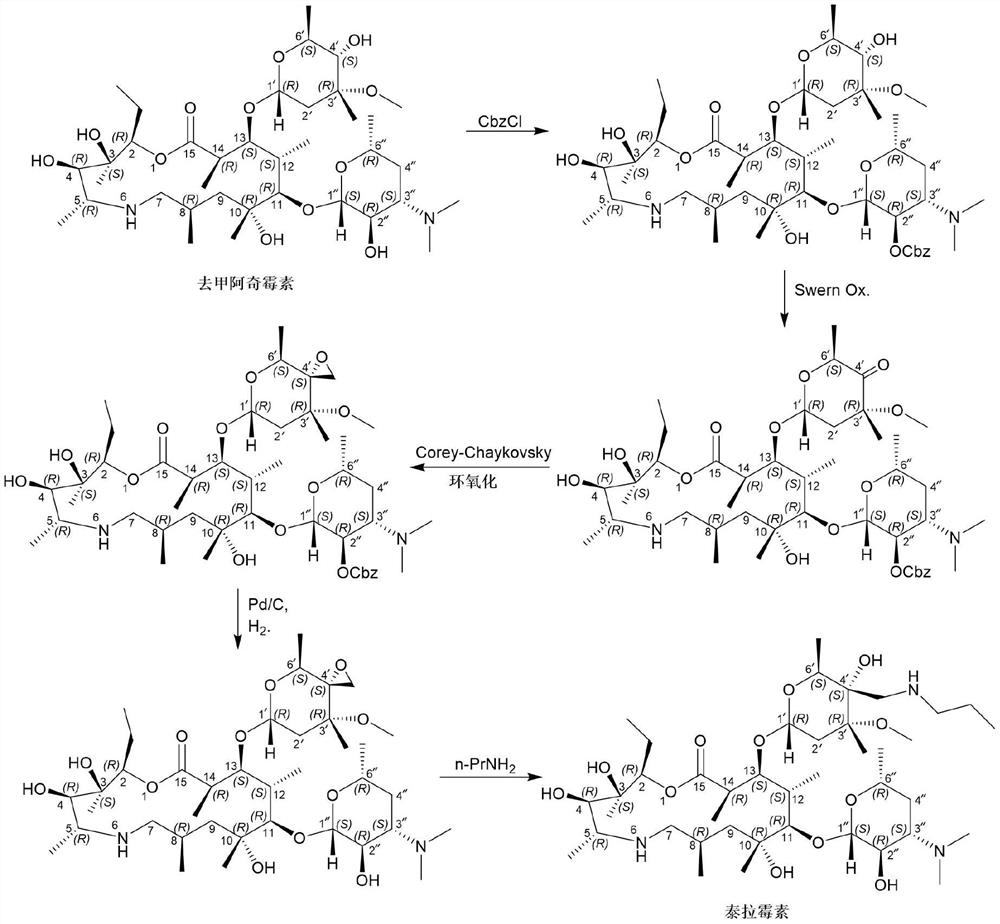

Synthesis of tulathromycin

PendingCN113861252AShort reaction timeGood prospects for industrializationSugar derivativesSugar derivatives preparationPentadecaneMethyl palmoxirate

The invention relates to synthesis of tulathromycin, in particular to a reaction of (2R, 3S, 4R, 5R, 8R, 10R, 11R, 12S, 13S, 14R)-2-ethyl-3, 4, 10-trihydroxy-13-[[3S, 4S, 6R, 8R]-8-methoxy-4, 8-dimethyl-1, 5-dioxaspiro [2, 5] oct-6-yl] oxy) 3, 5, 8, 10, 12, 14-hexamethyl-11-[[3, 4, 6-trideoxy-3-(dimethylamino)-beta-D-xylopyranosyl] oxy]-1-oxa-6-azacyclopentadecane-15-one monohydrate with n-propylamine in the presence of a solvent and ytterbium trifluoromethanesulfonate, so as to realize the synthesis of tulathromycin.

Owner:江苏君若药业有限公司

A Ce3+, Mn2+ double-doped apatite structure nitrogen oxide white light phosphor and its preparation method and application

ActiveCN106590655BGood colorImprove thermal stabilityEnergy efficient lightingLuminescent compositionsApatitePhosphor

The invention discloses Ce<3+> and Mn<2+> double doped apatite structure nitrogen oxide white phosphor and a preparation method and application thereof. The white phosphor has a chemical formula of Mg2-a-yAaY3-b-xBbSi3-cCcO11N: xCe<3+>, yMn<2+>, wherein A represents a composition of one or two of Sr and Ca, B represents a composition of one or more of Gd, La and Sc, C represents Ge, x, y, a, b and c represent mole fractions, x is greater than or equal to 0.01 and less than or equal to 0.12, y is greater than or equal to 0.01 and less than or equal to 0.20, a is greater than or equal to 0 and less than or equal to 0.2, b is greater than or equal to 0 and less than or equal to 0.5 and c is greater than or equal to 0 and less than or equal to 0.9. The white phosphor is used in a LED light source device, can produce high quality white light, can greatly simplify the process, and has good industrialization and application prospects.

Owner:ZHEJIANG UNIV OF TECH

Method and device for utilizing flying ash in electric power plant to produce floating beads

InactiveCN101524695AIncrease productivitySimple productivitySolid waste managementSolid waste disposalCombustion chamberPulverized fuel ash

The invention relates to a method and a device for utilizing flying ash in an electric power plant to produce floating beads, solving the problems that coal in the prior art generates a great amount of coal ash incapable of being effectively utilized so as to waste resources and pollute the environment, and the prior adopted method of specific gravity directly separates the floating beads from the coal ash so as to have low production efficiency and yield, hardly controlled product quality, and the like. The self-designed device utilizing the flying ash to produce the floating beads and the method using fuel gas as a powder feeding agent (flying ash) directly send the flying ash into a combustion chamber, and the flying ash is directly melted in a high-temperature high-speed gas flow generated by the fuel gas and pure oxygen in the combustion chamber to be liquid drops so as to produce a floating bead product. The method and the device enable the flying ash to reburn so that pulverized coal is converted into the floating bead product with a high added value and has the advantages of extremely simple production device and technology, high production efficiency and strong practicability. Floating beads can be widely applied, can be used as plastics and rubber filling, high-quality heat-insulating materials, building materials, advanced composite materials, and the like, thereby having favorable market application prospects and industrialized prospects.

Owner:SHENYANG INST OF AERONAUTICAL ENG

Preparation method for negative carbon material of lithium ion cell

InactiveCN1182610CImprove electrochemical performanceSimple structureElectrode manufacturing processesAnhydrous ethanolEpoxy

The present invention relates to a negative carbon material of lithium ion cell. It is made up by covering natural graphite powder surface with a layer of epoxy resin pyrolytic carbon, and its preparation method includes the following steps: dissolving liquid epoxy resin in anhydrous ethanol or acetone solvent, adding natural graphite powder to form paste-like mixture; adding ethanol solution of ethylenediamine, heating and solidifying, and pyrolytic treatment to obtain invented negative carbon material of lithium ion cell. Said invented product is high in quality, low in cost, possesses highspecific capacity and excellent circulating reversible property, and easy to implement industrial production.

Owner:潮州正龙电池工业有限公司

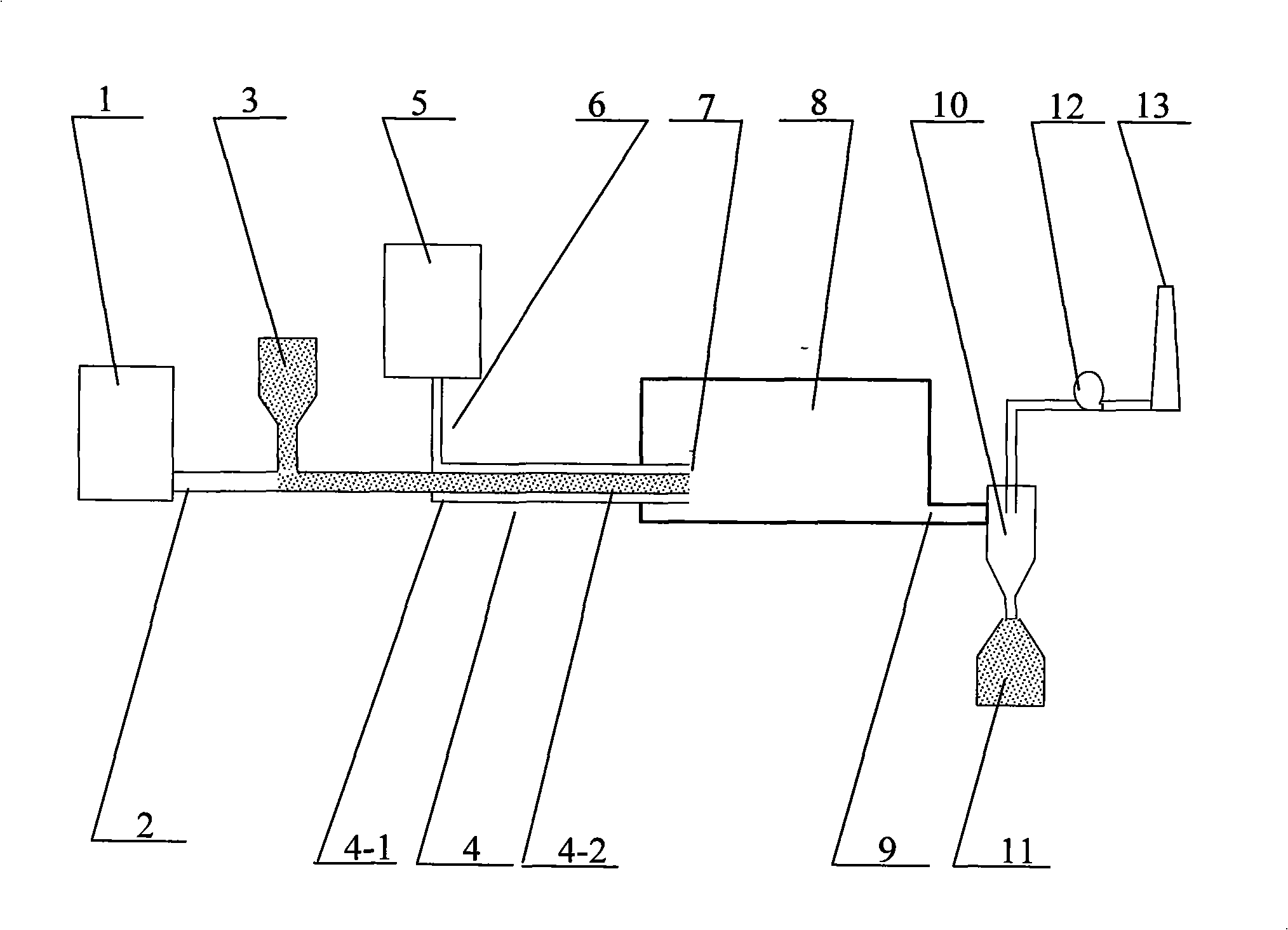

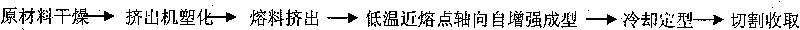

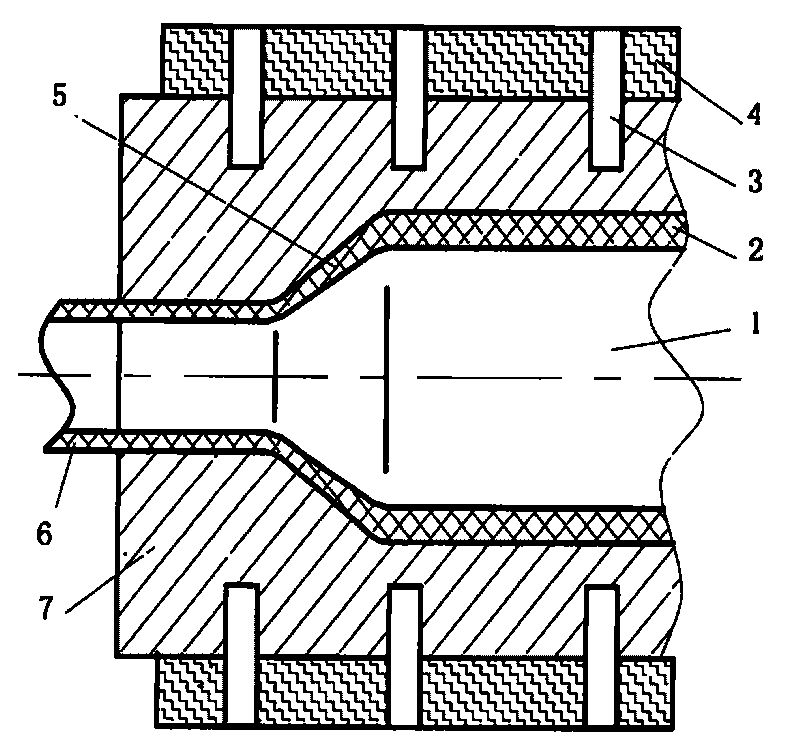

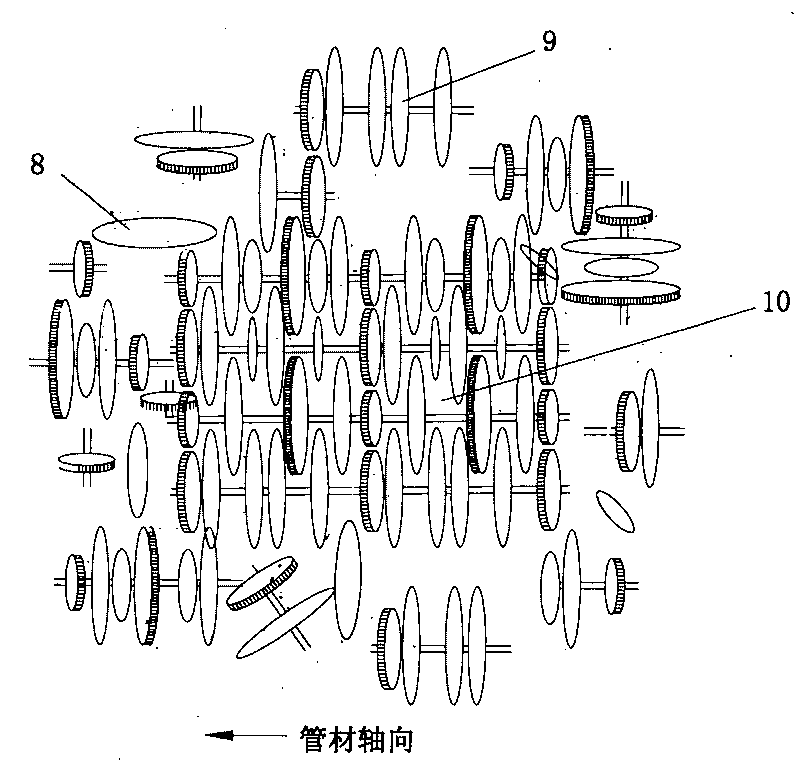

Low-temperature near-melting point extrusion molding principle and method for axial self-reinforced plastic pipe

The invention relates to a principle and a method for producing various plastic pipe workpieces, in particular to a low-temperature near-melting point extrusion molding principle and a low-temperature near-melting point extrusion molding method for an axial self-reinforced plastic pipe, which are characterized in that: an extrusion molding process is implemented under a circumferential shear stress field in a temperature environment of which the temperature is slightly higher than the melting point of the molded material. The method comprises the following processing steps: drying raw materials, plastifying by using an extruder, extruding melt, low-temperature near-melting point axial self-reinforced molding, cooling and shaping, and cutting and collecting. The strength and modulus of the plastic pipe produced by the method are both reinforced in the axial direction; the material performance is optimally configured, and the actual requirements of pipes on the material performance are met. The orientation degree of the reinforced pipe in the axial direction is higher than that of the common pipe; and the wafer thickness of the reinforced pipe is thicker, the crystallinity of the reinforced pipe is higher, so that the heat resistance of the pipe is obviously improved compared with that of the common pipe. The method and the principle have the advantages of less equipment investment, high production efficiency, low material cost, low production cost, excellent performance of products, capability of meeting industrialized production conditions and good industrialized prospect.

Owner:CHONGQING TECH & BUSINESS UNIV

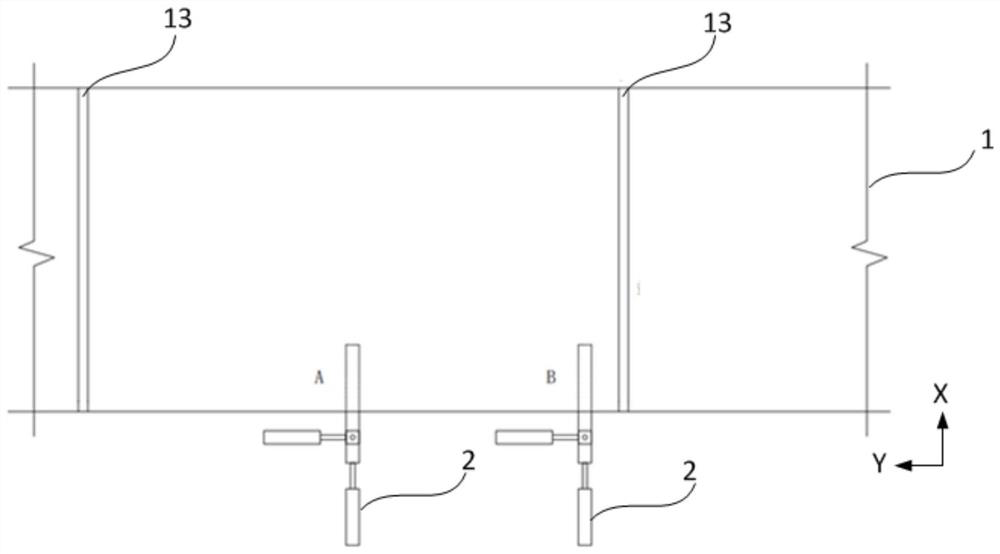

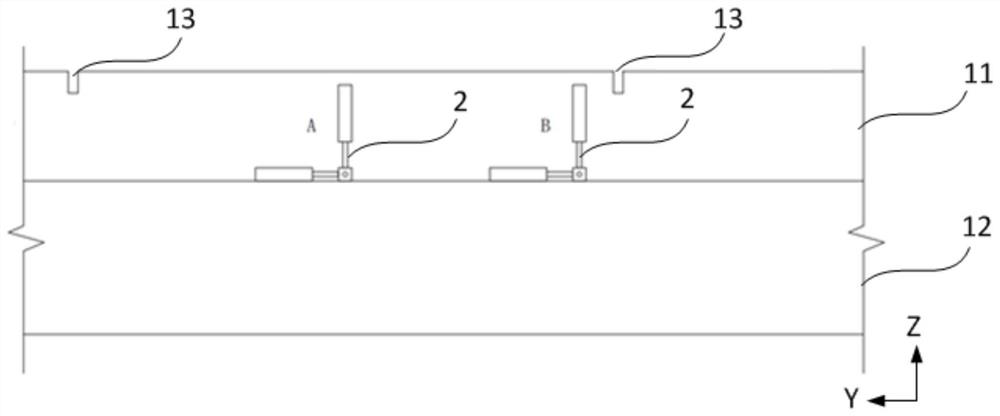

Early deformation monitoring structure and method for cement concrete pavement

PendingCN113587891AImprove operational efficiencyGood prospects for industrializationMeasurement devicesRoads maintainenceGeotechnical engineeringStructural engineering

The invention relates to the field of road engineering, in particular to a cement concrete pavement early deformation monitoring structure and method. The early deformation monitoring structure for the cement concrete pavement comprises a pavement body. The pavement body comprises a surface layer, a base layer and a pavement kerf positioned on the surface layer; and the plurality of three-axis displacement monitoring devices are uniformly arranged at intervals. The XY surface of the three-axis displacement monitoring device is arranged on the plane where the junction of the surface layer and the base layer is located, and the three-axis displacement monitoring device is at least partially arranged on the outer side of the pavement main body. According to the early deformation monitoring structure and method for the cement concrete pavement, the deformation condition of the cement concrete pavement in the initial operation stage can be monitored in real time. Therefore, pavement structural damage and potential safety hazards possibly caused by excessive deformation at the initial stage of pavement operation are monitored in time, and the effect of precaution is achieved.

Owner:TONGJI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com